Le Type Traditionnel Cages de mise-bas Pour Élevage Porcin représente une solution fondamentale dans les opérations modernes d'élevage porcin, conçue pour offrir un environnement maternel optimal tout en assurant la sécurité et le bien-être des truies et des porcelets nouveau-nés pendant la période critique du farrowing. Ces systèmes spécialisés de contention sont devenus des composants infrastructurels indispensables pour les exploitations porcines commerciales à travers le monde, offrant un environnement maîtrisé qui maximise l'efficacité de la reproduction tout en réduisant au minimum les risques liés à la mortalité des porcelets et aux complications maternelles. L'approche traditionnelle de conception met l'accent sur une fonctionnalité éprouvée grâce à des méthodologies de construction robustes qui privilégient la durabilité, la facilité d'entretien et la fiabilité opérationnelle dans diverses conditions agricoles et pratiques de gestion. Les équipes internationales d'approvisionnement et les distributeurs d'équipements agricoles considèrent ces systèmes de cages de farrowing comme des investissements essentiels pour la création ou la modernisation d'installations de production porcine, notamment dans les régions où les pratiques d'élevage intensif exigent des solutions d'hébergement standardisées capables d'accompagner des programmes de reproduction à grande échelle. La philosophie de conception fondamentale vise à créer des espaces sécurisés et confortables permettant les comportements maternels naturels, tout en assurant un confinement nécessaire afin d'éviter les blessures accidentelles aux nouveau-nés vulnérables, ce qui rend ces systèmes particulièrement précieux pour les exploitations cherchant à concilier bien-être animal et exigences d'efficacité productive. Les méthodes de fabrication impliquent généralement une structure en acier renforcé associée à des traitements de surface spécialisés, conçus pour résister aux effets corrosifs des environnements agricoles, y compris l'exposition aux produits chimiques de nettoyage, à l'humidité et à la matière organique présents dans les installations porcines modernes. L'intégrité structurelle repose sur des systèmes de support soigneusement calculés, capables de répartir uniformément les charges tout en répondant aux exigences physiques des truies adultes durant tout le processus de farrowing, garantissant ainsi une stabilité durable même sous une contrainte opérationnelle continue. Techniques de finition de surface intègrent couramment une galvanisation ou des applications de revêtements spécialisés qui offrent une résistance accrue à la rouille et à la détérioration, prolongeant ainsi la durée de vie opérationnelle de ces composants critiques d'infrastructure tout en réduisant les besoins de maintenance et les coûts de remplacement au fil du temps. Les considérations de conception englobent plusieurs éléments fonctionnels, notamment des panneaux latéraux réglables pouvant être adaptés pour accueillir des truies de différentes tailles, des systèmes d'alimentation intégrés permettant un accès contrôlé à la nutrition pendant la période de tétée, et des caractéristiques de drainage stratégiquement positionnées facilitant une gestion efficace des déchets et le respect des protocoles d'hygiène. La configuration spatiale inclut généralement des zones désignées pour les déplacements des porcelets et l'accès au tétage, tout en maintenant des limites de contention appropriées empêchant les déambulations ou l'exposition à des conditions dangereuses dans l'environnement plus large de l'élevage. Les possibilités de personnalisation fonctionnelle s'étendent à divers besoins opérationnels, notamment l'intégration de systèmes de régulation climatique, la compatibilité avec des systèmes d'alimentation automatisés, et des options d'extension modulaire permettant aux exploitations de faire évoluer leurs activités selon les exigences du marché ou les trajectoires de croissance des programmes d'élevage. Ces caractéristiques d'adaptabilité rendent les systèmes particulièrement attrayants pour les acheteurs internationaux, qui doivent tenir compte de réglementations variées, de conditions climatiques différentes et de méthodologies opérationnelles propres à divers marchés géographiques et approches culturelles de la gestion du bétail. L'adéquation à l'usage couvre des opérations de reproduction commerciale de différentes échelles, allant des fermes familiales de taille moyenne passant à des méthodes de production plus intensives aux grandes entreprises agricoles nécessitant des solutions d'équipement standardisées pouvant être intégrées efficacement dans les agencements existants et les protocoles de gestion. La polyvalence des conceptions traditionnelles de cages de farrowing permet leur mise en œuvre dans divers types de bâtiments, systèmes de ventilation et approches de gestion des déchets, offrant ainsi une flexibilité aux exploitations confrontées à des contraintes d'infrastructure variables ou à des calendriers d'expansion différents. La philosophie de cohérence de qualité met l'accent sur des processus de fabrication standardisés garantissant des caractéristiques de performance uniformes d'un lot de production à l'autre, permettant aux acheteurs de spécifier ces systèmes en toute confiance pour des projets multiphases ou des extensions d'installations, sans craindre d'incompatibilité ou de variations de performance. Cette cohérence revêt une importance particulière pour les distributeurs internationaux et les professionnels des achats, qui doivent garantir des spécifications fiables aux clients, quel que soit le moment de la commande ou les quantités requises. Les aspects logistiques orientés vers l'exportation incluent des solutions d'emballage robustes conçues pour préserver l'intégrité structurelle durant le transport international, avec une attention particulière portée à l'organisation des composants afin de faciliter les procédures d'assemblage dans les installations destinataires. La nature modulaire de nombreux systèmes traditionnels de cages de farrowing permet des solutions logistiques économiques tout en assurant que les assemblages complexes puissent être transportés sur de longues distances sans compromettre leur fonctionnalité ni nécessiter une expertise importante en réassemblage sur site d'installation. Les opportunités de collaboration en matière de personnalisation comprennent des cadres de coopération OEM et ODM permettant aux partenaires internationaux de définir des exigences dimensionnelles particulières, des préférences en matière de traitement de surface ou des caractéristiques d'intégration conformes aux pratiques agricoles régionales ou aux besoins de conformité réglementaire. Cette approche collaborative permet aux fournisseurs d'équipements agricoles d'offrir des solutions sur mesure répondant à des conditions de marché spécifiques, tout en conservant la fiabilité fondamentale et les caractéristiques de performance qui définissent les systèmes traditionnels de cages de farrowing. Les partenariats de fabrication vont souvent au-delà de simples relations d'approvisionnement en incluant des services d'assistance technique, des conseils d'installation et des consultations continues sur la maintenance, aidant ainsi les clients internationaux à maximiser le rendement de leur investissement et leur efficacité opérationnelle. Les attentes en matière de coopération à long terme visent à établir des relations commerciales durables capables d'accompagner l'évolution des normes industrielles, des améliorations technologiques et des réglementations changeantes en matière de bien-être animal, qui pourraient influencer les exigences de conception des cages de farrowing sur de longues périodes opérationnelles, garantissant ainsi que les investissements initiaux en équipement restent viables et conformes à mesure que les pratiques agricoles continuent de se développer et de se moderniser dans le secteur agricole mondial.

Type Traditionnel Cages de mise-bas Pour Élevage Porcin

-

Récupération optimisée pour les truies

Fournit un environnement propre et contrôlé, favorisant une récupération plus rapide et maximisant les performances de mise bas. -

Efficacité accrue du personnel

Une conception ergonomique facilite la surveillance et les soins apportés aux truies et aux porcelets par le personnel de l'élevage. -

Sécurité des porcelets assurée

Empêche efficacement les porcelets d'être écrasés ou piétinés par la truie, améliorant ainsi leur taux de survie. -

Hygiène et contrôle des maladies améliorés

Maintient des normes d'hygiène supérieures, réduisant l'exposition aux bactéries et diminuant la morbidité chez les porcelets.

- Vue d'ensemble

- Description

- Accessoires

- Parties

- Produits recommandés

Paramètres

Liste de configuration |

Configuration générale Mise à jour de la configuration |

Châssis |

24 pieds de soutien en fonte |

|

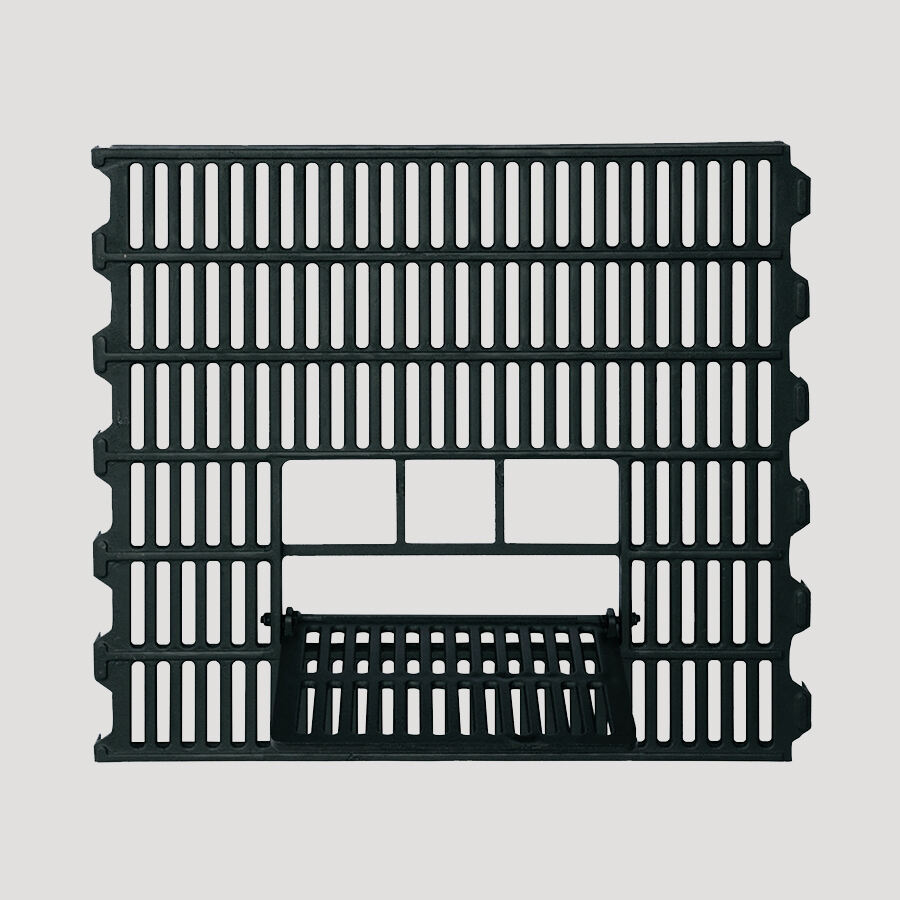

Fuite plaque à fumier |

12 plaques à fumier anti-fuite en BMC verte + 2 plaques chauffantes épaisses BMC orange |

Grand cadre |

4 cadres de position de truie (Tube d'acier d'une épaisseur de I pouce) |

|

Clôture |

2 grandes clôtures 2 PCS clôture de taille moyenne 2 clôtures de petite taille |

Porte |

2 portes avant (y compris le mangeoire pour porcs) 2 portes arrière |

|

Ingestion |

Configuration générale plateau d'alimentation en acier pour truies; plateau d'alimentation en plastique pour porcelets |

Boisson |

Configuration générale Abreuvoir à boules pour cochons; abreuvoir à tétines pour porcelets |

|

Configuration de mise à niveau plateau d'alimentation en acier; plateau anti-morsure pour porcelets |

Configuration de mise à niveau abreuvoir à boules pour cochons, bol d'alimentation inoxydable pour porcelets |

||

|

Autres |

4 barres anti-saut, 8 serre-croix |

Isolation |

Configuration générale : couveuse en plastique |

Configuration améliorée : couveuse en plastique épais |

Vidéo d'introduction du produit

https://www.youtube.com/embed/Rjm1YVME-4M?si=YS2dnmaGFMt656_U

Description

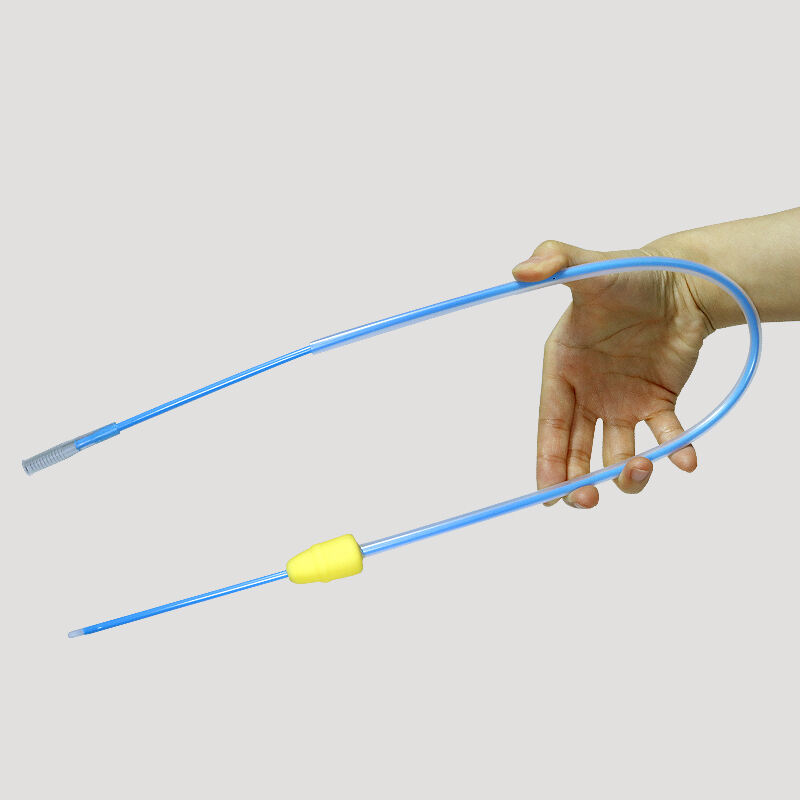

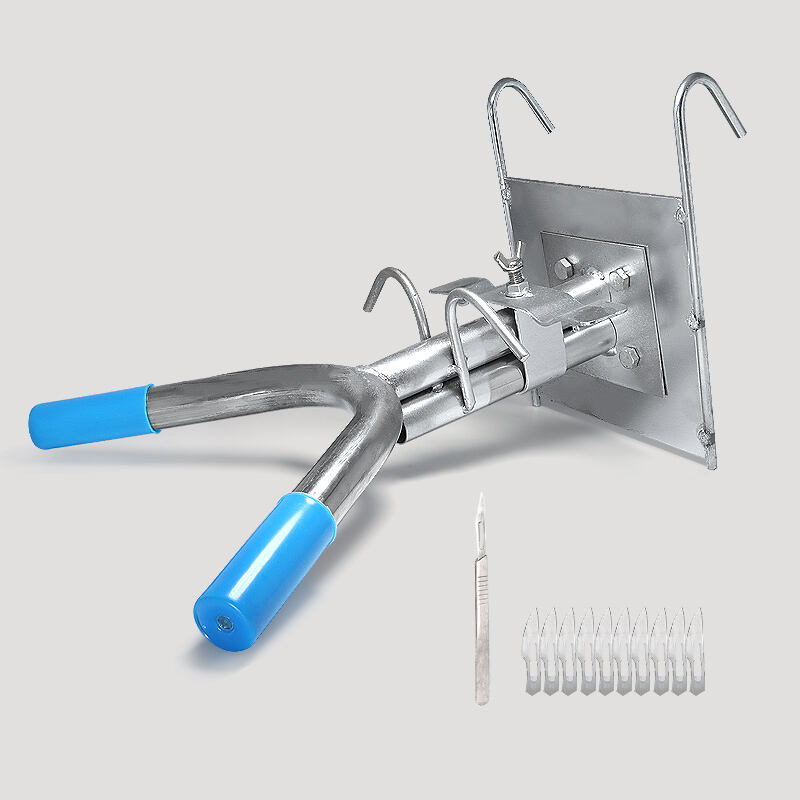

Accessoires

Parties