The Polypropylene Pp Chicken Transport Basket With Easy Opening Cap represents a specialized solution for agricultural and livestock transportation needs, combining durable polymer construction with practical functionality designed for efficient poultry handling across various operational environments. This innovative transport system addresses the critical requirements of modern agricultural operations, commercial poultry facilities, and livestock management enterprises seeking reliable, hygienic, and user-friendly containment solutions for safe bird transportation. The strategic integration of polypropylene materials ensures exceptional resistance to environmental factors, chemical exposure, and repeated sanitization processes while maintaining structural integrity under demanding operational conditions. The distinctive easy opening cap mechanism enhances operational efficiency by allowing swift access for loading and unloading procedures, reducing handling time and minimizing stress factors during transportation activities. Professional agricultural suppliers and equipment distributors recognize the importance of incorporating advanced polymer-based solutions that deliver consistent performance across diverse climate conditions and operational requirements. The manufacturing approach emphasizes precision molding techniques that create seamless surfaces, eliminating potential contamination points while ensuring smooth cleaning protocols essential for maintaining biosecurity standards in commercial poultry operations. International sourcing teams evaluating livestock handling equipment prioritize products that demonstrate versatility across multiple transportation scenarios, from short-distance farm transfers to extended commercial distribution networks. The polypropylene construction methodology incorporates advanced polymer science principles, delivering enhanced impact resistance, temperature stability, and chemical compatibility with standard sanitization compounds used throughout the agricultural industry. Design considerations for this transport basket extend beyond basic containment functionality, incorporating ventilation patterns that promote adequate airflow circulation while preventing escape attempts, ensuring both animal welfare compliance and operational security during transit periods. The easy opening cap system features intuitive operation mechanics that minimize training requirements for agricultural workers while maximizing accessibility under various working conditions, including situations requiring rapid deployment or emergency access protocols. Export-oriented manufacturing facilities producing agricultural equipment understand the necessity of creating products that meet diverse international quality expectations and regulatory compliance standards across different market regions. The surface treatment approach for polypropylene components emphasizes smooth finish quality that facilitates thorough cleaning procedures while resisting bacterial accumulation and organic material adherence commonly encountered in poultry handling environments. Customization possibilities encompass various capacity configurations, ventilation pattern modifications, and specialized cap mechanisms designed to accommodate specific operational requirements or regional preference variations identified through international market analysis. Quality consistency philosophy throughout the manufacturing process ensures uniform performance characteristics across production batches, supporting reliable supply chain operations for agricultural equipment distributors and commercial poultry facility procurement teams. The material selection process prioritizes food-grade polypropylene formulations that meet stringent safety standards while delivering long-term durability under continuous use conditions typical of commercial agricultural operations. Industrial design elements incorporate ergonomic considerations for handling personnel, including balanced weight distribution and secure grip areas that enhance safety during loading, transportation, and unloading procedures. Compatibility assessments with standard agricultural transportation systems ensure seamless integration into existing operational workflows without requiring significant equipment modifications or specialized handling protocols. Manufacturing expertise developed through extensive collaboration with international agricultural equipment suppliers enables consistent production quality while accommodating specific regional requirements and operational preference variations. The ventilation system design incorporates calculated airflow dynamics that maintain optimal environmental conditions for transported poultry while preventing contamination from external sources during transit periods. Surface engineering approaches focus on creating non-porous textures that resist moisture retention and facilitate rapid drying after sanitization procedures, supporting efficient turnaround times between usage cycles. OEM cooperation opportunities enable agricultural equipment manufacturers to incorporate customized branding, specialized features, or modified configurations that align with specific product line requirements or market positioning strategies. Logistics compatibility considerations include stackable design features that optimize storage space utilization and transportation efficiency for equipment distributors managing extensive inventory systems. The cap mechanism engineering emphasizes reliable closure security during transportation while maintaining effortless opening functionality for authorized personnel, balancing security requirements with operational convenience. International quality management systems ensure consistent material specifications and manufacturing standards that support global distribution networks and diverse regulatory compliance requirements across different agricultural markets. Long-term supplier cooperation expectations focus on maintaining consistent product availability, technical support capabilities, and responsive adaptation to evolving market requirements within the dynamic agricultural equipment sector, establishing reliable partnerships that support sustainable business growth and operational excellence for all stakeholders involved in the agricultural supply chain ecosystem.

Polypropylene Pp Chicken Transport Basket With Easy Opening Cap

-

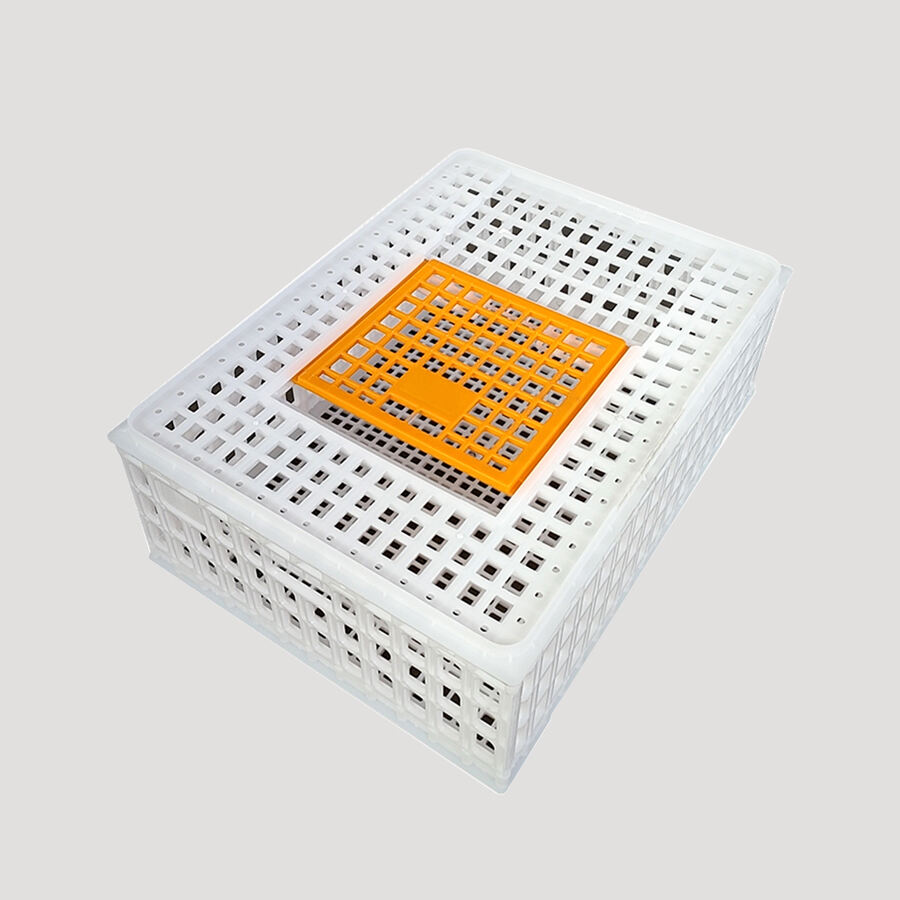

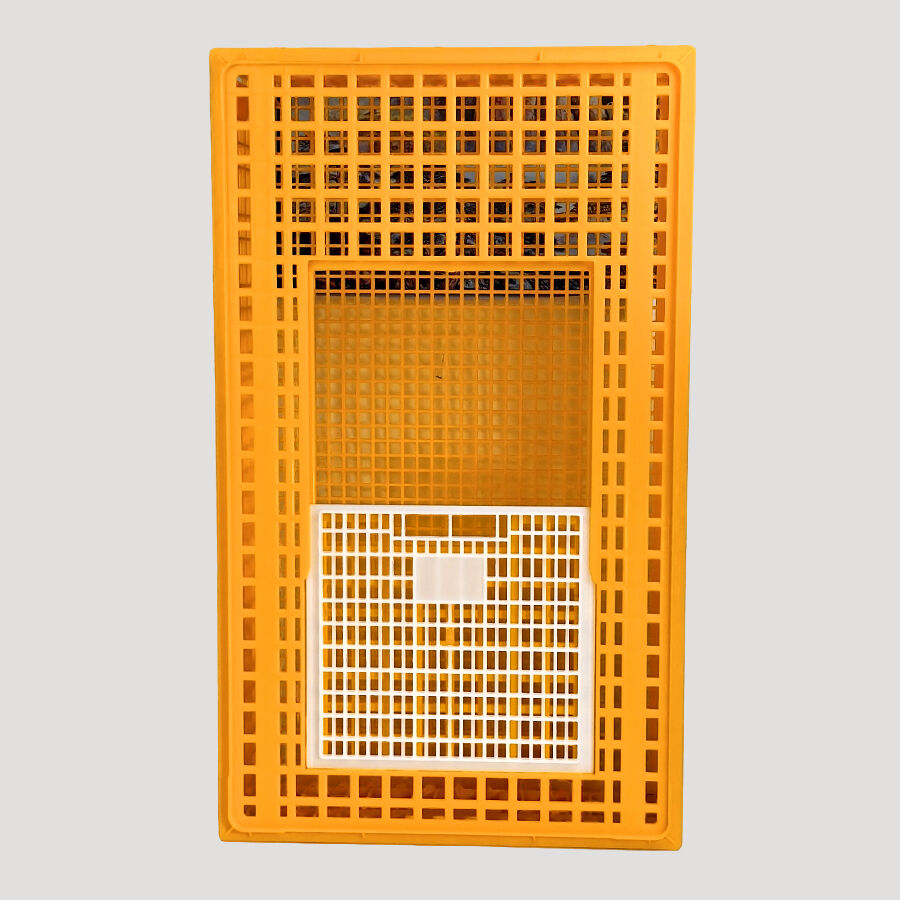

Durable plastic crate with top hatch, ensures safe and easy transport of poultry.

-

Easy-to-clean transport crate, ideal for chickens, ducks, and other small poultry.

-

Stackable, lightweight crate for efficient and hygienic live poultry transportation.

-

Secure locking top door and ventilated sides ensure safety and airflow in transit.

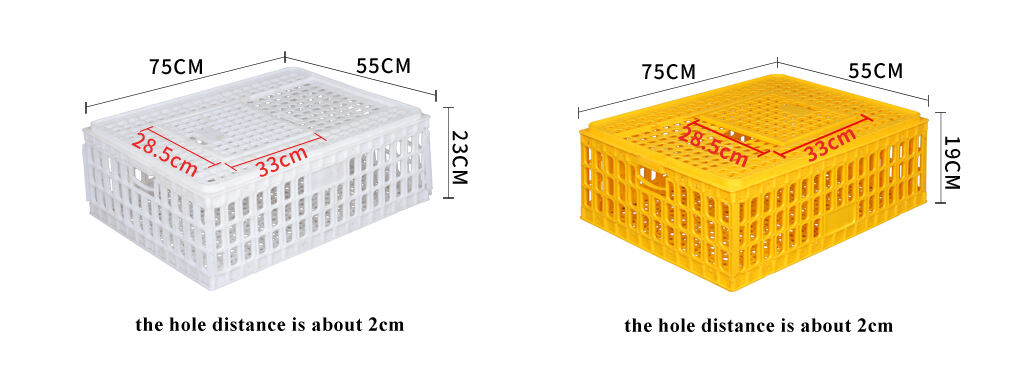

- Dimension:75*55*27cm 75*55*23cm 75*55*19cm

- Overview

- Size

- Details

- Recommended Products

Description

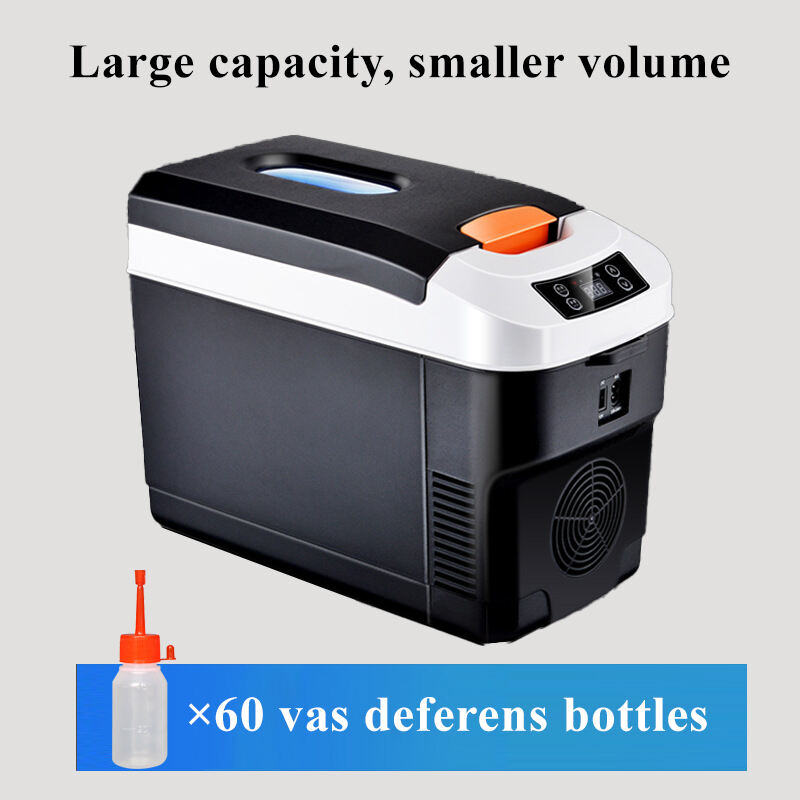

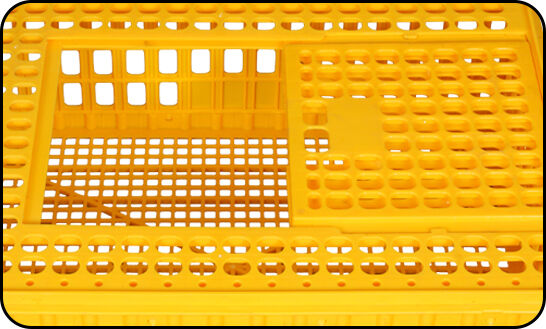

This yellow chicken transport box measures approximately 29.5 x 21.7 x 13 inches (75 x 55 x 23 cm) and comes in paper packaging for easy shipping. Simple self-assembly is required upon arrival. Designed for space efficiency, each crate can hold up to 13 adult chickens with a load capacity of over 50 kg, making it ideal for farms and large poultry operations. These crates are stackable to save transportation space and can be disassembled into flat sheets for convenient storage when not in use. The buckle design and push-pull door make loading and unloading birds quick and secure, while the ventilated mesh structure ensures proper airflow, suitable for long-distance transport. Crafted from heavy-duty plastic, this box is smooth, durable, corrosion-resistant, and built to withstand wear and harsh weather conditions. Perfect for transporting chickens, ducks, geese, birds, and other poultry, it’s an essential tool for farms and poultry keepers.

Product Introduction Video

Size

Details

|

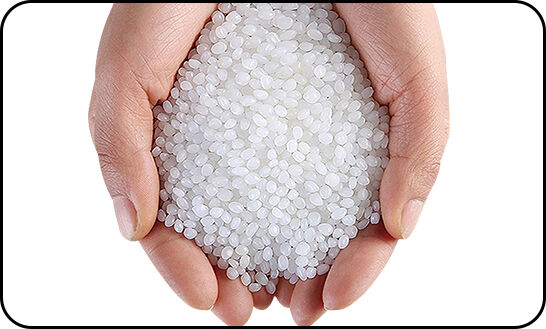

Industrial grade polypropylene clinker Corrosion resistant long service life can carry thousands of ship- ping turnovers |

|

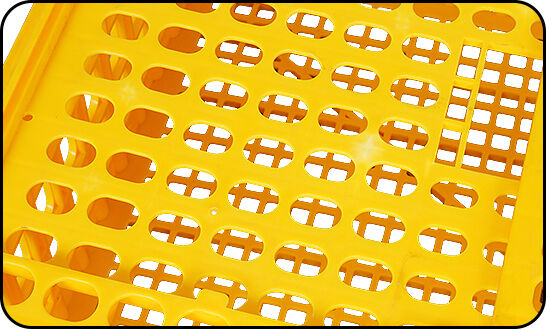

Can bear 800 catties more firm Oval opening design, no dead space, no dirt Smooth surface. easy to clean |

|

|

Scientific design offour corner stiffeners The edge is thickened to meet the high strength and frequent turnover |

|

Handrails for easy transport There are buckles on both sides ofthe chicken cage, which is more convenient andlabor-sav- ing to carry. |

|

|

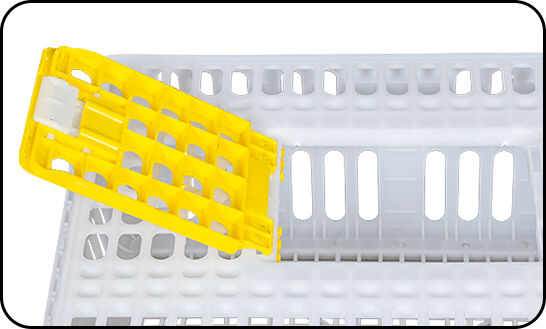

Enlarged flip cage door Spring flap design for easy access to poultry. |

|

Sliding eage door Sliding cage door design is more convenient for poultry access |

|

|

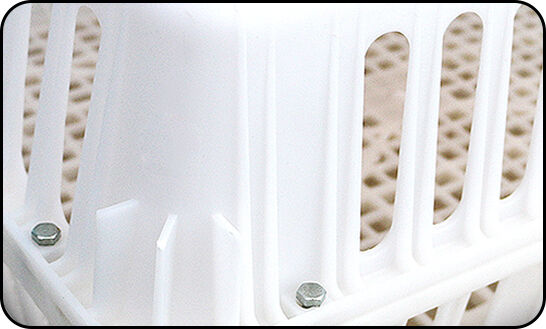

High quality screw fixing Easy and quick to assemble, just fix the four-side screws Convenient and not easy to fall off |

|

Self-locking buckle Assembled transport cages are designed with self-locking clips Easy to assemble and secure |

|