The Heavy Duty Galvanized Steel Cattle & Sheep Headlock represents a cornerstone solution in modern livestock management infrastructure, specifically engineered to meet the demanding requirements of commercial farming operations, veterinary facilities, and agricultural equipment distributors worldwide. This robust restraint system combines the inherent strength characteristics of heavy-gauge steel construction with the corrosion-resistant properties of hot-dip galvanization, creating a durable platform that withstands the physical demands of daily livestock handling while maintaining structural integrity across diverse environmental conditions. The galvanized coating process ensures comprehensive surface protection against moisture, ammonia exposure, and other corrosive elements commonly encountered in agricultural environments, while the underlying steel framework provides the mechanical strength necessary to safely secure animals during routine care procedures, medical examinations, and feeding operations. International buyers and sourcing professionals recognize this type of Heavy Duty Galvanized Steel Cattle & Sheep Headlock as an essential component in establishing efficient livestock management systems that prioritize both animal welfare and operational productivity. The design methodology incorporates ergonomic considerations for operator safety alongside animal comfort factors, featuring smooth-finished surfaces that minimize stress points while providing secure restraint capabilities. Manufacturing approaches typically involve precision welding techniques and carefully controlled galvanization processes that ensure uniform coating distribution and optimal adhesion characteristics, resulting in products that maintain their protective properties even under intensive use conditions. The versatility of this headlock system extends across multiple livestock species and operational scenarios, making it equally suitable for dairy operations, beef cattle management, sheep handling facilities, and mixed-species agricultural environments. Quality-conscious manufacturers focus on material selection protocols that emphasize consistency in steel grade specifications and galvanization standards, ensuring that each unit meets the performance expectations of professional livestock handlers and facility managers. The functional design accommodates various animal sizes through adjustable mechanisms that provide secure positioning without causing undue stress or discomfort to the animals being handled. Export-oriented production facilities understand the importance of packaging these units to withstand international shipping conditions while maintaining their structural integrity and surface finish quality throughout the logistics chain. The collaboration potential with OEM and ODM partners allows for customization options that address specific regional requirements, facility layouts, and operational preferences without compromising the fundamental safety and durability characteristics that define premium livestock handling equipment. Surface treatment considerations extend beyond basic galvanization to include finishing options that enhance both aesthetic appeal and functional performance, with smooth edges and rounded corners that reduce injury risks for both animals and handlers. The integration capabilities of this headlock system support compatibility with existing barn infrastructure and feeding systems, allowing for seamless incorporation into established livestock management workflows. Manufacturing expertise accumulated through extensive experience in agricultural equipment production ensures that quality consistency remains paramount across production runs, with attention to dimensional accuracy and assembly tolerances that guarantee proper fit and function in field applications. The material science behind galvanized steel construction provides long-term value through reduced maintenance requirements and extended service life, making these headlock systems attractive investments for agricultural businesses focused on operational efficiency and cost management. International distribution networks benefit from the standardized construction approaches that ensure compatibility with global agricultural practices while accommodating regional variations in livestock handling techniques and facility designs. The engineering philosophy emphasizes mechanical simplicity combined with robust construction, creating products that perform reliably in demanding agricultural environments while remaining accessible for routine maintenance and operational adjustments. Professional livestock handlers appreciate the balance between secure animal restraint and ease of operation that characterizes well-designed headlock systems, particularly in high-volume processing scenarios where efficiency and safety considerations must be carefully balanced. The comprehensive approach to product development includes consideration of environmental sustainability through the use of recyclable materials and manufacturing processes that minimize waste generation, aligning with the growing emphasis on responsible agricultural practices. Customization possibilities extend to dimensional variations, mounting configurations, and operational mechanisms that accommodate specific facility requirements while maintaining the fundamental performance characteristics that define professional-grade livestock handling equipment. The strategic importance of reliable livestock restraint systems in modern agricultural operations drives continuous refinement of design approaches and manufacturing techniques, ensuring that each Heavy Duty Galvanized Steel Cattle & Sheep Headlock unit represents the current state of industry best practices in terms of safety, durability, and operational effectiveness across diverse agricultural applications and international market requirements.

Heavy Duty Galvanized Steel Cattle & Sheep Headlock

- High-strength galvanized steel material: Made of premium galvanized steel, featuring excellent rust & corrosion resistance and strong weatherability. It adapts to humid and acidic/alkaline environments in farms, ensuring long service life.

- Stable restraint design: With precise positioning structure, it firmly fixes sheep heads, facilitating operations like vaccination, deworming, and weighing, while reducing animal stress responses.

- Flexible adjustable size: Suitable for sheep/cow at different growth stages (from lambs to adult sheep), enhancing equipment versatility and practicality.

- Wear & impact resistance: Thickened steel with rounded edge treatment avoids scratching sheep and withstands impact and wear from frequent use.

- Easy installation & maintenance: Modular design allows quick installation without complex tools, and daily cleaning is simple, reducing farm management costs.

- Overview

- Key Selling Point

- Recommended Products

Parameters

| The width | The size pipe | Usage |

| 400mm | 3mm Hot-dip galvanized pipe | Weaned calf 3-6 months |

| 500mm | 3mm Hot-dip galvanized pipe | Small breeding cattle 7-12 months |

| 600mm | 3mm Hot-dip galvanized pipe | Big breeding cattle 13-18 months |

| 660mm | 3mm Hot-dip galvanized pipe | Young cow |

| 750mm | 3mm Hot-dip galvanized pipe | Lactating cow |

| 1200mm | 3mm Hot-dip galvanized pipe | The cow stop breastfeeding |

Description

The sheep/cattle headlock is an excellent solution for efficient feeding and veterinary care, offering both durability and ease of use. Built with a robust 42 mm frame and 27 mm locking bar, it ensures long-lasting performance even under intensive farm use. The adjustable locking yoke allows collar widths from 90 mm to 180 mm, accommodating goats of various sizes. Each section features 7 spaces over 2.5 metres, and up to 6 sections can be linked, enabling the simultaneous release of up to 42 goats with a single control handle, significantly reducing labor time. The continuous system is designed with posts positioned at the back for optimal accessibility and safety. Additionally, an optional feed trough, specially designed by Jourdain, can be mounted directly onto the posts for integrated feeding management. This system offers flexibility, time savings, and improved handling for modern goat farming operations.

Key Selling Point:

|

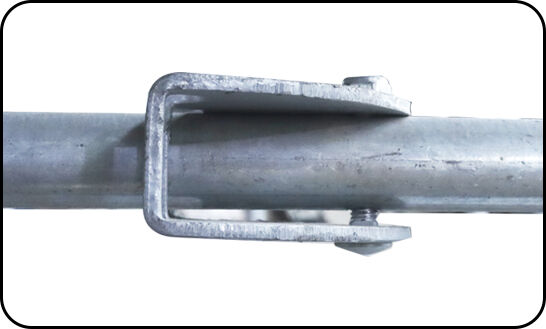

Good material The pipes used to make neck shackles are all made of inner and outer hot-dip galvanized steel pipes and integral hot-dip galvanized steel pipes. The coating penetrates the pipe body and has the characteristics of acid and corrosion resistance |

|

Using bolted connections Reduce the damage caused by burrs and other defects to cows,and prevent rusting and corrosion, making it safe and durable. |

|

|

Simple operation The neck lock device can lock one or more cows at the same time, and can also be controlled separately to meet the different needs of different cows. Each group of neck locks has a handle at the beginning, which can be opened simultaneously by gently twisting the neck locks ofthat group |

|

Buffer device No noise, reduced disturbance to cows. |

|