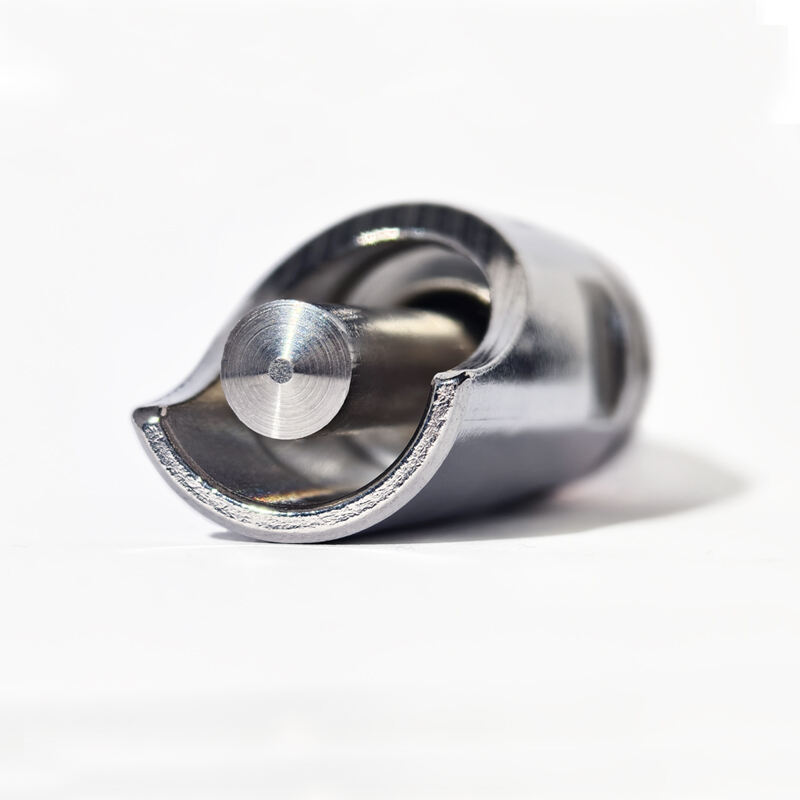

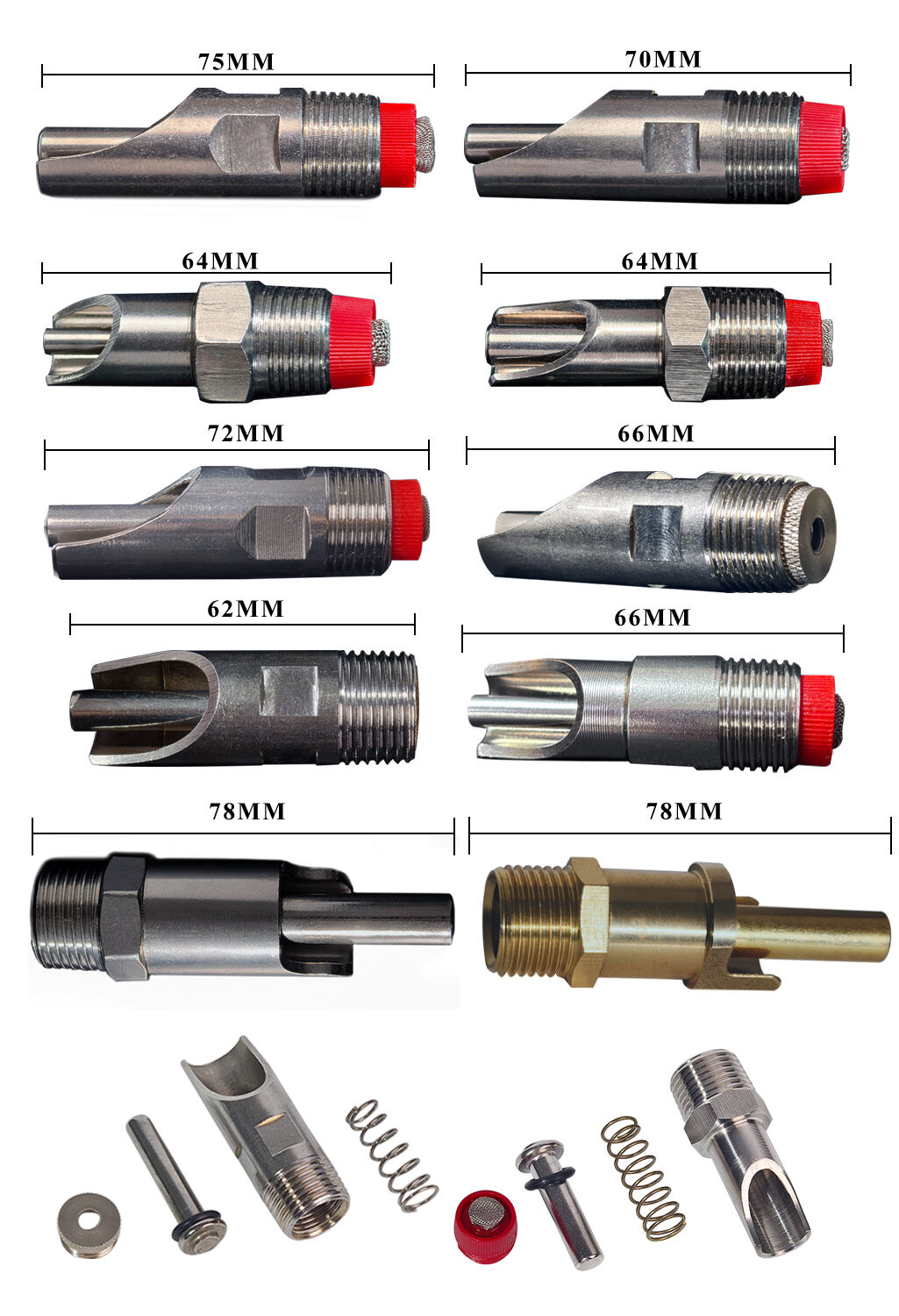

The Duckbill Type Automatic Stainless Steel Pig Nipple Drinker represents a sophisticated watering solution engineered to meet the demanding requirements of modern swine farming operations worldwide, combining the durability of premium stainless steel construction with the proven efficiency of duckbill valve technology to deliver consistent, reliable water access for pigs across all growth stages. This innovative drinking system incorporates a precisely engineered duckbill mechanism that responds to natural pig drinking behaviors, automatically dispensing fresh water when pressure is applied while maintaining a secure seal to prevent waste and contamination when not in use. The stainless steel construction ensures exceptional resistance to corrosion, chemical degradation, and physical wear, making it an ideal choice for the harsh environments typically encountered in commercial pig farming facilities where exposure to moisture, cleaning agents, and continuous use demands materials that can withstand prolonged operational stress without compromising performance or hygiene standards. International buyers and agricultural equipment distributors recognize this product as an essential component for establishing efficient livestock watering systems that support optimal animal welfare while minimizing operational maintenance requirements and reducing long-term replacement costs. The duckbill valve design philosophy centers on biomimetic principles that align with natural pig drinking instincts, featuring a flexible rubber or silicone duckbill component that opens under gentle pressure from the pig's snout or tongue, allowing controlled water flow that prevents spillage and reduces pen floor wetness, which contributes to healthier living conditions and improved feed conversion ratios. Manufacturing excellence in this product category requires sophisticated understanding of both metallurgical properties and animal behavior patterns, with production processes typically involving precision machining of stainless steel components, careful assembly of valve mechanisms, and rigorous quality testing to ensure consistent water flow rates and reliable sealing performance across thousands of activation cycles. The automatic functionality eliminates the need for manual water refilling in individual pens, significantly reducing labor requirements while ensuring continuous water availability, which is critical for maintaining pig health, growth rates, and overall production efficiency in commercial swine operations. Surface finishing techniques applied to the stainless steel housing typically include electropolishing or passivation treatments that create smooth, non-porous surfaces resistant to bacterial growth and easy to sanitize during routine cleaning protocols, addressing the strict hygiene requirements mandated by modern livestock production standards and regulatory frameworks governing food safety in meat production chains. Customization capabilities within this product category often encompass variations in mounting configurations, valve sensitivity adjustments, and integration compatibility with existing barn watering systems, allowing agricultural equipment suppliers to offer tailored solutions that accommodate diverse facility layouts and operational preferences encountered across different geographic markets and farming methodologies. The robust engineering inherent in quality duckbill pig drinkers extends to consideration of installation environments, with designs typically incorporating features that facilitate secure mounting to pen walls or posts while accommodating thermal expansion, vibration from animal activity, and potential impact from larger pigs without compromising structural integrity or operational reliability. Export-oriented manufacturing of these specialized agricultural components requires comprehensive understanding of international shipping requirements, packaging protocols that protect precision components during transit, and documentation standards that facilitate smooth customs clearance and end-user installation processes across diverse regulatory environments. Quality consistency in production batches becomes particularly critical when supplying large-scale farming operations or agricultural equipment distributors who require uniform performance characteristics across hundreds or thousands of units, necessitating manufacturing processes that incorporate statistical process control, dimensional verification, and functional testing protocols that ensure every unit meets established performance specifications. The economic value proposition for end users encompasses not only the initial equipment investment but also long-term operational benefits including reduced water waste, lower maintenance requirements, improved animal health outcomes, and enhanced facility cleanliness that collectively contribute to improved profitability and operational sustainability in competitive livestock production markets. Collaboration opportunities with original equipment manufacturers and private label partners often involve comprehensive product development support, including design optimization for specific application requirements, custom branding and packaging solutions, and technical documentation development that facilitates successful market introduction and customer support programs. Logistics compatibility considerations for international distribution include compact packaging designs that optimize shipping density, protective packaging that prevents damage during handling and transport, and modular product configurations that facilitate efficient inventory management and order fulfillment processes for distributors serving diverse customer bases across multiple geographic regions.

Duckbill Type Automatic Stainless Steel Pig Nipple Drinker

-

Splash-Resistant Duckbill Design: Minimizes water waste and keeps pens dry by preventing splashing during drinking.

-

Automatic & Hygienic Water Supply: Dispenses clean water only when triggered, reducing contamination and ensuring hydration.

-

Durable Stainless Steel Construction: Corrosion-resistant and built for long-term use in demanding farm environments.

-

Integrated Filter for Clean Water: Red plastic filter blocks debris, ensuring pigs get clean, safe drinking water.

-

Safe & Easy to Install: Smooth edges protect pigs' mouths; threaded base fits standard water lines for quick setup.

- Overview

- Size

- Details

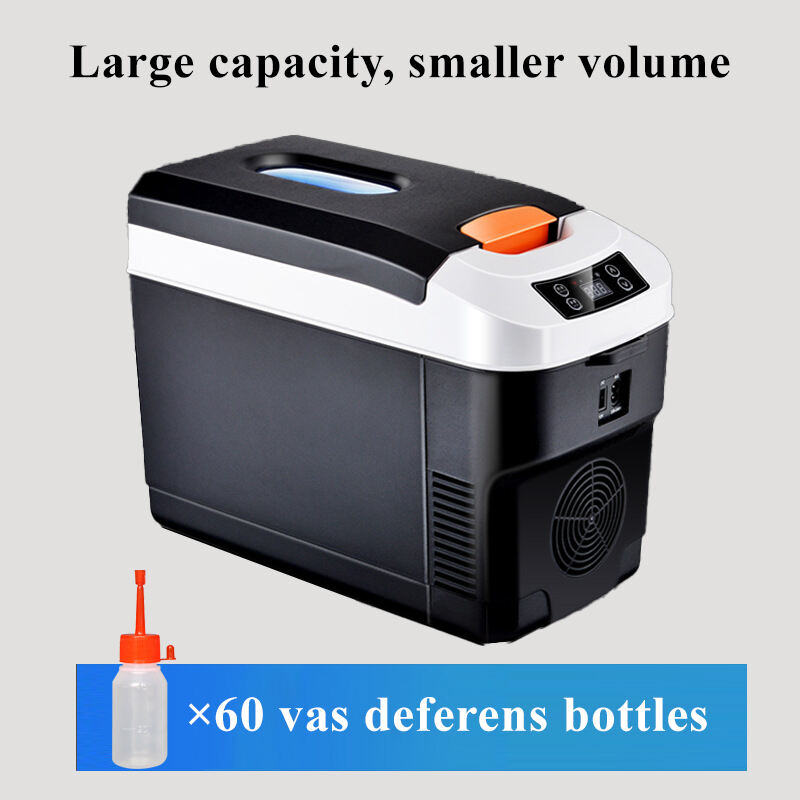

- Recommended Products

Description

The Stainless Steel Pig Nipple Waterer is designed to provide pigs with a clean, fresh, and constant water supply while minimizing waste. Crafted from high-quality stainless steel with a durable spring and dome screen and a red cap, it offers excellent anti-rust and anti-corrosion performance, ensuring long-lasting use in various farm conditions. Its leak-proof design prevents water loss, making it a cost-effective and eco-friendly choice.

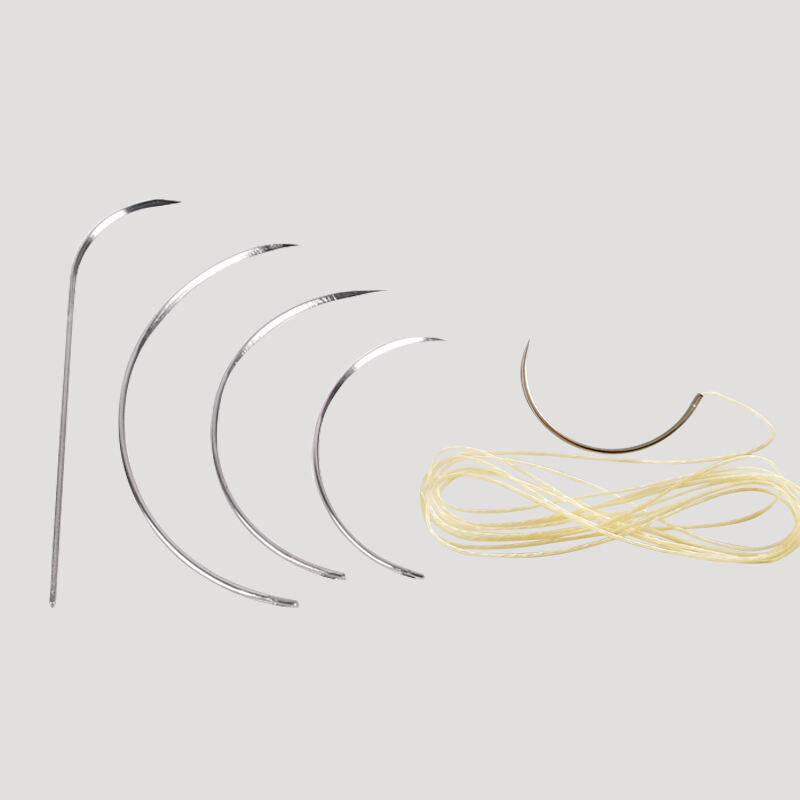

This nipple drinker is suitable for pigs of all sizes—including sows, boars, growers, piglets—and can also be used for other livestock like cattle. It works by releasing water only when the pig’s mouth touches the metal bar, automatically closing when not in use. This saves water, keeps pens drier, and reduces the labor required for water supply management.

The overall compact size (2.8 x 0.8 inches) makes it easy to fit in various setups. Pigs quickly learn how to use the drinker—rubbing a bit of peanut butter on the nipple can help train them.

Size

Details

|

Straw duckbill style pig spout |

| Red filter tip |  |

|

Copper cap is more durable |

| No harm to the pig's mouth |  |