The Automatic Plastic Pig Feeder represents a sophisticated feeding solution engineered specifically for modern swine production facilities seeking enhanced operational efficiency and consistent feed management protocols. This advanced feeding system incorporates durable thermoplastic construction materials that demonstrate exceptional resistance to agricultural environments while maintaining structural integrity under continuous operational demands. The automated dispensing mechanism eliminates manual feeding interventions, allowing livestock managers to establish precise feeding schedules that optimize growth rates and feed conversion ratios across diverse pig farming operations. Manufacturing processes for this feeding equipment utilize high-grade polymer compounds that resist corrosion from moisture, feed acids, and cleaning chemicals commonly encountered in commercial swine facilities, ensuring sustained performance throughout extended operational cycles. The feeder's design philosophy centers on maximizing feed efficiency while minimizing waste through controlled portion dispensing mechanisms that prevent over-feeding and reduce environmental contamination around feeding areas. International B2B sourcing professionals recognize this equipment as an essential component for modernizing agricultural operations, particularly in regions where labor costs and operational consistency present ongoing challenges for traditional feeding methodologies. Surface treatments applied during production enhance the plastic components' UV resistance and chemical stability, making these feeders suitable for both indoor confinement systems and outdoor pig farming installations where weather exposure requires additional material durability. The automated feeding mechanism incorporates adjustable timing controls that accommodate varying feed schedules based on pig age groups, nutritional requirements, and seasonal feeding protocols established by agricultural specialists and veterinary nutritionists. Customization possibilities extend to hopper capacity configurations, dispensing rate adjustments, and mounting system modifications that allow integration with existing barn infrastructure without requiring extensive facility renovations. These feeding systems demonstrate particular effectiveness in commercial swine operations where consistent feed delivery timing directly impacts animal welfare standards and production efficiency metrics measured by farm management teams. The robust plastic construction methodology ensures compatibility with standard agricultural cleaning procedures, including pressure washing and sanitization protocols required by food safety regulations governing livestock production facilities. Quality consistency approaches implemented throughout manufacturing processes focus on dimensional accuracy, component durability, and mechanical reliability that supports uninterrupted feeding operations essential for maintaining livestock health and productivity benchmarks. Export-oriented handling considerations include protective packaging systems that prevent damage during international shipping while maintaining component alignment and calibration settings established during factory testing procedures. Agricultural equipment distributors appreciate the straightforward installation requirements that minimize on-site technical support needs while ensuring proper system functionality across diverse farming environments and management approaches. The feeder's operational flexibility accommodates various feed types commonly used in swine nutrition programs, from pelleted commercial feeds to custom-blended nutritional formulations developed for specific growth phases or breeding programs. Collaboration opportunities with OEM and ODM partners enable customization of feeding capacity specifications, control system interfaces, and structural modifications that address regional farming practices or specialized production requirements identified through market research and customer feedback analysis. Long-term supplier cooperation expectations emphasize consistent product availability, technical support accessibility, and continuous improvement initiatives that incorporate evolving agricultural technology trends and regulatory compliance requirements affecting international livestock equipment markets. The feeding system's design integration capabilities extend to compatibility with barn automation systems, environmental monitoring equipment, and data collection platforms used by progressive farming operations to optimize production efficiency and animal welfare outcomes. Packaging and logistics compatibility considerations ensure efficient container loading for international shipment while protecting critical mechanical components from transit damage that could compromise installation timelines or operational functionality upon delivery. Manufacturing experience accumulated through extensive agricultural equipment production enables consistent quality delivery and technical refinement that addresses practical challenges encountered in real-world swine production environments across different climatic conditions and management systems. The automated feeding mechanism reduces labor requirements associated with manual feeding routines while providing more consistent feed delivery timing than traditional methods, supporting improved feed conversion ratios and standardized growth performance across pig populations. Surface finish options accommodate different aesthetic preferences and operational requirements, with smooth finishes facilitating easy cleaning and textured surfaces providing enhanced grip for handling during installation and maintenance procedures conducted by farm personnel or technical service teams.

Automatic Plastic Pig Feeder

-

Durable & Safe Material – Made from non-toxic, corrosion-resistant plastic that ensures long service life and piglet safety.

-

Automatic & Efficient Feeding – Consistently dispenses feed, reducing labor and improving feeding management.

-

Hygienic & Easy to Clean – Smooth surfaces and detachable parts make cleaning fast and sanitary.

-

Piglet-Friendly Design – Low height, anti-spill structure, and bright colors promote comfortable, independent feeding.

-

Large Capacity & Easy Installation – Holds enough feed for multiple piglets and is lightweight for quick setup or relocation.

- Overview

- Size

- Details

- Recommended Products

Description

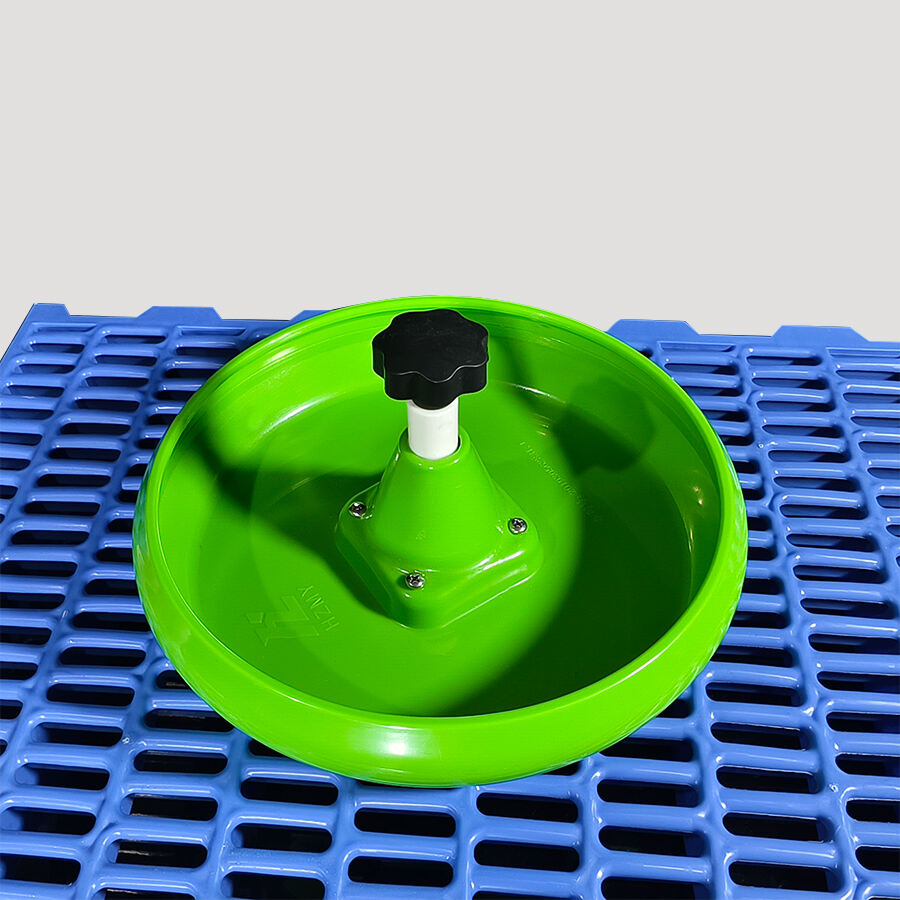

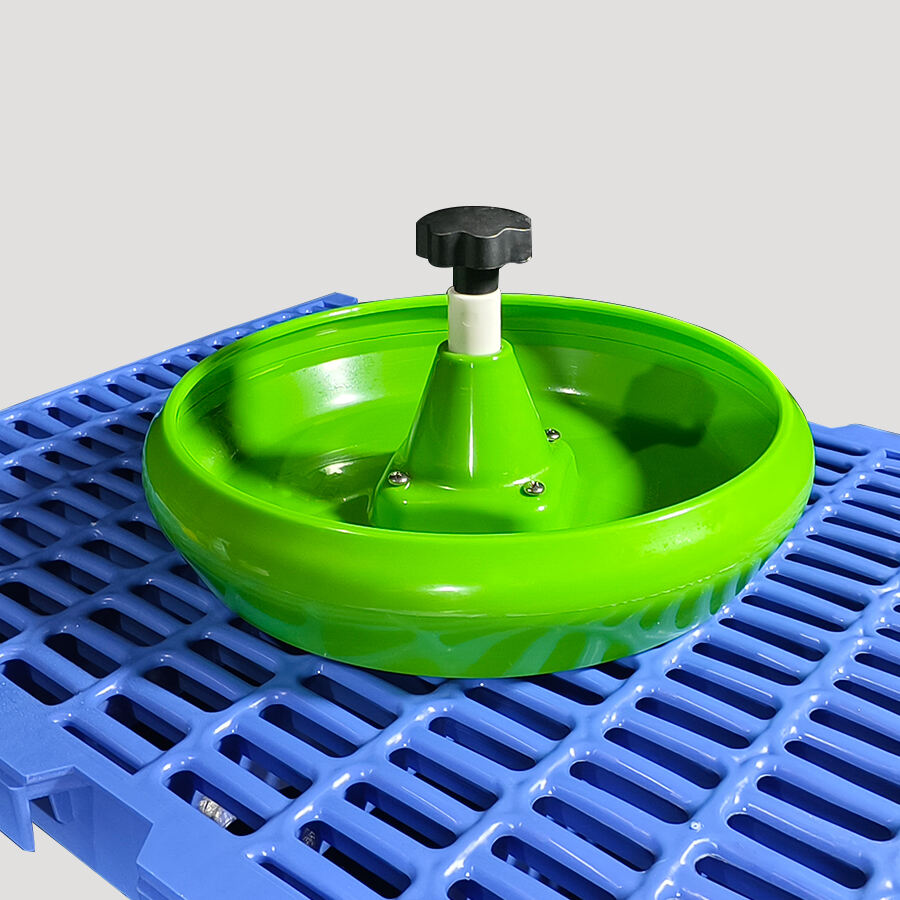

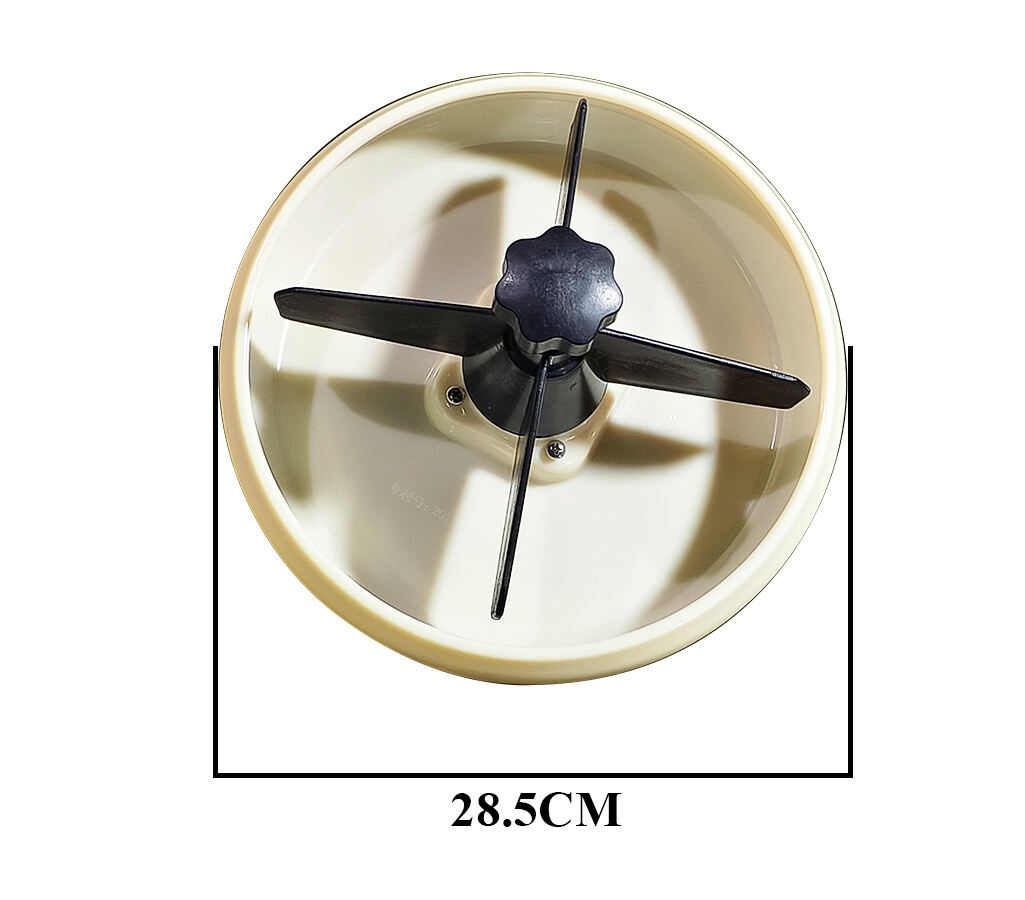

This piglet feeder is a practical tool for piglet feeding management. It features a circular trough design with a central rotating blade structure, allowing multiple piglets to eat simultaneously and effectively avoiding food competition. Made of durable material, it ensures a long service life. Additionally, its simple structure makes it easy to clean and disinfect, helping maintain a hygienic feeding environment and reducing the risk of piglet diseases. The trough can hold a certain amount of feed, reducing feeding frequency and saving labor costs. In all, this feeder provides an efficient, hygienic, and labor-saving feeding solution for piglet breeding. Its dimension is 28.5*28.5cm.

Certificate

Size

Details

|

Column design There are four food troughs in total, so you don't have to worry about the pigs grabbing food, and the feeding is more efficient. |

|

Separator baffle is removable The baffle is removable and easy to clean |

|

|

ABS food grade material Safe and durable,protect the food safety of piglets |

|

Bottom hook Firmly hang the fecal leakage board and prevent it from moving casually |

|