The Industrial Ventilation Exhaust Cooling Fan for Poultry Animal Husbandry Equipment represents a critical component in modern agricultural facility management, designed specifically to address the complex ventilation requirements of commercial poultry operations, livestock breeding facilities, and animal husbandry environments where maintaining optimal air quality and temperature control directly impacts productivity and animal welfare. These specialized exhaust cooling systems are engineered to handle the demanding operational conditions characteristic of agricultural settings, where high humidity levels, airborne particulates, and continuous operation requirements necessitate robust construction and reliable performance standards that exceed those of conventional industrial fans. The fundamental design philosophy centers on delivering consistent airflow management while withstanding the corrosive environments commonly found in animal housing facilities, where ammonia concentrations, moisture accumulation, and organic debris create challenging operational conditions that require specialized material selection and protective coatings to ensure long-term functionality and durability. Manufacturing approaches for these ventilation systems typically incorporate heavy-duty motor assemblies with enhanced weather resistance, corrosion-resistant housing materials such as galvanized steel or specialized aluminum alloys, and precision-engineered blade configurations optimized for moving large volumes of air while minimizing energy consumption and operational noise levels that could potentially stress livestock populations. The construction methodology emphasizes structural integrity through reinforced mounting systems capable of handling continuous vibration loads, while incorporating weather-sealed electrical components that maintain operational reliability in high-humidity environments where traditional electrical systems might experience premature failure or safety concerns. Surface treatment applications often include specialized powder coating systems or hot-dip galvanizing processes that provide comprehensive protection against environmental factors while maintaining the aesthetic appearance required for professional agricultural installations where equipment visibility and facility presentation impact operational efficiency and regulatory compliance considerations. Functional customization possibilities extend beyond basic airflow capacity adjustments to include variable speed control integration, automated temperature response systems, and remote monitoring capabilities that align with modern precision agriculture practices where data collection and automated environmental control systems contribute to optimized production outcomes and resource utilization efficiency. These ventilation solutions demonstrate particular suitability across diverse agricultural applications including broiler houses, layer facilities, swine operations, dairy barns, and specialty livestock breeding environments where each application presents unique airflow requirements, mounting configurations, and environmental resistance specifications that benefit from tailored engineering approaches and application-specific modifications. The adaptability of these systems to different facility layouts allows for both wall-mounted and roof-mounted configurations, with corresponding adjustments to motor orientation, housing design, and electrical connection requirements that accommodate the architectural constraints and operational preferences of various agricultural facility designs. Quality consistency philosophy throughout the manufacturing process emphasizes standardized component sourcing, rigorous assembly procedures, and comprehensive performance testing that ensures each unit meets the demanding reliability standards expected in commercial agricultural operations where equipment downtime can result in significant economic losses and animal welfare concerns. Export-oriented handling considerations incorporate robust packaging methodologies designed to protect precision components during international shipping, while accounting for the size and weight characteristics of industrial ventilation equipment that require specialized logistics coordination and handling procedures to maintain product integrity throughout the distribution chain. The engineering approach recognizes that agricultural facilities often operate in remote locations where service accessibility may be limited, necessitating design strategies that prioritize maintenance accessibility, component replaceability, and operational simplicity that enables facility operators to perform routine maintenance procedures without requiring specialized technical expertise or extensive downtime periods. Customization collaboration opportunities extend to OEM and ODM cooperation frameworks where agricultural equipment manufacturers, system integrators, and facility designers can work with ventilation specialists to develop application-specific solutions that integrate seamlessly with broader environmental control systems, building automation platforms, and agricultural management software that collectively contribute to comprehensive facility optimization. The development process accommodates specific voltage requirements, motor specifications, and control interface preferences that align with regional electrical standards and existing facility infrastructure, ensuring compatibility with local installation practices and regulatory requirements that vary across international markets. Packaging and logistics compatibility considerations address the unique challenges of shipping industrial ventilation equipment to diverse global destinations, incorporating modular design elements where appropriate to optimize shipping efficiency while maintaining structural integrity, and providing comprehensive installation documentation that supports successful deployment across varied technical expertise levels and cultural contexts. Manufacturing experience in producing ventilation equipment for demanding industrial applications provides the foundation for understanding the critical performance requirements that distinguish agricultural ventilation systems from general industrial fans, including enhanced corrosion resistance, improved moisture tolerance, and specialized mounting systems that accommodate the structural characteristics of agricultural buildings. Long-term supplier cooperation expectations focus on establishing partnerships that extend beyond initial equipment delivery to encompass ongoing technical support, replacement parts availability, and collaborative development of enhanced solutions that respond to evolving agricultural practices, regulatory requirements, and technological advances in precision agriculture that continuously reshape the operational landscape of modern animal husbandry facilities worldwide.

- Overview

- Parameters

- Size

- Details

- Recommended Products

Description

Evaporative Cooling Equipment: The Preferred Choice for Pig Farming

This evaporative cooling equipment stands as the most popular solution in the pig farming industry, thanks to its exceptional cooling performance and eco-friendly design. It features a specialized paper honeycomb structure and must be used in conjunction with negative-pressure fans. Equipped with evaporative cooling pads, it effectively improves the hot and humid environment in pig houses during hot weather, creating a comfortable space for livestock.

Boasting high efficiency and energy savings, this cooling method pairs fans with swamp cooler pads to achieve evaporative cooling with minimal power consumption. Its excellent ventilation performance, enabled by the synergy of cooling pads and fans, rapidly expels hot air from pig houses, ensuring efficient air circulation.

Prioritizing health and environmental friendliness, the system uses water as a cooling medium—non-polluting and capable of purifying the air, safeguarding both pig health and the surrounding environment. It also offers wide applicability, suitable for various spaces plagued by hot air and poor ventilation beyond pig farms.

Built for maximum durability, the evaporative cooling pads are crafted from wood-pulp paper coated with a layer of glue, delivering corrosion resistance, mildew resistance, and strong water absorption. Additionally, the equipment is easy to install, with lightweight components and snap-on designs simplifying setup. Maintenance is equally hassle-free, as the cooling pads can be easily disassembled and reassembled for regular cleaning, ensuring long-term reliable operation.

Parameters

| Model |

Inner Diameter |

Fan Blade Diameter |

| 18 inches | 460mm | 430mm |

| 24 inches | 640mm | 620mm |

| 32 inches | 830mm | 800mm |

Size

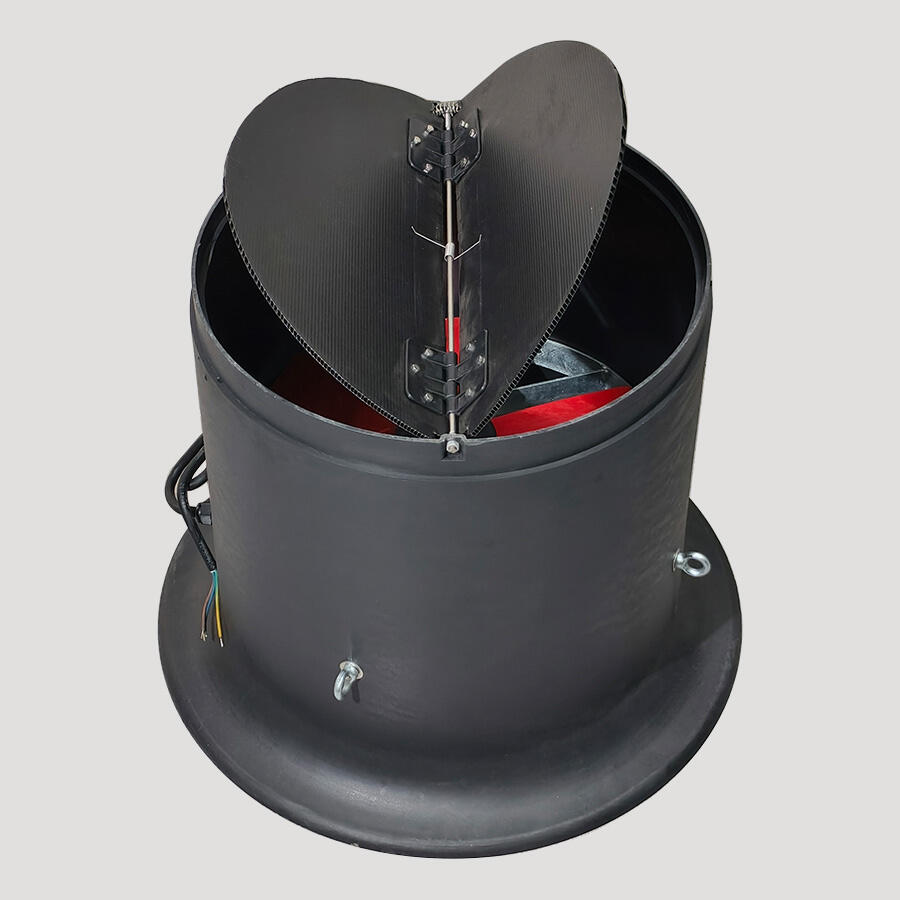

Details

|

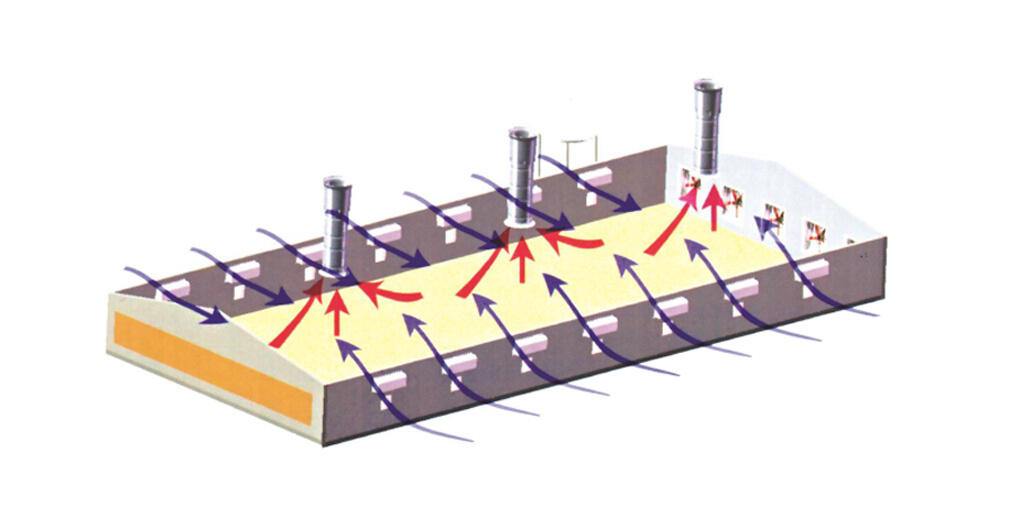

The vertical direction of air flow can make the ventilation more uniform,avoiding cross-infection and reducing the risk of livestock and poultry |

| The vertical ventilation inwinter can change the temperature gradient in the house the temperature is low in the roof area, and the lower level of the lower livestock poultry activity area is high |  |

|

Rotary stablely, quietly to improve the inner environment of room |

| Using complete senior axis bearing , no lubrication,solidlow fault rate |  |

|

Corrosion resistance,acid and alkali proof, long service life |