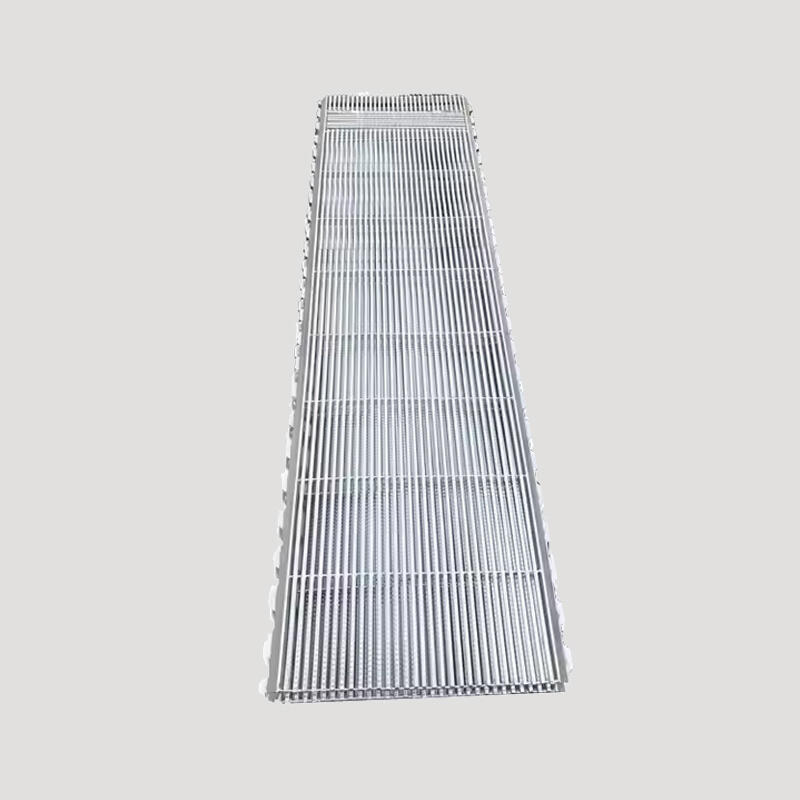

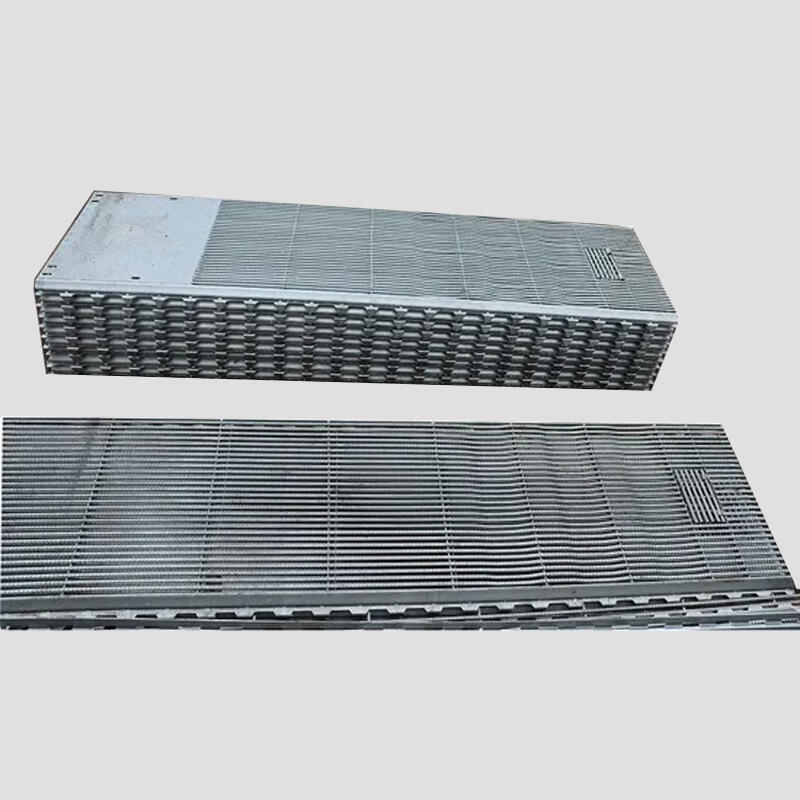

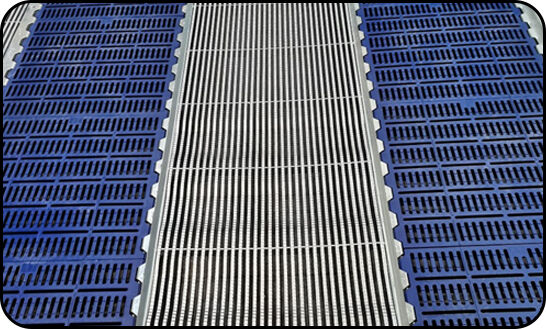

The Hot-Dip Galvanizing Steel Rod Pig Slat Floor represents a pinnacle of agricultural infrastructure engineering, specifically designed to address the demanding requirements of modern swine farming operations across global markets. This specialized flooring system combines the inherent strength and durability of steel rod construction with the superior corrosion resistance provided by hot-dip galvanizing processes, creating a comprehensive solution that meets the rigorous standards expected by international buyers, agricultural equipment distributors, and farm infrastructure specialists. The product stands as a testament to advanced metallurgical techniques applied to livestock management infrastructure, where the intersection of material science and practical farming needs creates opportunities for enhanced operational efficiency and long-term cost effectiveness. In the context of contemporary agricultural practices, where biosecurity, animal welfare, and operational sustainability are paramount concerns, this galvanized steel rod flooring system addresses multiple functional requirements simultaneously while maintaining the structural integrity necessary for heavy-duty commercial applications. The hot-dip galvanizing process ensures that each steel rod component receives uniform zinc coating coverage, providing exceptional protection against the corrosive effects of moisture, ammonia, and other aggressive substances commonly encountered in swine housing environments. This protective treatment extends far beyond surface-level coating applications, as the galvanizing process creates a metallurgical bond between the zinc and steel substrate, resulting in a composite material that exhibits superior performance characteristics compared to alternative finishing methods. The steel rod construction methodology employed in manufacturing these slat floors incorporates precision engineering principles that balance structural requirements with practical functionality, ensuring optimal drainage capabilities while providing secure footing for livestock. Manufacturing approaches for these specialized flooring systems involve careful consideration of rod spacing, diameter specifications, and overall dimensional tolerances that accommodate various housing configurations and operational requirements. The design philosophy underlying this product reflects deep understanding of swine behavior patterns, waste management needs, and cleaning protocols essential for maintaining hygienic environments in commercial farming operations. Surface treatments applied during the galvanizing process create a finish that resists bacterial adherence while remaining easy to sanitize using standard agricultural cleaning equipment and procedures. Functional customization possibilities encompass variations in rod spacing configurations, overall panel dimensions, and connection mechanisms that allow integration with existing barn structures or new construction projects. These customization options reflect the diverse needs of international markets, where regional farming practices, building codes, and operational preferences may require specific adaptations while maintaining core performance characteristics. Application suitability extends across various scales of swine operations, from smaller specialty farms to large-scale commercial facilities, demonstrating the versatility inherent in well-engineered agricultural infrastructure solutions. The product serves effectively in breeding facilities, nursery operations, finishing barns, and quarantine areas where consistent flooring performance is essential for maintaining animal health and operational efficiency. Quality consistency philosophy underpinning the manufacturing process emphasizes reproducible results across production batches, ensuring that international buyers receive products meeting identical specifications regardless of order timing or quantity requirements. This commitment to consistency extends to material sourcing, processing parameters, and quality control measures that verify conformance to established performance standards. Export-oriented handling considerations have been integrated into the product design and packaging approaches, recognizing that international shipments require robust construction capable of withstanding transportation stresses while maintaining dimensional accuracy and surface finish integrity. The modular nature of slat floor panels facilitates efficient container loading and reduces shipping costs for overseas buyers, while standardized connection methods simplify installation procedures across different geographic markets. Customization collaboration opportunities reflect manufacturing capabilities that extend beyond standard product offerings, accommodating specific dimensional requirements, specialized connection systems, and unique operational constraints that may arise in diverse agricultural environments. Original equipment manufacturer partnerships and original design manufacturer cooperation represent strategic approaches to serving international markets, where local assembly requirements or regional specifications may necessitate collaborative development processes. These cooperative arrangements leverage manufacturing expertise while respecting regional market knowledge and distribution capabilities essential for successful market penetration. Packaging and logistics compatibility considerations ensure that products arrive at destination facilities in optimal condition, ready for immediate installation or inventory storage as required by individual operational schedules. The packaging approach protects galvanized surfaces from damage while providing clear identification and handling instructions that facilitate efficient warehouse management and installation processes. Long-term supplier cooperation expectations reflect understanding that agricultural infrastructure represents significant capital investments requiring ongoing support, technical assistance, and potential expansion capabilities as farming operations evolve and grow. The relationship between suppliers and international buyers extends beyond initial product delivery to encompass technical consultation, replacement part availability, and adaptation support for changing operational requirements. This comprehensive approach to customer relationships recognizes that successful agricultural operations depend on reliable infrastructure performance over extended service periods, where initial product quality represents only the foundation of ongoing operational success.

Hot-Dip Galvanizing Steel Rod Pig Slat Floor

-

Strong & Corrosion-Resistant – Made from hot-dip galvanized steel, offering excellent durability and rust resistance in harsh farm conditions.

-

High Load-Bearing Capacity – Supports heavy pigs such as sows and finishers without bending or damage.

-

Safe & Animal-Friendly Design – Anti-slip surface and smooth rod edges reduce injuries and improve pig comfort.

-

Efficient Waste Drainage – Slatted design keeps pens clean and dry, improving hygiene and reducing disease risk.

-

Easy Maintenance & Installation – Quick to install, simple to clean, and requires minimal upkeep, saving labor and operational costs.

- Overview

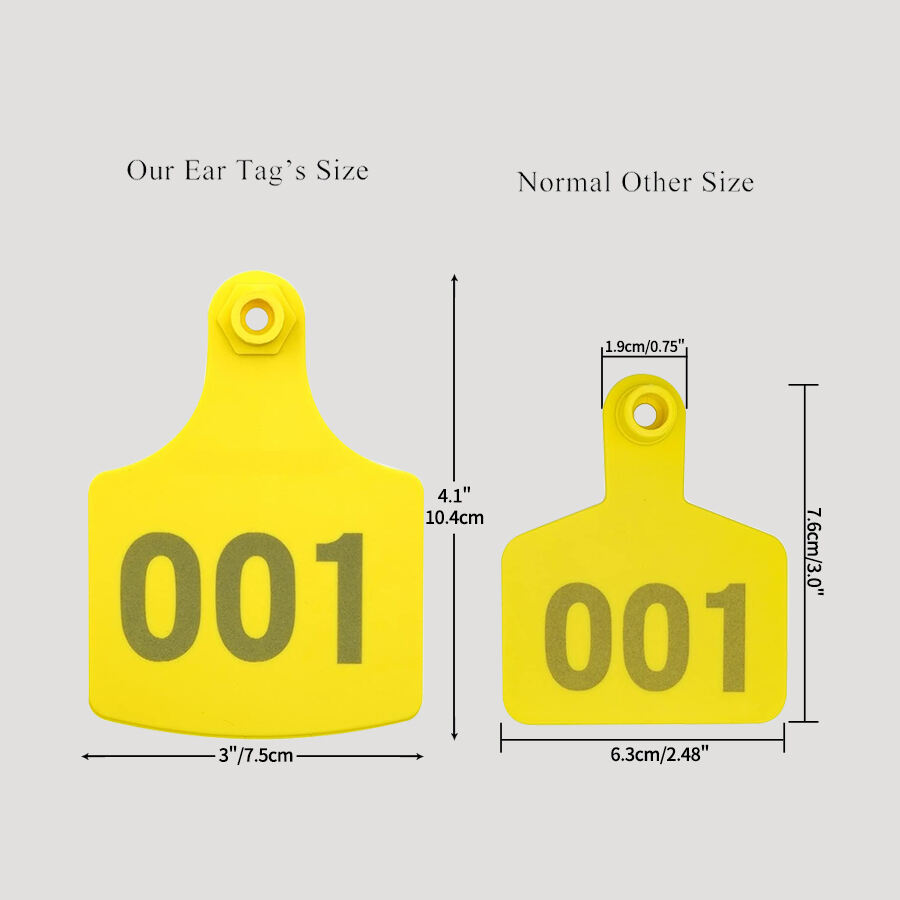

- Size

- Details

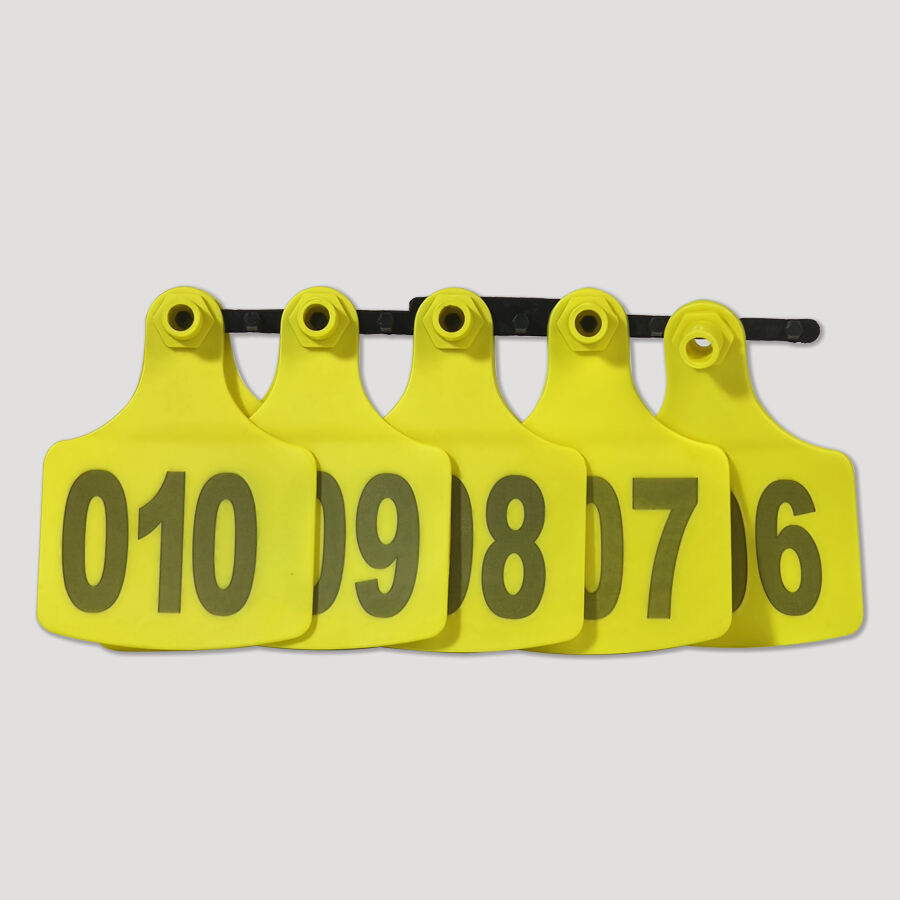

- Recommended Products

Description

1. Exceptional Durability

2. Optimal Hygiene and Manure Management

3. High Load - Bearing Capacity

4. Animal - Friendly Design

5. Easy Installation and Compatibility

6. Cost - Effective in the Long Run

Certificate

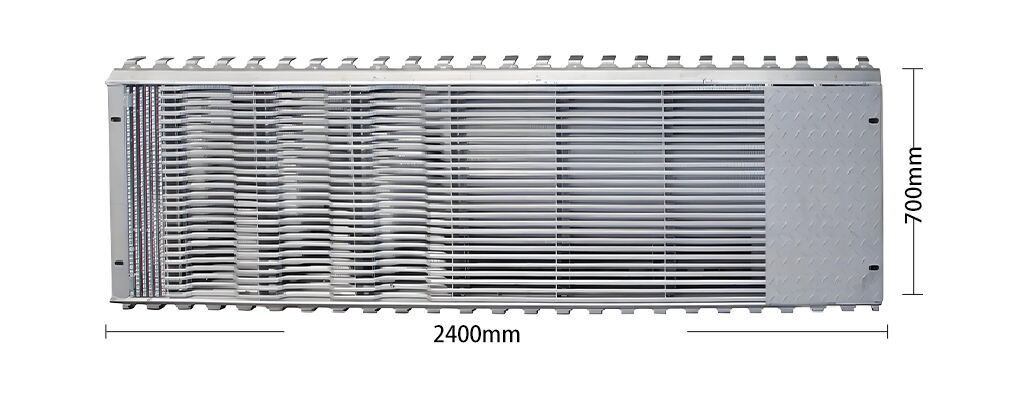

Size

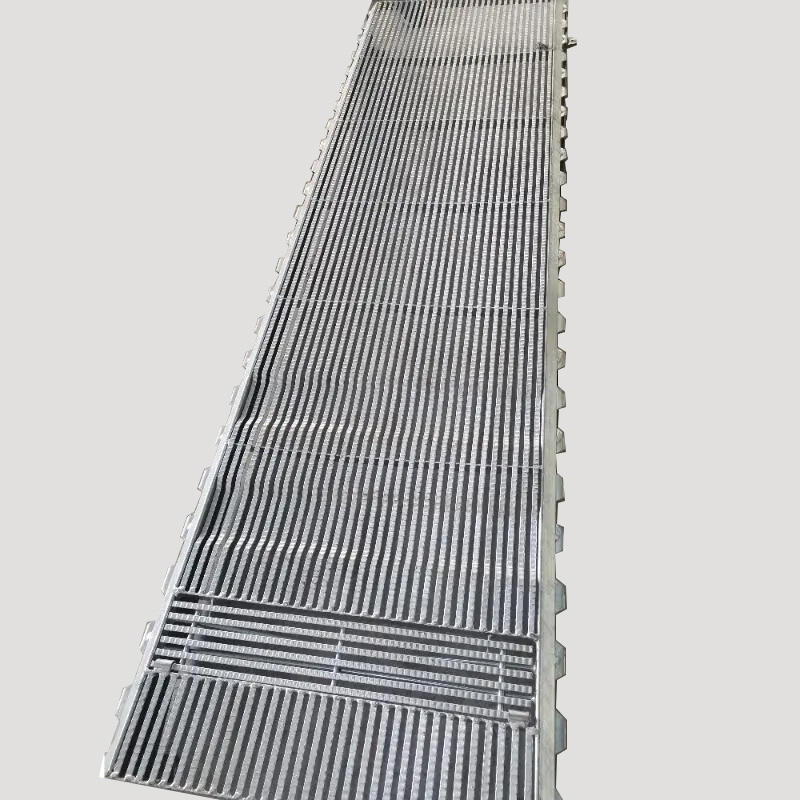

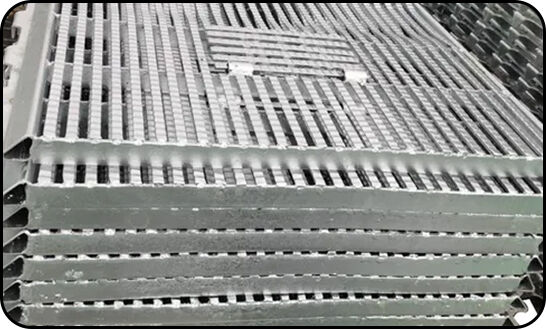

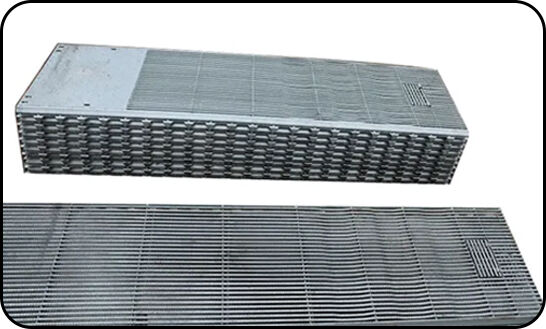

Details

|

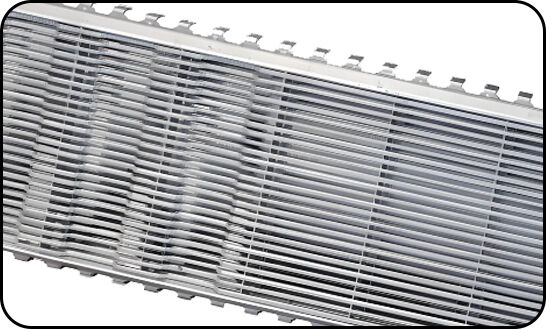

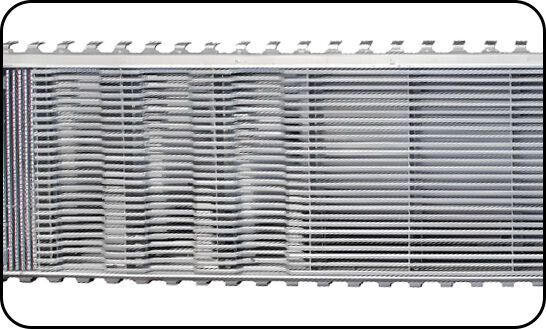

High quality material Made of high-quality steel, sturdy and durable, with strong corrosion resistance and long service life. |

|

Triangular design Unique triangular design effectively disperses livestock pressure and reduces hoof damage. |

|

|

Cleaning and maintenance The leakage gap is scientifically reasonable and can quickly separate feces and urine, making it easy to clean and maintain. |

|

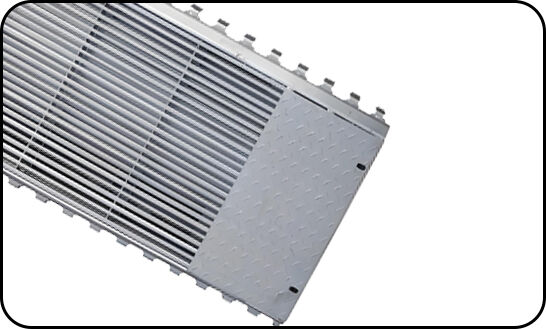

Easy to install Adapting to various breeding environments, whether it is large-scale pig farms or small-scale breeders, can improve breeding efficiency and create clean and hygienic breeding spaces. |

|

|

High load-bearing capacity, stable and durable |

| Strong maintainability |  |

|

Efficient fecal leakage and easyinstallation |

| Ventilation and Breathability |  |