The Single Sided EU-Style Pig Farrowing Crate represents a sophisticated approach to modern swine husbandry infrastructure, specifically engineered to meet the evolving welfare standards and operational requirements of contemporary pig farming operations across international markets. This specialized farrowing equipment embodies the European Union's progressive philosophy toward animal welfare while maintaining the practical efficiency that commercial producers demand in their breeding facilities. The single-sided configuration distinguishes this farrowing system from traditional double-sided alternatives, offering enhanced accessibility for farm personnel while providing pregnant sows with a controlled environment that balances protection with natural movement capabilities during the critical farrowing and early lactation periods. International B2B buyers, particularly those serving European, North American, and Asia-Pacific markets, increasingly prioritize equipment that demonstrates compliance with stringent animal welfare regulations while delivering measurable operational benefits in terms of labor efficiency, piglet survival rates, and overall facility management. The EU-style designation reflects adherence to comprehensive welfare protocols that emphasize adequate space allocation, proper ventilation integration, and design elements that support natural maternal behaviors without compromising safety for both animals and farm workers. Manufacturing approaches for such specialized agricultural equipment typically involve precision metalworking techniques, utilizing high-grade galvanized steel components that resist corrosion in the demanding farm environment while maintaining structural integrity under continuous use conditions. The single-sided framework design facilitates streamlined installation procedures in both new construction projects and retrofit applications within existing farrowing facilities, making this equipment particularly attractive to international distributors serving diverse agricultural markets with varying infrastructure constraints. Surface treatment considerations for pig farrowing equipment encompass multiple protective layers, including zinc galvanization processes that provide long-term durability against moisture, cleaning chemicals, and the naturally corrosive conditions present in livestock housing environments. The strategic positioning of access panels, feeding mechanisms, and waste management integration points reflects careful engineering analysis of workflow patterns common in professional swine operations, ensuring that daily maintenance routines can be performed efficiently without disrupting the critical bonding period between sows and their offspring. Functional customization possibilities within this farrowing crate category allow OEM partnerships to address specific regional preferences, climate considerations, and integration requirements with existing farm automation systems such as feeding dispensers, environmental control units, and monitoring technology platforms. Application suitability extends beyond traditional commercial pig farming to include research facilities, breeding operations focused on genetic improvement programs, and specialized production systems targeting premium pork markets where animal welfare documentation provides competitive advantages in consumer-conscious markets. The design philosophy underlying EU-style farrowing equipment emphasizes creating an environment where natural farrowing behaviors can occur safely while providing farm personnel with necessary intervention access when complications arise during the birthing process. Quality consistency philosophy in the manufacture of such critical agricultural infrastructure involves rigorous attention to welding standards, component tolerances, and finish uniformity that ensures reliable performance across diverse climatic conditions and management practices encountered in global swine production systems. Export-oriented handling considerations become particularly relevant for international suppliers, as farrowing crates must withstand extended shipping periods, container loading procedures, and destination country import inspection processes without suffering damage that could compromise their structural integrity or safety features upon installation. The single-sided configuration offers specific advantages in facility layout optimization, allowing farm designers to create more flexible pen arrangements that can accommodate varying group sizes and operational workflows while maintaining compliance with space allocation requirements mandated by progressive animal welfare standards. Customization collaboration opportunities between manufacturers and international buyers often focus on adapting standard designs to incorporate region-specific feeding systems, flooring preferences, and integration requirements with local waste management infrastructure. OEM and ODM cooperation frameworks in the agricultural equipment sector typically emphasize long-term partnership development, technical support provision, and continuous product refinement based on field performance feedback from diverse global markets. The metalworking expertise required for producing reliable farrowing equipment encompasses understanding of livestock behavior patterns, structural engineering principles, and materials science considerations that ensure optimal performance throughout extended service life cycles typical in commercial agricultural applications. Packaging and logistics compatibility factors influence design decisions, particularly regarding modular assembly approaches that minimize shipping volumes while maintaining ease of field installation without requiring specialized construction equipment or extensive technical training for farm personnel. International sourcing teams evaluating farrowing equipment suppliers increasingly emphasize manufacturers with demonstrated experience in cross-cultural communication, technical documentation translation capabilities, and understanding of diverse regulatory environments governing livestock housing standards across different continental markets. The progressive evolution toward single-sided farrowing systems reflects broader industry trends emphasizing operational transparency, enhanced animal monitoring capabilities, and improved integration with modern farm management software platforms that track individual animal performance metrics and facility utilization efficiency. Long-term supplier cooperation expectations in the agricultural equipment sector encompass ongoing technical support, replacement parts availability, and collaborative product development initiatives that address emerging challenges in sustainable livestock production practices.

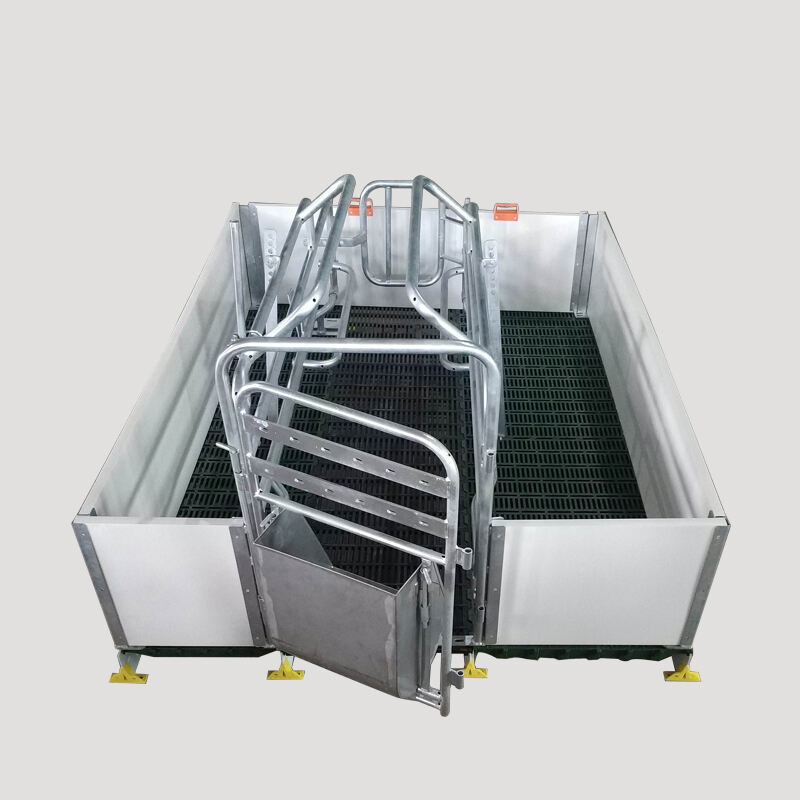

Single Sided EU-Style Pig Farrowing Crate

-

Adjustable Design – Length and width can be easily adjusted to accommodate sows of different sizes, ensuring comfort and efficiency.

-

Durable Construction – Made from high-quality galvanized steel and corrosion-resistant materials for long-lasting use in harsh farm environments.

-

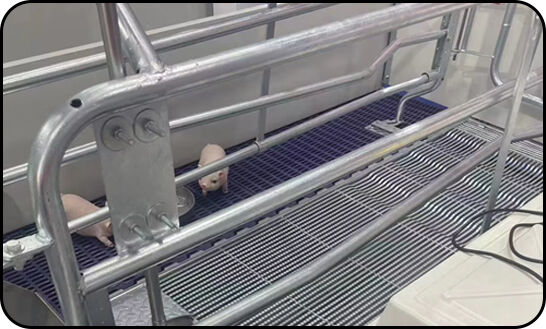

Improved Piglet Safety – Specialized design minimizes the risk of piglets being crushed, enhancing survival rates.

-

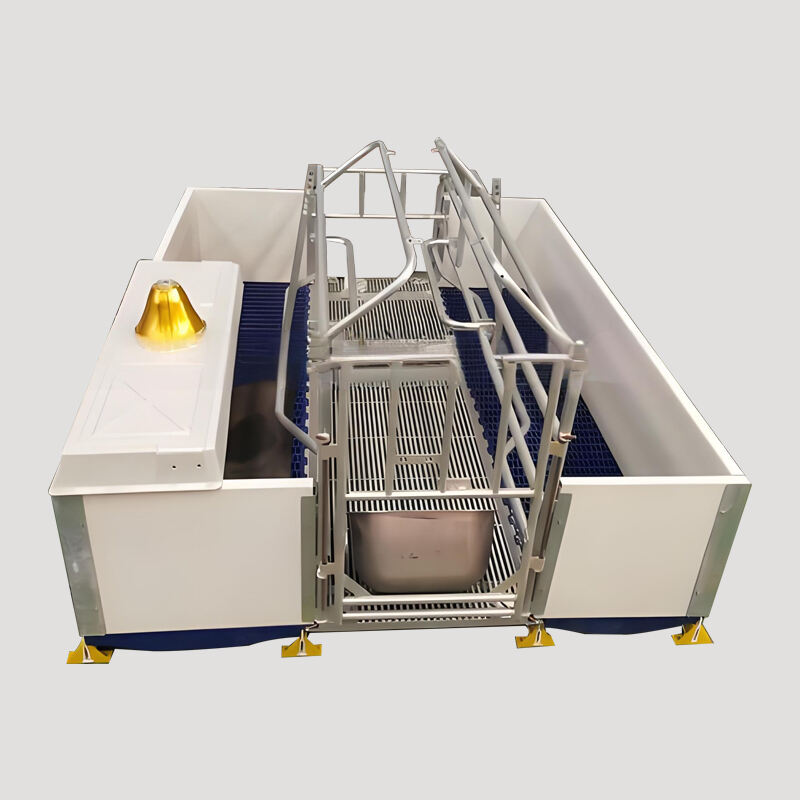

High-Capacity Stainless Steel Feeder – Equipped with a sturdy tipping trough for convenient feeding and easy cleaning.

-

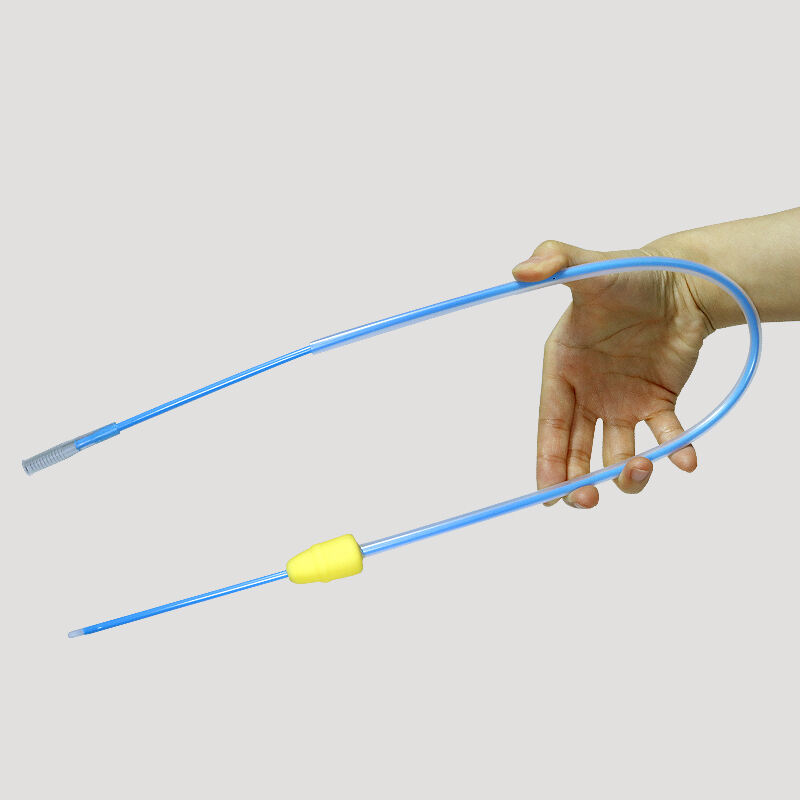

Complete Farrowing Setup – Includes anti-slip flooring, heating lamp area, and water supply system to create an optimal environment for sows and piglets.

- Overview

- Size

- Details

- Recommended Products

Desription

Wanqing Animal Husbandry is a trusted and reputable manufacturer of European Style Farrowing Crates in China, with years of experience serving farms of all sizes. Designed with a scientific and practical approach, our farrowing crates are engineered to ensure the comfort of sows, the safety of piglets, and the efficiency of farm operations. Their proven performance and long-lasting durability have made them a preferred choice among farmers both domestically and internationally.

One of the key advantages of our farrowing crates is their adjustable length and width, allowing them to easily accommodate sows of varying sizes and breeds. This flexibility not only improves animal welfare but also maximizes the usability of the equipment across different farming operations. Each crate is equipped with a high-capacity stainless steel tipping trough, firmly fixed to the structure, which ensures a hygienic, corrosion-resistant, and easy-to-clean feeding solution.

At Wanqing Animal Husbandry Group, we are dedicated to bringing the most advanced European design concepts to our customers, integrating innovation with practicality. We understand that modern farming requires cost-effective solutions without sacrificing quality, safety, or durability. Our production process follows strict quality control standards, ensuring that every crate meets international requirements and withstands the demands of long-term use.

By combining cutting-edge design, robust materials, and user-friendly installation, our farrowing crates help farmers save on labor costs, improve feeding efficiency, and enhance the overall productivity of their farms. Whether you run a small family-owned farm or a large-scale commercial operation, Wanqing farrowing crates are built to deliver reliable performance year after year.

Choose Wanqing Animal Husbandry — where advanced design meets lasting value, helping farmers around the world achieve better results in livestock management.

Product Introduction Video

https://www.youtube.com/embed/Rjm1YVME-4M?si=YS2dnmaGFMt656_U

Certificate

Size

Details

|

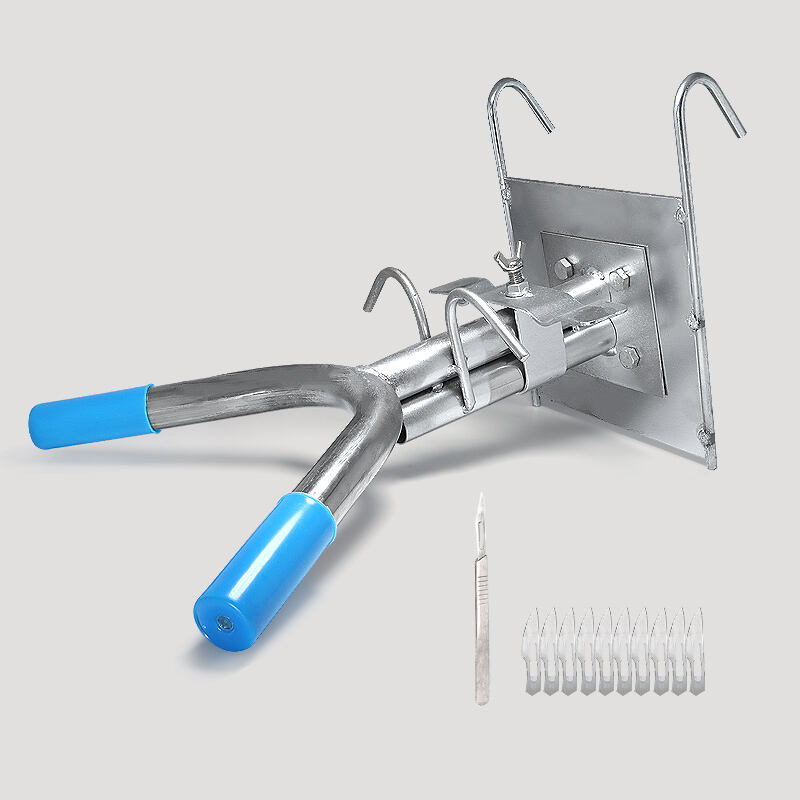

A Crate A round tube with a diameter of 32 * 2.5mm, with adjustable space on both sides,and a width that can be adjusted according to the sow's body and litter size. It can withstand pressure toavoid pressure on the sow, and the back door can be fully opened for easy entry and exit of the sow; |

|

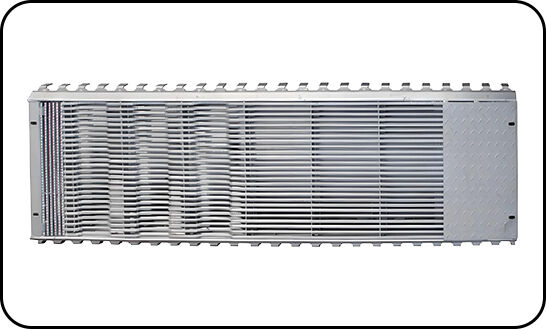

Fence PVC board, thickness: 30mm or 35mm, height: 500mm or 600mm, 3kg/m; |

|

|

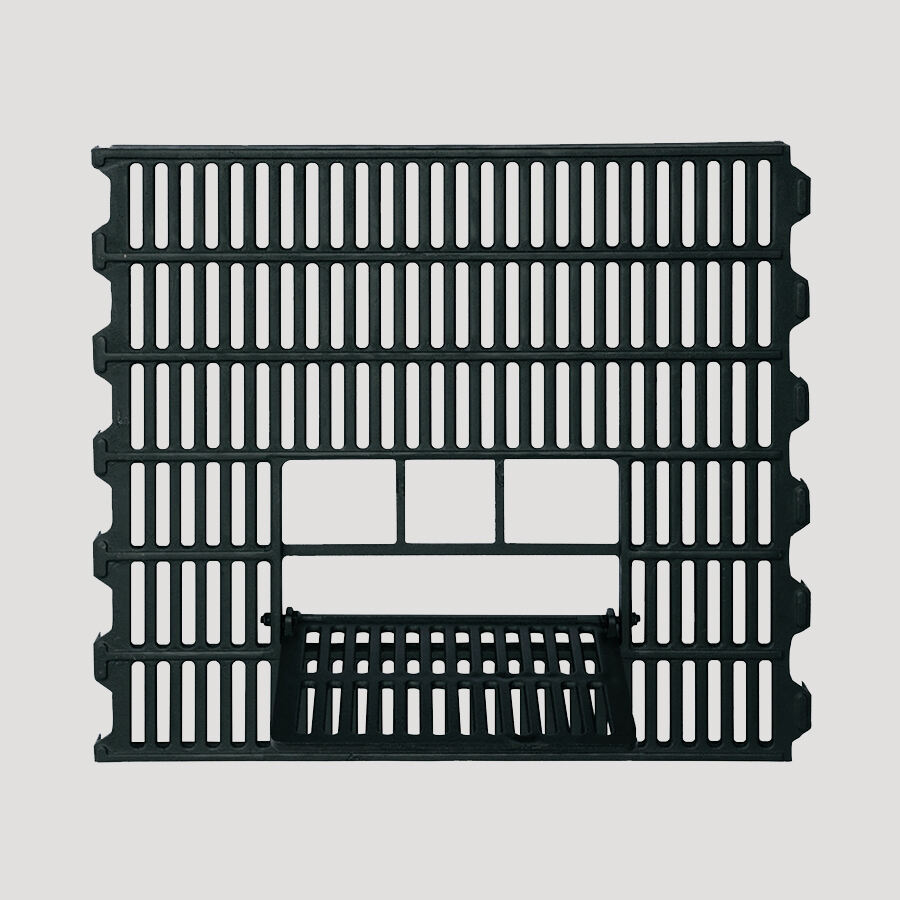

Plastic piglet Flat noodles High strength, anti slip, no water accumulation, durable, and harmless to feet; PP8030 fresh material, ensuring durability and corrosion resistance; |

|

Steel sow Flat noodles Not broken; Anti corrosion and anti-oxidation, removing surface burrs; Back steel strip with one fecal hole. |

|

|

Warm house with heated floor or heating lamp |

|

304 stainless steel sow trough, 304 stainless steel piglet trough |

|