The Adjustable 0.5-6ml Revolving Dose Cup Plastic Automatic Continuous Veterinary Syringe for Cattle/Pig/Sheep represents a sophisticated approach to livestock medication administration, engineered specifically for modern agricultural operations that demand precision, efficiency, and animal welfare considerations in their daily husbandry practices. This specialized veterinary instrument addresses the critical need for accurate dosage delivery across diverse livestock populations, incorporating advanced polymer materials and mechanical engineering principles that ensure consistent performance throughout extended operational periods while minimizing stress factors for both animals and operators. The revolving dose cup mechanism integrated into this veterinary syringe system provides exceptional versatility in dosage selection, allowing agricultural professionals to transition seamlessly between different medication volumes without requiring multiple instruments or time-consuming equipment changes that can disrupt workflow efficiency in busy farm environments. Professional veterinarians, livestock managers, and agricultural technicians increasingly recognize the importance of automated continuous delivery systems that reduce human error while maintaining precise dosage control, particularly when managing large herds where individual animal treatment protocols must be executed rapidly yet accurately to ensure therapeutic effectiveness and regulatory compliance.

Manufacturing excellence in veterinary instrumentation requires sophisticated understanding of both mechanical precision and biological safety standards, with this automatic continuous syringe incorporating high-grade plastic components specifically selected for their chemical resistance, durability under field conditions, and compatibility with a broad spectrum of veterinary pharmaceuticals commonly used in cattle, pig, and sheep management protocols. The plastic construction methodology employed in this device leverages advanced polymer science to deliver lightweight operation without compromising structural integrity, ensuring that operators can maintain steady control during extended treatment sessions while the materials resist degradation from exposure to various medication formulations, cleaning agents, and environmental factors typical in agricultural settings. Quality consistency philosophy drives the manufacturing approach for this veterinary equipment, with production processes designed to maintain uniform performance characteristics across individual units, ensuring that agricultural operations can rely on predictable dosage accuracy regardless of which specific syringe is selected from their equipment inventory. International sourcing teams evaluating veterinary instrumentation suppliers increasingly prioritize manufacturers who demonstrate comprehensive understanding of agricultural workflow requirements, regulatory considerations, and the critical importance of equipment reliability in situations where animal health outcomes depend directly on precise medication administration.

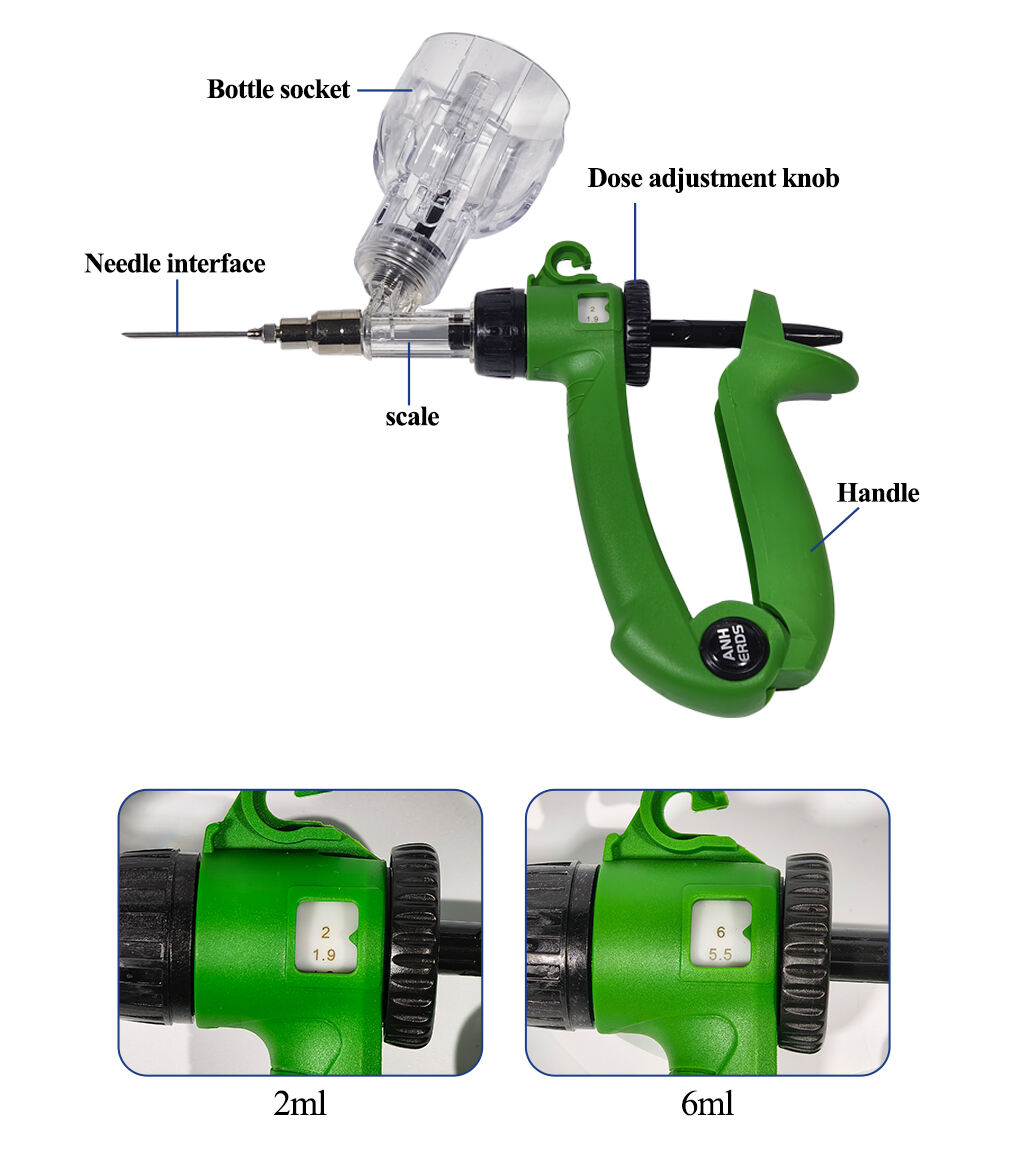

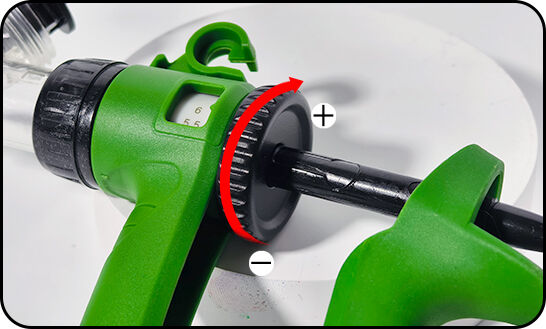

Design considerations for this adjustable veterinary syringe extend beyond basic functionality to encompass ergonomic factors that reduce operator fatigue during extended use periods, with the automatic continuous mechanism minimizing repetitive strain while the revolving dose cup system provides intuitive operation that reduces training requirements for farm personnel across varying skill levels and experience backgrounds. Surface treatment approaches for the plastic components emphasize easy cleaning and sanitization protocols essential for maintaining biosecurity standards in livestock operations, with smooth surfaces and minimal crevice formations that prevent bacterial accumulation while facilitating rapid turnaround between animal treatments or different medication types. Functional customization possibilities inherent in this syringe design accommodate diverse operational requirements encountered across different agricultural markets, with the adjustable volume range spanning from precision applications requiring minimal dosages to larger volume treatments necessary for adult livestock, ensuring versatility that supports comprehensive herd management strategies without requiring multiple specialized instruments that increase equipment costs and storage complexity.

Application suitability across cattle, pig, and sheep operations reflects careful consideration of the unique physiological and behavioral characteristics of each livestock species, with the automatic continuous delivery system particularly valuable in swine operations where rapid processing is essential, cattle management where animal size variations demand flexible dosing options, and sheep handling where precision becomes critical due to smaller body weights and corresponding medication sensitivity factors. Export-oriented handling considerations influence the robust construction methodology employed in manufacturing this veterinary equipment, ensuring that devices maintain operational integrity throughout international shipping processes, various climate exposures, and the diverse storage conditions encountered in global agricultural markets where equipment reliability cannot be compromised by transportation or environmental stresses. Packaging and logistics compatibility factors have been integrated into the design philosophy, with compact dimensions and protective plastic construction facilitating efficient shipping arrangements while maintaining device protection standards necessary for international distribution networks serving agricultural customers worldwide.

Customization collaboration opportunities with OEM and ODM partners reflect manufacturing flexibility that supports private label development, specification modifications, and volume production arrangements suitable for distributors serving regional agricultural markets with specific regulatory requirements or operational preferences that may differ from standard configurations. Long-term supplier cooperation expectations emphasize consistent quality delivery, technical support availability, and manufacturing scalability that ensures reliable supply chain management for distributors and end users who depend on uninterrupted access to essential veterinary instrumentation for their livestock operations. Manufacturing experience accumulated through extensive cooperation with international agricultural equipment distributors provides deep understanding of field performance requirements, durability expectations, and the critical importance of maintaining consistent product quality standards that support professional reputation and customer satisfaction in veterinary instrument applications. The continuous automatic mechanism incorporated into this syringe design represents advanced engineering solutions specifically developed for agricultural environments where equipment must perform reliably under demanding conditions while delivering precise results that directly impact animal health outcomes and operational efficiency standards expected by modern livestock management professionals worldwide.