The Ductile Cast Iron Sow Slatted Floor represents a specialized flooring solution engineered specifically for modern swine production facilities, combining the inherent durability of ductile cast iron with precision-designed slat configurations that optimize animal comfort, waste management efficiency, and operational hygiene standards. This advanced flooring system addresses the demanding requirements of commercial pig farming operations where conventional concrete or steel alternatives may fall short in terms of longevity, maintenance requirements, and overall performance consistency. Ductile cast iron, distinguished from traditional gray cast iron by its enhanced mechanical properties and improved impact resistance, provides the foundational strength necessary to withstand the continuous loading, moisture exposure, and aggressive cleaning protocols characteristic of intensive livestock environments. The material's unique metallurgical structure, achieved through controlled cooling processes and spheroidal graphite formation, delivers exceptional tensile strength while maintaining the corrosion resistance essential for agricultural applications where exposure to organic acids, cleaning chemicals, and high-humidity conditions is inevitable. Manufacturing processes for these specialized flooring components typically involve advanced foundry techniques that ensure dimensional accuracy, surface consistency, and structural integrity across large production runs, enabling livestock facility operators to achieve uniform installation standards and predictable performance outcomes. The slat design itself incorporates carefully calculated opening dimensions and spacing ratios that facilitate efficient waste removal while providing adequate support for animals of varying sizes and weights, with surface texturing options available to enhance traction and reduce slip incidents without compromising cleaning effectiveness. From an international sourcing perspective, these ductile cast iron flooring systems have gained recognition among progressive livestock operations seeking to modernize their facilities with equipment that can withstand decades of intensive use while maintaining hygienic conditions and supporting animal welfare objectives. The inherent properties of ductile cast iron, including its resistance to thermal shock and ability to maintain structural stability under varying temperature conditions, make it particularly suitable for facilities operating in diverse climatic zones where seasonal temperature fluctuations could compromise inferior materials. Surface treatment options for these flooring components may include specialized coatings or finishing processes designed to further enhance corrosion resistance, improve cleanability, or provide additional antimicrobial properties, depending on specific facility requirements and regional regulatory standards. Customization possibilities extend beyond basic dimensional variations to include modified slat patterns, drainage configurations, and integration features that accommodate specific barn layouts, ventilation systems, and waste management infrastructure, enabling facility designers and operators to optimize their installations for maximum efficiency and compliance with evolving industry standards. Quality consistency represents a fundamental consideration in the production of these flooring systems, as variations in material composition, casting quality, or dimensional accuracy can significantly impact installation success, long-term durability, and overall facility performance, making supplier selection and manufacturing oversight critical factors in procurement decisions. The agricultural industry's increasing focus on sustainable production practices has elevated the importance of equipment longevity and resource efficiency, positioning ductile cast iron flooring solutions as environmentally responsible choices that minimize replacement frequency and reduce long-term material consumption. Export-oriented suppliers typically implement comprehensive quality control protocols that address international shipping requirements, including protective packaging systems, corrosion prevention measures, and documentation standards that facilitate customs clearance and installation planning across diverse global markets. Collaboration opportunities with OEM and ODM partners often encompass not only product customization but also technical support services, installation guidance, and ongoing maintenance recommendations that help international buyers maximize their investment returns while ensuring compliance with local agricultural regulations and animal welfare standards. The modular nature of slatted flooring systems enables flexible installation approaches that can accommodate phased facility construction, retrofit applications, and future expansion plans, providing buyers with scalable solutions that adapt to changing operational requirements. Packaging and logistics considerations for these heavy-duty flooring components typically involve specialized handling procedures, protective materials, and shipping configurations designed to prevent damage during international transport while optimizing container utilization and minimizing freight costs. Long-term supplier relationships in this specialized market segment often evolve beyond simple product transactions to encompass technical partnerships that support ongoing facility optimization, performance monitoring, and continuous improvement initiatives that benefit both livestock producers and equipment suppliers. The durability characteristics of ductile cast iron, combined with proper installation and maintenance practices, contribute to total cost of ownership advantages that become increasingly apparent over extended operational periods, making these flooring systems attractive investments for facility operators focused on long-term profitability and operational efficiency. Industry experience demonstrates that successful implementation of ductile cast iron slatted flooring requires careful consideration of supporting infrastructure, including adequate drainage systems, proper ventilation design, and compatible cleaning equipment that complement the flooring's performance characteristics and maximize its operational benefits.

Ductile Cast Iron Sow Slatted Floor

-

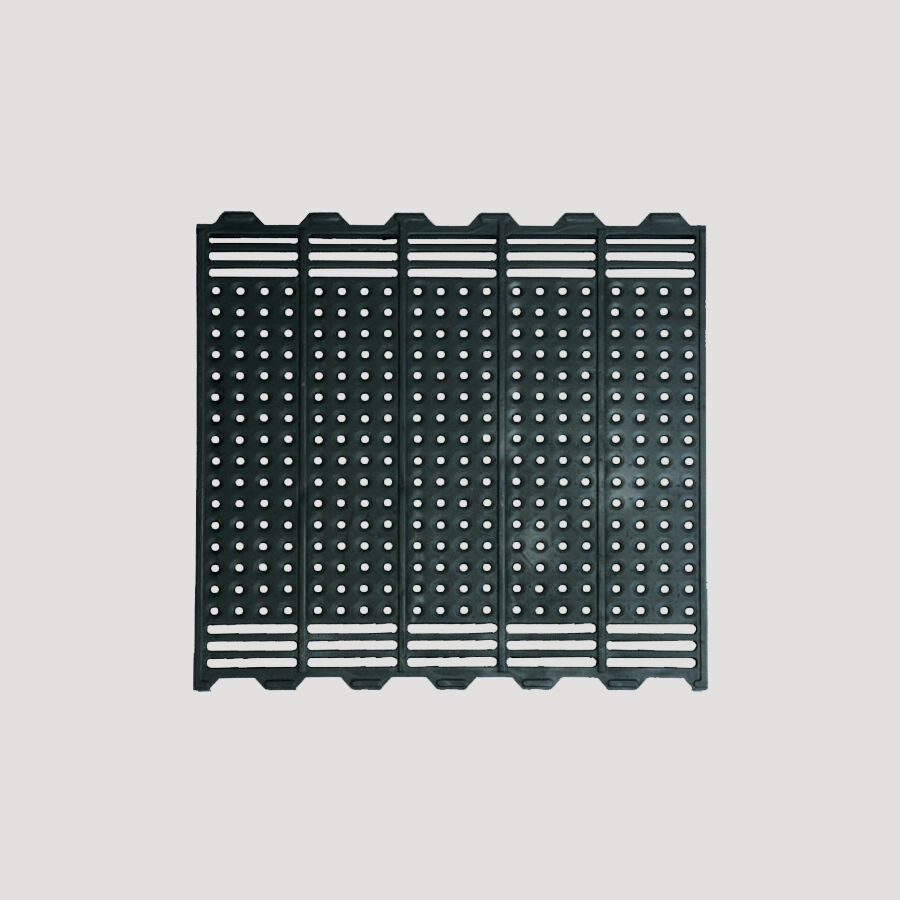

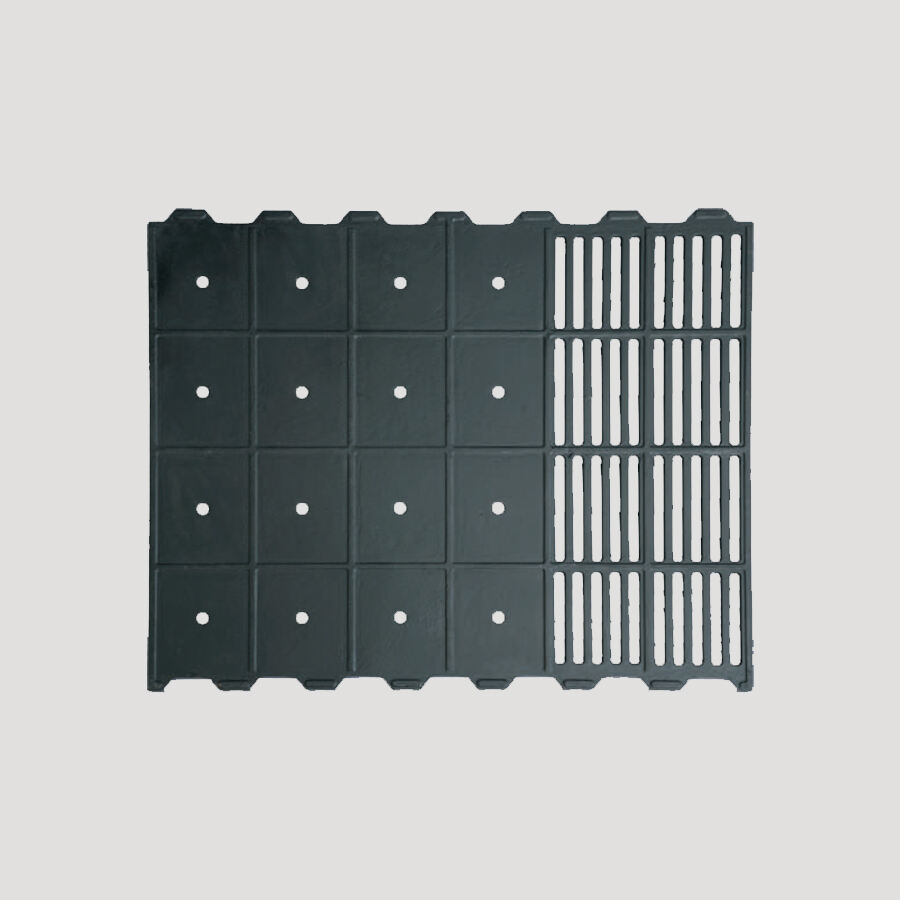

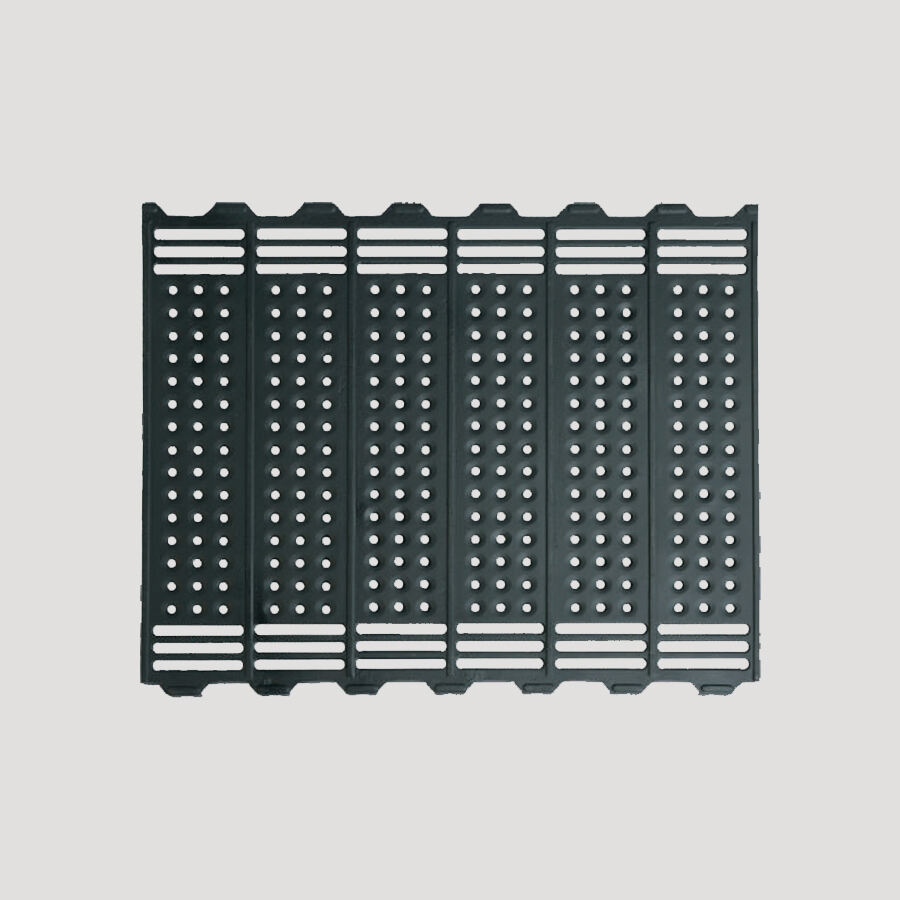

High Strength & Durability – Made from ductile cast iron with excellent load-bearing capacity, ideal for supporting heavy sows.

-

Safe & Slip-Resistant Surface – Textured finish reduces slipping and injuries, while smooth edges protect hooves and legs.

-

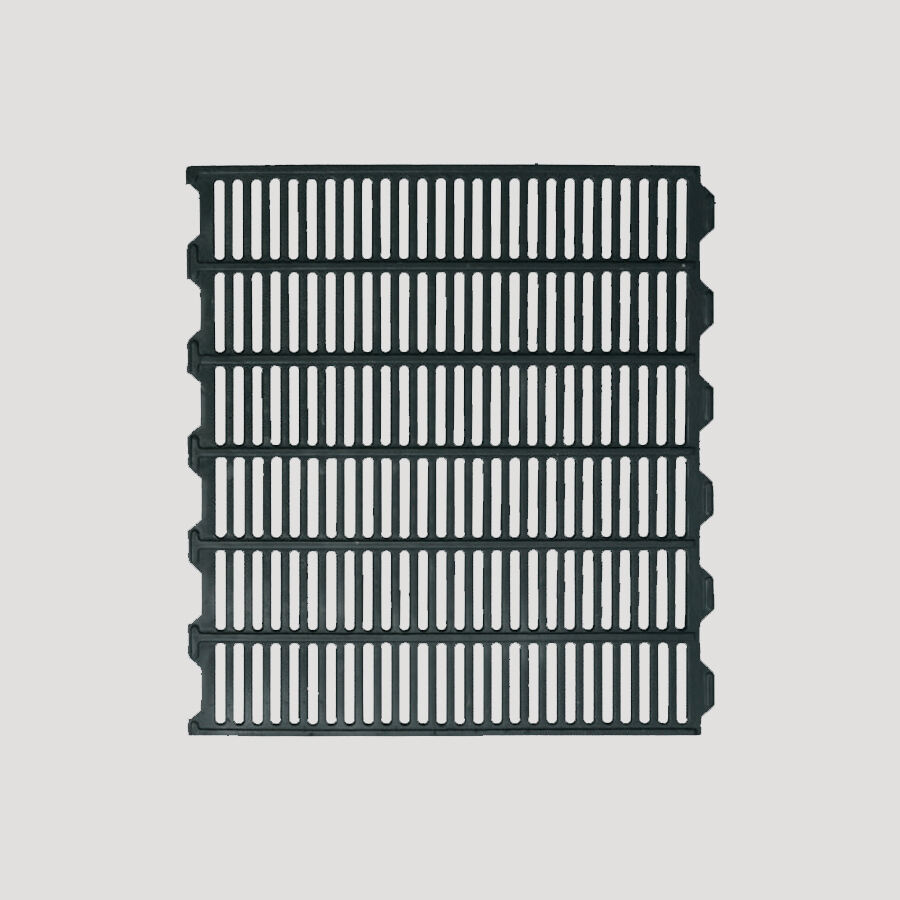

Efficient Waste Management – Optimized slat spacing allows for effective drainage, keeping the floor dry and clean.

-

Corrosion & Wear Resistant – Built for long-term use in wet, high-pressure farm environments without rust or structural damage.

-

Easy to Clean & Versatile – Compatible with farrowing and gestation crates, simple to disinfect, and supports farm biosecurity.

- Overview

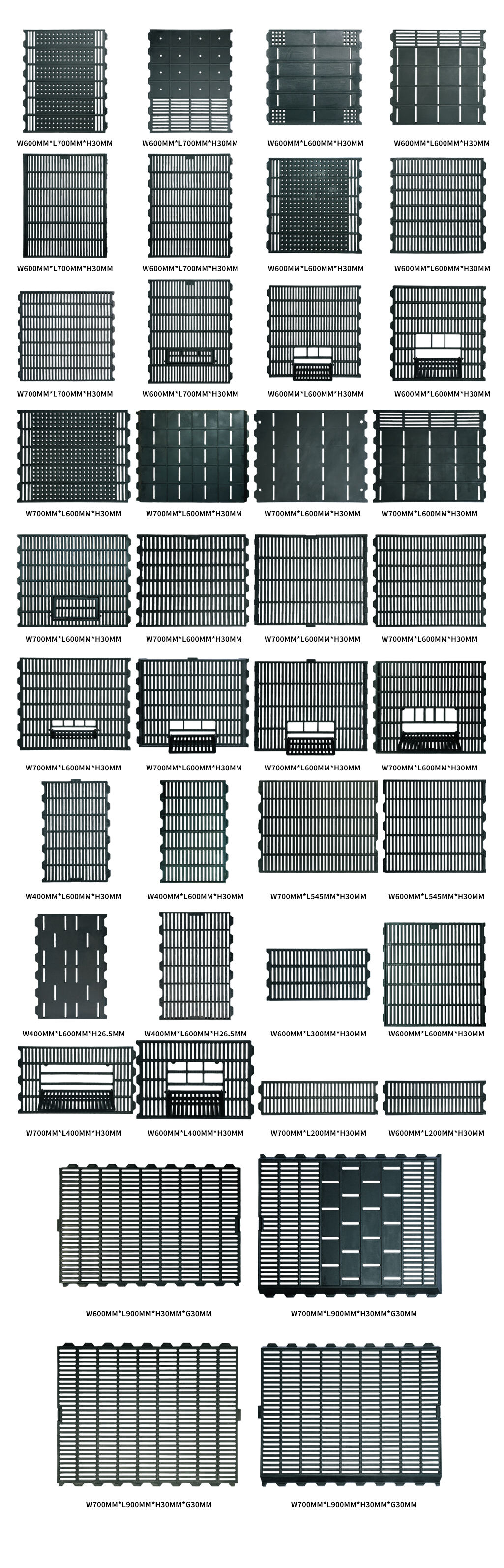

- Size

- Details

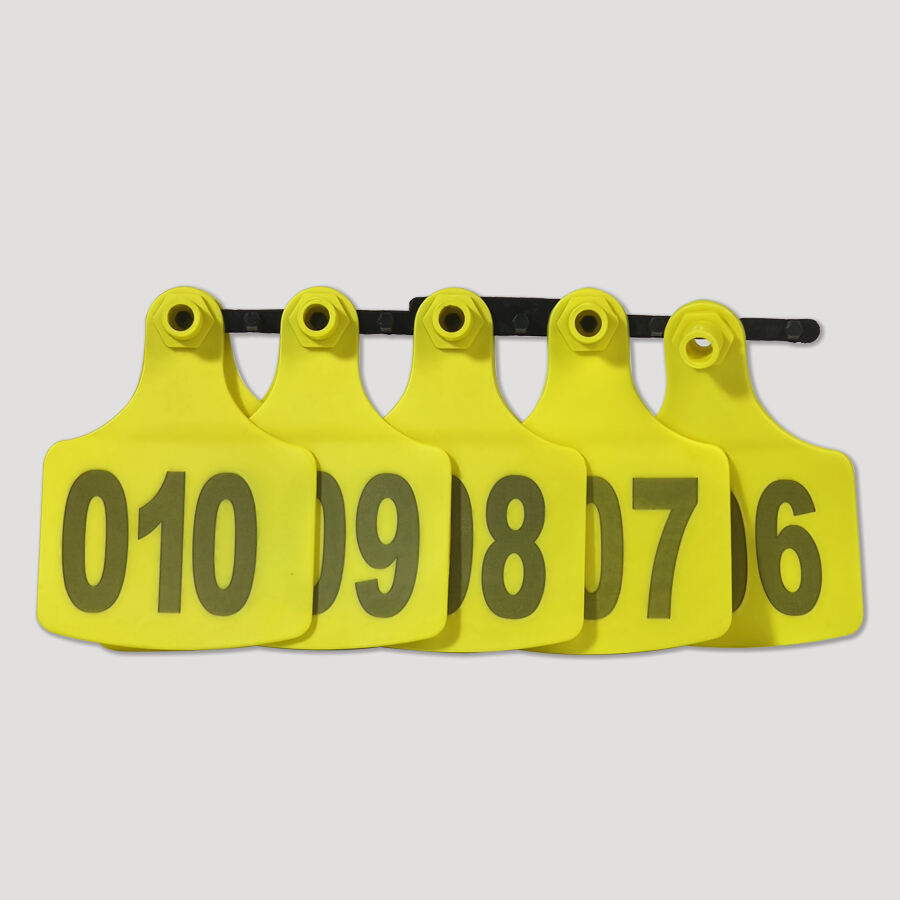

- Recommended Products

Description

Certificate

Size

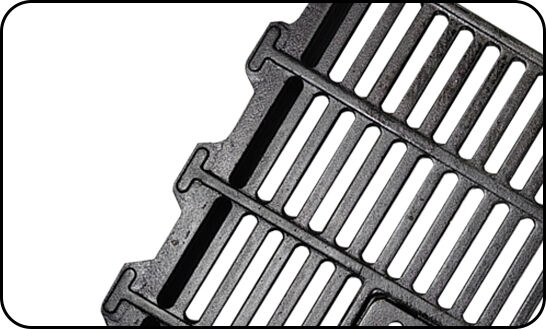

Details

|

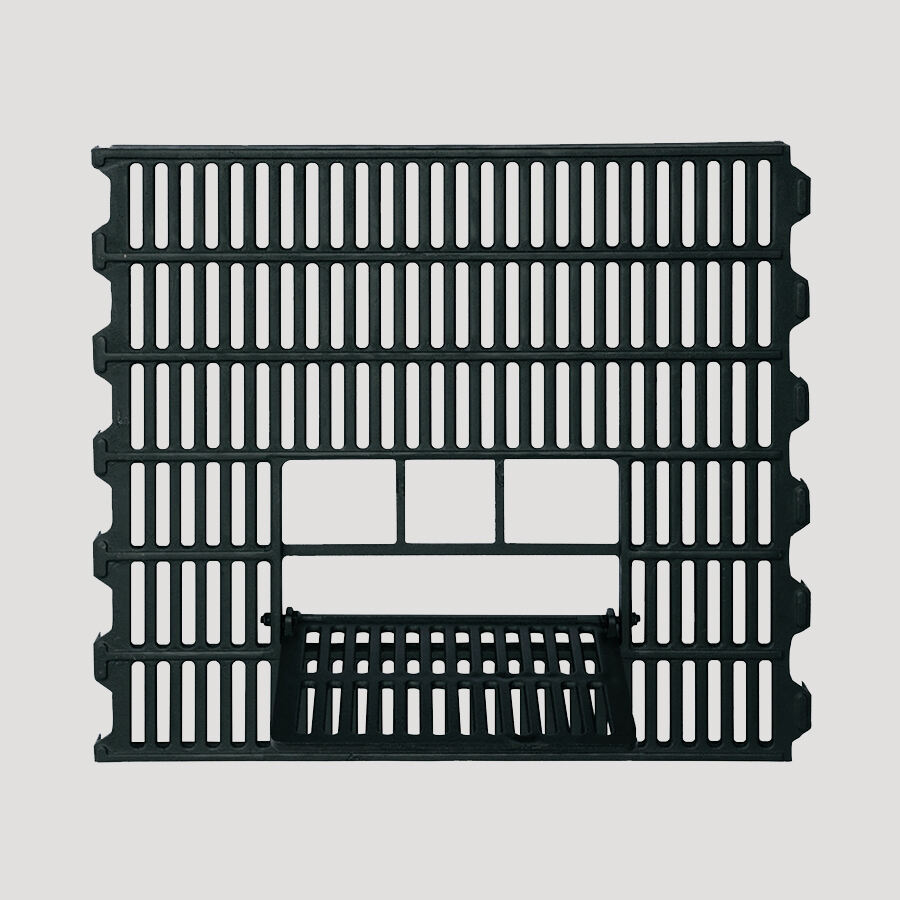

10mm Gap Anti-squeezing sow nipples |

|

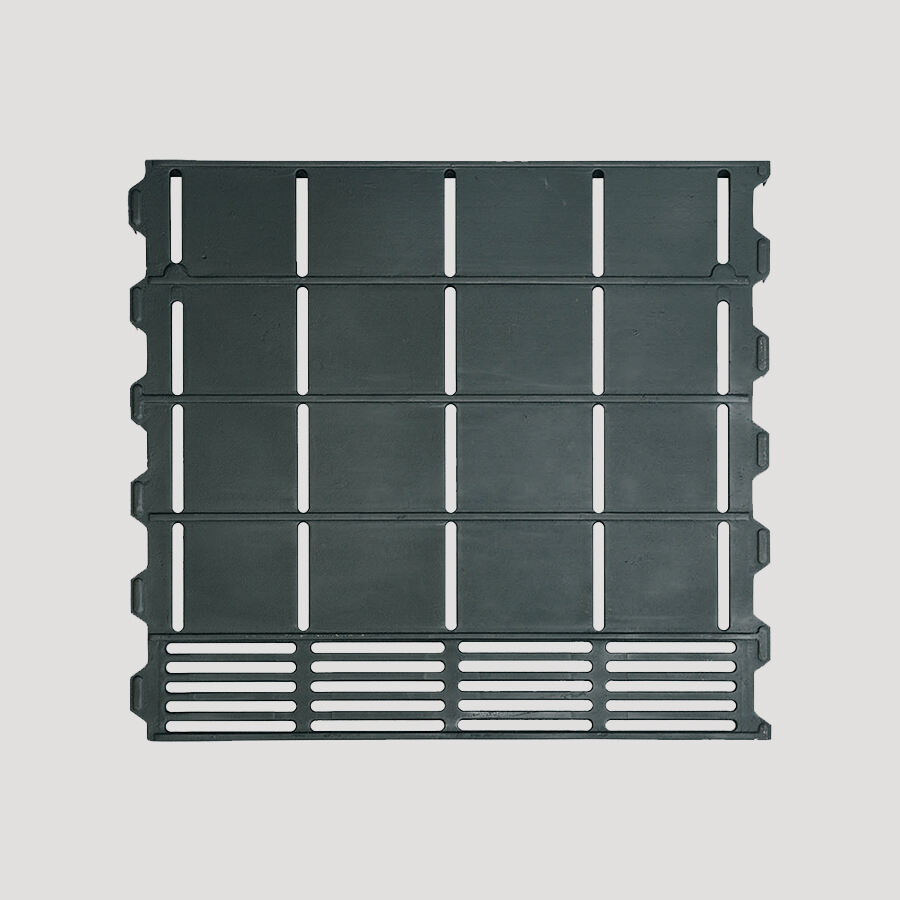

Gap is smooth without hurting hands Durable, non-slip, easy to clean. |

|

|

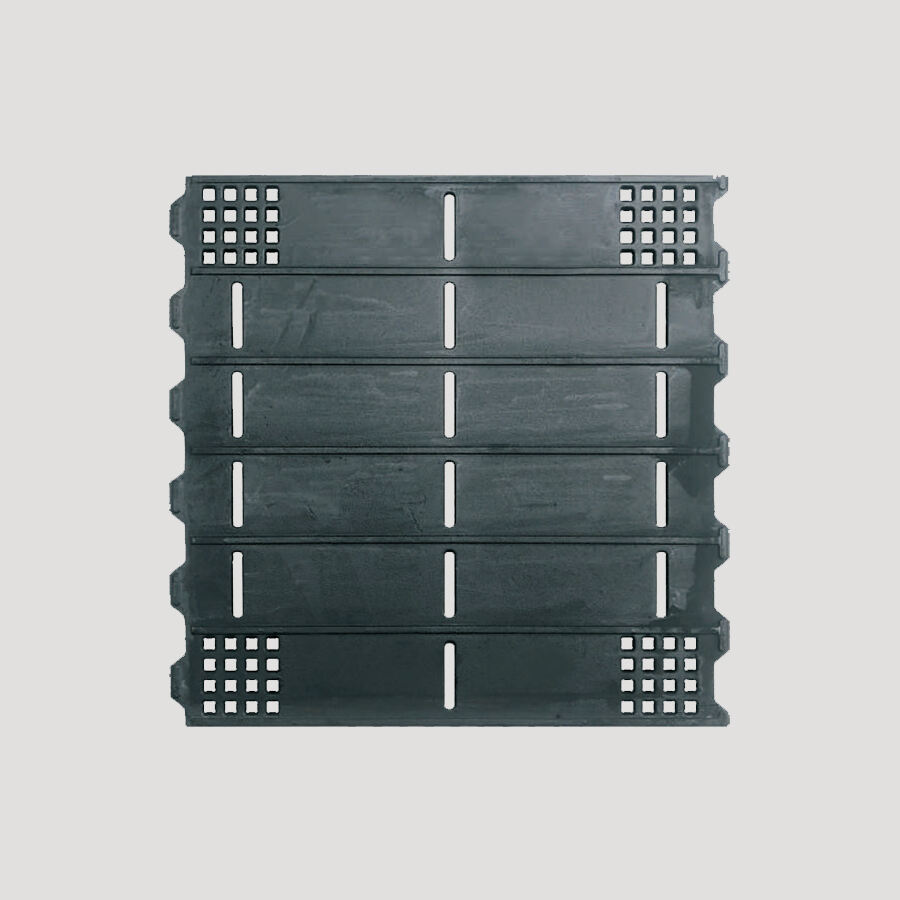

With serrated mounting slot With zigzag mounting slot, seamless connection, easy installation and removal |

|

Cast Iron Floor mounted on galvanized steel beams. Durable, non-slip, easy to clean. |

|