Understanding the Critical Role of Modern Poultry Transportation Systems

The poultry industry has evolved significantly over the years, and at its heart lies the crucial need for efficient and humane transportation solutions. Chicken transport crates have become an indispensable component of modern poultry farming operations, serving as the primary means of safely moving birds between different locations. These specialized containers not only protect the welfare of the birds but also streamline the entire logistics process, making them a cornerstone of successful poultry management.

From small family farms to large commercial operations, the proper handling and transportation of chickens directly impacts both animal welfare and business profitability. The design and implementation of chicken transport crates reflect years of research and development in animal husbandry, combining practical functionality with essential safety features that benefit both the birds and handlers.

The Evolution of Poultry Transportation Equipment

Traditional Methods vs Modern Solutions

In the early days of poultry farming, chickens were often transported in makeshift containers or basic wooden crates that provided minimal protection and comfort. These rudimentary methods frequently resulted in injuries, stress, and mortality during transport. Today's chicken transport crates represent a dramatic improvement, featuring advanced materials, ergonomic designs, and ventilation systems that prioritize animal welfare.

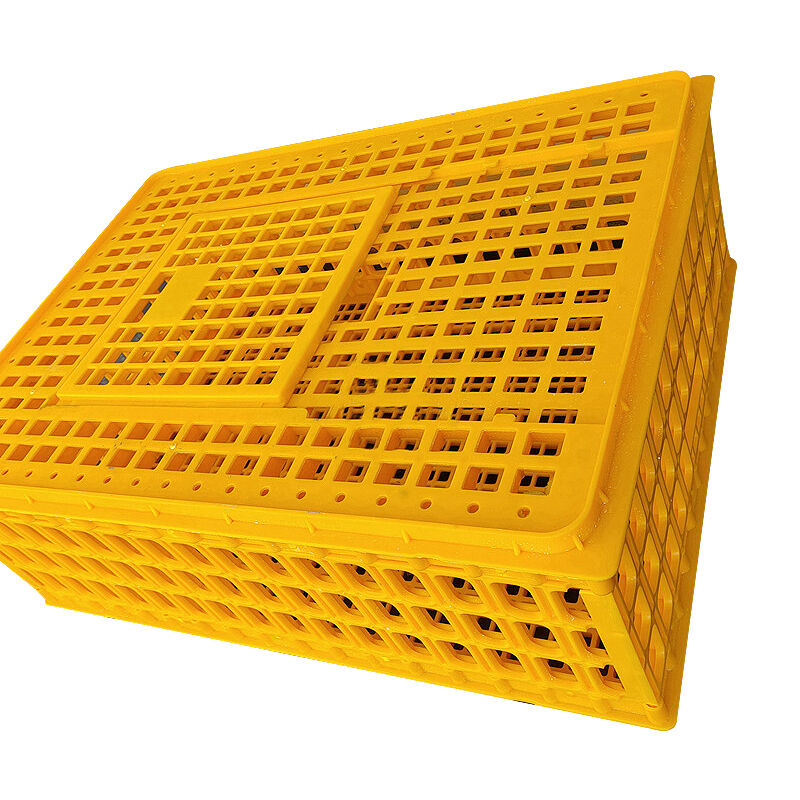

Modern crates are typically constructed from durable, food-grade plastics or reinforced materials that can withstand repeated use and thorough cleaning. This evolution in materials and design has significantly reduced transportation-related losses while improving overall efficiency in the poultry supply chain.

Technological Advancements in Crate Design

Recent innovations in chicken transport crates have introduced features like improved airflow systems, secure latching mechanisms, and stackable designs that optimize space utilization during transport. These advancements ensure better temperature regulation, reduced stress levels, and easier handling for workers. The implementation of such technologies has revolutionized how poultry farms manage their transportation logistics.

Additionally, modern crates often incorporate biosecurity features that help prevent disease transmission between flocks. This aspect has become increasingly important as the industry focuses on maintaining high health standards and meeting strict regulatory requirements.

Key Benefits of Professional Transport Solutions

Enhanced Animal Welfare Standards

Proper chicken transport crates play a vital role in maintaining high animal welfare standards throughout the transportation process. The designs incorporate specific features that minimize stress, prevent injury, and ensure adequate ventilation. Birds can maintain their natural posture while being protected from adverse weather conditions and physical trauma.

These specialized containers also help regulate temperature and humidity levels, crucial factors in preventing heat stress or cold exposure during transit. The result is significantly reduced mortality rates and improved overall bird condition upon arrival at their destination.

Operational Efficiency and Cost Savings

Investment in quality chicken transport crates yields substantial returns through improved operational efficiency. The standardized dimensions and stackable nature of modern crates optimize vehicle space utilization, allowing for more efficient loading and unloading processes. This translates to reduced labor costs and faster turnaround times between shipments.

The durability of contemporary transport crates also means lower replacement costs over time, while their design features facilitate quick cleaning and sanitization between uses. These factors contribute to a more streamlined and cost-effective transportation operation.

Essential Features of Quality Transport Crates

Design Elements for Maximum Protection

Superior chicken transport crates incorporate several critical design elements that ensure optimal protection during transit. The walls feature carefully sized openings that provide adequate ventilation while preventing escape or injury. Smooth interior surfaces minimize the risk of bruising or feather damage, while robust external construction protects against impact during handling.

The floor design typically includes anti-slip surfaces and proper drainage capabilities, essential for maintaining hygiene and preventing birds from slipping during transport. These features work together to create a secure environment that prioritizes both safety and comfort.

Maintenance and Sanitation Considerations

The ability to thoroughly clean and sanitize transport crates between uses is crucial for maintaining biosecurity protocols. Quality crates are designed with smooth surfaces and minimal corners or crevices where debris might accumulate. This design approach facilitates efficient cleaning processes and reduces the risk of disease transmission.

Regular maintenance checks and proper storage of chicken transport crates extend their operational lifespan and ensure consistent performance. This systematic approach to crate management is essential for maintaining high standards in poultry transportation.

Regulatory Compliance and Industry Standards

Meeting Transportation Guidelines

The poultry industry operates under strict regulations regarding animal transport, and chicken transport crates must meet specific standards to ensure compliance. These requirements typically cover aspects such as minimum space allowances, ventilation requirements, and structural integrity standards. Staying current with these regulations is essential for maintaining operational licenses and accessing various markets.

Professional transport crates are designed to meet or exceed these regulatory requirements, providing farmers with confidence in their compliance status while ensuring optimal conditions for their birds during transport.

Future Trends and Innovations

The future of chicken transport crates continues to evolve with emerging technologies and changing industry needs. Innovations in materials science are leading to lighter yet more durable crate options, while smart monitoring systems are being integrated to track environmental conditions during transit. These advancements promise to further improve both efficiency and animal welfare standards.

Sustainability considerations are also driving changes in crate design, with manufacturers exploring eco-friendly materials and focusing on products with longer operational lifespans. These developments reflect the industry's commitment to responsible practices and continuous improvement.

Frequently Asked Questions

How do chicken transport crates improve animal welfare?

Chicken transport crates enhance animal welfare through specialized design features including proper ventilation, temperature regulation, and protection from injury. They provide adequate space for natural positioning while preventing overcrowding, and their construction ensures stable conditions during transit, significantly reducing stress and mortality rates.

What materials are best for transport crates?

The most effective chicken transport crates are typically made from high-grade, food-safe plastics or reinforced polymers. These materials offer excellent durability, are easy to clean and sanitize, resist corrosion, and maintain structural integrity through repeated use. They also help regulate temperature and provide necessary ventilation while being lightweight enough for efficient handling.

How often should transport crates be replaced?

The lifespan of chicken transport crates depends on various factors including usage frequency, handling practices, and maintenance routines. Quality crates typically last 3-5 years with proper care and regular maintenance. However, they should be inspected regularly for damage and replaced immediately if they show signs of structural compromise that could affect bird safety or welfare.