The ABS/PP Material Durable Automatic Water Pressure Control Valve for Pig Drinking System represents a sophisticated engineering solution specifically designed to address the critical water management requirements of modern swine farming operations, establishing itself as an indispensable component for maintaining optimal hydration levels while ensuring efficient resource utilization throughout large-scale agricultural facilities. This advanced pressure control mechanism incorporates premium grade acrylonitrile butadiene styrene and polypropylene materials, creating a robust foundation that delivers exceptional resistance to chemical degradation, temperature fluctuations, and mechanical stress commonly encountered in demanding livestock environments. The strategic selection of these thermoplastic compounds ensures superior dimensional stability and long-term performance reliability, making this automatic water pressure control valve an ideal choice for international distributors seeking dependable solutions for their agricultural equipment portfolios. The precision-engineered valve assembly features meticulously calibrated internal components that automatically regulate water flow and pressure parameters, eliminating the need for constant manual monitoring while maintaining consistent water availability for livestock throughout varying operational conditions. These sophisticated control mechanisms integrate seamlessly with existing pig drinking systems, providing seamless compatibility with both traditional watering infrastructure and contemporary automated feeding installations. The valve's innovative design philosophy emphasizes maintenance efficiency, incorporating accessible adjustment points and simplified cleaning protocols that reduce operational downtime while extending service intervals, thereby enhancing overall system productivity and cost-effectiveness for end users. Manufacturing excellence remains paramount in the production process, utilizing advanced injection molding techniques and precision machining operations to ensure consistent dimensional accuracy and surface finish quality across every unit produced. The careful selection of raw materials undergoes rigorous quality assessment protocols, ensuring that each component meets stringent international standards for agricultural equipment while maintaining compatibility with various water quality conditions and chemical treatment systems commonly employed in modern pig farming facilities. Surface treatment processes enhance the valve's natural resistance to corrosion and bacterial growth, incorporating specialized finishing techniques that create smooth, non-porous surfaces ideal for maintaining hygienic conditions in livestock watering applications. The valve's ergonomic design considerations facilitate straightforward installation procedures, accommodating various mounting configurations and piping arrangements to suit diverse facility layouts and operational requirements. Customization capabilities extend beyond standard specifications, allowing for tailored pressure ranges, connection types, and flow control characteristics to meet specific regional requirements or unique application parameters requested by international buyers and original equipment manufacturers. These flexible manufacturing approaches enable seamless integration with existing infrastructure while providing opportunities for system optimization based on local water pressure conditions, climate considerations, and specific livestock management protocols. Quality consistency philosophy drives every aspect of the production process, from initial material inspection through final product testing, ensuring that each valve meets identical performance standards regardless of production batch or manufacturing schedule. The valve's robust construction methodology incorporates reinforced stress points and enhanced sealing mechanisms, providing reliable operation under continuous duty cycles while maintaining precise pressure control accuracy over extended service periods. Export-oriented handling considerations influence packaging design and protective measures, ensuring product integrity during international shipping and storage while facilitating efficient inventory management for global distribution networks. The valve's compact form factor optimizes shipping efficiency while reducing warehousing requirements, making it an attractive option for international suppliers managing diverse product portfolios across multiple markets. Collaboration opportunities with original equipment manufacturers and system integrators provide pathways for developing customized solutions that address specific regional requirements or unique application challenges encountered in international pig farming operations. These partnership approaches enable the development of comprehensive watering system packages that incorporate the valve as a critical component within larger automated livestock management solutions. The valve's compatibility with various water treatment systems and filtration equipment ensures seamless integration with existing facility infrastructure, while its resistance to common agricultural chemicals and cleaning agents maintains performance reliability throughout regular maintenance cycles. Long-term supplier cooperation expectations emphasize consistent product availability, technical support capabilities, and responsive communication channels that facilitate successful business relationships with international distributors and end-user customers. The valve's proven design reliability and manufacturing consistency support confidence in establishing ongoing supply agreements and developing market presence across diverse geographic regions. Advanced engineering principles incorporated into the valve's internal mechanism design optimize pressure response characteristics and flow regulation precision, ensuring stable performance across varying input pressure conditions and downstream demand fluctuations typical of large-scale pig drinking installations.

ABS/PP Material Durable Automatic Water Pressure Control Valve for Pig Drinking System

- Overview

- Size

- Details

- Recommended Products

Description

Automatic Water Level Controllers for sows are essential devices in sow breeding, designed to automatically regulate water levels in drinking equipment, ensuring sows have constant access to stable and clean drinking water—this not only boosts breeding efficiency but also significantly enhances sow health. These controllers mainly work on two principles: the float principle and the electronic induction principle. For the float-type, a float moves up and down with water levels to control the inlet valve; when water level drops, the float sinks to open the valve and let water flow into the trough, while it rises to close the valve once the water reaches the set height. The electronic induction-type uses sensors to detect water level changes, sending signals to a controller that further operates solenoid valves, enabling more accurate and sensitive water level control.

In terms of structure, float-type controllers consist of a float, connecting rod, inlet valve and fixed bracket, where the float drives the connecting rod to open or close the valve. Electronic induction-type ones include water level sensors, a controller, solenoid valve and power supply—sensors transmit water level information to the controller, which then controls the solenoid valve. These controllers offer multiple advantages: they guarantee a steady water supply to meet sows’ physiological needs, improving their health and productivity; they save water by avoiding overflow or long-term running water waste; they reduce labor as no frequent manual checks or refills are needed, lowering workload and preventing water shortages; and they maintain hygiene by matching closed or semi-closed drinking systems, reducing external impurities and disease risks.

For installation, place the device where sows can easily access, with convenient water and drainage connections—ensure float movement is unobstructed for float-type, and correct sensor position/angle plus proper electrical connection for electronic-type. For maintenance, regularly check for damage, blockages or leaks, clean dirt on floats/sensors, protect electronic components from moisture and dust, and clean troughs/filters based on water quality to prevent scaling and ensure accurate control.

Size

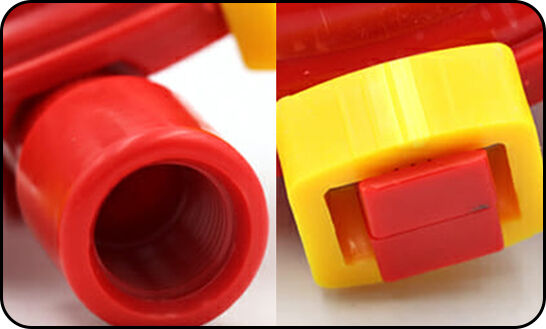

Details

|

Six-claw knob design, quick and easy to disassemble |

|

One-button switch,convenient and quick to drink water |

|

|

High-quality silicone gasket, seal is not easy to seepage |

|

It can supply water for a whole pigpen without power consumption |

|

|

Secure and durable screw fixation, refuse water leakage |

|

Raw material, smooth and delicate surface, safe and non-toxic |

|