The Automatic Plastic+Stainless Steel Feeder Wet and Dry Pig Feed Saving Trough represents a sophisticated advancement in modern swine feeding systems, engineered to optimize feed distribution efficiency while maintaining the highest standards of durability and hygiene in intensive livestock operations. This innovative feeding solution seamlessly integrates premium food-grade plastic components with robust stainless steel elements, creating a hybrid construction that leverages the lightweight, corrosion-resistant properties of advanced polymer materials alongside the exceptional strength and antimicrobial characteristics inherent to high-quality stainless steel fabrication. The thoughtful material selection ensures optimal performance across diverse environmental conditions, from temperature fluctuations to moisture exposure, making this feeding system particularly well-suited for international markets where climate variations and operational requirements differ significantly across geographical regions. Professional agricultural equipment distributors and livestock facility managers worldwide recognize the value of this dual-material approach, as it addresses the fundamental challenges of feed waste reduction while maintaining the structural integrity essential for continuous commercial operation. The automatic dispensing mechanism incorporates precision-engineered components that facilitate consistent feed delivery, accommodating both wet and dry feed formulations without compromising flow characteristics or portion accuracy, thereby supporting optimal nutrition management protocols essential for modern swine production efficiency. International sourcing professionals appreciate the versatility of this feeding system, as it adapts seamlessly to various installation configurations and facility layouts, whether integrated into new construction projects or retrofitted into existing livestock housing structures. The stainless steel components undergo specialized surface treatments that enhance resistance to organic acid exposure and facilitate thorough sanitization procedures, critical factors for maintaining biosecurity standards in commercial swine operations while extending operational lifespan through reduced corrosion susceptibility. Manufacturing excellence in this sector demands comprehensive understanding of international quality expectations, material compatibility requirements, and the diverse regulatory frameworks governing livestock equipment across different export markets, ensuring that each feeding system meets or exceeds the stringent performance criteria established by discerning agricultural professionals globally. The plastic components utilize advanced polymer formulations specifically selected for their impact resistance, UV stability, and thermal expansion characteristics, properties that remain consistent across extended operational periods while maintaining dimensional stability under varying load conditions typical of intensive feeding environments. Design considerations extend beyond mere functionality to encompass ease of maintenance, cleaning accessibility, and component serviceability, recognizing that efficient livestock operations require equipment systems that minimize downtime while maximizing operational reliability throughout extended service periods. Customization capabilities within this product category enable adaptation to specific facility requirements, operational preferences, and regional feeding protocols, allowing distributors and end-users to specify modifications that align with local practices while maintaining the core performance advantages inherent to the original design specifications. The feed-saving functionality addresses the critical economic considerations that drive modern livestock management decisions, incorporating features that minimize spillage, reduce contamination risks, and optimize feed conversion ratios through controlled dispensing mechanisms that respond effectively to animal feeding behaviors. Export-oriented manufacturing approaches ensure consistent quality standards regardless of destination market, with comprehensive quality assurance protocols that verify material integrity, dimensional accuracy, and functional performance before shipment, supporting the reliability expectations that characterize successful long-term supplier relationships in the international agricultural equipment sector. Collaboration opportunities with distributors and regional partners encompass technical support, installation guidance, and ongoing maintenance recommendations, reflecting a comprehensive service philosophy that extends beyond mere product delivery to encompass operational success throughout the equipment lifecycle. The versatility of this feeding system extends across various swine production methodologies, from intensive confinement operations to alternative housing systems, demonstrating adaptability that supports diverse management philosophies while maintaining consistent performance standards essential for commercial viability. Logistics compatibility considerations include packaging optimization for efficient transportation, component protection during international shipping, and modular design elements that facilitate cost-effective distribution while ensuring arrival condition integrity across extended supply chains typical of global agricultural equipment markets.

Automatic Plastic+Stainless Steel Feeder Wet and Dry Pig Feed Saving Trough

-

Dual Feeding System – Allows pigs to consume dry feed and water simultaneously, enhancing feed utilization and digestion efficiency.

-

Large-Capacity Hopper – Holds a significant amount of feed, reducing refill frequency and saving labor time and costs.

-

Durable & Long-Lasting Build – Made from strong, wear-resistant materials for extended use in harsh farming environments.

-

Hygienic & Easy to Clean – Simple structure enables fast cleaning and disinfection, minimizing disease risks and improving sanitation.

-

Efficient Feeding Management – Automatically dispenses feed, ensuring consistent availability and improving overall farm productivity.

- Overview

- Size

- Details

- Recommended Products

Product Introduction Video

https://youtube.com/shorts/eU2jTRrrY0o?si=51K-pPXJJGxtJYCW

Certificate

Size

Details

|

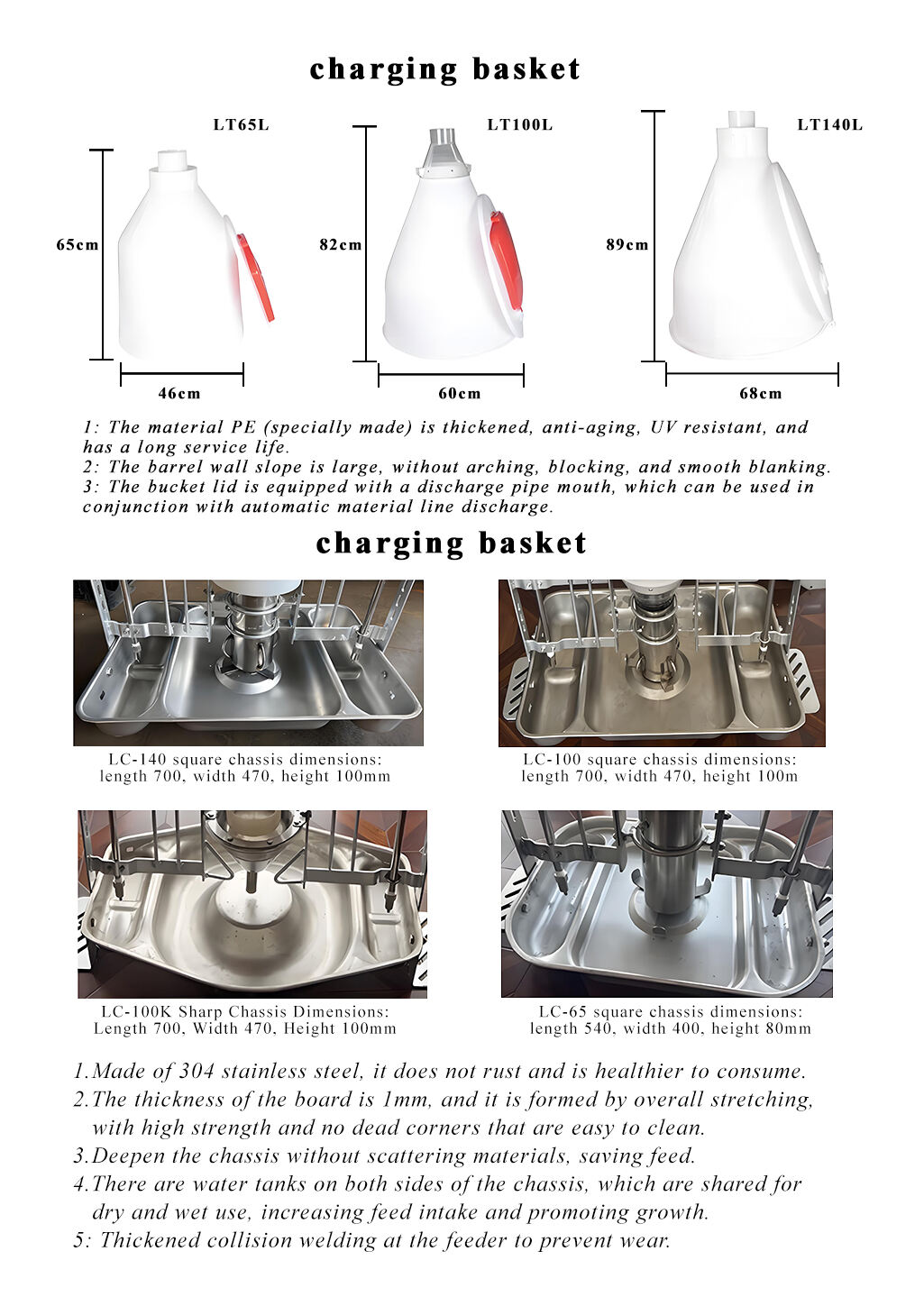

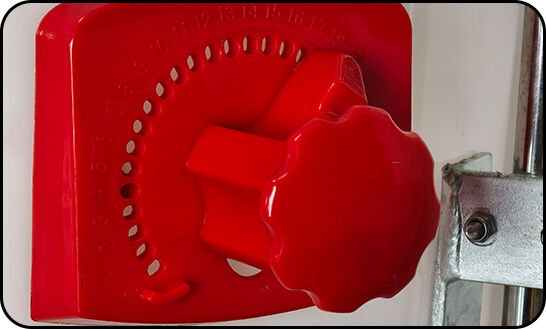

Save feed Deepening the chassis without scattering materials, precise and controllable discharge volume |

|

Smooth material cutting Smooth barrel wall,steep slope, anti arch device to remove arch material |

|

|

Durable Bucket: anti-aging and thickening Chassis: 304, deepened and thickened Other: Hot dip galvanized+stainless steel Structure: Stable, firm, and impact resistant |

|

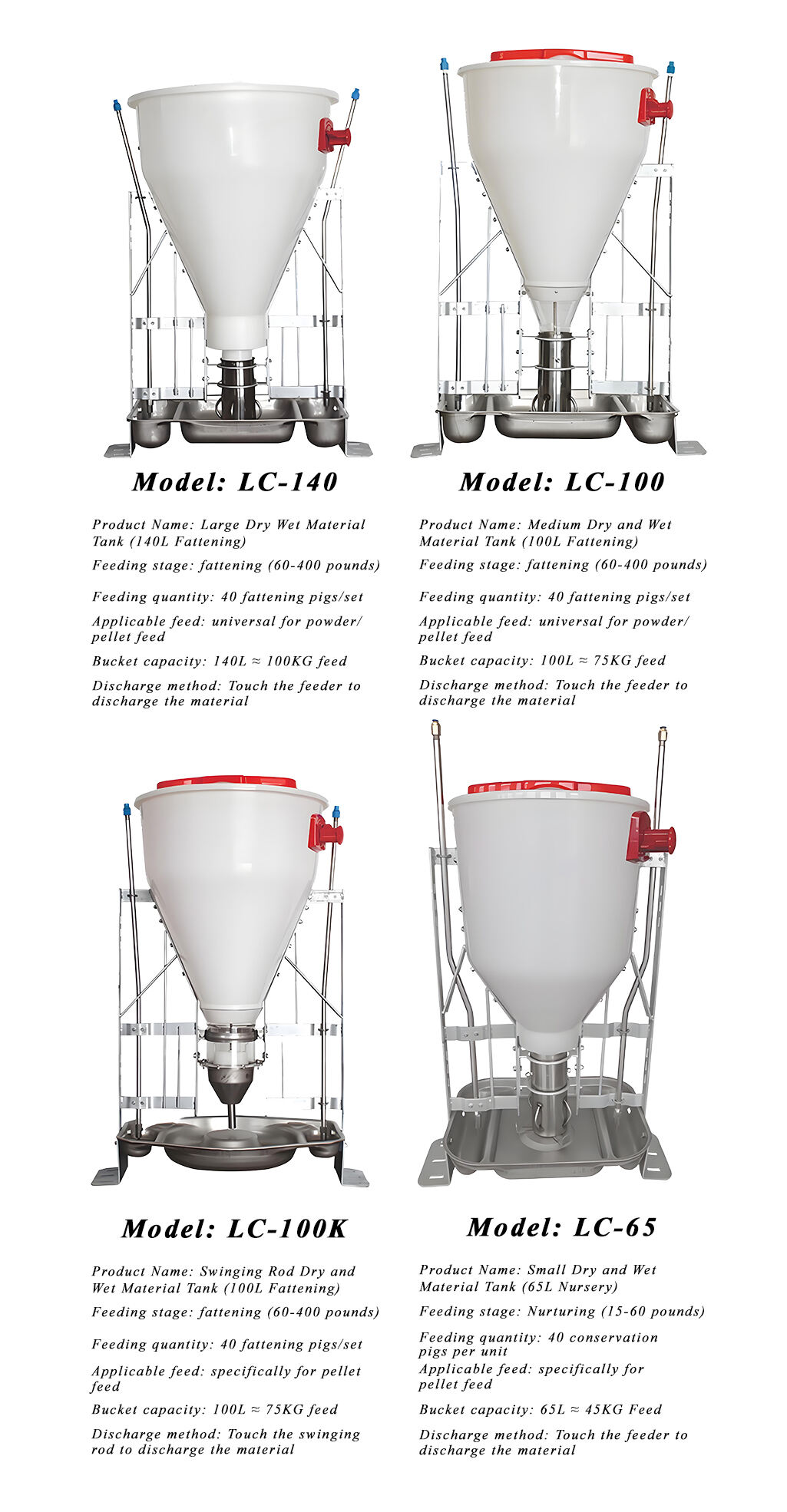

Complete specifications Conservation and fattening:65L/100L/140L, 40KG, 70KG.Powder granule material: 100KG |

|