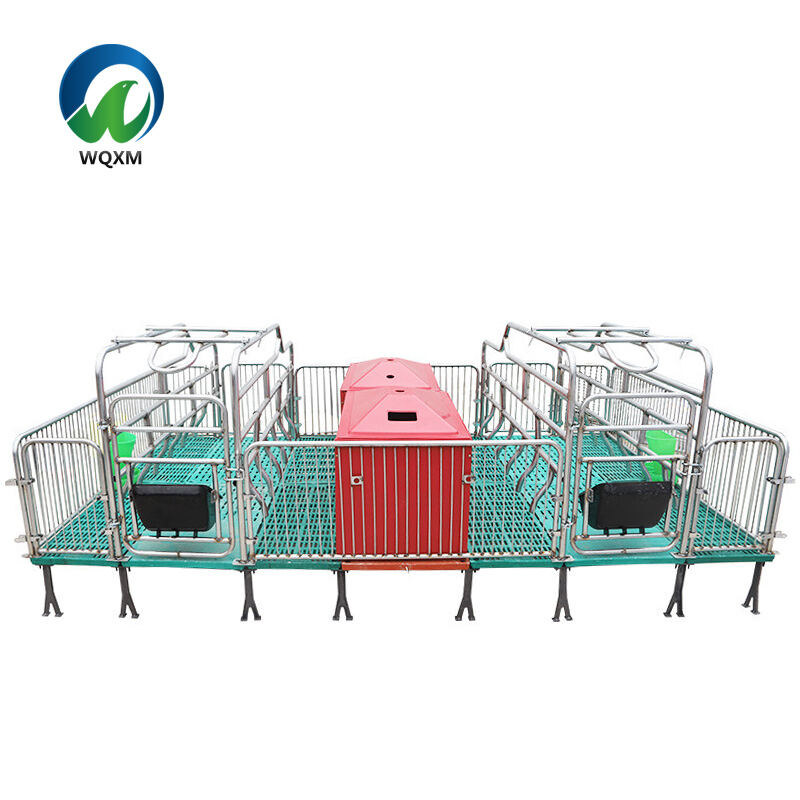

new pig farrowing crate

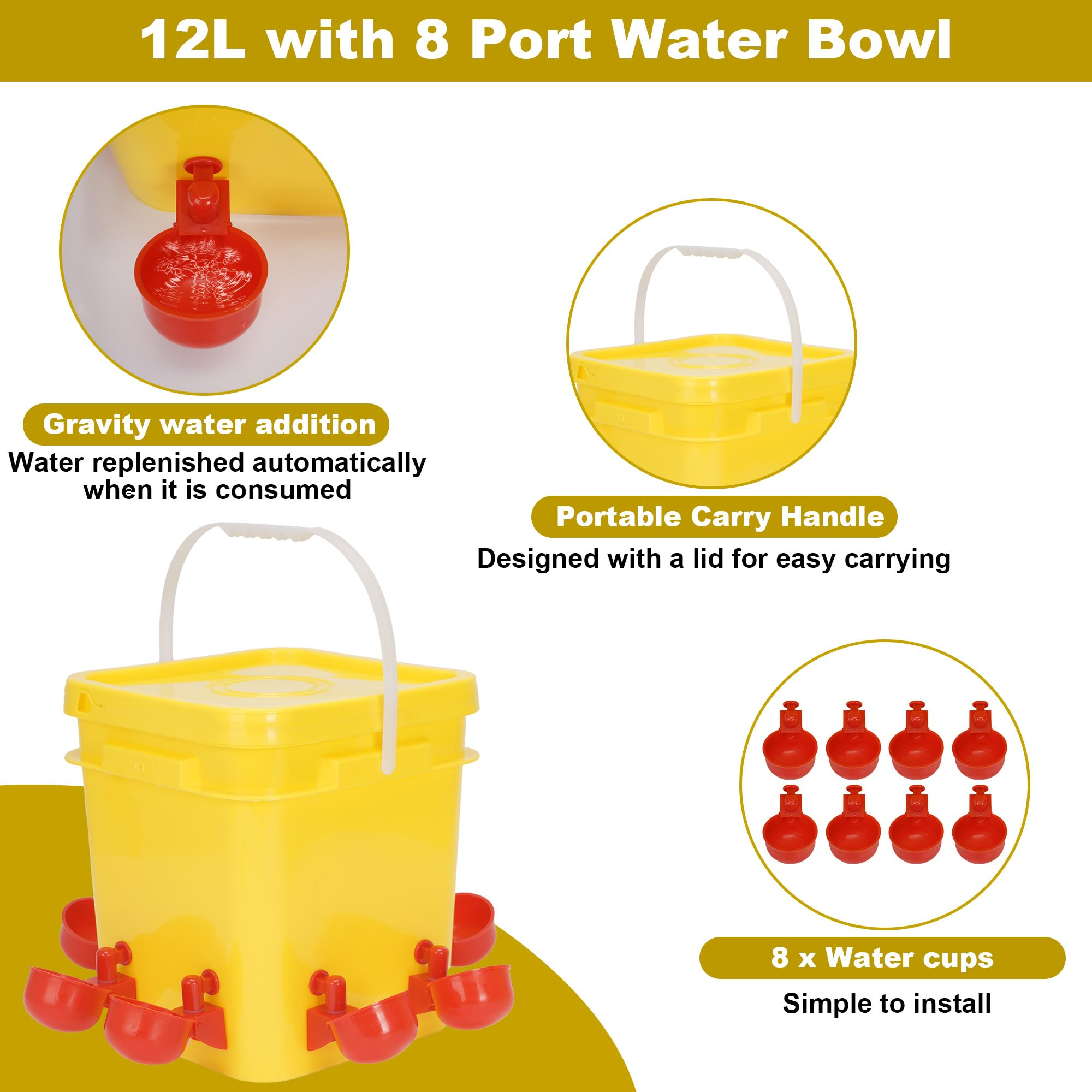

The new pig farrowing crate represents a significant advancement in swine management technology, offering a comprehensive solution for both sows and piglets during the critical farrowing period. This state-of-the-art system features an adjustable width mechanism that can accommodate sows of various sizes, ensuring optimal comfort and movement control. The crate is constructed from heavy-duty galvanized steel, providing exceptional durability and longevity while maintaining hygiene standards. The flooring system incorporates a unique tri-zone design, with specialized areas for the sow and piglets, including a heated creep area for newborns. Advanced safety features include anti-crush rails and finger protection systems, significantly reducing the risk of piglet mortality. The crate's innovative design also includes an integrated feeding and watering system, positioned for easy access by the sow while preventing feed waste. Height-adjustable panels allow farmers to monitor and assist during farrowing while maintaining a secure environment. The structure's modular design facilitates easy installation and maintenance, with removable panels for thorough cleaning. This farrowing crate system also features improved ventilation channels and waste management systems, contributing to better environmental control and animal welfare.