The Rubber/Stainless Steel/Plastic 220V Electric Piglet Heating Plate for Hog represents a sophisticated thermal management solution specifically engineered for modern swine production facilities seeking reliable and efficient heating systems for newborn piglet care. This versatile heating plate incorporates multiple material options including durable rubber surfaces, corrosion-resistant stainless steel construction, and high-grade plastic components, providing livestock operations with flexible configuration choices that align with diverse operational requirements and facility specifications. The integration of these premium materials ensures optimal heat distribution while maintaining structural integrity under demanding agricultural environments where consistent temperature regulation is critical for piglet survival and development. Professional swine producers and agricultural equipment distributors recognize the importance of selecting heating solutions that deliver consistent thermal performance while withstanding the rigorous conditions inherent in commercial livestock operations, making this electric heating plate an essential component for comprehensive piglet management systems. The sophisticated design philosophy behind this heating equipment emphasizes both functional efficiency and operational reliability, incorporating advanced heating elements that operate seamlessly within standard electrical infrastructure while providing the precise temperature control necessary for optimal piglet comfort and health outcomes. Agricultural facilities across international markets have increasingly demanded heating solutions that offer superior material durability combined with energy-efficient operation, positioning this heating plate as an ideal choice for export-oriented suppliers and distributors serving global livestock production markets. The strategic combination of rubber, stainless steel, and plastic materials creates a multi-layered approach to heating plate construction that addresses various operational challenges including moisture resistance, thermal conductivity, electrical safety, and long-term durability under continuous use conditions. International procurement teams specializing in agricultural equipment sourcing appreciate the comprehensive material selection offered by this heating plate, as it allows for customized specifications that meet specific regional requirements and operational preferences while maintaining consistent quality standards across different market segments. The rubber surface components provide excellent insulation properties and comfortable contact surfaces for piglets, while the stainless steel elements ensure superior heat conduction and resistance to corrosion from cleaning chemicals and moisture exposure common in swine production environments. Plastic components contribute lightweight characteristics and additional insulation benefits while maintaining cost-effectiveness for large-scale procurement projects. Manufacturing excellence in agricultural heating equipment requires careful attention to material selection, thermal engineering, and electrical safety considerations, particularly when developing products intended for international distribution to diverse agricultural markets with varying operational standards and regulatory requirements. The electric heating plate's design incorporates proven thermal management principles that optimize heat distribution patterns while minimizing energy consumption, addressing the growing demand from agricultural operations for sustainable and cost-effective heating solutions. Professional livestock equipment suppliers understand that successful piglet heating systems must balance several critical factors including initial equipment cost, operational efficiency, maintenance requirements, and long-term reliability, making comprehensive material selection a fundamental consideration in product development and market positioning strategies. The versatility offered by multiple material options enables this heating plate to serve diverse application scenarios ranging from small-scale family farms to large commercial swine production facilities, providing flexibility for distributors and resellers targeting varied customer segments across different geographical markets. International agricultural equipment trade often requires heating solutions that can adapt to different electrical standards, environmental conditions, and operational practices, making the robust construction and material diversity of this heating plate particularly valuable for export-oriented manufacturing and distribution strategies. The careful engineering of thermal distribution systems within the heating plate ensures uniform temperature delivery across the entire surface area, preventing hot spots or cold zones that could compromise piglet comfort and health outcomes, while the durable material construction supports extended operational lifespans under demanding agricultural conditions. Professional agricultural equipment procurement teams increasingly emphasize supplier partnerships that can provide consistent quality standards, reliable delivery performance, and comprehensive technical support for heating equipment installations, making manufacturer expertise and international cooperation capabilities essential factors in successful long-term business relationships. The integration of multiple material technologies within a single heating plate design demonstrates advanced manufacturing capabilities and comprehensive understanding of agricultural equipment requirements, positioning suppliers to effectively compete in sophisticated international markets where technical excellence and operational reliability are paramount considerations for equipment purchasing decisions. Quality assurance protocols in agricultural heating equipment manufacturing must address material consistency, electrical safety standards, thermal performance verification, and durability testing procedures that ensure consistent product performance across different production batches and market destinations, supporting the development of trusted supplier relationships with international distributors and end-user agricultural operations.

- Overview

- Size

- Details

- Recommended Products

Description

Size

|

|

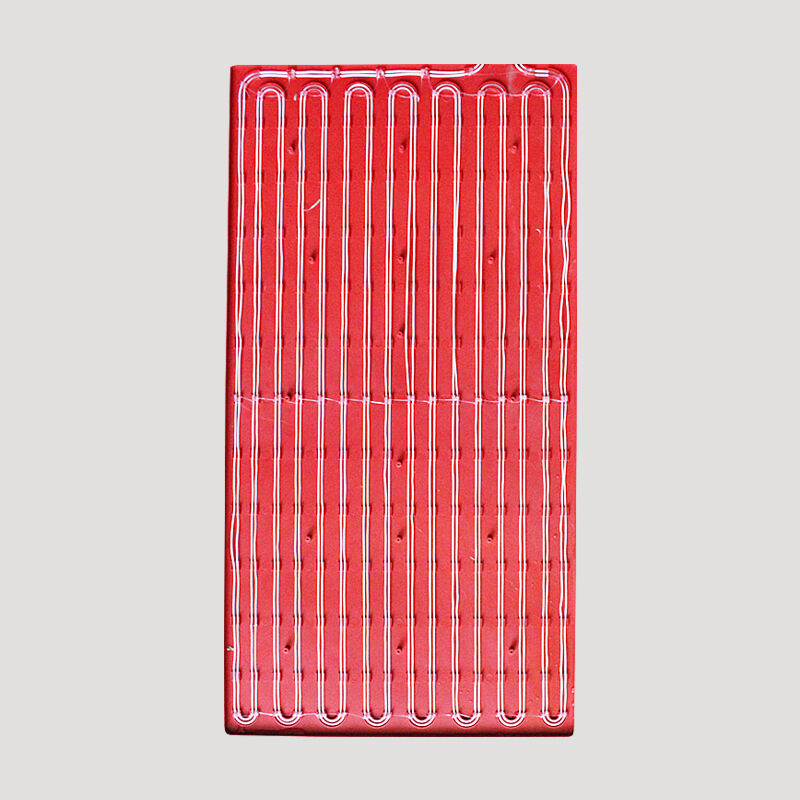

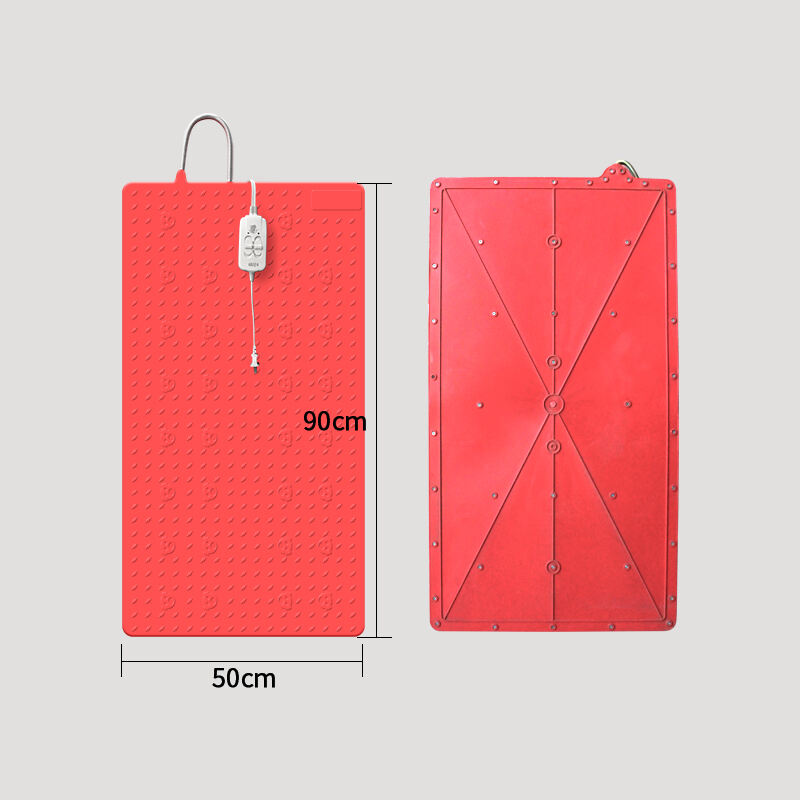

Material: Pure solid raw material mixed slurry Size: 50*90/55*100/100*150CM Power: 80W-160W |

|

|

|

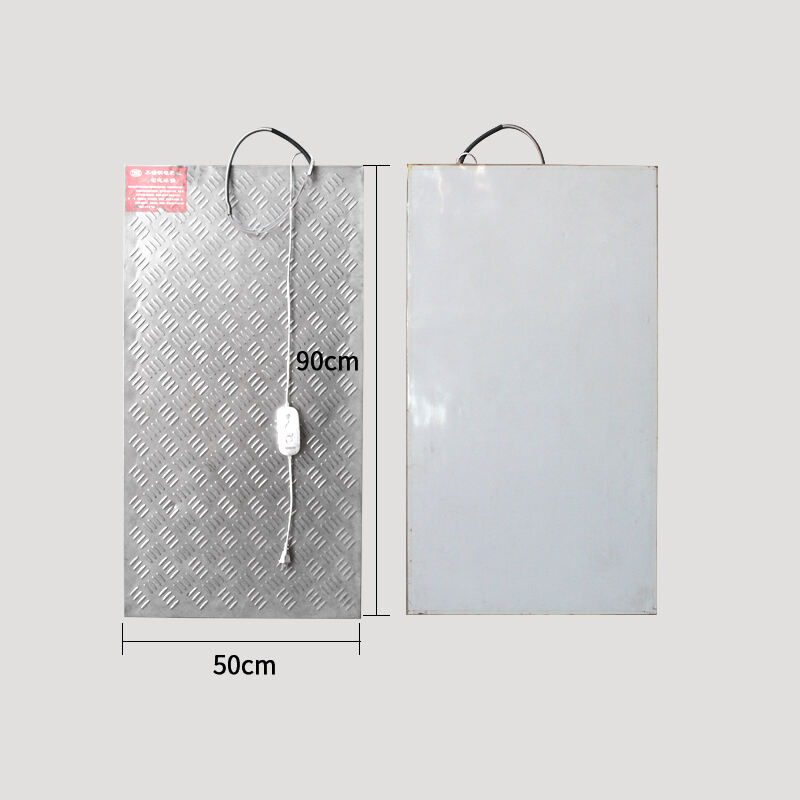

Material: Stainless steel material Size: 50*90/55*100/100*150cm Power: 50W-100W |

|

|

|

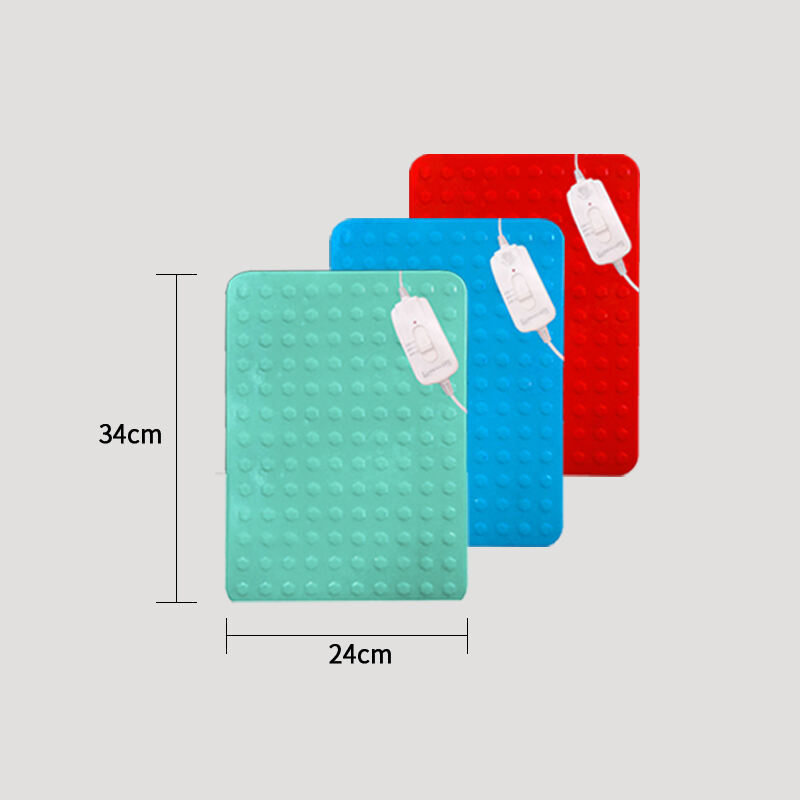

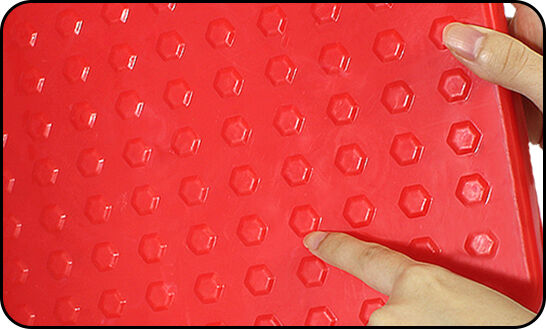

Material: high-strength plastic steel shell+ thick heating wire Power:60W_120W Specification: 6 pieces/box(About 4 kg per piece) |

Details

|

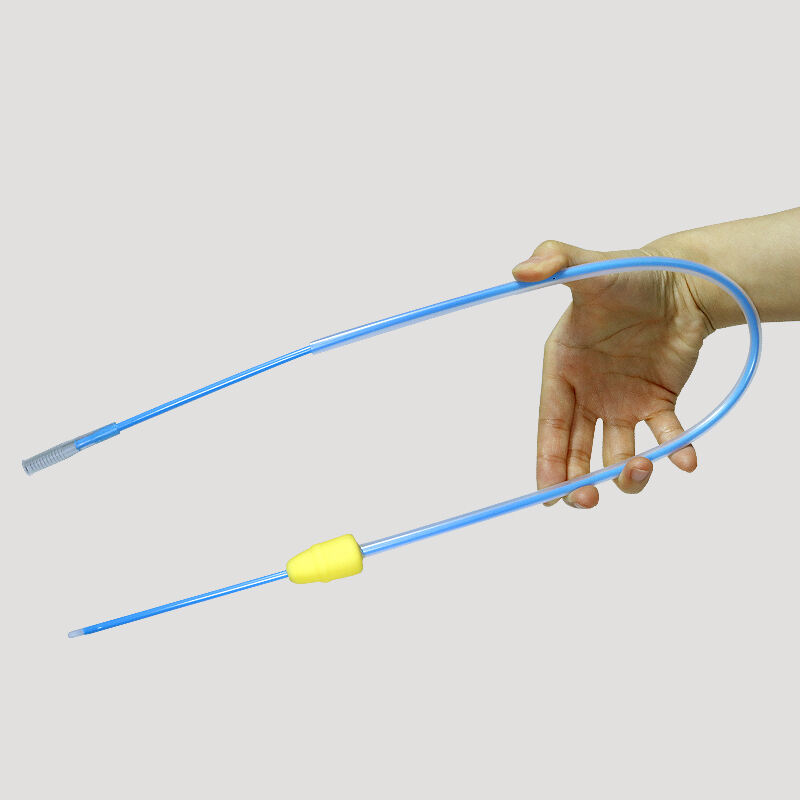

Waterproof & anti-burnout heating wire, safe structure. |

|

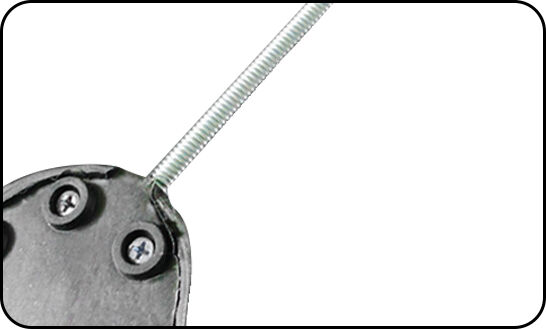

Thickened heating wire, flame-retardant and leakage-proof. |

|

|

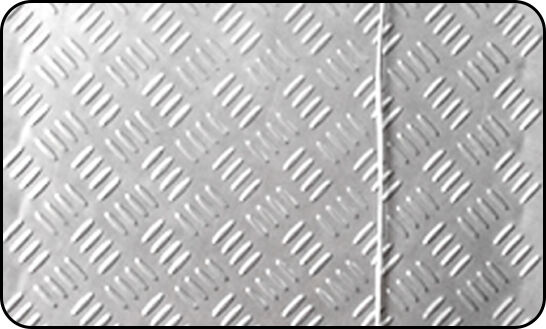

It features non-slip properties, comfortable use, and long-lasting durability. |

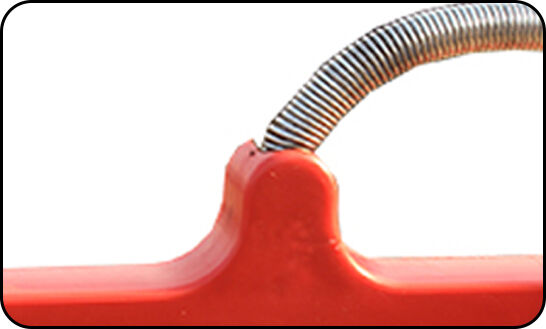

| It features a stable design, ensuring safety and peace of mind |  |