Modern Poultry Transport: Key Design Elements of Chicken Transport Crates

The transportation of live poultry requires carefully engineered solutions that prioritize both animal welfare and operational efficiency. Chicken transport crates have evolved significantly over the years, incorporating innovative design features that address the complex needs of the poultry industry. These specialized containers play a vital role in ensuring birds reach their destination safely while maintaining optimal conditions throughout the journey.

Today’s advanced chicken transport crates represent the pinnacle of extensive research and hands-on expertise in poultry handling. Leading designs are rooted in a deep understanding of avian behavior, stringent ventilation requirements, and the rigorous demands of commercial logistics. This comprehensive guide explores the critical design features that elevate these tools to deliver both exceptional performance and humane animal care.

Structural Design and Material Innovation

Premium Materials for Uncompromising Durability and Hygiene

High-performance chicken transport crates are constructed using food-grade plastic polymers and reinforced composite materials that offer unparalleled durability without sacrificing lightweight maneuverability. These materials are specifically selected for their resistance to aggressive cleaning agents and ability to withstand repeated high-pressure sanitization cycles. Their seamless, non-porous surfaces eliminate bacterial harborages, ensuring thorough decontamination between uses to meet strict biosecurity standards.

The robust structural integrity of these materials enables crates to endure the physical stresses of stacking, loading, and long-haul transportation while providing unyielding protection for the birds inside. Modern polymer formulations also deliver superior thermal stability, helping to regulate internal temperatures and shield poultry from extreme environmental fluctuations during transit.

Modular Design for Maximum Operational Efficiency

Industry-leading chicken transport crates feature innovative modular designs with precision-engineered stacking and interlocking mechanisms. This design approach maximizes vehicle cargo space utilization by up to 30% while ensuring absolute stability during transportation, even over uneven terrain. The modular construction also optimizes storage efficiency when crates are not in use, as units can be nested or collapsed to minimize warehouse space requirements by up to 50%.

These designs incorporate reinforced corner guards and edge protection systems to prevent damage during handling, significantly extending the equipment's operational lifespan. The ability to replace individual components rather than entire units delivers substantial long-term cost savings, reducing total cost of ownership for poultry producers and transporters.

Ventilation and Temperature Regulation

Precision Airflow Engineering for Consistent Environmental Control

Superior chicken transport crates integrate strategically positioned ventilation ports that are calibrated to create uniform airflow patterns throughout the container. These openings are engineered to maintain optimal air circulation rates while shielding birds from direct drafts and excessive wind exposure. The placement, size, and angle of ventilation holes are meticulously calculated using computational fluid dynamics to ensure even air distribution, regardless of the crate's position in a stacked configuration.

Advanced designs often feature adaptive ventilation systems with graduated airflow patterns that can be adjusted to meet specific requirements based on ambient weather conditions and transport duration. This adaptability is critical for maintaining ideal oxygen levels and temperature ranges across diverse climatic zones and seasonal variations.

Proactive Temperature Management Systems

Modern crates include design elements specifically focused on temperature regulation. This includes the use of materials with appropriate thermal conductivity and the incorporation of features that help prevent heat buildup. Some designs feature additional ventilation options that can be adjusted based on weather conditions and transport requirements.

The most effective systems also consider the impact of bird density on temperature management, with designs that optimize space while preventing dangerous heat accumulation. These features work together to maintain appropriate temperature ranges throughout the journey.

Access and Handling Systems

Ergonomic Loading Door Mechanisms for Stress-Free Operations

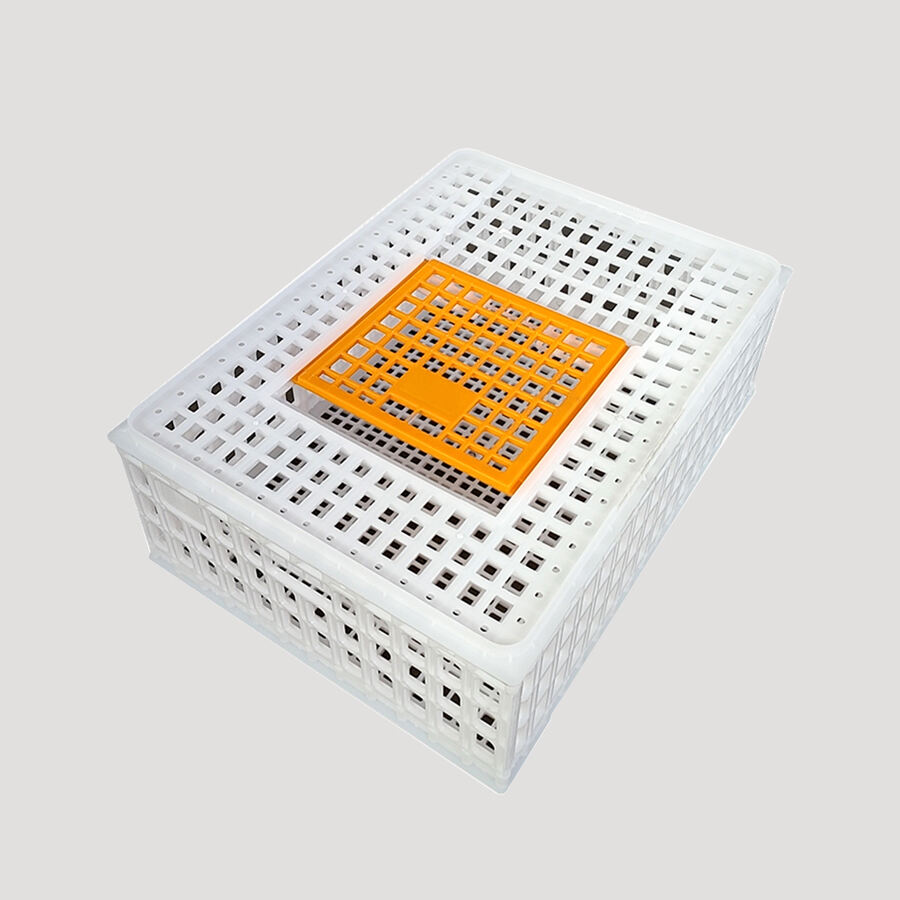

The design of loading and unloading doors is a defining feature of high-performance chicken transport crates. Top-tier systems incorporate smooth-operating sliding or hinged door mechanisms that minimize stress during poultry handling procedures. These precision-engineered systems are designed to prevent accidental opening during transport while enabling quick, effortless access when required.

Advanced door designs prioritize operator ergonomics, requiring minimal force to operate while ensuring secure, tamper-proof closure. The positioning and dimensions of access points are optimized to facilitate both manual loading processes and seamless integration with automated poultry handling systems, enhancing operational efficiency in large-scale facilities.

Human-Centric Handling Features for Workplace Safety

Premium chicken transport crates are equipped with thoughtfully designed grip points and handling surfaces that promote safe and efficient manual handling. These features are strategically positioned to encourage proper lifting techniques, reducing the risk of musculoskeletal injuries for workers. Textured surfaces and non-slip grip zones ensure secure handling even in wet or slippery conditions, minimizing workplace accidents.

Many industrial-grade designs also include integrated features for mechanical handling, such as forklift-compatible bases and attachment points for automated material handling systems. These elements drastically improve operational efficiency in high-volume transport operations, reducing labor costs and streamlining logistics workflows.

Safety and Monitoring Capabilities

Bird-Centric Safety Features for Transit Protection

Premium chicken transport crates incorporate numerous safety features designed specifically to protect birds during transit. This includes rounded corners and smooth interior surfaces that prevent injury, along with appropriate floor texturing that provides secure footing without risking claw or foot damage.

Advanced designs also consider the spacing between birds, incorporating dividers or compartments when necessary to prevent overcrowding and ensure each bird has adequate space. These features help reduce stress and potential injury during transport.

Integrated Monitoring Infrastructure for Real-Time Visibility

Modern transport crates are increasingly equipped with features that enable seamless integration with smart monitoring systems. This includes dedicated mounting points for temperature and humidity sensors, RFID tag placement areas for inventory tracking, and compatibility with IoT-enabled monitoring platforms. These capabilities allow transporters to track environmental conditions in real time, ensuring optimal conditions for poultry throughout the journey.

The ability to monitor crate conditions provides actionable data for refining transport protocols and ensuring full compliance with global animal welfare regulations. This technological integration represents a significant advancement in poultry transport management, enabling data-driven decisions that enhance both animal welfare and operational efficiency.

Frequently Asked Questions

How often should chicken transport crates be replaced?

High-quality chicken transport crates typically deliver a service life of 5-7 years when maintained properly, though this can vary based on usage intensity and adherence to maintenance protocols. Regular inspections should be conducted to identify signs of wear, damage, or material degradation. Replacement is recommended when structural integrity is compromised or when cleaning effectiveness is diminished, to ensure ongoing biosecurity and animal safety.

What is the optimal stacking height for chicken transport crates?

The optimal stacking height depends on the specific crate design, vehicle specifications, and bird density, but generally should not exceed 4-5 layers. This configuration ensures adequate ventilation, structural stability, and ease of access. Always follow manufacturer guidelines and consider critical factors such as journey duration, ambient temperature, and road conditions when determining stacking configurations.

How can transport crate ventilation be optimized for different weather conditions?

Ventilation optimization can be achieved through three key strategies: adjusting bird density to match environmental conditions, using weather-appropriate covering materials during extreme conditions, and ensuring proper spacing between stacked crates to maintain airflow. Advanced crate designs feature adjustable ventilation panels that can be modified in real time based on weather conditions and transport requirements, ensuring optimal air circulation and temperature control in any climate.