The Automatic Stainless Steel Pig Feeding Trough for Nursery Fattening Swine Piglets represents a sophisticated approach to modern swine production equipment, engineered specifically to address the demanding requirements of commercial pig farming operations worldwide. This advanced feeding system combines robust stainless steel construction with automated functionality to deliver consistent, hygienic feed distribution for growing piglets during their critical nursery and fattening phases. The integration of durable metallic materials with precision engineering creates a feeding solution that meets the stringent hygiene standards required in contemporary livestock management while supporting optimal growth performance in young swine populations. International buyers and agricultural equipment distributors recognize the importance of reliable feeding infrastructure in maximizing livestock productivity, making this automated trough system an essential component for modern pig farming facilities across diverse geographical markets. The sophisticated design methodology behind this feeding equipment reflects extensive understanding of swine behavioral patterns and nutritional requirements, ensuring that each feeding session delivers appropriate portions while minimizing waste and contamination risks. Professional livestock equipment sourcing teams frequently evaluate feeding systems based on durability, automation capabilities, and material quality, with stainless steel construction providing superior corrosion resistance and longevity compared to alternative materials commonly used in agricultural applications. The automated feeding mechanism incorporated into this trough system eliminates manual intervention requirements, reducing labor costs and ensuring consistent feeding schedules that align with optimal growth protocols for nursery piglets transitioning into fattening phases. Manufacturing excellence in agricultural equipment requires comprehensive understanding of operational environments, material science principles, and automation technologies, which this feeding system demonstrates through its thoughtful integration of these technical elements. The surface treatment processes applied to the stainless steel components ensure smooth, non-porous finishes that facilitate thorough cleaning and sanitization procedures essential for maintaining biosecurity standards in commercial swine operations. Customization possibilities within this feeding system framework accommodate varying farm sizes, pig population densities, and specific operational preferences, allowing agricultural equipment suppliers to offer tailored solutions that align with individual client requirements. The versatility of this automated feeding technology extends across multiple swine production scenarios, from small-scale specialized breeding operations to large-scale commercial fattening facilities, demonstrating adaptability that international buyers value when establishing long-term equipment procurement strategies. Quality consistency philosophy embedded in the manufacturing approach ensures that each trough unit meets identical performance standards regardless of production batch or destination market, providing reliability assurance that global distributors require when building their agricultural equipment portfolios. Export-oriented handling considerations have been integrated into the design specifications, with component geometry and assembly procedures optimized for efficient packaging, transportation, and installation across international shipping networks. The collaborative approach to OEM and ODM partnerships enables agricultural equipment manufacturers to incorporate this feeding technology into broader swine management systems, creating comprehensive solutions that address multiple operational aspects simultaneously. Material selection criteria prioritize food-grade stainless steel alloys that maintain structural integrity under continuous exposure to feed materials, cleaning chemicals, and varying environmental conditions typical in pig farming facilities. The automated dispensing mechanism operates through mechanical principles that ensure reliable performance without requiring complex electronic systems that might complicate maintenance procedures in agricultural environments. Packaging and logistics compatibility features include modular component design that optimizes shipping container utilization while ensuring secure protection during international transportation, reducing freight costs and delivery complexity for overseas buyers. Long-term supplier cooperation expectations encompass ongoing technical support, component availability assurance, and adaptation capabilities that allow this feeding system to evolve alongside changing industry standards and regulatory requirements. The engineering approach underlying this automated trough system reflects deep understanding of swine nutrition science, acknowledging that consistent feed access during nursery and fattening periods directly influences growth rates, feed conversion efficiency, and overall production economics. Professional agricultural equipment buyers recognize that investing in high-quality feeding infrastructure creates operational advantages that extend beyond immediate cost considerations, generating long-term value through improved animal performance and reduced maintenance requirements. The manufacturing processes employed in producing this stainless steel feeding system incorporate precision fabrication techniques that ensure dimensional accuracy and surface quality consistency, critical factors in achieving reliable automated operation over extended service periods.

- Overview

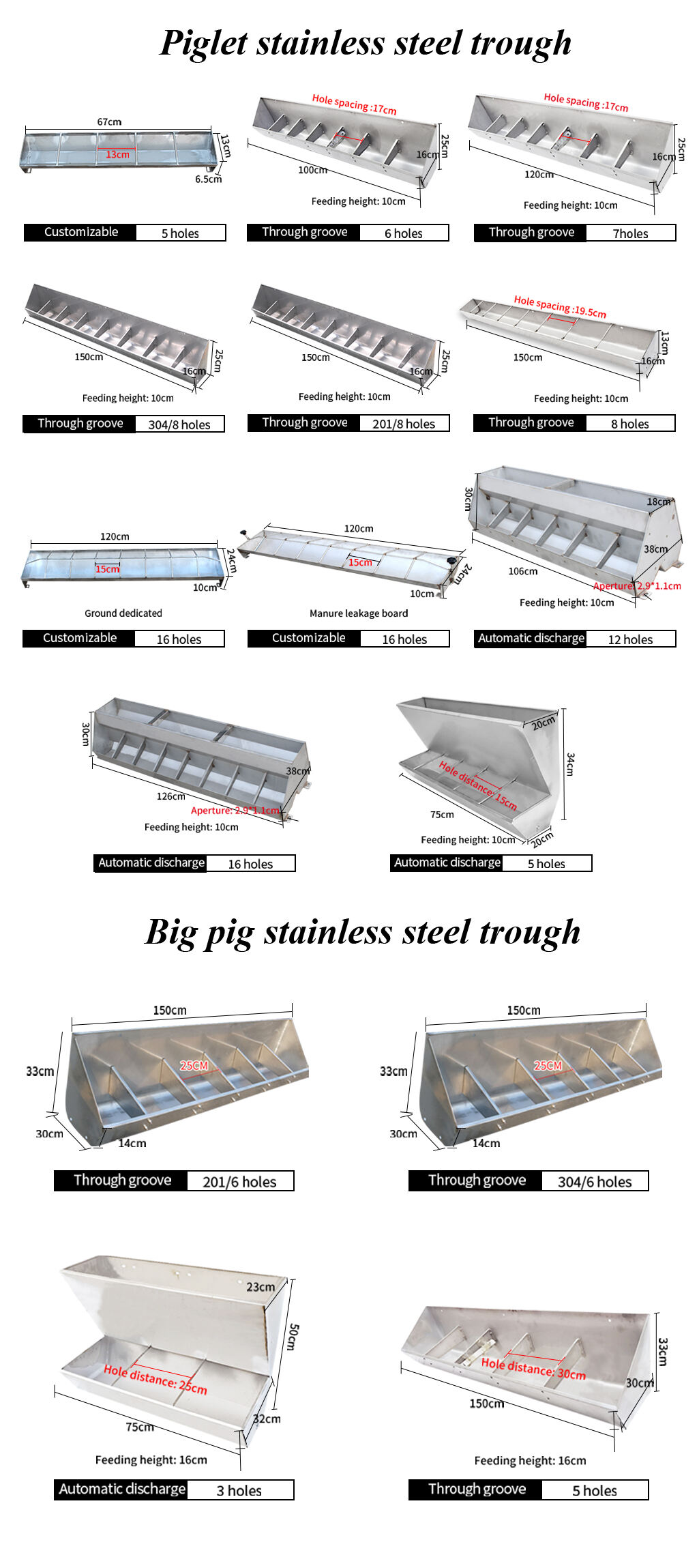

- Size

- Details

- Recommended Products

Description

【Stainless Steel Material, Durable Like "Iron Man"】

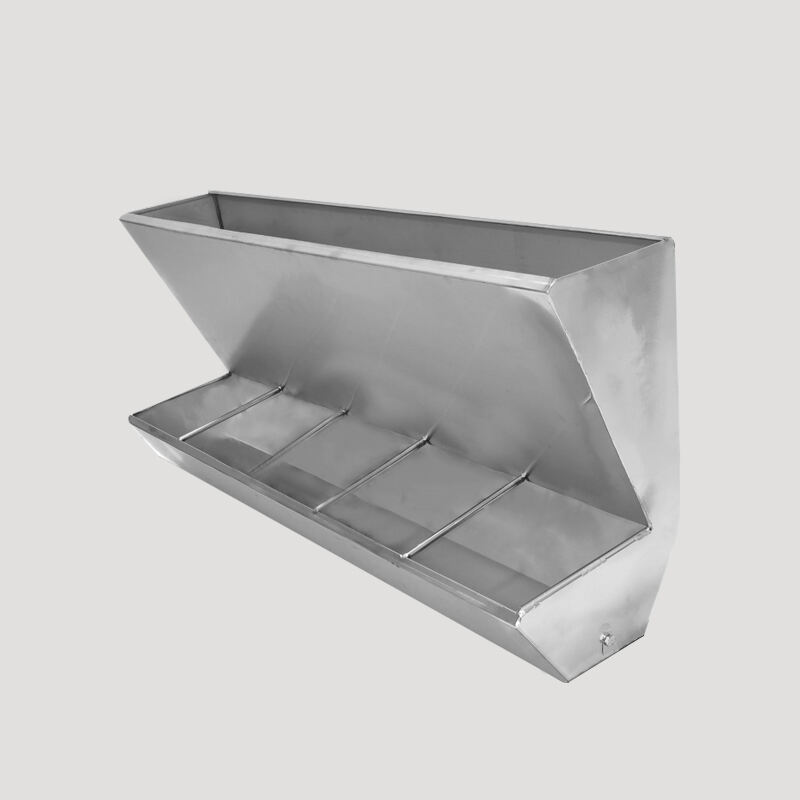

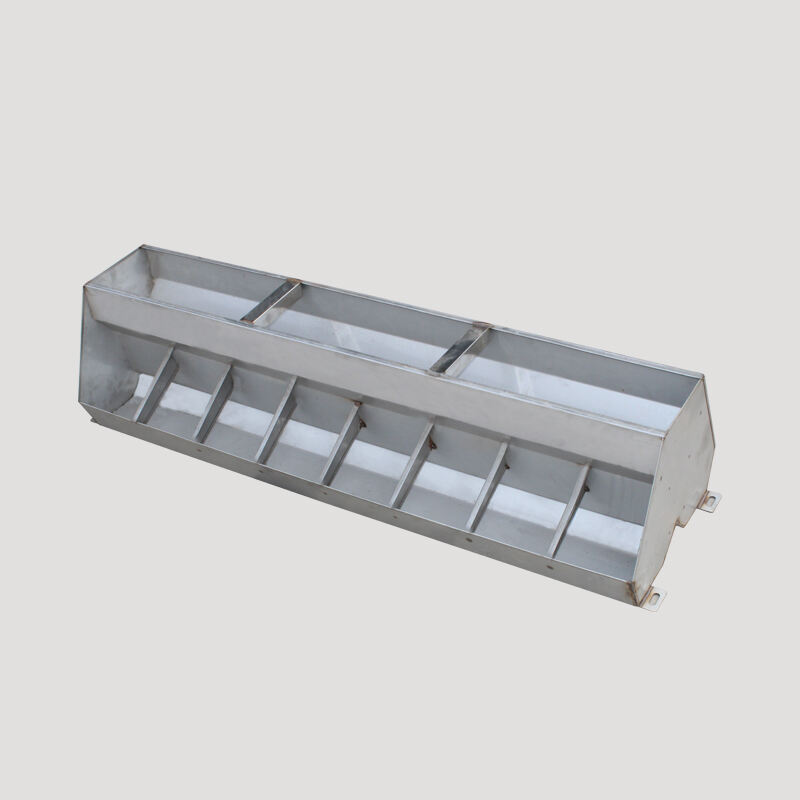

This pig feeder is made of high - quality stainless steel, with "hardcore protection". It can not only easily withstand daily collisions and wear, but also effectively prevent rust and corrosion in the humid environment of the pigsty. It remains stable and like new even after long - term use. Just like Iron Man's armor, it is indestructible, eliminating the trouble of frequently replacing feeders and reducing breeding costs.

It adopts a scientific rectangular design, and the length and width have been repeatedly measured: piglets in the nursery period can easily reach the feed, and big pigs in the fattening period can also eat comfortably, truly achieving "one feeder for all stages". At the same time, the reasonable trough structure can reduce feed spillage and waste, allowing every bite of feed to be accurately eaten by pigs, just like preparing an "exclusive dining bowl" for each pig, which is fair and saves feed.

The stainless steel material has an "easy - to - clean property". After feeding, just rinse with water, there is no residue or dirt hanging in the trough, and it is easy to avoid bacteria breeding from feed residues. There is no need to scrub hard, and the dietary hygiene of the pigsty can be maintained, reducing the risk of pigs getting sick. It is as simple and efficient as washing dishes daily, saving a lot of cleaning time for farmers.

Size

Details

|

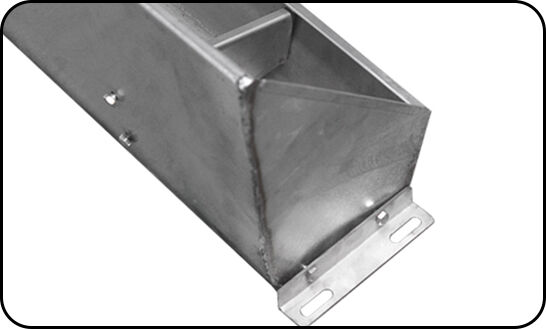

Rounded corner design Reduce mold and deterioration of feed due to dead ends, and save costs |

|

Fixed plate design There are fixed pieces on both sides of the bottom, which are strong and resis- tant to arching, stable and not over- turned |

|