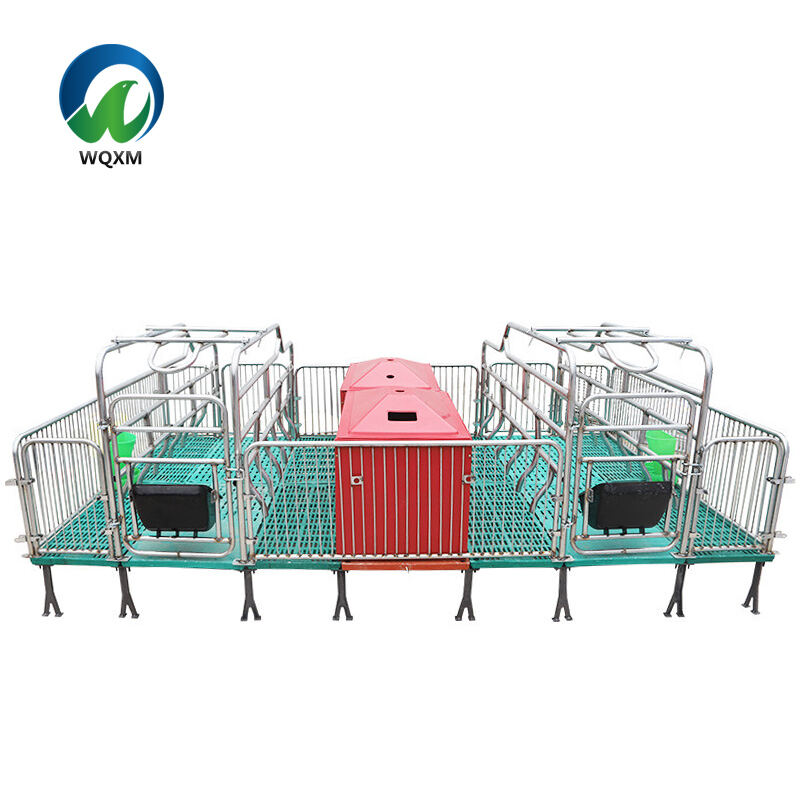

pig farrowing crate factory

A pig farrowing crate factory specializes in manufacturing essential equipment for modern swine operations, focusing on the production of high-quality farrowing crates that ensure the safety and welfare of both sows and piglets during the critical birthing and nursing periods. These facilities incorporate advanced manufacturing processes, utilizing precision engineering and robust materials to create durable, efficient housing solutions. The factory employs state-of-the-art automation systems and quality control measures throughout the production line, ensuring consistent product quality and dimensional accuracy. Their manufacturing capabilities typically include metal fabrication, welding, coating application, and assembly processes, all optimized for large-scale production. The facility's design incorporates dedicated areas for raw material storage, production stages, quality testing, and finished product warehousing. Modern pig farrowing crate factories also emphasize sustainable manufacturing practices, implementing energy-efficient systems and waste reduction protocols. They maintain strict adherence to international standards for livestock equipment manufacturing, ensuring their products meet or exceed industry regulations for animal welfare and farm safety requirements. The factory's technical expertise extends to customization options, allowing for modifications to meet specific farm requirements and regional regulations.