The Plastic Large Capacity Cattle Drinking Bowl represents a sophisticated solution for modern livestock management systems, engineered to meet the demanding requirements of agricultural operations that prioritize animal welfare, operational efficiency, and long-term durability. This specialized watering equipment addresses the fundamental need for reliable hydration infrastructure in cattle farming environments, where consistent water access directly impacts animal health, productivity, and overall farm economics. The design philosophy behind this large capacity drinking bowl centers on providing unrestricted water access for multiple animals while maintaining hygienic conditions and reducing maintenance overhead for farm operators. Contemporary agricultural practices increasingly demand equipment that can withstand the rigorous demands of high-volume livestock operations, and this plastic cattle drinking bowl delivers through its robust construction methodology and thoughtful engineering approach. The selection of premium-grade plastic materials ensures resistance to the harsh environmental conditions typically encountered in agricultural settings, including temperature fluctuations, UV exposure, chemical cleaning agents, and the physical stress imposed by large animals during regular use. Manufacturing processes incorporate advanced polymer science techniques to achieve optimal material density and structural integrity, resulting in a product that maintains its functional characteristics throughout extended service periods. The large capacity design consideration specifically addresses the water consumption patterns of cattle, which can vary significantly based on factors such as ambient temperature, feed composition, lactation status, and overall herd size dynamics. Surface treatments applied during the manufacturing process enhance the bowl's resistance to bacterial growth and facilitate routine cleaning procedures, contributing to improved livestock health outcomes and simplified maintenance protocols. The ergonomic design elements consider both animal comfort and operational practicality, incorporating features that encourage natural drinking behaviors while providing easy access for cleaning and inspection activities. Quality consistency represents a fundamental aspect of our manufacturing philosophy, with rigorous process controls ensuring that each unit meets the same high standards regardless of production batch or seasonal variations in manufacturing conditions. The bowl's structural design incorporates engineering principles that distribute stress loads effectively, preventing crack formation or structural failure even under conditions of heavy use by large animal populations. Export-oriented packaging approaches protect the product during international shipping while maintaining cost efficiency for overseas buyers and distributors operating in diverse market conditions. The plastic composition offers distinct advantages over traditional materials, including reduced weight for easier installation and handling, elimination of corrosion concerns that commonly affect metal alternatives, and simplified repair procedures when maintenance becomes necessary. Customization possibilities within the manufacturing process allow for adaptation to specific operational requirements, including modifications to mounting systems, capacity adjustments, and integration with automated water delivery systems commonly employed in modern cattle facilities. Industry applications extend across various cattle management scenarios, from small-scale family farms to large commercial operations, dairy facilities, feedlots, and specialized breeding operations that require reliable water infrastructure. The bowl's design compatibility with different installation methods provides flexibility for facility managers working with existing infrastructure or planning new construction projects. Long-tail variations in application scenarios demonstrate the product's versatility across different agricultural contexts, supporting everything from pasture-based grazing systems to confined feeding operations and temporary holding facilities. International buyers particularly appreciate the consistent quality standards maintained throughout the manufacturing process, which support reliable supply chain operations and predictable performance outcomes across different climate zones and operational environments. Collaboration with OEM partners and custom packaging suppliers enables tailored solutions that meet specific regional requirements or unique operational constraints faced by different agricultural markets. The sustainability aspects of plastic construction contribute to environmental responsibility goals while maintaining the functional performance required for professional agricultural applications. Distribution partnerships with livestock equipment suppliers and agricultural cooperative networks facilitate market access for farmers seeking reliable water system components. Logistics compatibility ensures efficient shipping and handling procedures that minimize transportation costs while protecting product integrity during international distribution. Manufacturing experience accumulated through extensive cooperation with agricultural equipment suppliers worldwide informs continuous improvement initiatives that enhance product performance and user satisfaction. Quality assurance protocols incorporate feedback from field applications to refine design elements and manufacturing processes, ensuring that the product evolution remains aligned with practical farming requirements and industry best practices.

Plastic Large Capacity Cattle Drinking Bowl

-

Large Water Capacity – Designed to hold ample water, ensuring continuous hydration for cattle and large livestock.

-

Durable & Weather-Resistant – Made of impact-resistant, durable plastic that withstands outdoor farm conditions.

-

Automatic Refill System – Integrated float valve maintains consistent water levels with minimal manual effort.

-

Animal-Safe & Easy to Clean – Smooth, rounded edges protect animals and allow for quick, hygienic cleaning.

-

Easy Installation & Low Maintenance – Simple to mount with minimal upkeep, ideal for barns, pastures, and feedlots.

- Overview

- Size

- Details

- Recommended Products

Description

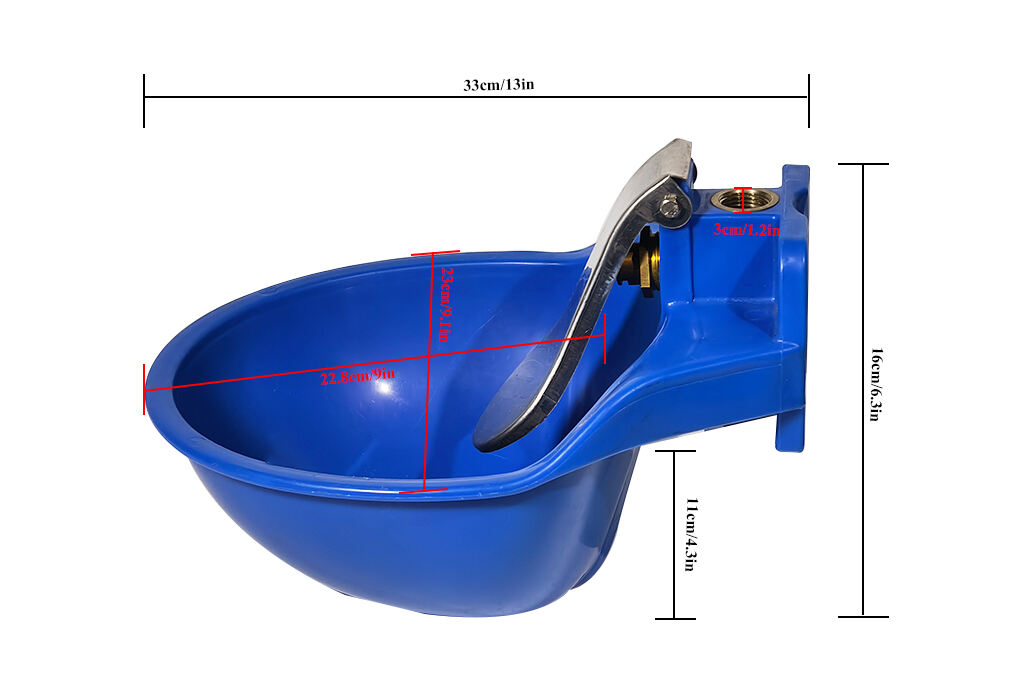

Size

Details

|

Thickened plastic beef bowl Stainless steel valve touch water not afraid of falling not afraid of arch |

|

Copper lock switch design touch water outlet |

|

|

Four-hole fixation The unique four-hole fixed design is more firm and stable |

|

Touch switch Waterinlet 3cm water pipe standard interface |

|

|

Thickened plastic press tongue Plastic tongue is not afraid of ice tongue in winter |

|

Thicken the rim The bowl is smooth and round around the edges without hurting the cow's mouth |

|