The Plastic Sheep & Goat Long Feeding Trough represents a fundamental advancement in agricultural feeding equipment design, specifically engineered to meet the demanding requirements of modern livestock operations across diverse international markets. This specialized feeding solution combines durable polymer construction with thoughtful ergonomic considerations to deliver exceptional functionality for sheep and goat farmers seeking reliable, long-term feeding infrastructure. The trough's extended linear design maximizes feeding capacity while ensuring optimal access for multiple animals simultaneously, addressing the critical need for efficient group feeding systems in commercial agricultural environments. Built from high-grade plastic materials that resist weathering, chemical degradation, and impact damage, this feeding trough demonstrates superior durability characteristics compared to traditional metal or wooden alternatives, making it particularly valuable for international buyers operating in varied climatic conditions. The polymer construction methodology employed in manufacturing ensures consistent dimensional stability across temperature fluctuations while maintaining structural integrity under continuous use conditions. Professional livestock equipment manufacturers recognize the importance of surface smoothness in feeding applications, and this trough features carefully engineered interior surfaces that facilitate easy cleaning and prevent feed accumulation in corners or crevices. The elongated profile design accommodates natural feeding behaviors of sheep and goats while minimizing competition and stress among animals during feeding periods. International distributors appreciate the lightweight characteristics of plastic construction, which significantly reduce shipping costs and handling complexity during global distribution processes. The material selection process prioritizes food-safe polymer compounds that comply with agricultural equipment standards across multiple international markets, ensuring broad compatibility with diverse regulatory environments. Manufacturing processes incorporate precision molding techniques that maintain consistent wall thickness and structural uniformity, critical factors for long-term performance reliability in demanding agricultural applications. The trough's design philosophy emphasizes ease of installation and maintenance, featuring integrated mounting provisions that accommodate various positioning configurations to suit different facility layouts and operational preferences. Quality consistency represents a cornerstone of the manufacturing approach, with systematic production controls ensuring each unit meets established performance standards regardless of production batch or destination market. The feeding trough's generous length specification provides adequate feeding space for multiple animals while maintaining practical handling dimensions for farm personnel during cleaning and maintenance activities. Surface treatment considerations include smooth finish characteristics that resist bacterial accumulation while facilitating rapid cleaning protocols essential for maintaining optimal hygiene standards in livestock operations. Export-oriented design elements account for international shipping requirements, including stackable configurations that optimize container utilization and reduce transportation costs for large-quantity orders. The versatile nature of plastic construction enables customization opportunities for OEM partners seeking specific color schemes, dimensional modifications, or branding applications to meet particular market requirements. Agricultural equipment sourcing teams frequently evaluate feeding systems based on total cost of ownership, and this plastic feeding trough delivers exceptional value through reduced maintenance requirements and extended service life compared to alternative materials. The manufacturing facility maintains comprehensive quality management systems that support consistent production capabilities for international customers requiring reliable supply chain partnerships. Collaboration opportunities with distributors and private label partners encompass various customization levels, from standard color modifications to completely tailored designs that incorporate specific functional enhancements. The feeding trough's compatibility with automated feeding systems makes it particularly attractive for modern agricultural operations implementing mechanized feed distribution technologies. Environmental considerations influence contemporary agricultural equipment selection, and the recyclable nature of the plastic construction aligns with sustainability initiatives increasingly important to international buyers. Professional installation teams appreciate the reduced weight characteristics that simplify handling during setup procedures while maintaining structural strength sufficient for heavy-duty agricultural applications. The design accommodates various feed types commonly used in sheep and goat operations, from pelletized concentrates to chopped forages, with interior geometry optimized for efficient feed presentation and minimal waste generation. International cooperation opportunities extend beyond simple product supply to encompass technical support, application guidance, and ongoing partnership development that supports long-term business relationships. Packaging solutions for international shipment utilize protective materials and space-efficient configurations that ensure product integrity during extended transportation cycles while minimizing overall shipping costs. The feeding trough's proven performance in diverse operational environments demonstrates reliability characteristics that support confident specification by agricultural consultants and facility designers worldwide. Manufacturing experience accumulated through extensive international cooperation provides deep understanding of varied market requirements and application-specific performance expectations that inform continuous product development initiatives.

Plastic Sheep & Goat Long Feeding Trough

-

Durable plastic trough with metal frame, easy to clean and perfect for multiple sheep feeding.

-

Sturdy, rustproof sheep feeder made of plastic and steel, ideal for clean and efficient feeding.

-

Lightweight, durable plastic trough with stable frame, great for group feeding on farms.

- Dimension:39inch*11.8inch,large capacity for food

- Overview

- Size

- Details

- Key Selling Points

- Recommended Products

Description

The sheep feeding trough is designed to make livestock feeding easier, more efficient, and long-lasting. With a large capacity of up to 66 lbs of feed and 11 gallons of water, it can accommodate 8 sheep feeding simultaneously, making it ideal for daily use. Crafted from durable PP plastic with a high-quality galvanized metal stand, this feeder is built to withstand extreme weather conditions while offering a no-waste, rust-proof design.

It features 7 adjustable height levels, making it versatile for different animals: low settings for chickens, ducks, and geese, medium for lambs, and high for goats and horses. The rivet nut design allows quick and simple adjustments. Additionally, reinforced fixing devices ensure stability on muddy soil, cement, or wooden floors. Suitable for farms, homes, courtyards, and sheep sheds, this feeder meets the needs of various animals while ensuring durability and convenience for everyday feeding.

Product Introduction Video

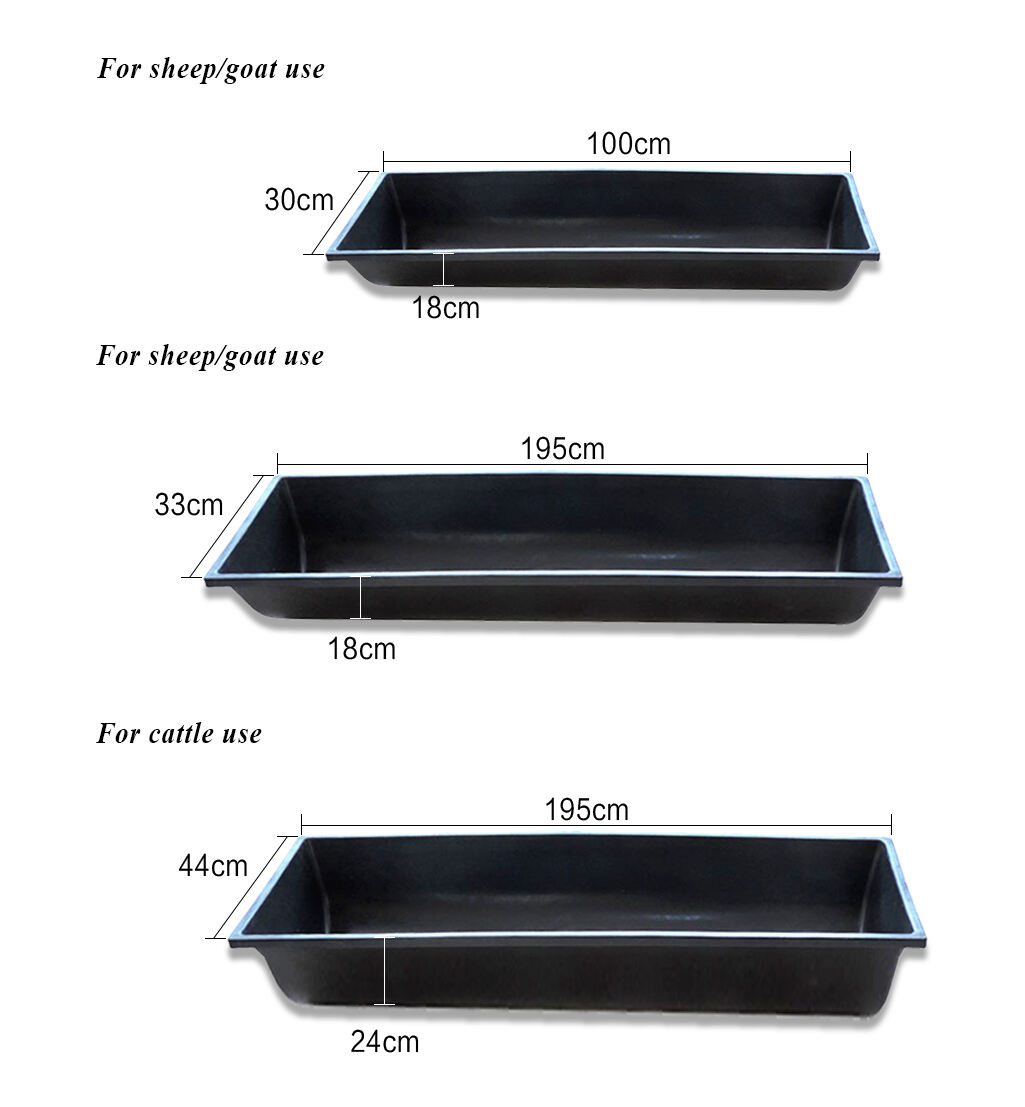

Size

Details

|

Smooth surface, safe and healthy |

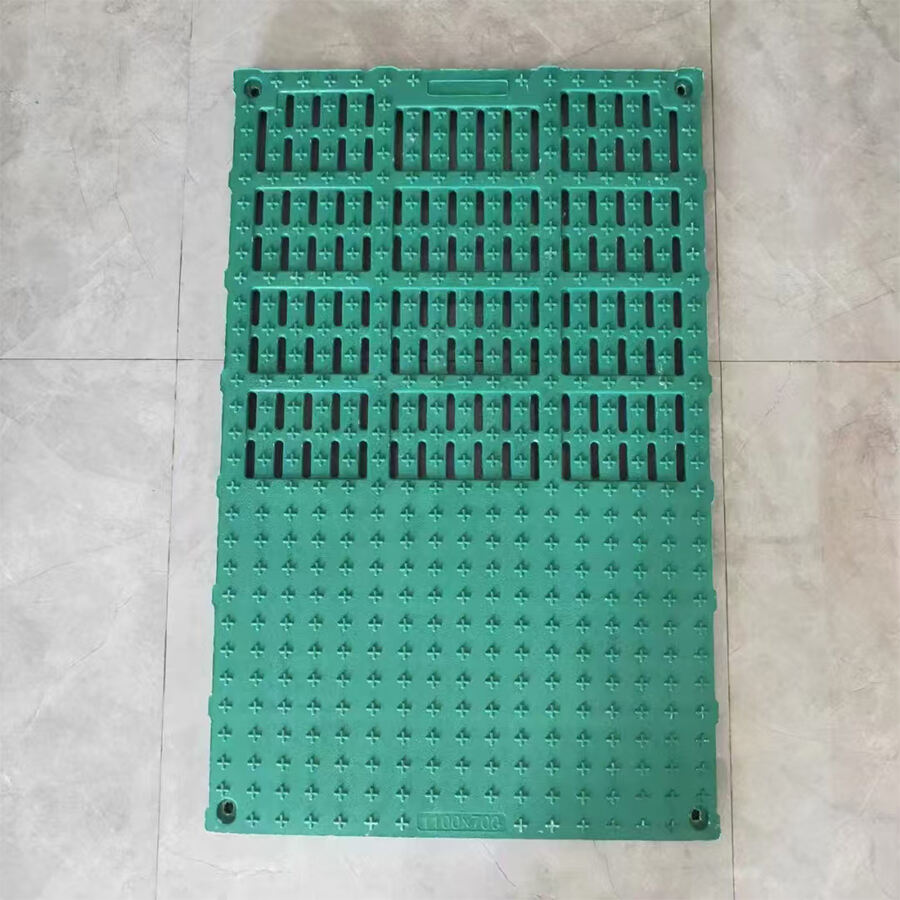

| Buckle design, unlimited extension |  |

|

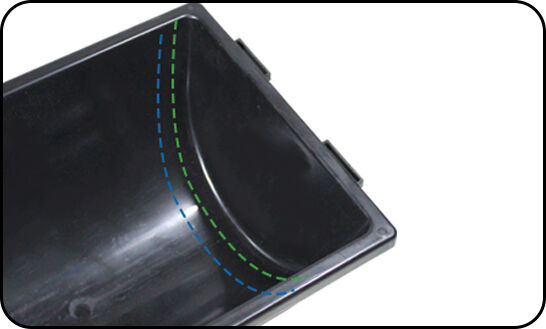

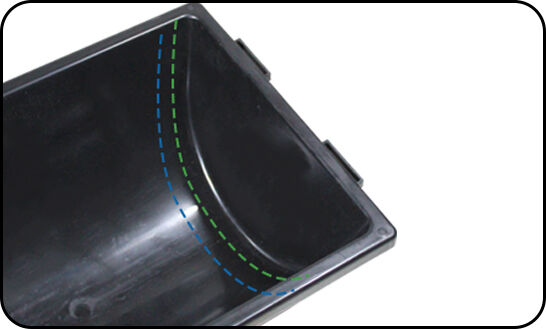

Curved design, no food residue |

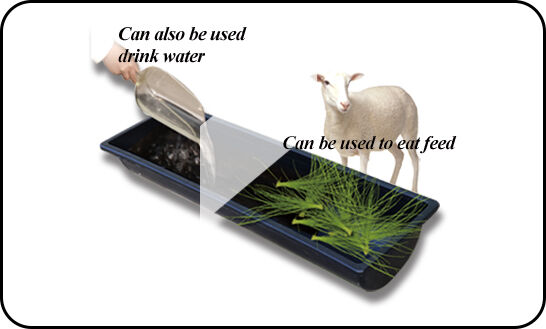

| One slot can be dual-use |  |

Key Selling Points

|

Flat edges, easy to fix |

| Smooth surface, safe and healthy |  |

|

Curved design, no food residue |

| Front and back display |  |