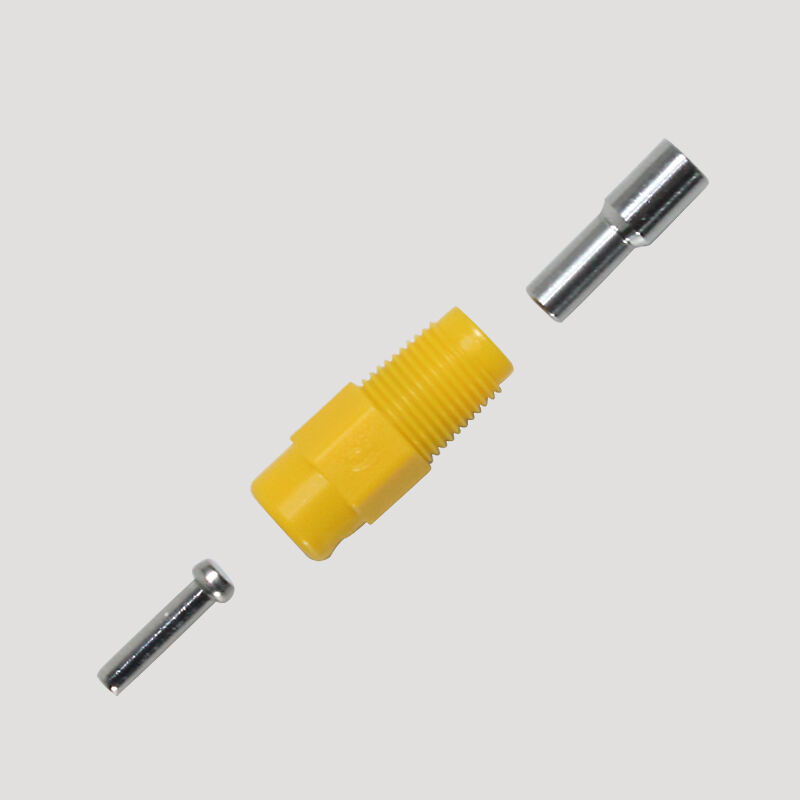

The Stainless Steel Poultry Nipple Drinker represents a sophisticated approach to modern poultry hydration systems, engineered specifically for commercial farming operations, agricultural distributors, and livestock equipment suppliers seeking reliable water delivery solutions across diverse international markets. This precision-manufactured drinking mechanism combines the inherent durability of stainless steel construction with carefully calibrated flow control technology, positioning itself as an essential component for professional poultry facilities worldwide that prioritize water quality, system longevity, and operational efficiency. International B2B buyers increasingly recognize that premium stainless steel poultry nipple drinkers offer superior performance characteristics compared to conventional plastic alternatives, particularly in environments where hygiene standards, temperature fluctuations, and continuous usage patterns demand exceptional material resilience. The corrosion-resistant properties of stainless steel construction ensure consistent functionality across various climatic conditions, making these drinking systems particularly valuable for export-oriented agricultural equipment suppliers who serve diverse geographical markets with varying environmental challenges. Manufacturing excellence in stainless steel poultry watering systems begins with careful material selection, where food-grade stainless steel alloys provide the foundation for products that maintain their structural integrity and surface smoothness throughout extended operational periods. The manufacturing process typically involves precision machining of the nipple mechanism, ensuring optimal water flow rates that accommodate different poultry species while preventing waste and maintaining consistent access to fresh water. Surface finishing techniques applied during production create smooth, non-porous exteriors that resist bacterial accumulation and simplify cleaning protocols, essential factors for maintaining biosecurity standards in commercial poultry operations. Design considerations for professional-grade stainless steel poultry nipple drinkers encompass multiple functional elements, including the activation mechanism sensitivity, water flow regulation, mounting compatibility, and integration flexibility with existing watering infrastructure. The nipple activation system requires precise engineering to ensure responsive triggering by birds while preventing accidental water release, achieving an optimal balance between accessibility and conservation. Connection threading and mounting configurations are standardized to facilitate seamless integration with various piping systems, allowing distributors and system integrators to incorporate these components into comprehensive watering solutions without compatibility concerns. Customization possibilities for OEM and ODM partnerships extend beyond basic functional specifications to include specialized surface treatments, connection configurations, and flow rate adjustments tailored to specific poultry management requirements. Collaborative development opportunities with international suppliers often involve adapting nipple sensitivity levels for different bird sizes, creating specialized mounting solutions for unique facility layouts, or developing integrated filter connections for enhanced water quality management. These customization capabilities enable equipment distributors to offer differentiated solutions that address specific regional farming practices or particular customer requirements, strengthening their competitive positioning in local markets. Application versatility across poultry industry segments demonstrates the broad market appeal of quality stainless steel nipple drinkers, serving broiler operations, layer facilities, breeder farms, and specialty poultry producers with equal effectiveness. The robust construction characteristics make these systems particularly suitable for high-density farming environments where equipment reliability directly impacts operational continuity and animal welfare standards. Integration compatibility with automated feeding systems, environmental control technologies, and facility management software creates opportunities for comprehensive agricultural automation solutions that appeal to modern farming operations seeking operational optimization. Quality consistency philosophy underlying professional stainless steel poultry equipment manufacturing emphasizes systematic production controls, material traceability, and performance validation throughout the manufacturing process. Experienced manufacturers implement comprehensive quality assurance protocols that ensure each nipple drinker meets established performance standards before reaching international customers, recognizing that equipment reliability directly impacts customer satisfaction and long-term business relationships. Consistent dimensional accuracy, surface finish quality, and functional performance across production batches enables distributors to confidently specify these products for large-scale installations without concerns about unit-to-unit variation affecting system performance. Export-oriented handling considerations recognize the importance of protective packaging, corrosion prevention during transit, and documentation completeness for international shipping requirements. Proper packaging protocols ensure that stainless steel surfaces remain pristine during extended transportation periods, while comprehensive product documentation facilitates customs clearance and installation procedures in destination markets. Understanding of international shipping dynamics allows manufacturers to optimize package dimensions and weight distribution to minimize logistics costs while maintaining product protection standards expected by professional buyers. Long-term supplier cooperation expectations in the B2B poultry equipment sector emphasize technical support availability, product development collaboration, and market responsiveness that enables distributors to build sustainable business relationships with their downstream customers. Successful partnerships typically involve ongoing communication regarding market feedback, technical improvements, and emerging application requirements that drive continuous product refinement. The combination of proven manufacturing expertise, material science knowledge, and international business understanding creates a foundation for supplier relationships that support market expansion and customer satisfaction objectives across diverse geographical regions and agricultural market segments.

Stainless Steel Poultry Nipple Drinker

-

Clean & Hygienic Water Supply: Provides fresh water on demand, minimizing contamination and keeping bedding dry.

-

Durable & Corrosion-Resistant: Made with stainless steel and high-quality plastic for long-lasting use.

-

360° Drinking Access: Birds/Chicken can drink from any angle, improving comfort and hydration efficiency.

-

Easy Installation & Maintenance: Compatible with pipes or buckets, simple to install and clean.

-

Efficient & Waste-Reducing Design: Leak-proof system reduces water waste and supports farm hygiene.

- Overview

- Size

- Details

- Recommended Products

Description

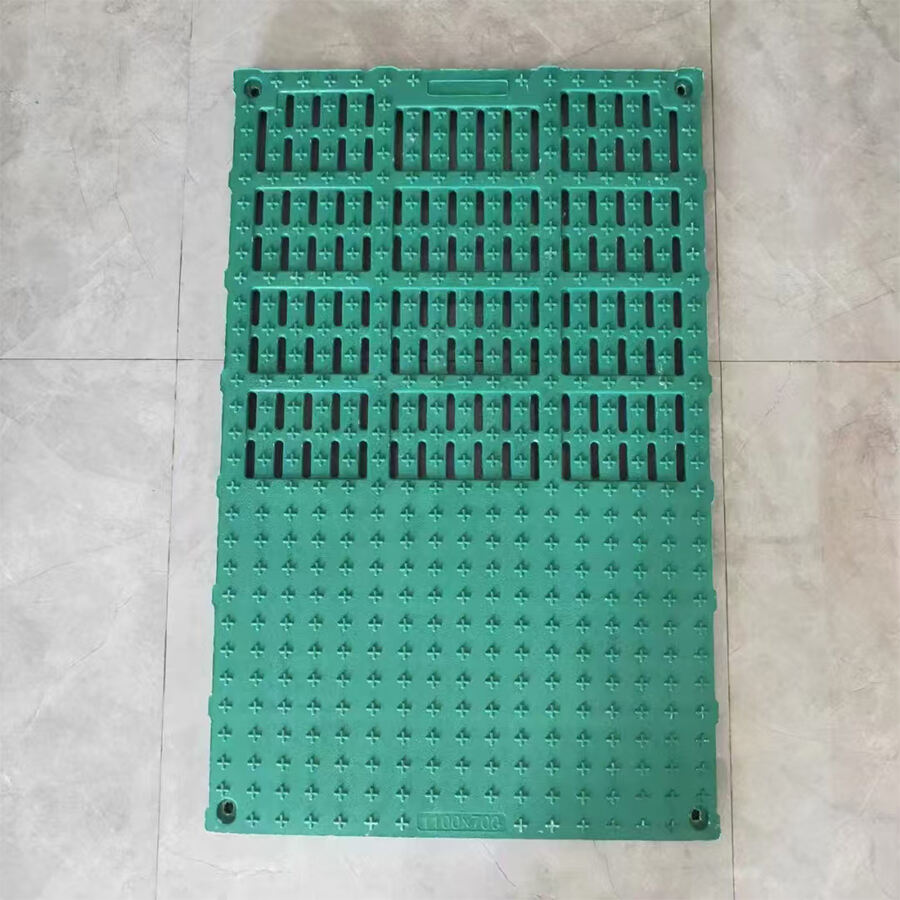

Size

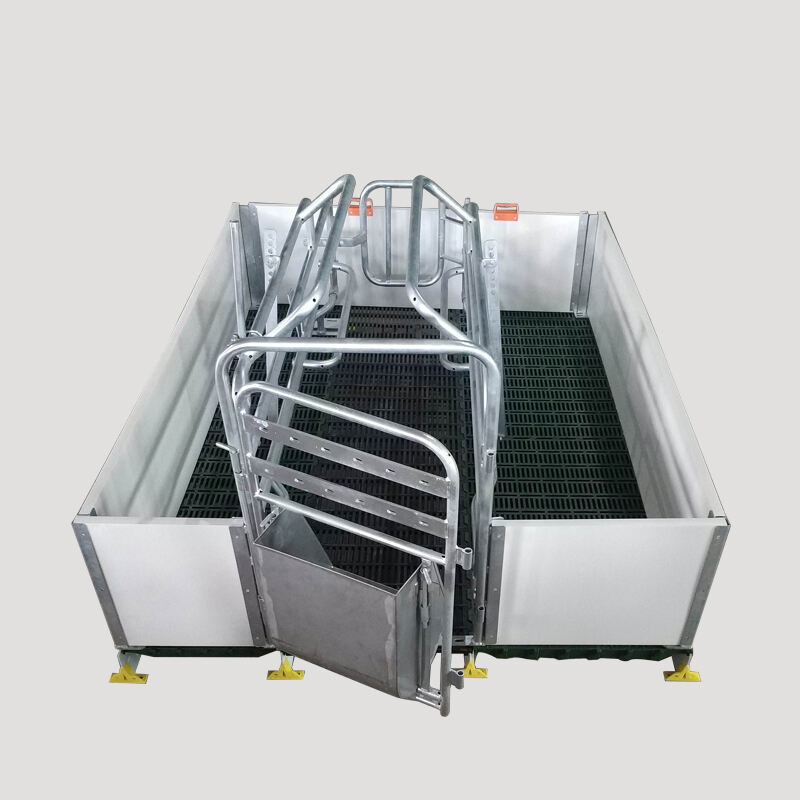

Details