The New Type Automatic Poultry Chicken Quail Hanging Water Drinking Cups represent a sophisticated advancement in modern poultry watering systems, engineered to address the critical hydration needs of commercial poultry operations while streamlining farm management protocols and enhancing operational efficiency across diverse agricultural environments. These innovative drinking solutions integrate precision-engineered water distribution mechanisms with robust construction materials, delivering consistent and reliable water access for chickens, quails, and various poultry species throughout their production cycles. The automatic functionality eliminates manual water replenishment tasks, reducing labor requirements while ensuring continuous water availability that promotes optimal bird health and productivity standards essential for commercial poultry enterprises. International sourcing professionals recognize these hanging water drinking cups as essential infrastructure components that contribute significantly to modernizing poultry facilities and meeting stringent animal welfare requirements demanded by global agricultural standards and regulatory frameworks. The hanging design methodology maximizes space utilization within poultry housing structures while maintaining accessibility for birds of different sizes and developmental stages, creating an efficient water distribution network that accommodates varying flock densities and housing configurations commonly encountered in commercial poultry operations worldwide. Manufacturing processes employed in producing these automatic drinking systems incorporate advanced polymer engineering techniques and precision molding technologies that ensure dimensional accuracy, structural integrity, and long-term durability under demanding agricultural conditions characterized by high humidity, temperature fluctuations, and intensive usage patterns. The material composition typically features food-grade polymers and corrosion-resistant metal components specifically selected for their compatibility with potable water systems and resistance to chemical degradation from water treatment additives commonly used in commercial poultry operations. Design considerations encompass multiple factors including ergonomic accessibility for various poultry species, water flow regulation mechanisms that prevent spillage while ensuring adequate consumption rates, and modular installation systems that facilitate scalable deployment across facilities of different sizes and configurations. Surface treatments and finishing processes enhance the hygienic properties of these drinking cups, incorporating antimicrobial characteristics and smooth surface textures that resist bacterial accumulation while simplifying cleaning and sanitization procedures essential for maintaining water quality standards required in professional poultry production environments. Functional customization possibilities enable adaptation to specific operational requirements, including adjustable mounting systems for different cage heights, variable water flow controls to accommodate species-specific consumption patterns, and specialized connecting hardware compatible with existing water distribution infrastructure commonly installed in established poultry facilities. Application suitability extends across multiple poultry industry segments including commercial egg production facilities, broiler operations, specialty poultry breeding programs, and small-scale farming enterprises seeking professional-grade watering solutions that deliver consistent performance and operational reliability over extended service periods. The versatility of these hanging water drinking cups makes them particularly valuable for international agricultural suppliers serving diverse market segments where standardization and quality consistency represent fundamental purchasing criteria for procurement decisions. Quality consistency philosophy underlying the manufacturing approach emphasizes rigorous material selection protocols, standardized production processes, and comprehensive testing procedures that validate performance characteristics under simulated operational conditions representative of real-world poultry farming environments encountered across different geographical regions and climatic conditions. Export-oriented handling considerations include protective packaging systems designed to prevent damage during international shipping, compact packaging configurations that optimize container utilization for cost-effective logistics, and documentation support that facilitates customs clearance procedures in various destination markets commonly served by agricultural equipment distributors and poultry supply specialists. Our manufacturing experience in producing precision-engineered agricultural components enables consistent delivery of products that meet international quality expectations while maintaining competitive positioning in global markets characterized by demanding performance requirements and price sensitivity factors that influence purchasing decisions across different market segments. Customization collaboration opportunities encompass OEM partnerships where these automatic drinking cups can be integrated into comprehensive poultry housing systems, private labeling arrangements for distributors seeking branded product offerings, and specialized modifications addressing unique operational requirements identified by agricultural consultants and system integrators working with specific customer applications. ODM cooperation possibilities include development of enhanced versions incorporating additional features such as water level monitoring systems, temperature regulation capabilities, and modular expansion components that enable system growth as operations scale up or modify their production methodologies to meet changing market demands and regulatory requirements. Packaging and logistics compatibility considerations ensure that these hanging water drinking cups can be efficiently integrated into existing supply chain operations, with standardized packaging dimensions that optimize warehouse storage efficiency and shipping cost management while providing adequate protection against handling damage during transportation and distribution phases. Long-term supplier cooperation expectations focus on establishing sustainable business relationships that support ongoing product availability, technical support services, and collaborative development initiatives aimed at continuous improvement of product performance and adaptation to evolving industry requirements driven by technological advancement and changing agricultural practices implemented across global poultry production systems.

New Type Automatic Poultry Chicken Quail Hanging Water Drinking Cups

-

Automatic Water Refill – Provides fresh water automatically when birds peck, ensuring constant hydration without overflow or waste.

-

Durable & Safe Material – Made of high-quality, non-toxic plastic that is wear-resistant, rust-proof, and long-lasting.

-

Easy Installation – Simple to mount on cages or pipes with standard fittings; ideal for poultry farms and backyard coops.

-

Hygienic Design – Keeps water clean and reduces contamination risk by limiting spillage and contact with bedding.

-

Versatile Use – Suitable for chickens, quail, pigeons, and other small poultry; perfect for automated watering systems.

- Overview

- Size

- Washing Steps

- Details

- Recommended Products

Description

The New Type Automatic Poultry Drinking Cup is an innovative and practical solution for providing clean, fresh water to your poultry and small animals. Made from durable, cold-resistant plastic, this drinking cup is built to withstand harsh farm environments while offering a long service life. Its bright red color makes it easy to spot and monitor.

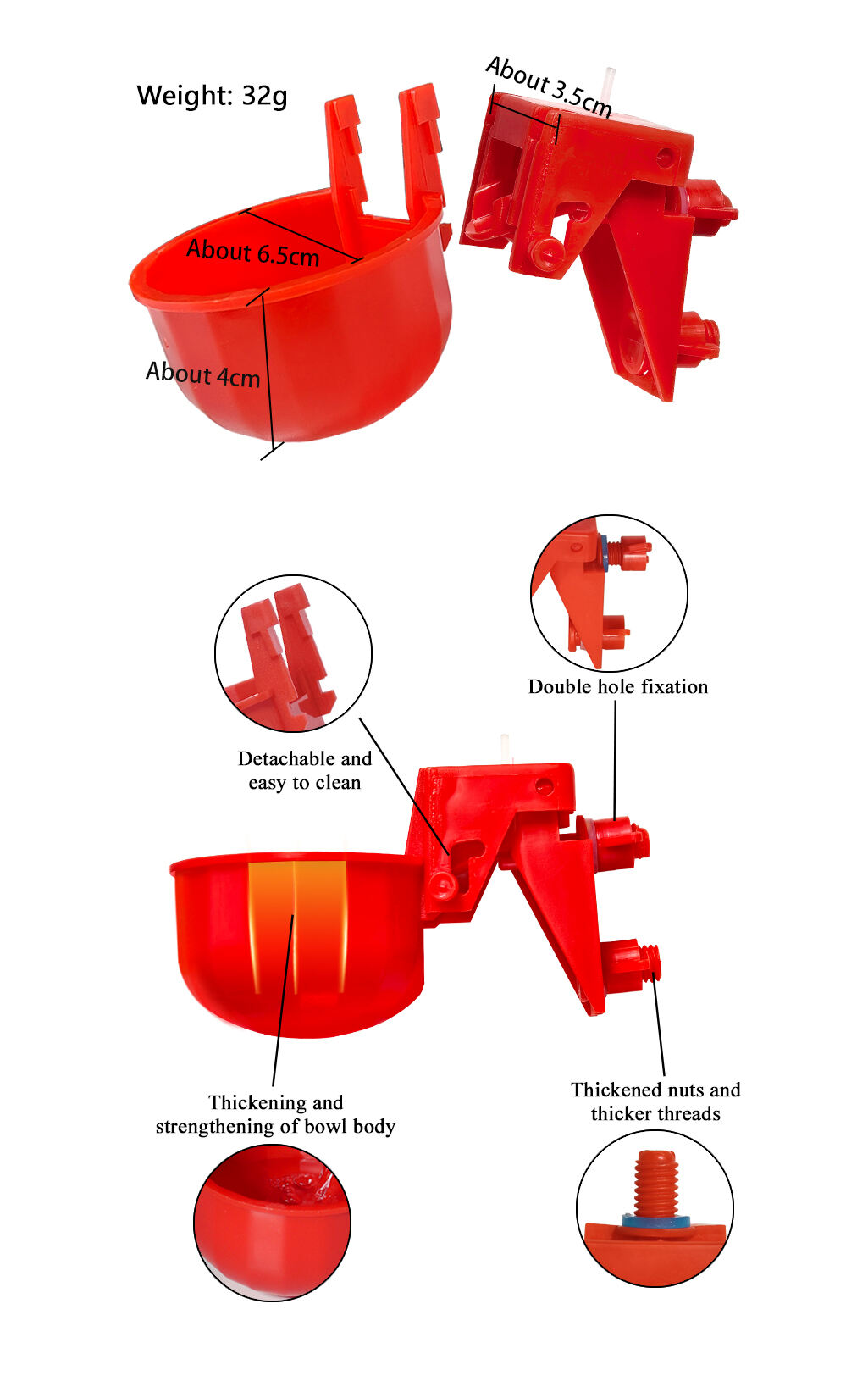

With a bowl size of 63mm (2.48 inches) and total dimensions of 105 x 63 x 40mm (4.13 x 2.48 x 1.57 inches), the cup features a smooth, rounded rim that is safe and gentle on the mouths of chickens, rabbits, quail, and other small animals. The drinker is compatible with pipes or tanks with an inner diameter of 6mm (0.24 inches), making it easy to connect to most standard watering systems.

The system is designed for automatic water flow—once connected to a hose or tank, water is dispensed as animals peck at the trigger. When the bowl fills, water flow automatically stops, preventing spills and reducing waste. Its large water capacity reduces the need for constant refilling, helping farmers save time and labor.

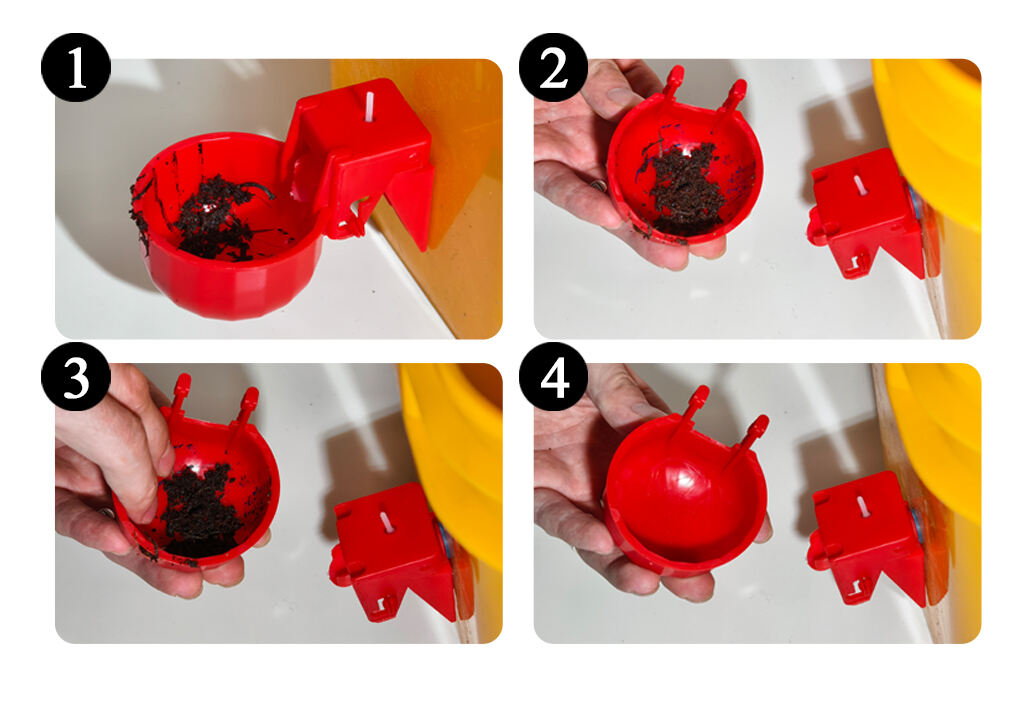

This new model is not only easy to install, but also manually disassemblable, allowing for thorough cleaning and maintenance. The thoughtful design makes it extremely user-friendly and hygienic, keeping your livestock healthy by ensuring a constant supply of clean water.

Ideal for chickens, rabbits, mice, and other small animals, this automatic waterer is a must-have for poultry farms, backyard coops, and breeders. Whether you're a commercial farmer or hobbyist, this cup is designed to improve your workflow and animal welfare.

Product Introduction Video

Size

Washing Steps

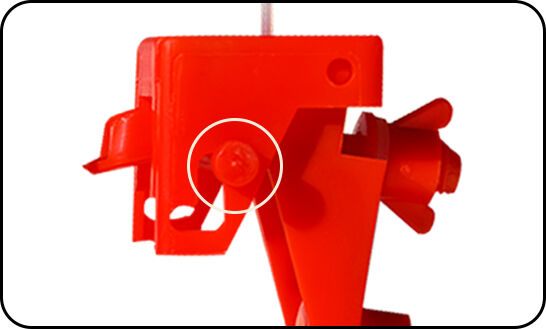

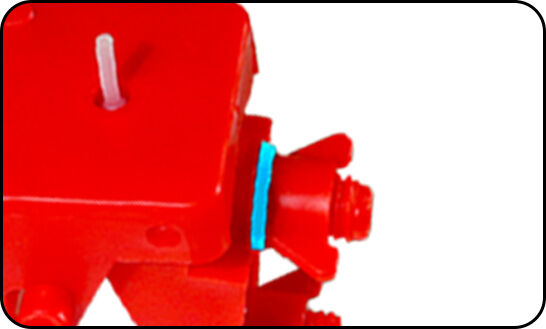

Details

|

When the stick is on the upper side, the bowl can be removed and the water can also be stopped |

|

When the stick is on the upper side, the bowl can be removed and the water can also be stopped |

|

|

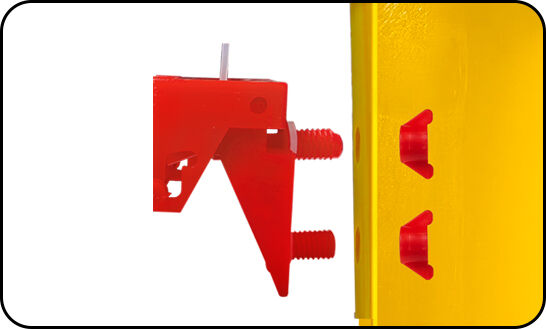

Double nut fixation is more stable and does not tilt |

|

Upgrading, thickening, and deepening threads to prevent slipping |

|