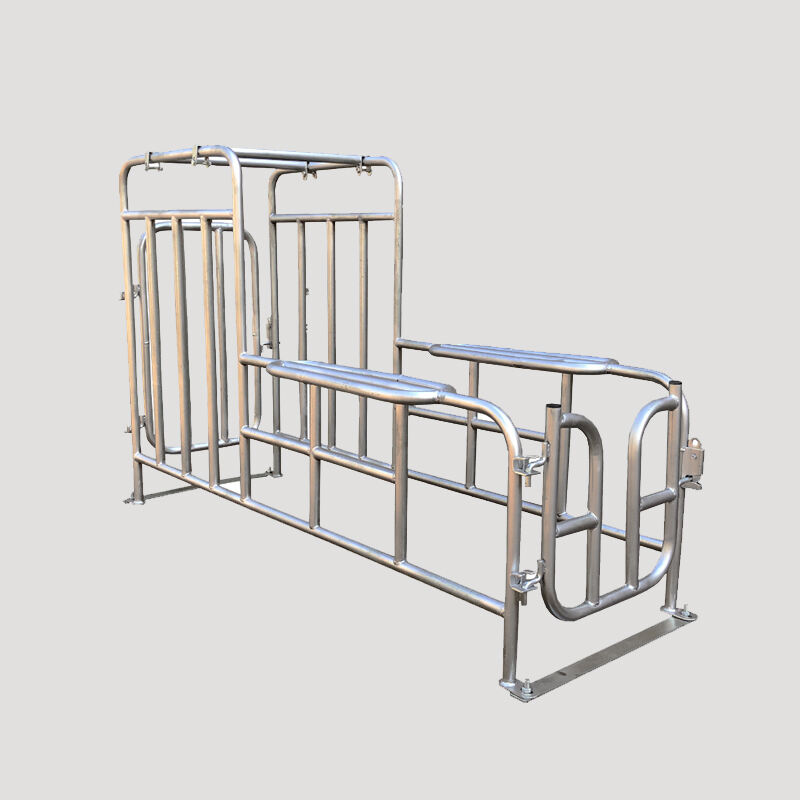

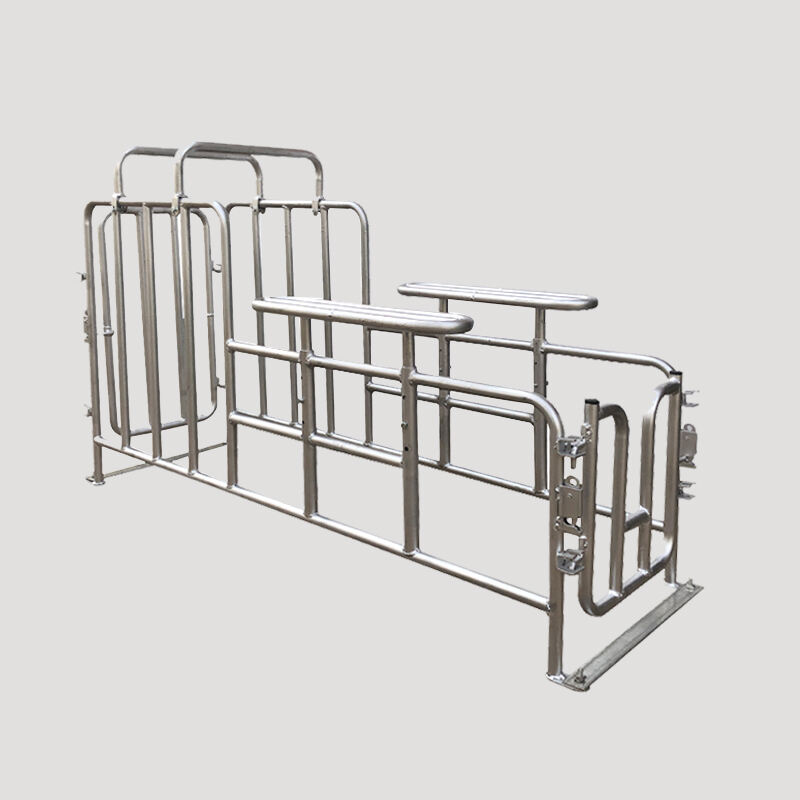

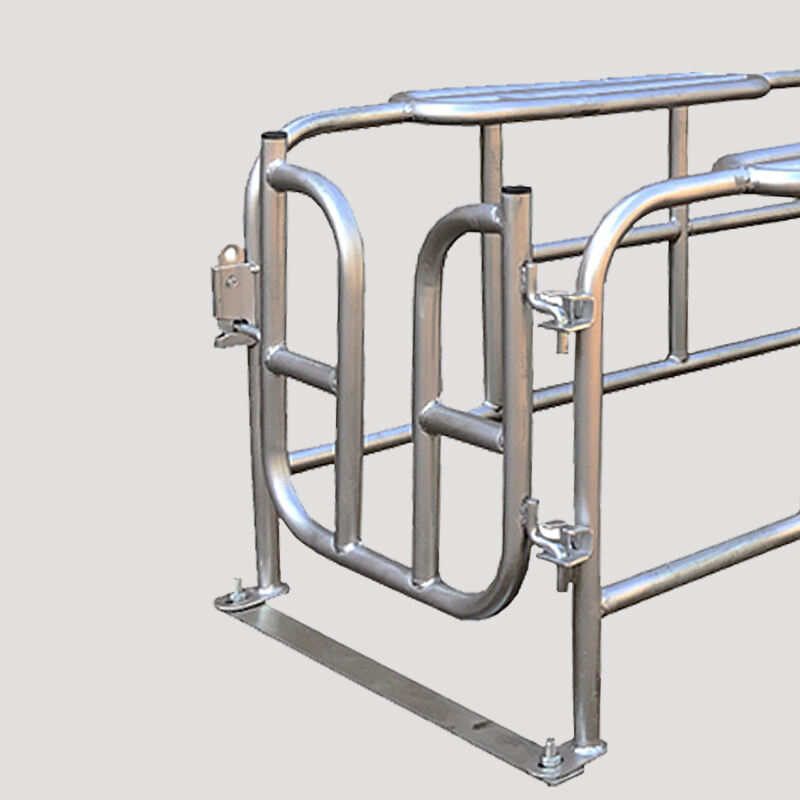

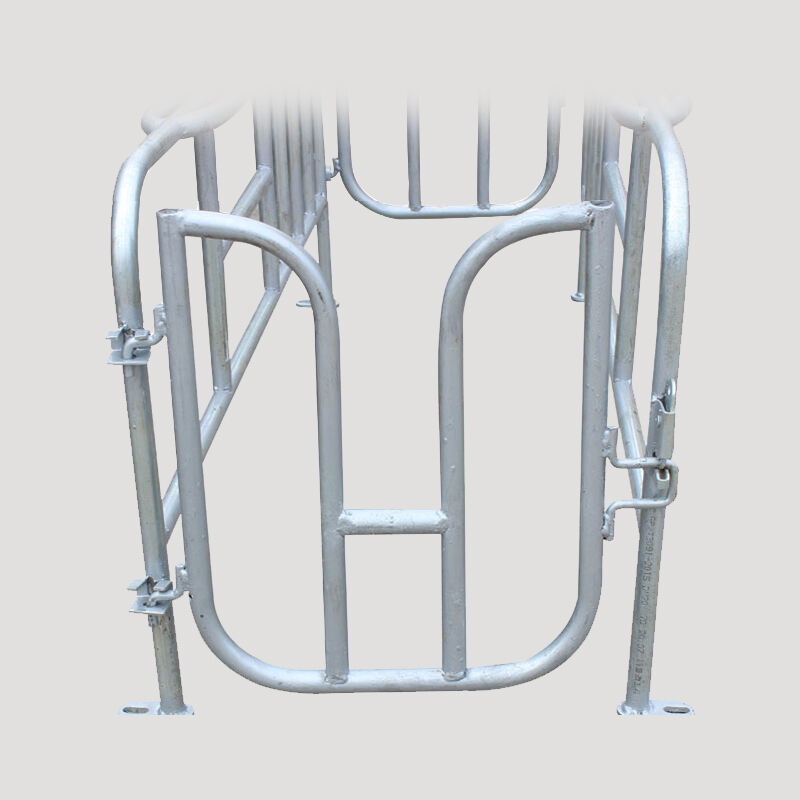

The Hot Galvanized Gestation Fattening Pigs Positioning Cage for Sow Breeding represents a sophisticated approach to modern swine management infrastructure, engineered to meet the demanding requirements of commercial pig farming operations worldwide. This specialized breeding equipment incorporates advanced hot galvanization technology to create a durable, corrosion-resistant framework that withstands the challenging environmental conditions inherent in livestock facilities. The hot galvanization process involves immersing the steel components in molten zinc, creating a metallurgically bonded protective layer that significantly extends the operational lifespan of the positioning cage while maintaining structural integrity under continuous exposure to moisture, ammonia, and other corrosive elements commonly found in agricultural environments. International sourcing professionals recognize this type of equipment as essential infrastructure for establishing efficient breeding programs that optimize space utilization while ensuring animal welfare compliance across diverse regulatory frameworks. The strategic positioning capabilities of this cage system enable precise control over sow movement during critical gestation and fattening phases, facilitating improved breeding outcomes through enhanced monitoring and care protocols. Manufacturing approaches for this specialized equipment typically involve precision welding techniques combined with careful attention to dimensional accuracy, ensuring that each unit maintains consistent spacing specifications that accommodate various sow sizes while providing adequate comfort and mobility range. The galvanized surface treatment not only provides exceptional corrosion resistance but also creates a smooth, hygienic surface that simplifies cleaning and sanitization procedures, contributing to improved biosecurity measures within breeding facilities. Design considerations for effective sow positioning systems encompass multiple factors including optimal bar spacing, gate mechanisms, feeding access points, and waste management integration, all of which must be carefully balanced to create functional equipment that supports both animal welfare standards and operational efficiency requirements. Customization possibilities within this product category allow for adaptation to specific facility layouts, breeding protocols, and regional regulatory requirements, making these positioning cages suitable for diverse agricultural operations ranging from small-scale breeding programs to large commercial swine production facilities. The versatility of galvanized steel construction makes these units particularly well-suited for export markets where equipment must demonstrate reliable performance across varying climatic conditions and facility management practices. Quality consistency represents a fundamental aspect of manufacturing excellence in this sector, with experienced producers implementing comprehensive quality control measures throughout the fabrication process to ensure that each positioning cage meets stringent durability and safety standards expected by international buyers and distributors. The modular nature of many positioning cage designs facilitates efficient shipping and installation procedures, reducing logistical complexities associated with international equipment procurement while enabling flexible facility configuration options. Surface finish quality plays a crucial role in the long-term performance of galvanized positioning cages, as proper zinc coating application and thickness control directly impact the equipment's resistance to environmental degradation and maintenance requirements over extended operational periods. Export-oriented handling considerations include protective packaging strategies that prevent damage during transit while maintaining cost-effective shipping configurations that optimize container utilization for international buyers seeking to establish or expand their breeding operations. The collaborative approach to equipment customization often involves detailed consultation processes between manufacturers and end-users to ensure that specific operational requirements, facility constraints, and regional preferences are appropriately addressed within the final product specifications. OEM and ODM cooperation opportunities in this sector enable the development of specialized positioning cage variants that incorporate unique features or modifications requested by distributors serving particular market segments or geographical regions with distinct regulatory or operational requirements. Packaging and logistics compatibility considerations encompass not only the physical dimensions and weight distribution of individual units but also the coordination of complementary equipment shipments, spare parts availability, and technical documentation necessary for successful installation and operation. The emphasis on sustainable manufacturing practices within the agricultural equipment sector has led to increased adoption of recyclable materials and energy-efficient production processes, positioning galvanized steel positioning cages as environmentally responsible choices for modern swine breeding operations. Long-term supplier cooperation expectations typically involve ongoing technical support, replacement parts availability, and potential equipment upgrades or modifications as breeding practices evolve and facility requirements change over time, establishing partnerships that extend well beyond initial equipment procurement transactions and contribute to the overall success of international agricultural development initiatives.

- Overview

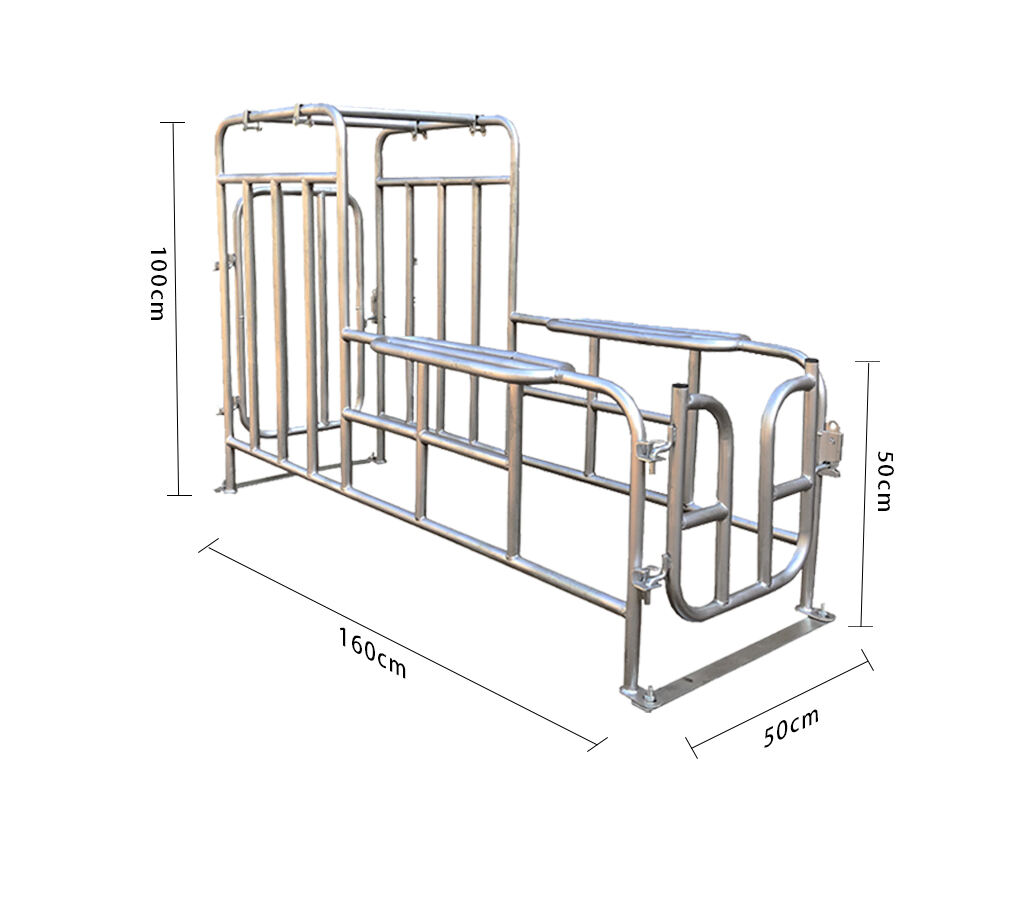

- Size

- Details

- Recommended Products

Description

This piglet suction respirator is a game-changer for newborn piglet care, replacing inefficient traditional breathing assistance methods (such as manual suction) with a more reliable solution. It directly addresses critical challenges in pig farming—effectively resolving piglet asphyxia caused by amniotic fluid buildup, thoroughly removing residual amniotic fluid from the respiratory tract, and providing stable assisted breathing to weak newborns.

Designed for user-friendliness, it has an ergonomic handle that perfectly fits the palm’s natural grip; the pull-out mechanism ensures comfortable, labor-saving operation, allowing one-handed use even for farmers with no professional experience. Crafted from top-tier materials, it delivers consistent, superior performance and long-term reliability. Its mouth-shaped anastomosis design not only generates strong suction for thorough mucus removal but also ensures a gentle fit to avoid discomfort for piglets.

Moreover, it exhibits excellent load-bearing capacity, high structural strength, corrosion resistance (suitable for humid farm environments), and impressive toughness. Made of eco-friendly, non-toxic materials, it supports multiple recycling uses, balancing practicality with sustainability for modern pig farming operations.

Product Introduction Video

Certificate

Size

Details

|

Hot-dip galvanized treatment Strong and durable, strong corrosion resistance |

|

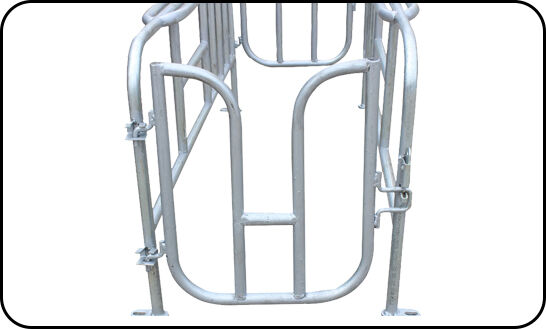

Simple and convenient operation U-shaped back door, drive the sow into the door, and the sow can be directly bred |

|

|

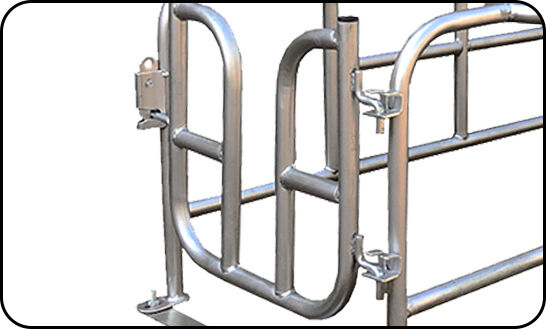

Thickened firmware Thickened steel fittings, corrosion resistance, firm welding and high reliability |