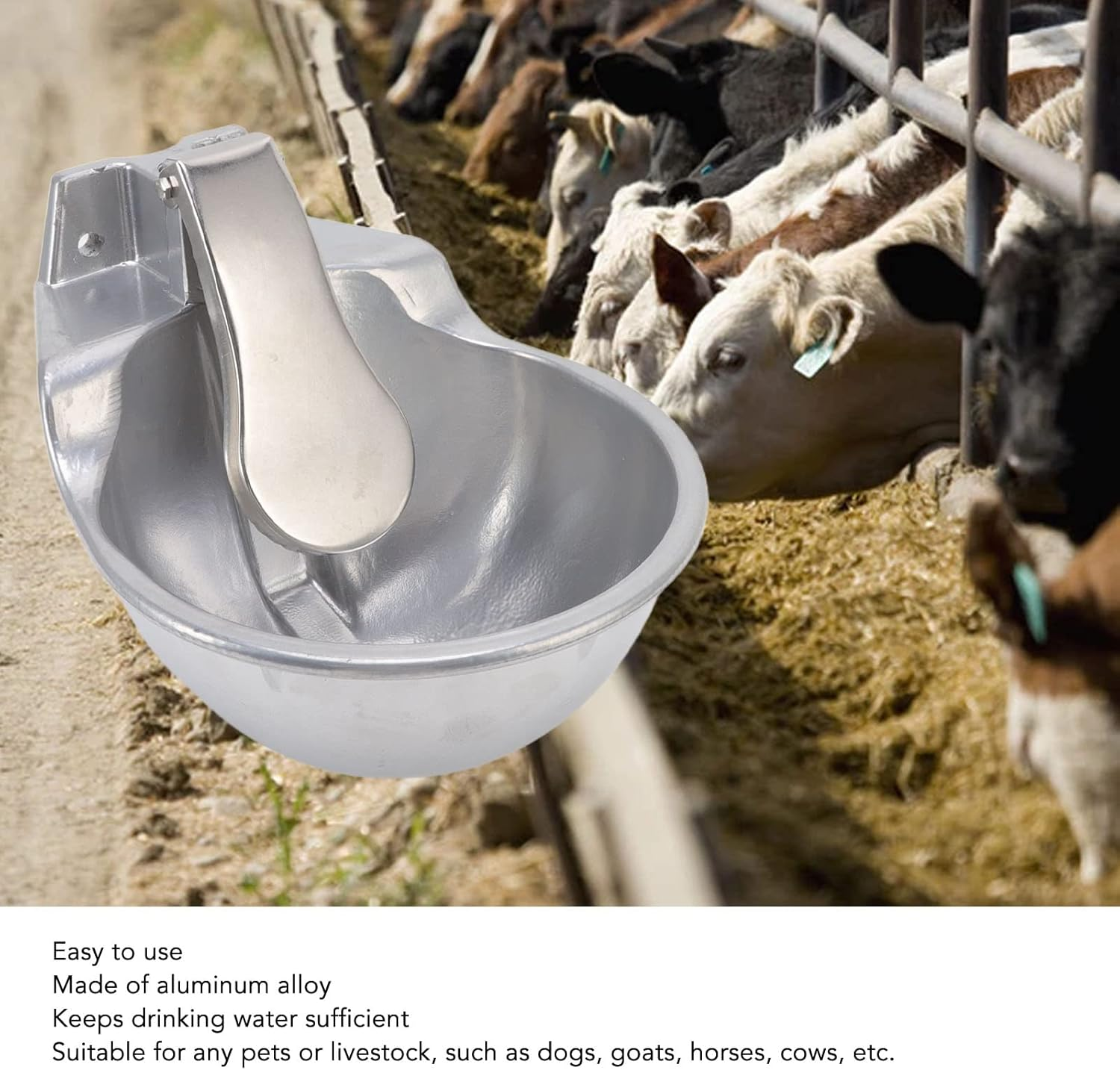

cattle drinking bowl factory

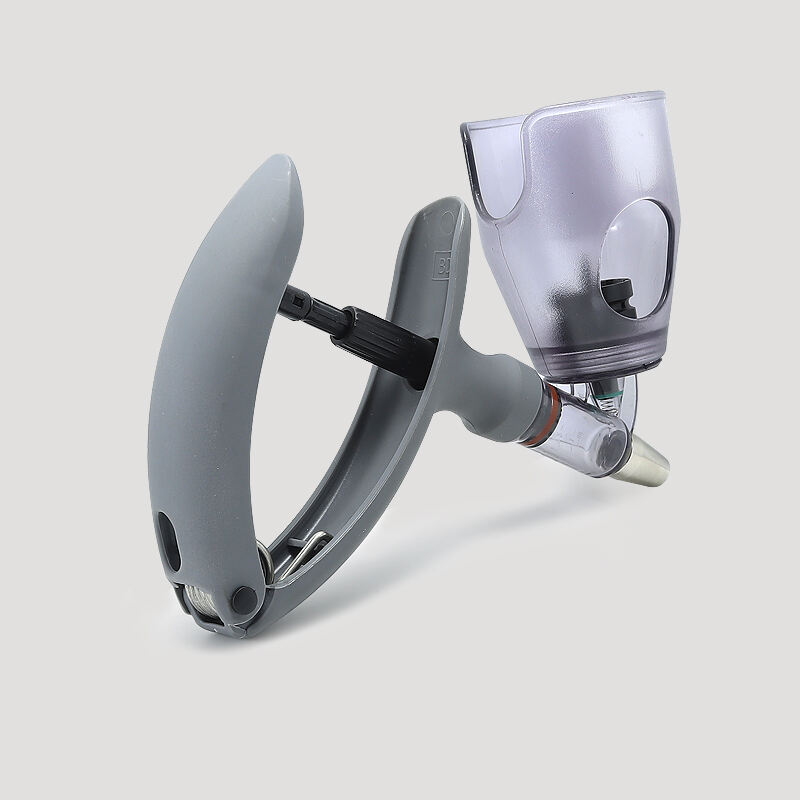

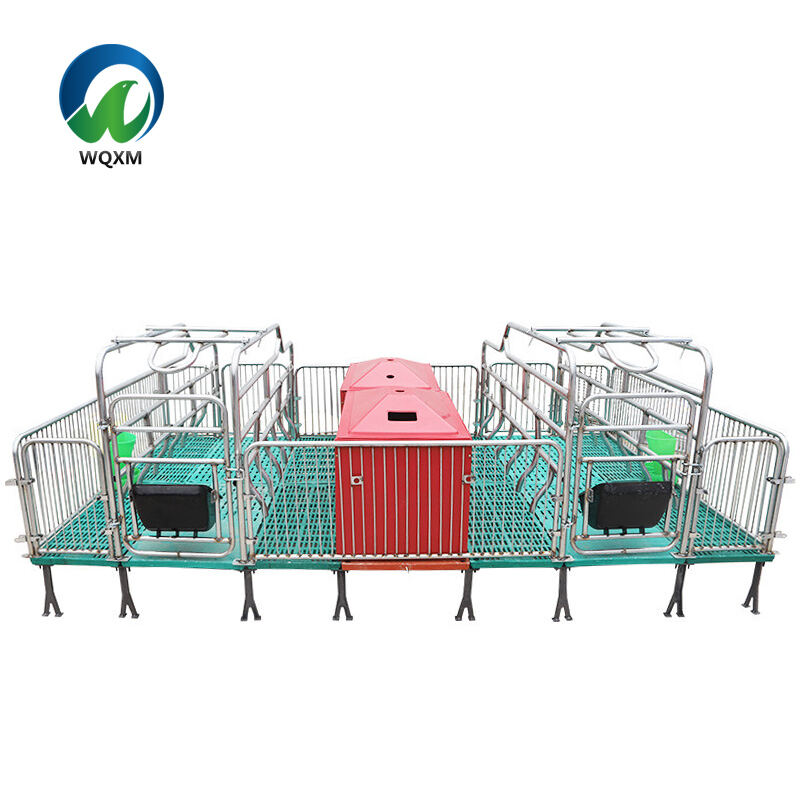

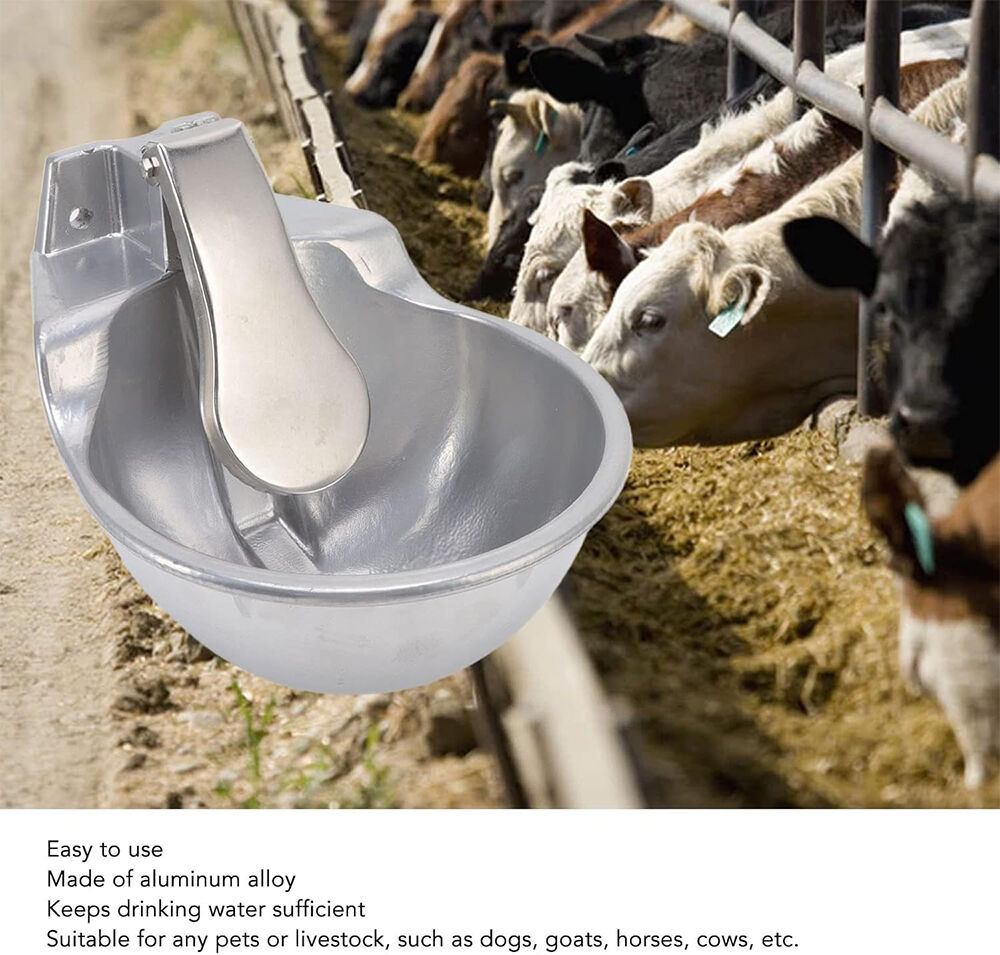

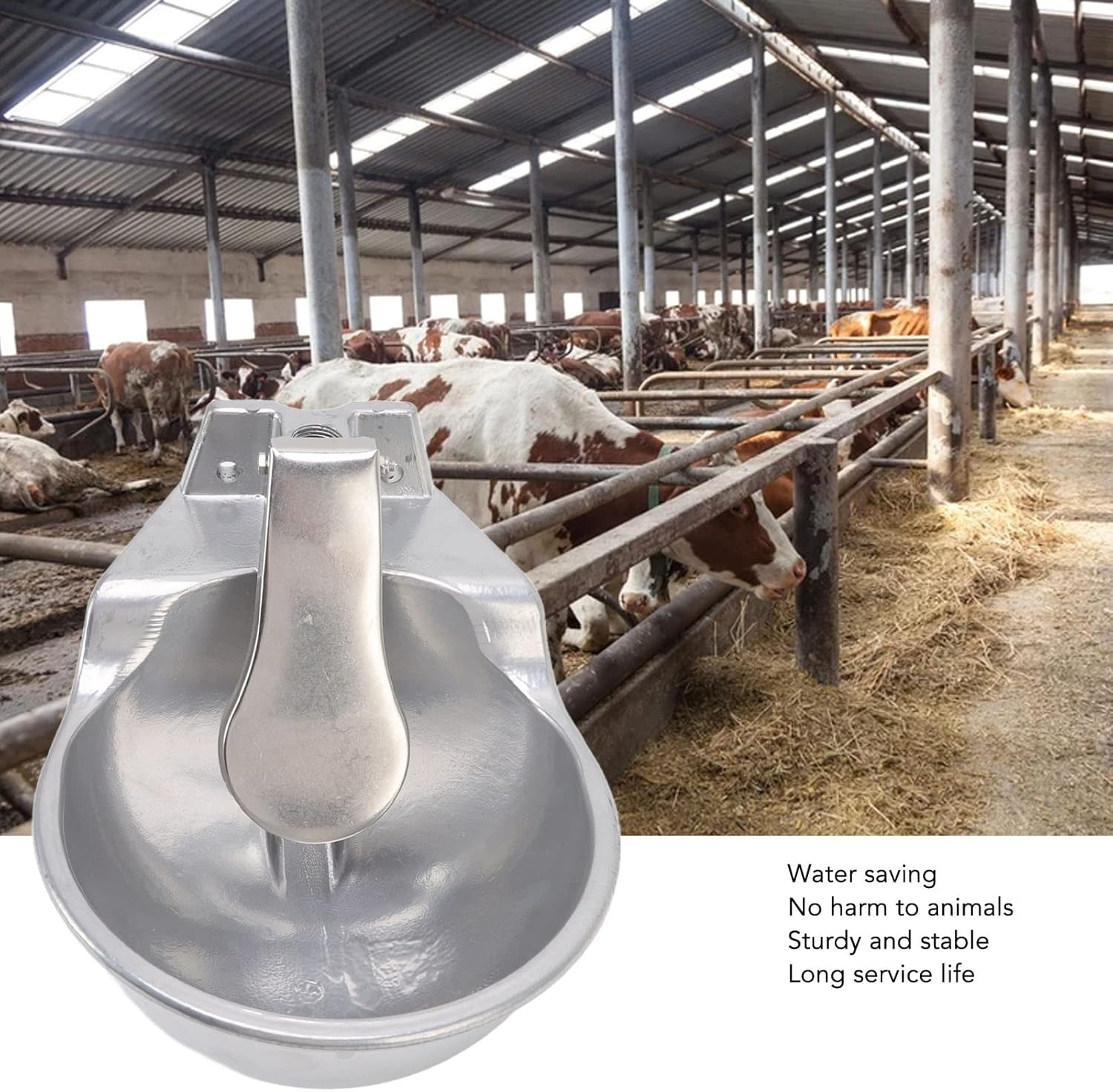

The cattle drinking bowl factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality water delivery systems for livestock operations. This modern facility combines advanced automation technology with precision engineering to create durable, efficient drinking solutions for cattle. The factory's production line incorporates quality control measures at every stage, from raw material inspection to final product testing, ensuring each drinking bowl meets stringent industry standards. The facility utilizes advanced casting techniques and premium grade stainless steel in their manufacturing process, resulting in products that demonstrate exceptional durability and resistance to corrosion. The factory's production capabilities extend to various models of drinking bowls, including automatic water level control systems, frost-resistant designs for cold climates, and high-flow options for large cattle operations. Each product undergoes rigorous testing for water pressure resistance, valve functionality, and structural integrity. The facility also maintains a dedicated research and development department that continuously works on improving product designs and incorporating feedback from livestock farmers. With an annual production capacity of thousands of units, the factory serves both domestic and international markets, providing essential equipment for modern cattle farming operations while maintaining consistent quality standards throughout the manufacturing process.