The Quail Bird Chicken Pigeon Drinkers And Feeder represents a comprehensive solution for professional poultry management systems, addressing the critical hydration and nutrition requirements of various avian species through innovative design engineering and robust construction methodologies. This specialized feeding and watering equipment serves as an essential infrastructure component for commercial poultry operations, small-scale farming enterprises, and specialized bird breeding facilities worldwide, where consistent access to clean water and feed directly impacts productivity, health outcomes, and operational efficiency. The versatile nature of these integrated systems accommodates the diverse physiological requirements of quails, chickens, pigeons, and other domestic fowl, recognizing that different species exhibit varying feeding behaviors, beak sizes, and consumption patterns that must be addressed through thoughtful design considerations. Manufacturing approaches for these comprehensive feeding solutions typically incorporate food-grade materials such as stainless steel, high-density polyethylene, and specialized polymer composites that resist corrosion, bacterial growth, and chemical degradation under continuous exposure to moisture, feed particles, and cleaning agents commonly used in agricultural environments. The engineering philosophy underlying these systems emphasizes durability, ease of maintenance, and operational reliability, ensuring that end users can depend on consistent performance across extended operational periods without frequent replacement or intensive servicing requirements. Design considerations encompass multiple functional aspects including flow control mechanisms, anti-contamination features, adjustable height configurations, and capacity optimization to accommodate varying flock sizes and consumption rates while minimizing waste and preventing spillage that could attract pests or create unsanitary conditions. Surface treatments applied during manufacturing often include antimicrobial coatings, UV-resistant finishes, and texturized surfaces that enhance grip while facilitating thorough cleaning protocols essential for maintaining hygienic feeding environments. The modular nature of many contemporary feeder and drinker systems allows for scalable implementation, where individual units can be interconnected or expanded to serve growing operations without requiring complete system overhauls, thereby supporting the evolving needs of dynamic agricultural enterprises. Functional customization possibilities extend to specialized nozzle configurations, automated refill mechanisms, temperature regulation features for cold climate operations, and integrated monitoring capabilities that enable remote oversight of consumption patterns and system status. Application suitability spans diverse operational contexts including commercial egg production facilities, meat processing operations, specialty breed conservation programs, educational institutions with agricultural curricula, and research facilities conducting nutritional or behavioral studies on avian species. The adaptability of these systems makes them equally valuable for indoor controlled environment operations and outdoor free-range configurations, with design variants specifically engineered to withstand various environmental challenges including temperature fluctuations, precipitation exposure, and wind loading considerations. International sourcing teams and distributors increasingly recognize the importance of partnering with manufacturers who demonstrate consistent quality delivery, comprehensive understanding of global regulatory requirements, and proven experience in developing solutions that meet diverse market specifications across different geographical regions. The collaborative approach to product development often involves detailed consultation processes where manufacturers work closely with end users to understand specific operational challenges, environmental constraints, and performance expectations, resulting in customized solutions that optimize efficiency while maintaining cost-effectiveness. Export-oriented handling considerations include robust packaging methodologies that protect delicate components during international shipping, comprehensive installation documentation translated into multiple languages, and design specifications that accommodate varying electrical standards and plumbing configurations found in different markets worldwide. Quality consistency philosophy encompasses rigorous testing protocols that verify material integrity, functional reliability, and safety compliance across production batches, ensuring that international buyers receive products that meet their specified requirements regardless of manufacturing timing or facility location. The emphasis on sustainable manufacturing practices increasingly influences material selection, production methodologies, and end-of-life considerations, with many suppliers adopting recycling programs and environmentally responsible disposal recommendations that align with global sustainability initiatives. Long-term supplier cooperation expectations focus on establishing partnerships that extend beyond initial product delivery to encompass ongoing technical support, replacement part availability, system upgrade pathways, and knowledge transfer that enables distributors and end users to maximize the value derived from their equipment investments while maintaining optimal operational performance throughout extended service lifecycles.

Quail Bird Chicken Pigeon Drinkers And Feeder

-

Versatile Use – Suitable for quail, chickens, pigeons, and other small birds or poultry.

-

Durable & Safe – Made from high-quality, non-toxic plastic for long-lasting, safe use.

-

Anti-Spill & Hygienic – Prevents waste and keeps feed and water clean and uncontaminated.

-

Easy to Use & Monitor – Wide-mouth design for quick refilling and transparent containers for easy level checking.

-

Portable & Stable – Lightweight, easy to clean, and designed to prevent tipping over.

- Overview

- Size

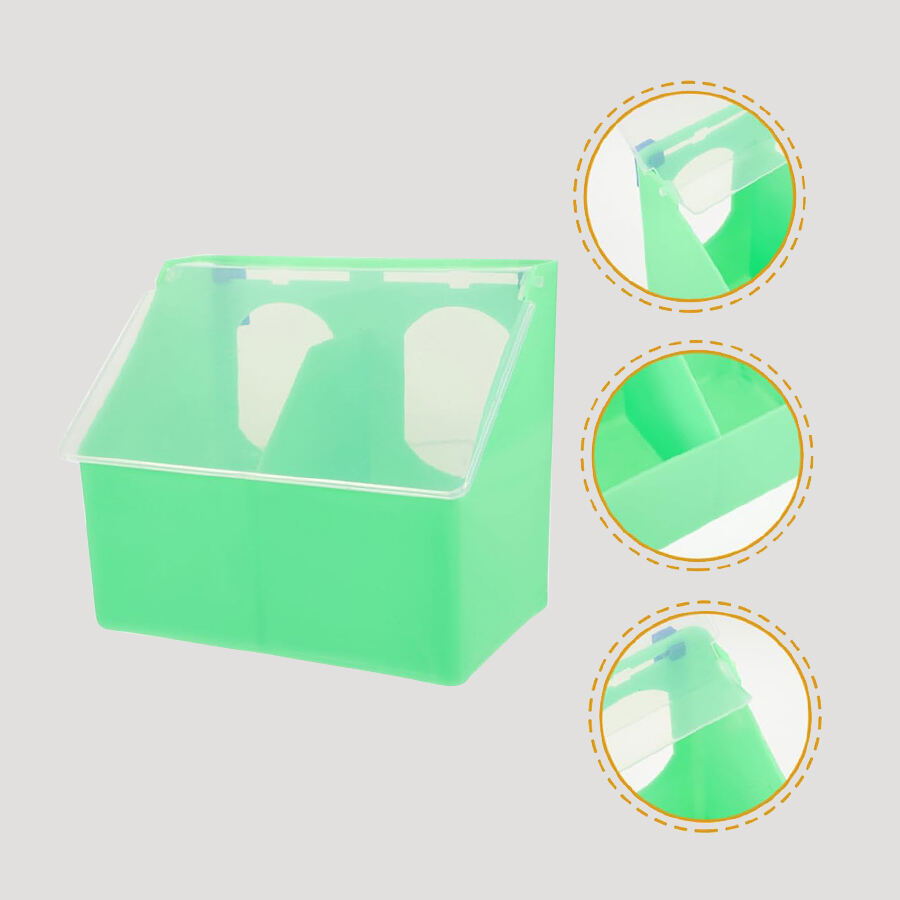

- Details

- Recommended Products

Description

Our versatile Chicken/Pigeon/Bird/Quail feeder is designed for easy installation on any bird cage, making it a practical solution for holding food or water. This hanging feeder cup is crafted for convenience—lightweight, easy to clean, and reusable—ensuring long-lasting use for all your feathered friends. Ideal for parakeets, pigeons, and other small birds, it serves as both a bird food bowl and a water dispenser, offering essential support for your pet’s daily care. The feeder’s sturdy construction ensures durability, while its design minimizes spillage and helps keep your bird cage cleaner with less food waste. Whether you are an experienced bird keeper or just starting, this feeder bowl makes feeding simple and mess-free. It also makes a thoughtful gift for friends and family who love raising birds. Enhance your bird care routine with this practical, reliable, and space-saving feeding solution.

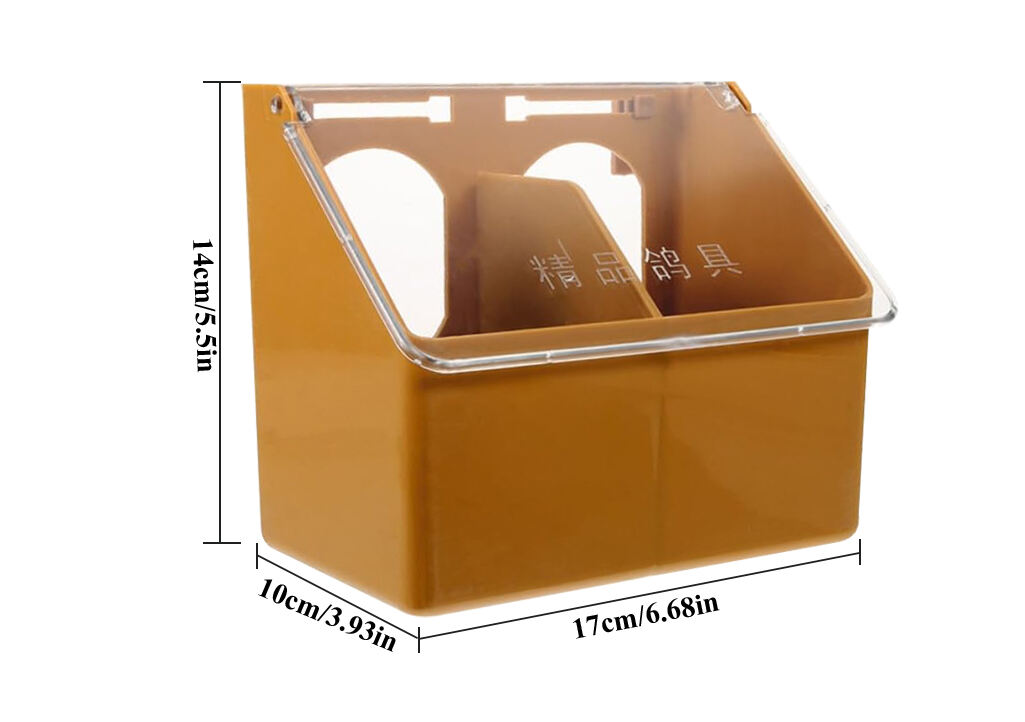

Size

Details

|

Hanging Buckle Mounting There is hanging buckle on the back of thefeeding bowl, can be well fixed on any sizebird cage or pigeon cage |

|

Transparent Lid Which plays the role ofwaterpro of and ash-proof |

|

|

Two Hole Model There are 2 holes, you can let 2 birds eat at the same time.or one for feed one for water. |

|

Ventilation Perforation There are many holes in the back of the feeding bowl for ventilation perforations to keep the food fresh |

|