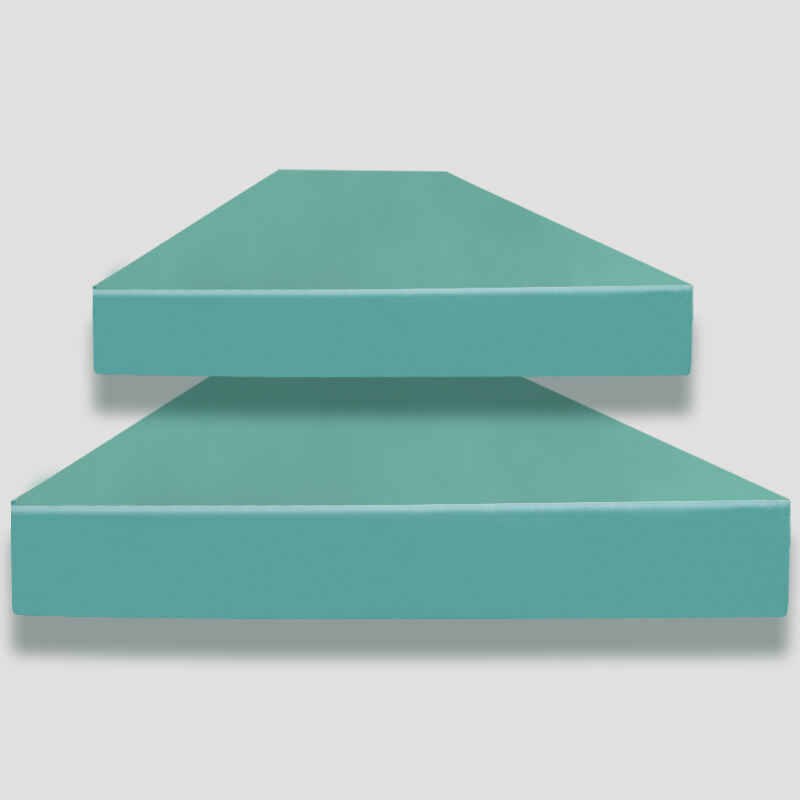

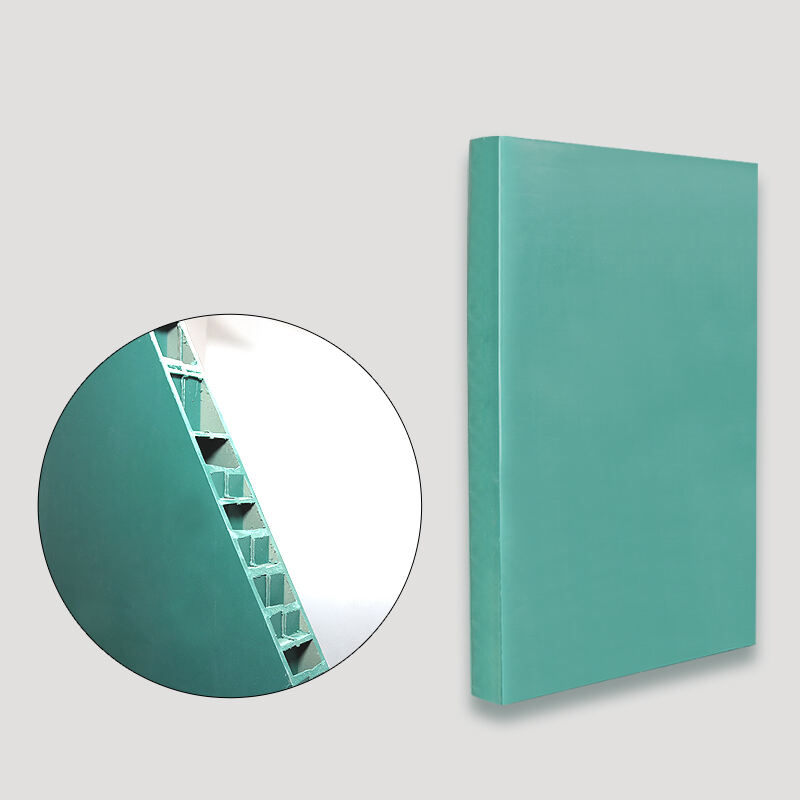

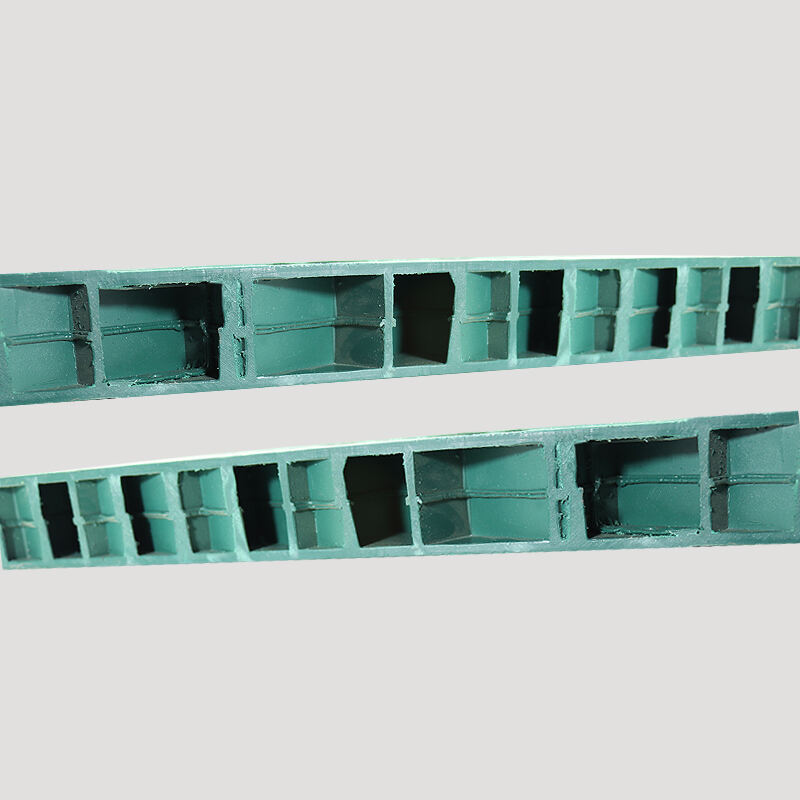

The PP Hollow Board Pig Pen Partition for Breeding Equipment represents a sophisticated advancement in modern livestock facility infrastructure, specifically engineered to address the evolving requirements of commercial pig breeding operations across diverse international markets. This innovative partition solution leverages the superior properties of polypropylene hollow board construction to deliver exceptional durability, hygiene maintenance capabilities, and operational efficiency within intensive farming environments. The strategic utilization of hollow board technology provides optimal structural integrity while maintaining lightweight characteristics that facilitate installation flexibility and long-term maintenance accessibility. Professional pig breeding facilities increasingly recognize the critical importance of partition systems that can withstand the demanding conditions inherent in livestock environments, including exposure to moisture, chemical cleaning agents, and the physical impact associated with animal movement and feeding activities. The polypropylene material foundation ensures consistent performance across varying temperature ranges and humidity levels, making this partition system particularly suitable for international deployment where environmental conditions may fluctuate significantly between different geographical regions. Manufacturing processes for this specialized breeding equipment incorporate advanced extrusion techniques that create uniform wall thickness throughout the hollow board structure, resulting in predictable load-bearing characteristics and consistent dimensional stability over extended operational periods. The inherent chemical resistance of polypropylene material provides exceptional compatibility with standard agricultural disinfectants and cleaning protocols, enabling facility managers to maintain optimal hygiene standards without compromising the structural integrity or aesthetic appearance of the partition system. Surface treatments applied during the manufacturing process enhance the natural properties of the base material, creating smooth, non-porous surfaces that resist bacterial colonization and facilitate thorough cleaning procedures essential for disease prevention in livestock environments. Design considerations for this pig pen partition system encompass multiple functional requirements including animal safety, operational efficiency, and maintenance accessibility, with particular attention paid to edge finishing and joint construction that eliminates potential injury hazards while ensuring secure installation. The modular nature of hollow board construction enables flexible configuration options that accommodate varying pen dimensions and layout requirements, allowing breeding facility operators to optimize space utilization according to specific operational parameters and animal management protocols. Customization possibilities extend beyond dimensional variations to include color selection options that support facility organization systems and visual management approaches commonly employed in professional breeding operations. International sourcing teams evaluating partition solutions for breeding equipment applications recognize the importance of supplier partnerships that demonstrate consistent quality control measures and comprehensive understanding of agricultural industry requirements. The manufacturing approach for this specialized equipment emphasizes quality consistency across production batches, ensuring that facilities expanding their operations or replacing existing infrastructure can rely on uniform performance characteristics regardless of order timing or quantity requirements. Export-oriented handling considerations incorporate protective packaging methods and dimensional optimization that minimize shipping costs while ensuring product integrity during international transit, supporting cost-effective procurement for overseas breeding facility development projects. Collaboration opportunities with OEM and ODM partners extend the application potential of this partition system through specialized modifications that address unique facility requirements or regional regulatory compliance needs. The versatility of polypropylene hollow board construction allows for integration with various mounting systems and hardware configurations, supporting compatibility with existing facility infrastructure and future expansion planning considerations. Professional breeding operations benefit from partition solutions that balance initial investment requirements with long-term operational cost efficiency, and the durability characteristics of properly manufactured hollow board systems contribute significantly to favorable total cost of ownership calculations. Logistics compatibility considerations ensure that packaging and shipping arrangements accommodate the dimensional requirements of partition panels while maintaining protection standards necessary for international freight handling. Quality assurance protocols implemented throughout the manufacturing process reflect extensive experience in producing agricultural equipment that meets the demanding performance standards expected by professional livestock breeding operations. The commitment to manufacturing excellence extends beyond individual product quality to encompass comprehensive supplier cooperation that supports ongoing facility development and operational optimization initiatives. Distributors and sourcing professionals recognize the value of establishing relationships with manufacturers who demonstrate consistent capability in delivering specialized agricultural equipment that meets both immediate installation requirements and long-term operational performance expectations. The strategic importance of reliable partition systems in modern pig breeding facilities continues to drive demand for innovative solutions that combine proven material technologies with manufacturing expertise specifically focused on agricultural applications.

PP Hollow Board Pig Pen Partition for Breeding Equipment

1. Durability and Long - lasting

2. Hygienic and Easy to Clean

3. Lightweight and Easy to Install

4. Customizable Design

5. Cost - effective

- Overview

- Size

- Details

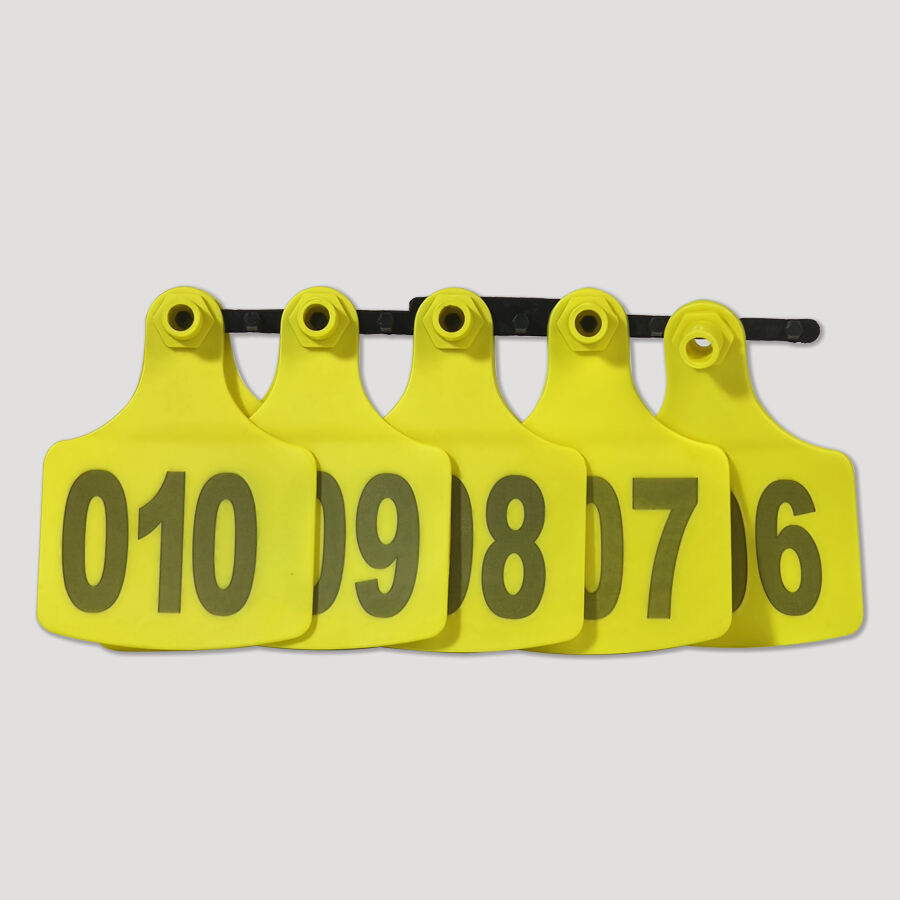

- Recommended Products

Description

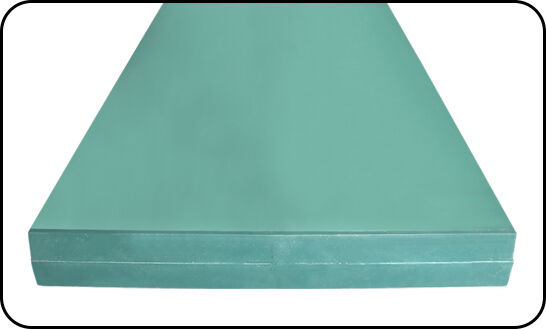

The PP Breeding Thickened Pig Fence stands as a premium solution tailored for modern pig farming operations. Crafted from high-grade polypropylene (PP), this fence delivers exceptional durability, withstanding diverse environmental stressors to maintain long-term reliability.

Its thickened structure further boosts strength and sturdiness, effectively confining pigs of all sizes and temperaments—even resisting the constant pushing, rubbing, and chewing common in pig pens.

The smooth PP surface offers added practicality: it is easy to clean and disinfect, helping uphold a hygienic environment for pigs while preventing rust or corrosion. This durability reduces the need for frequent replacements, cutting down on long-term costs.

Installation is streamlined and hassle-free, saving farmers valuable time and labor during setup. Blending functional design with consistent performance, this PP pig fence is a cost-effective, essential addition to any professional pig breeding facility.

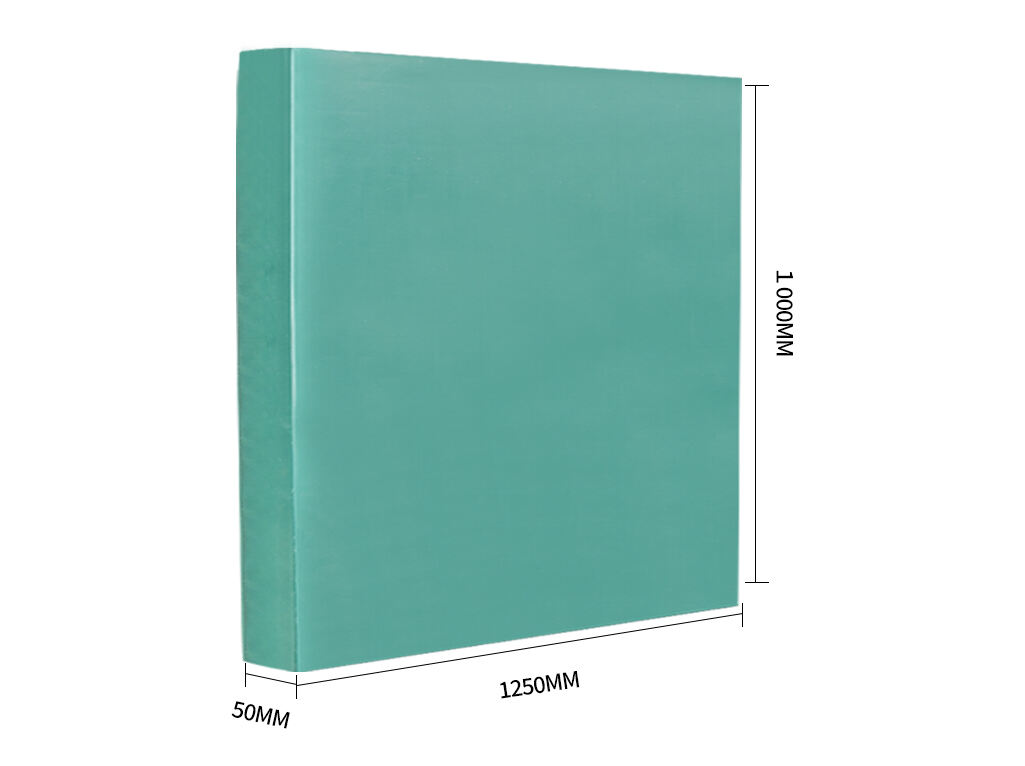

Size

Details

|

Thick and durable Thickened fence design, impact re- sistance, friction resistance, long service life |

|

Easy to install Easy to install and save labor and time |

|

|

Acid and alkali resistant Made of high-quality new materi- als, can withstand acid and alkali environment and high and low temperature |

|

Factory direct sales Factory direct delivery, sufficient supply, fast delivery |

|