The Hot Dip Galvanized Steel Pipe Crate Nursery Pen and Weaning Crate for Piglet and Pig Farm represents a sophisticated approach to modern swine management infrastructure, designed specifically to meet the demanding requirements of commercial pig farming operations across global markets. This specialized agricultural equipment combines advanced metallurgical engineering with practical livestock handling considerations, delivering a robust containment solution that addresses the critical phases of piglet development from birth through weaning transitions. The hot dip galvanization process employed in manufacturing these steel pipe crates creates a zinc-iron alloy coating that fundamentally transforms the base material's resistance characteristics, establishing a protective barrier that withstands the corrosive elements commonly encountered in agricultural environments including moisture, ammonia compounds, and organic acids present in livestock facilities. International buyers and agricultural equipment distributors recognize this galvanized steel construction as a premium choice for long-term investment in farm infrastructure, where durability and hygiene maintenance directly impact operational efficiency and animal welfare standards. The crate design philosophy emphasizes modularity and adaptability, allowing farm operators to configure nursery and weaning spaces according to specific breed requirements, facility layouts, and production methodologies while maintaining consistent structural integrity throughout various installation scenarios. Professional livestock equipment suppliers appreciate the engineering balance achieved between material strength and practical functionality, as the steel pipe framework provides necessary containment security while facilitating essential management activities including feeding, cleaning, health monitoring, and animal movement protocols. The galvanized surface treatment not only extends the operational lifespan of these crates but also simplifies maintenance procedures, as the smooth, non-porous finish resists bacterial accumulation and enables efficient sanitization protocols required in modern pig farming operations. Agricultural facility planners and farm construction specialists frequently specify this type of galvanized steel infrastructure for new installations and facility upgrades, recognizing that proper nursery and weaning environments directly correlate with piglet survival rates, growth performance, and overall production outcomes. The versatility of these crate systems extends beyond basic containment functions, as many configurations incorporate adjustable features that accommodate different growth stages, ventilation requirements, and feeding arrangements while maintaining the structural stability essential for safe livestock management. Export-oriented manufacturers typically engineer these products to accommodate international shipping requirements, ensuring that crate components can be efficiently packed, transported, and reassembled at destination facilities without compromising structural specifications or surface protection qualities. The hot dip galvanization process itself represents a sophisticated metallurgical treatment where steel components are immersed in molten zinc baths, creating molecular bonding between the protective coating and base material that surpasses alternative surface treatments in terms of adhesion strength and corrosion resistance performance. Quality-conscious agricultural equipment buyers recognize that this manufacturing approach delivers consistent protective characteristics across all crate components, eliminating the variability sometimes associated with spray-applied or electroplated finishes that may exhibit uneven coverage or premature failure under demanding farm conditions. Professional swine facility designers often integrate these galvanized crate systems into comprehensive barn planning strategies that consider airflow patterns, waste management systems, and operational workflow optimization, appreciating how standardized crate dimensions and mounting configurations facilitate systematic facility layouts. The weaning transition represents a particularly critical period in pig production where environmental consistency and containment reliability directly influence animal stress levels and subsequent performance outcomes, making the selection of appropriate crate infrastructure a strategic decision for commercial operations. International agricultural trade professionals understand that suppliers of galvanized steel livestock equipment must demonstrate consistent manufacturing capabilities and quality control procedures to meet the diverse certification requirements encountered across different export markets and regional agricultural standards. The collaborative relationship between equipment manufacturers and farm operators often extends beyond initial product supply to include ongoing technical support, customization consultation, and facility planning assistance that leverages accumulated experience in swine management infrastructure development. Modern pig farming operations increasingly demand equipment solutions that balance initial investment considerations with long-term operational costs, recognizing that properly specified galvanized steel crate systems typically deliver favorable total cost of ownership through reduced maintenance requirements, extended service life, and consistent performance reliability that supports predictable production planning. The surface characteristics achieved through hot dip galvanization create an ideal foundation for additional treatments or modifications that may be required for specific applications, while maintaining the fundamental corrosion protection that ensures structural integrity throughout extended agricultural service environments where equipment reliability directly impacts animal welfare and production efficiency outcomes.

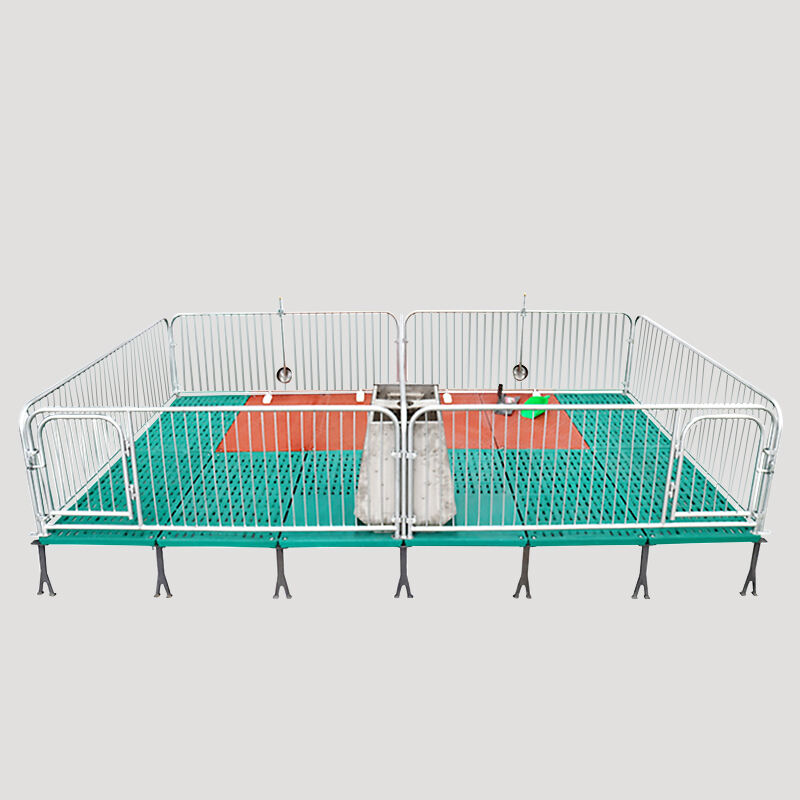

Hot Dip Galvanized Steel Pipe Crate Nursery Pen and Weaning Crate for Piglet and Pig Farm

-

Durable Hot-Dip Galvanized Steel – Built with fully hot-dip galvanized pipes for exceptional corrosion resistance, ensuring a long-lasting and rust-proof piglet housing solution.

-

Safe and Comfortable Design – Smooth, rounded pipe edges prevent injury while providing a secure and stress-free environment for piglets during the weaning and nursery stage.

-

Easy to Clean & Maintain – Designed for effortless cleaning and disinfection, maintaining high hygiene standards to reduce disease risk and improve piglet health.

-

Customizable Size & Layout – Crate dimensions and configurations can be customized to meet different farm layouts, offering flexibility for various pig farming operations.

-

Quick Installation & Strong Support – Sturdy structure with easy-to-assemble design and stable support legs ensures a reliable and practical solution for piglet management.

- Overview

- Type

- Details

- Recommended Products

Description

Piglet Nursery Bed – High-Quality Solution for Piglet Care

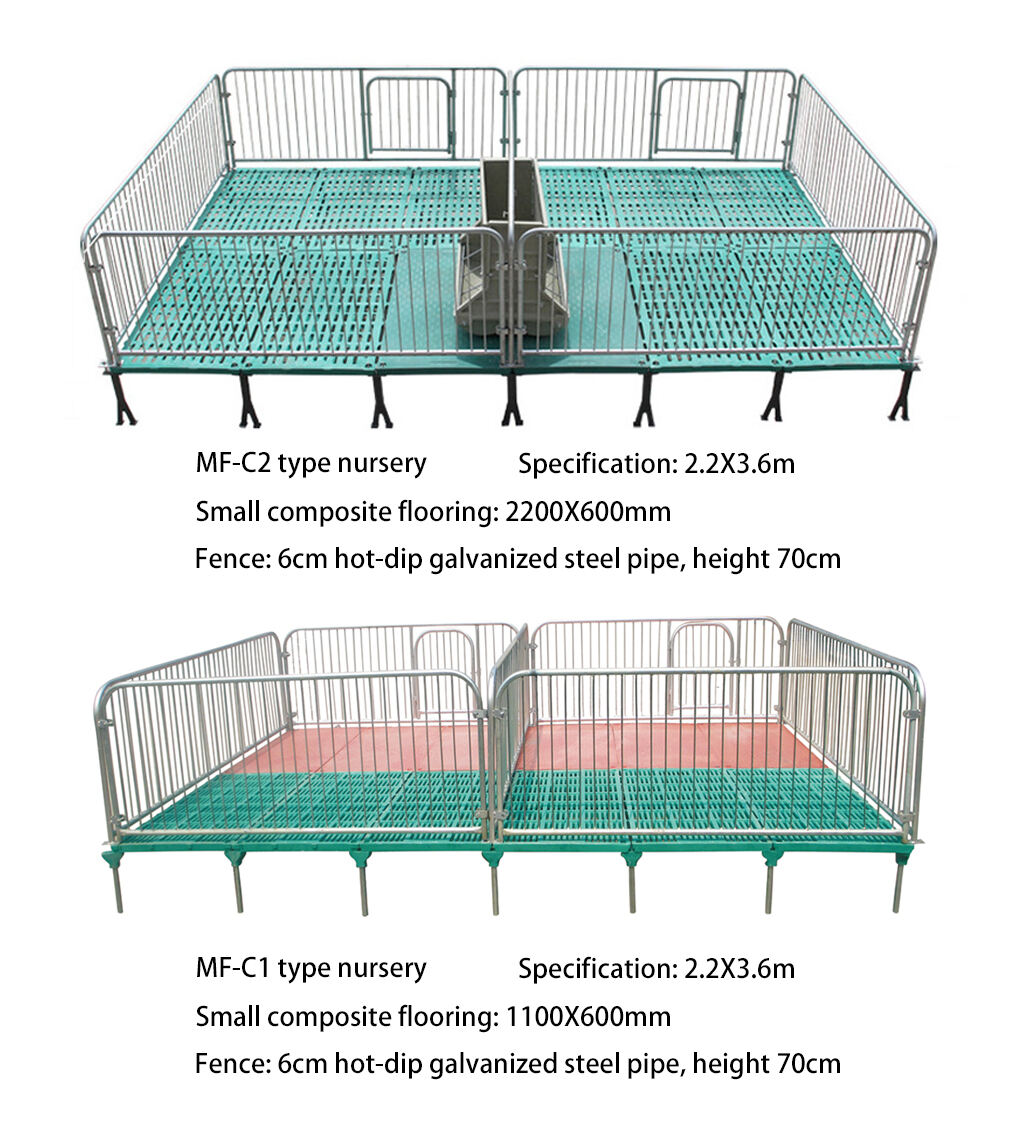

The piglet nursery bed is an essential piece of equipment designed to enhance piglet survival rates, minimize the incidence of diseases, and improve overall farm management efficiency. By providing a clean, safe, and well-structured environment, it delivers significant economic benefits to farmers. The nursery bed is suitable for piglets after weaning and can be customized to meet various size requirements.

Superior Design & Construction

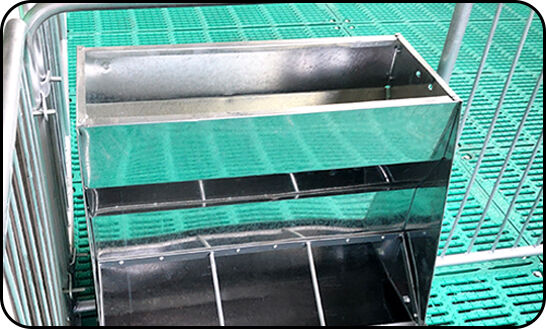

Each nursery bed is built with a strong surrounding fence and a durable slatted floor made of either woven wire mesh or high-quality plastic. The slatted design ensures excellent manure drainage, keeping the surface clean and dry while improving hygiene. Underneath, flat steel supports provide exceptional load-bearing capacity. The feed trough is a double-sided 6-hole design made from 1.2mm steel plates, paired with durable drinkers to meet piglets’ feeding needs. The standard dimension is 1800*2200*1000mm, but customized sizes are available.

The frame is crafted from 2.2mm thick hot-dip galvanized steel pipes, welded with precision bevel joints for a smooth, aesthetically pleasing, and highly durable finish. Partition panels use 8mm round steel, ensuring strength and long-lasting performance.

Easy Installation & Maintenance

The bed frame and panels are bolted together for quick assembly, while side panels use pin connections for easy disassembly and cleaning. Installation requires precise positioning, ensuring equal distances between legs and maintaining alignment for stability. All welding joints undergo full welding, cleaning, and anti-rust coating for added protection.

By combining superior materials, thoughtful design, and easy assembly, the piglet nursery bed provides farmers with a reliable, hygienic, and cost-effective solution for raising piglets after weaning.

Product Introduction Video

https://www.youtube.com/embed/Rjm1YVME-4M?si=YS2dnmaGFMt656_U

Certificate

Type

Details

|

Double-sided six-hole nursery trough, more food positions, quantitative feed The piglet does not grab food, has a balanced nutrition, and grows strong! |

|

European style latch Made of hot-dip galvanized Touch and close |

|

|

Solid plate under the trough A solid plate is used under the trough, Prevent the feed from leaking when the piglets eat, Save feed |

|

Heighten the fence Prevent the piglet from jumping, Take care of the piglet |

|

|

Multiple cast iron legs, Under each dung slab All have cast iron legs, Strong, stable and load-bearing. |