The Automatic Plastic Sheep Drinking Bowl represents a sophisticated solution for modern livestock management systems, engineered specifically to address the hydration needs of sheep flocks while minimizing labor requirements and ensuring consistent water access across various farming operations. This innovative drinking system combines advanced plastic manufacturing techniques with precision-engineered automatic water dispensing mechanisms, creating a durable and efficient watering solution that caters to the unique behavioral patterns and physiological requirements of sheep in both commercial and small-scale agricultural environments. The automatic functionality eliminates the need for constant manual water refilling, allowing farmers and livestock managers to focus their attention on other critical aspects of animal husbandry while maintaining optimal hydration levels for their flocks. The plastic construction offers significant advantages over traditional metal alternatives, including superior resistance to corrosion, reduced weight for easier installation and maintenance, and enhanced compatibility with various water quality conditions commonly encountered in agricultural settings. Manufacturing processes for these automatic drinking systems typically involve high-grade polymer materials that undergo rigorous molding and assembly procedures to ensure structural integrity and long-term performance reliability under demanding outdoor conditions. The design considerations encompass multiple factors including water flow regulation, debris filtration, freeze resistance capabilities, and ergonomic accessibility that accommodates sheep of different sizes and ages within the same flock. Surface treatments applied during production often include UV stabilization compounds that protect the plastic components from degradation caused by prolonged sun exposure, while antimicrobial additives help maintain water quality and reduce bacterial growth within the system. Customization possibilities for these automatic sheep drinking bowls extend beyond basic functional requirements to include variations in bowl capacity, mounting configurations, valve sensitivity adjustments, and integration compatibility with existing water supply infrastructure. The versatility of plastic as a manufacturing material allows for precise molding of complex geometries that optimize water flow dynamics while minimizing splash and waste, contributing to more efficient water usage and cleaner livestock areas. Quality consistency philosophy underlying professional manufacturing of these systems emphasizes standardized production processes, rigorous material selection criteria, and comprehensive testing protocols that ensure each unit meets performance expectations across diverse operational environments. Export-oriented handling considerations include robust packaging designs that protect delicate internal mechanisms during international shipping, while maintaining compact dimensions that optimize container loading efficiency and reduce transportation costs for bulk orders. The automatic mechanism typically incorporates pressure-activated valves or float-controlled dispensing systems that respond to water level changes, ensuring continuous availability without overflow or dry conditions that could stress the animals. Installation flexibility represents another key advantage, with mounting options designed to accommodate various fence types, post configurations, and height requirements that suit different sheep breeds and management practices. Maintenance requirements remain minimal due to the self-cleaning properties of smooth plastic surfaces and the simplicity of the automatic dispensing mechanism, though periodic inspection and basic cleaning procedures help ensure optimal long-term performance. Customization collaboration opportunities with OEM and ODM partners enable agricultural equipment distributors and farming cooperatives to develop specialized versions that address specific regional requirements, climate considerations, or integration needs with existing livestock management systems. The durability characteristics of high-quality plastic construction provide excellent resistance to impact damage, temperature fluctuations, and chemical exposure from water treatment additives commonly used in agricultural water systems. Packaging and logistics compatibility considerations ensure that these drinking bowls can be efficiently shipped in various quantities, from individual replacement units to large-scale installations for commercial sheep operations, with protective packaging that prevents damage during handling and storage. Long-term supplier cooperation expectations focus on consistent product availability, technical support for installation and troubleshooting, and ongoing collaboration to develop improved versions that incorporate feedback from field applications and evolving industry requirements. The automatic water dispensing technology reduces water waste compared to traditional open trough systems while providing sheep with fresh, clean water on demand, supporting optimal animal health and productivity in modern livestock operations. Professional manufacturing experience in developing these specialized agricultural products ensures that each automatic plastic sheep drinking bowl meets the demanding requirements of commercial farming operations while remaining accessible and practical for smaller-scale producers seeking to improve their livestock management efficiency.

- Overview

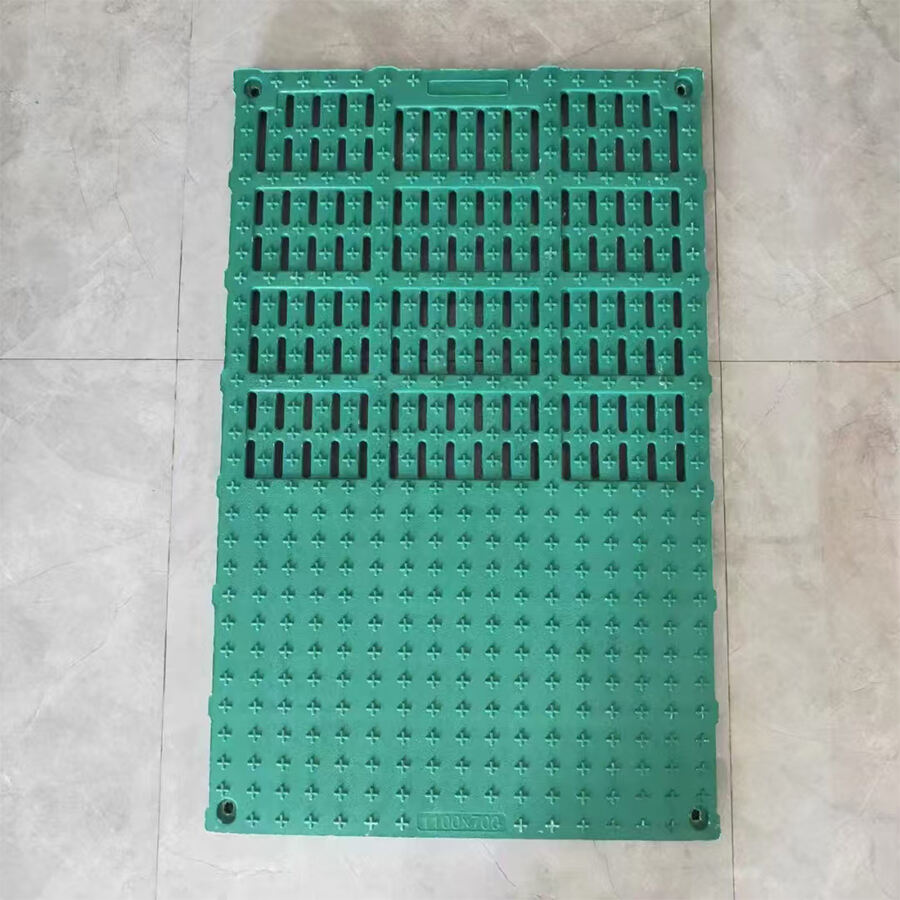

- Size

- Details

- Recommended Products

Description

Our automatic animal waterers offer a reliable, hands-free hydration solution tailored to diverse animal care needs, taking the hassle out of daily feeding and watering routines while prioritizing your animals’ well-being. For general livestock and pets, the waterer maintains a consistent water level at all times—eliminating the need for frequent manual checks and refills, reducing your daily chores significantly. Paired with a complementary plastic feeder bowl, it creates a convenient all-in-one spot for nutrition, ensuring your pets and small animals stay hydrated and fed without extra effort.

When it comes to larger livestock like cattle, our dedicated automatic cattle waterer is designed to meet their higher water demands with a continuous, steady supply. Crafted from durable plastic, it stands up to the rough, demanding conditions of farm environments—resisting impacts, weathering, and wear for long-term reliability, so you never have to worry about constant replacements or repairs.

For furry companions like dogs, we’ve combined functionality into a 2-in-1 feeder and waterer. This comprehensive solution provides a single, accessible spot for both food and water, simplifying pet care. Its user-friendly design also allows for easy installation, whether in a backyard, barn, or indoor space, fitting seamlessly into your daily routine.

Poultry owners benefit from our practical poultry water feeder, which features a precision copper valve to control water flow. This valve minimizes spills and water waste, keeping the coop clean and dry while ensuring your chickens, ducks, or other poultry always have access to fresh, clean water. By cutting down on constant refills, it saves you valuable time and energy that can be redirected to other farm tasks.

Across all applications—from goats and pigs to poultry and pets—our automatic waterers share a focus on durability and efficiency. The tough plastic construction ensures longevity, even with daily use, and the automatic design reduces reliance on manual labor. This makes them an ideal choice for busy farms, homesteads, or pet owners who want to provide consistent, high-quality care without sacrificing time or convenience.

Product Introduction Video

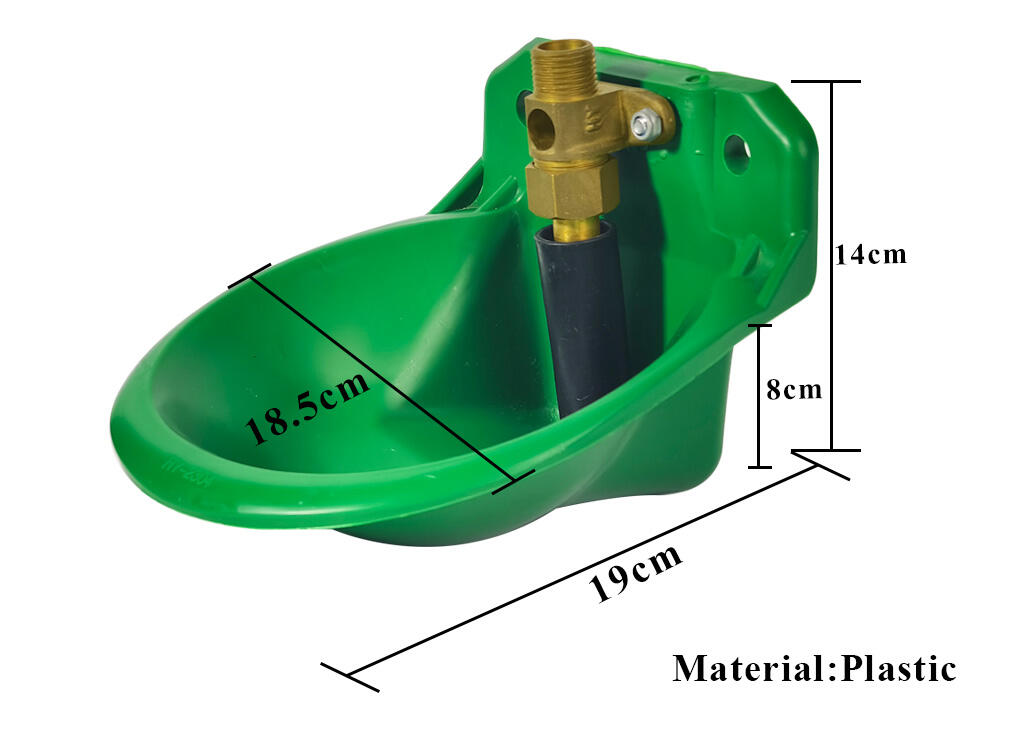

Size

Details

|

Virgin material copper valve, durable |

|

Fixed holes on both sides, easy to use |

|

|

Smooth edges, to prevent injuries |

| Sheep head physiological design |  |