The Splash Resistant Stainless Steel Pig Nipple Drinker represents a sophisticated watering solution engineered specifically for modern swine production facilities seeking optimal hygiene standards and operational efficiency in their livestock management systems. This premium drinking apparatus incorporates advanced stainless steel construction methodologies that ensure exceptional durability and corrosion resistance, making it particularly suitable for demanding agricultural environments where moisture exposure and frequent cleaning protocols are standard operating procedures. The splash-resistant design philosophy centers on minimizing water wastage while maintaining consistent access to clean drinking water for pigs across various growth stages, from weaning through finishing phases. Manufacturing excellence in this category demands precise attention to surface finishing techniques, where the stainless steel components undergo specialized treatments to achieve smooth, non-porous surfaces that resist bacterial accumulation and facilitate thorough sanitization procedures. International B2B buyers and agricultural equipment distributors increasingly recognize the importance of investing in robust watering infrastructure that can withstand the mechanical stresses associated with active pig behavior while maintaining structural integrity over extended operational periods. The engineering approach behind this nipple drinker system emphasizes flow control mechanisms that respond appropriately to animal activation pressure, delivering adequate water volumes without creating excessive spillage that could compromise pen hygiene or waste valuable resources. Stainless steel selection for livestock watering applications involves careful consideration of alloy compositions that provide optimal balance between strength, corrosion resistance, and manufacturing workability, ensuring that the finished products meet stringent agricultural industry standards for food safety and animal welfare. The splash-resistant functionality emerges through thoughtful valve design and positioning strategies that direct water flow patterns in ways that minimize environmental contamination while ensuring reliable access for animals of different sizes and drinking behaviors. Professional livestock equipment sourcing teams understand that superior watering systems contribute significantly to overall herd health outcomes by reducing stress factors associated with inadequate hydration access and maintaining cleaner living environments that support optimal growth performance. Quality manufacturing processes for these specialized drinking devices involve precision machining techniques and assembly protocols that ensure consistent performance characteristics across production batches, supporting the reliability expectations of commercial farming operations and industrial livestock facilities. The international agricultural equipment market increasingly demands watering solutions that combine functional excellence with maintenance efficiency, driving innovation in materials selection and component design approaches that minimize downtime and reduce operational complexity for farm management teams. Custom manufacturing capabilities within this product category enable adaptation to specific facility requirements, including mounting configurations, flow rate specifications, and integration compatibility with existing barn infrastructure systems. OEM cooperation opportunities in livestock watering equipment manufacturing allow agricultural equipment distributors to develop branded product lines that meet regional market preferences while maintaining consistent quality standards and performance reliability. Export-oriented manufacturing practices ensure that these stainless steel pig nipple drinkers comply with various international agricultural equipment standards and shipping requirements, facilitating smooth logistics processes for global distribution networks. The durability characteristics inherent in properly manufactured stainless steel watering components translate to reduced replacement frequency and lower total cost of ownership for livestock producers, making these systems attractive investment options for facilities planning long-term operational strategies. Surface treatment technologies applied during manufacturing processes enhance the natural corrosion resistance of stainless steel while creating textures that promote effective cleaning and disinfection procedures, supporting biosecurity protocols essential in modern swine production environments. Collaborative development approaches between manufacturers and agricultural equipment suppliers enable continuous improvement in product design, incorporating feedback from field applications to refine functionality and address emerging industry requirements. Professional installation and maintenance considerations for these watering systems involve understanding proper mounting heights, securing methods, and routine inspection procedures that maximize system longevity and ensure consistent performance throughout operational lifespans. The integration of splash-resistant watering technology into comprehensive barn management systems supports overall facility efficiency by reducing labor requirements associated with water system maintenance while promoting healthier living conditions for livestock populations.

Splash Resistant Stainless Steel Pig Nipple Drinker

-

Splash-Resistant & Water-Saving: Minimizes water waste and keeps pens dry, improving hygiene and reducing cleaning effort.

-

Durable Stainless Steel Build: Corrosion-resistant and long-lasting, suitable for harsh farm environments.

-

Clean & Controlled Water Supply: Delivers fresh water on demand while preventing contamination and overflow.

-

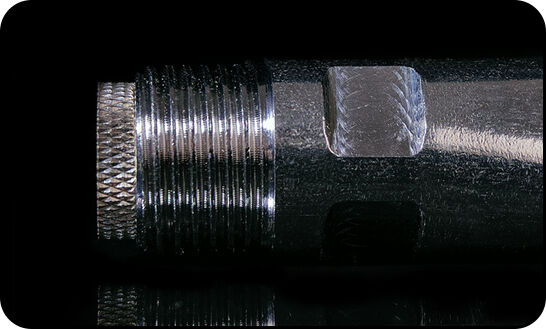

Easy Installation & Secure Fit: Threaded design ensures quick setup and leak-proof connection to water systems.

-

Safe & Versatile Use: Smooth edges and universal design fit pigs of all sizes and all stages—farrowing to finishing.

- Overview

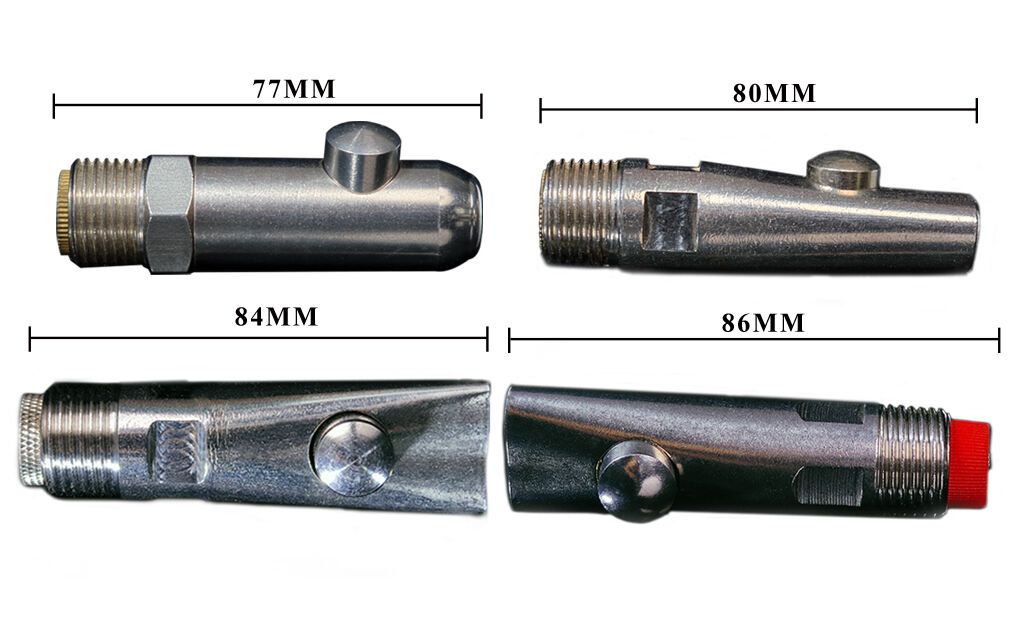

- Size

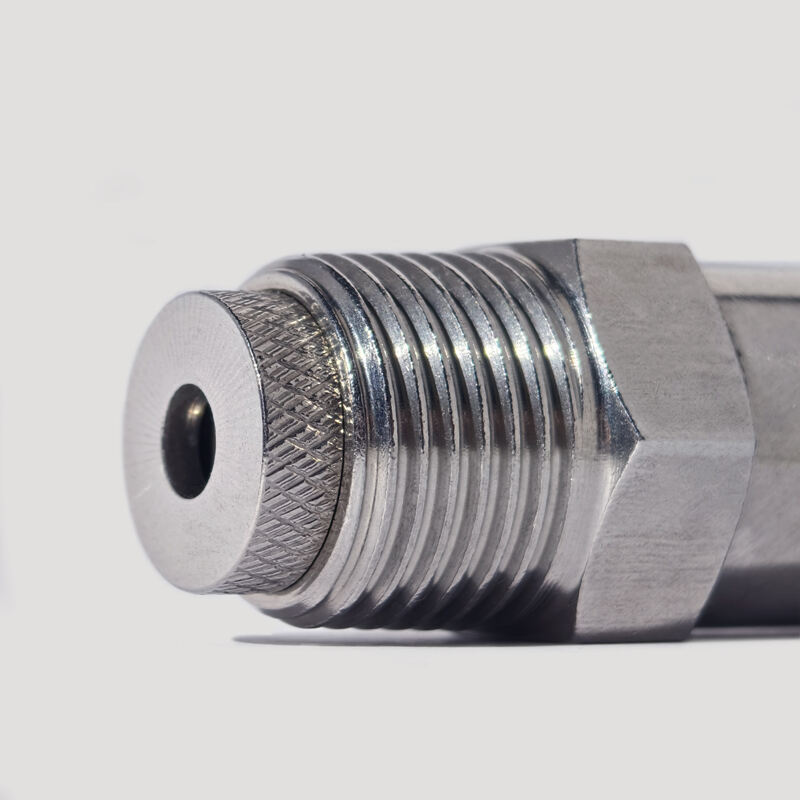

- Details

- Recommended Products

Description

Size

Details

|

Splash proof marble style |

| Nipple Plastic Red Hlat |  |

|

Copper cap is more durable |

| Clear thread, durable |  |