Le support en Acier Inoxydable 304 pour la Castration de Porcelets représente une avancée cruciale dans les équipements modernes de gestion porcine, spécifiquement conçue pour répondre aux exigences rigoureuses des exploitations porcines commerciales à travers le monde. Cet instrument vétérinaire spécialisé allie la résistance supérieure à la corrosion et les propriétés hygiéniques de l'acier inoxydable médical à une conception de précision qui facilite des interventions de castration de porcelets sûres, efficaces et respectueuses du bien-être animal. Le choix de l'acier inoxydable de qualité comme matériau principal garantit une durabilité exceptionnelle face aux conditions environnementales difficiles couramment rencontrées dans les installations d'élevage, notamment l'exposition aux produits chimiques de nettoyage, à l'humidité et à la matière organique, qui dégraderaient rapidement des matériaux de moindre qualité. Au-delà de son rôle fondamental en élevage porcin, ce cadre de castration illustre l'évolution plus large de la fabrication d'équipements vétérinaires vers des solutions standardisées et conformes aux normes internationales, soutenant ainsi l'accent croissant mis par l'industrie mondiale de l'élevage sur les protocoles de bien-être animal et l'efficacité opérationnelle. Les propriétés antimicrobiennes intrinsèques de la construction en acier inoxydable réduisent considérablement le risque de contamination croisée entre les interventions, répondant ainsi aux préoccupations critiques de biosécurité que doivent gérer les exploitations modernes afin de préserver la santé du troupeau et de respecter la réglementation. Les fabricants d'équipements vétérinaires professionnels reconnaissent que la pénétration réussie sur les marchés internationaux exige des produits capables de résister à des conditions climatiques variées, allant de l'humidité tropicale aux variations saisonnières tempérées, ce qui rend particulièrement précieuses les caractéristiques de résistance à la corrosion de la construction en acier inoxydable pour les fournisseurs orientés vers l'exportation et desservant les marchés agricoles mondiaux. Les considérations ergonomiques intégrées dans la conception de ce cadre de castration résultent d'une étroite collaboration entre professionnels vétérinaires et ingénieurs en fabrication, produisant un outil qui minimise la fatigue physique des opérateurs tout en maximisant la précision procédurale et la sécurité. Les techniques de finition de surface appliquées lors du processus de fabrication assurent des surfaces lisses et non poreuses, résistantes à l'adhérence bactérienne et facilitant les protocoles de nettoyage approfondi essentiels au maintien d'un environnement de travail stérile. L'intégrité structurelle de la construction en acier inoxydable permet au cadre de supporter des cycles répétés de stérilisation par diverses méthodes, y compris l'autoclavage à vapeur, la désinfection chimique et les procédures de sanitarisation à haute température couramment utilisées dans les pratiques vétérinaires professionnelles. Les équipes internationales d'approvisionnement évaluant les fournisseurs d'équipements vétérinaires accordent une priorité croissante aux produits qui démontrent des normes de qualité cohérentes d'un lot à l'autre, sachant que la fiabilité de l'équipement influence directement la continuité des opérations et les résultats en matière de bien-être animal. La philosophie de conception modulaire à la base de ce cadre de castration permet des opportunités de personnalisation pouvant répondre à des préférences régionales spécifiques ou à des exigences opérationnelles uniques, sans compromettre les caractéristiques fondamentales de sécurité et de fonctionnalité qui définissent les équipements vétérinaires de qualité professionnelle. Les processus de fabrication employés dans la production d'outils vétérinaires de haute qualité intègrent généralement plusieurs points de contrôle qualité vérifiant la précision dimensionnelle, la qualité de la finition de surface et l'intégrité structurelle avant que les produits n'entrent dans les circuits de distribution internationaux. La compatibilité de la construction en acier inoxydable avec diverses méthodes de stérilisation rend ce cadre de castration particulièrement adapté à une intégration fluide dans les protocoles existants des installations vétérinaires, réduisant ainsi la courbe d'apprentissage liée à l'adoption de nouveaux équipements et minimisant les perturbations des flux de travail établis. Les fabricants orientés vers l'exportation savent que des partenariats à long terme réussis avec des distributeurs internationaux reposent sur une qualité de produit constante, une gestion fiable de la chaîne d'approvisionnement et des capacités de support technique réactives capables de répondre aux exigences variées des marchés dans différentes régions géographiques. La polyvalence de l'acier inoxydable en tant que matériau de fabrication permet une flexibilité de production qui soutient à la fois les gammes de produits standards et les solutions de fabrication sur mesure adaptées à des besoins clients spécifiques ou à des préférences de marché régionales. Les utilisateurs professionnels d'équipements vétérinaires reconnaissent de plus en plus les avantages liés au coût total de possession associé à des matériaux et méthodes de construction haut de gamme, comprenant que l'investissement initial dans des outils de qualité se traduit généralement par une durée de service prolongée, des besoins de maintenance réduits et une fiabilité opérationnelle améliorée sur de longues périodes. Les caractéristiques de surface lisse des composants en acier inoxydable correctement finis facilitent les procédures rapides de nettoyage et de désinfection, soutenant ainsi les flux de travail efficaces essentiels aux exploitations d'élevage à haut volume, où la gestion du temps impacte directement la productivité et la rentabilité globales. Les capacités de fabrication avancées permettent l'intégration de fonctionnalités ergonomiques et d'améliorations de sécurité protégeant à la fois les animaux et les opérateurs humains pendant les procédures de castration, reflétant l'engagement continu de l'industrie à améliorer les normes de bien-être dans tous les aspects de la gestion du bétail. Les propriétés de résistance chimique de la construction en acier inoxydable de qualité garantissent la compatibilité avec une large gamme d'agents de nettoyage et de désinfectants couramment utilisés dans les environnements vétérinaires, offrant une flexibilité opérationnelle qui s'adapte aux différents protocoles d'installation et aux exigences réglementaires. Les normes internationales de qualité régissant la fabrication d'équipements vétérinaires soulignent l'importance de la traçabilité des matériaux et de processus de production cohérents, assurant que chaque unité réponde aux critères de performance établis, indépendamment du lot de production ou du lieu de fabrication. L'accent croissant mis à l'échelle mondiale sur des pratiques agricoles durables a accru la demande pour des équipements durables et à longue durée de vie, qui minimisent la consommation de ressources grâce à une durée de service prolongée et une fréquence de remplacement réduite, positionnant ainsi la construction en acier inoxydable de haute qualité comme un choix écologiquement responsable pour les exploitations agricoles soucieuses de l'avenir.

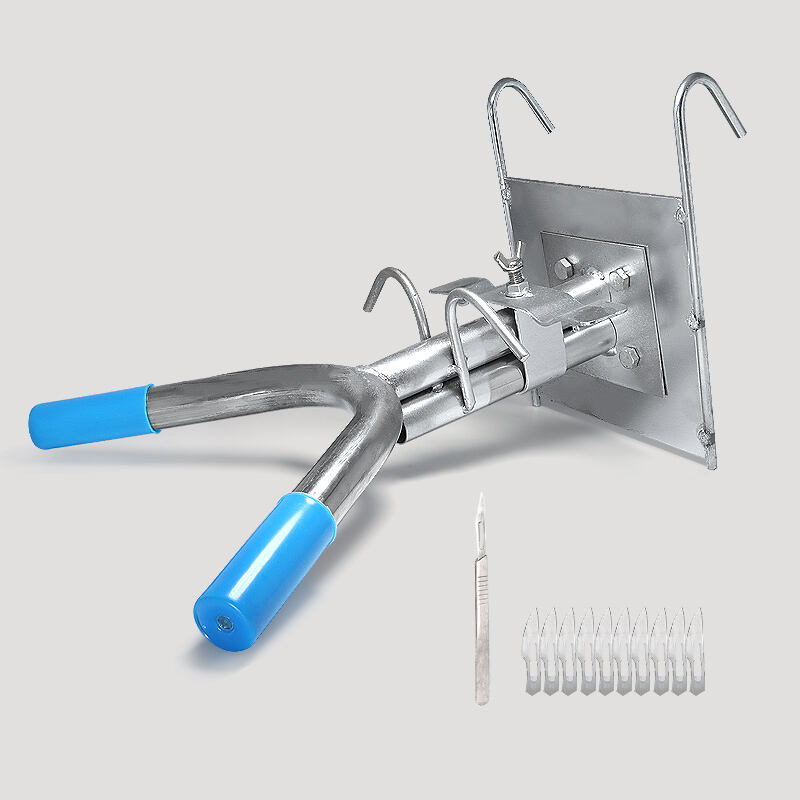

- Vue d'ensemble

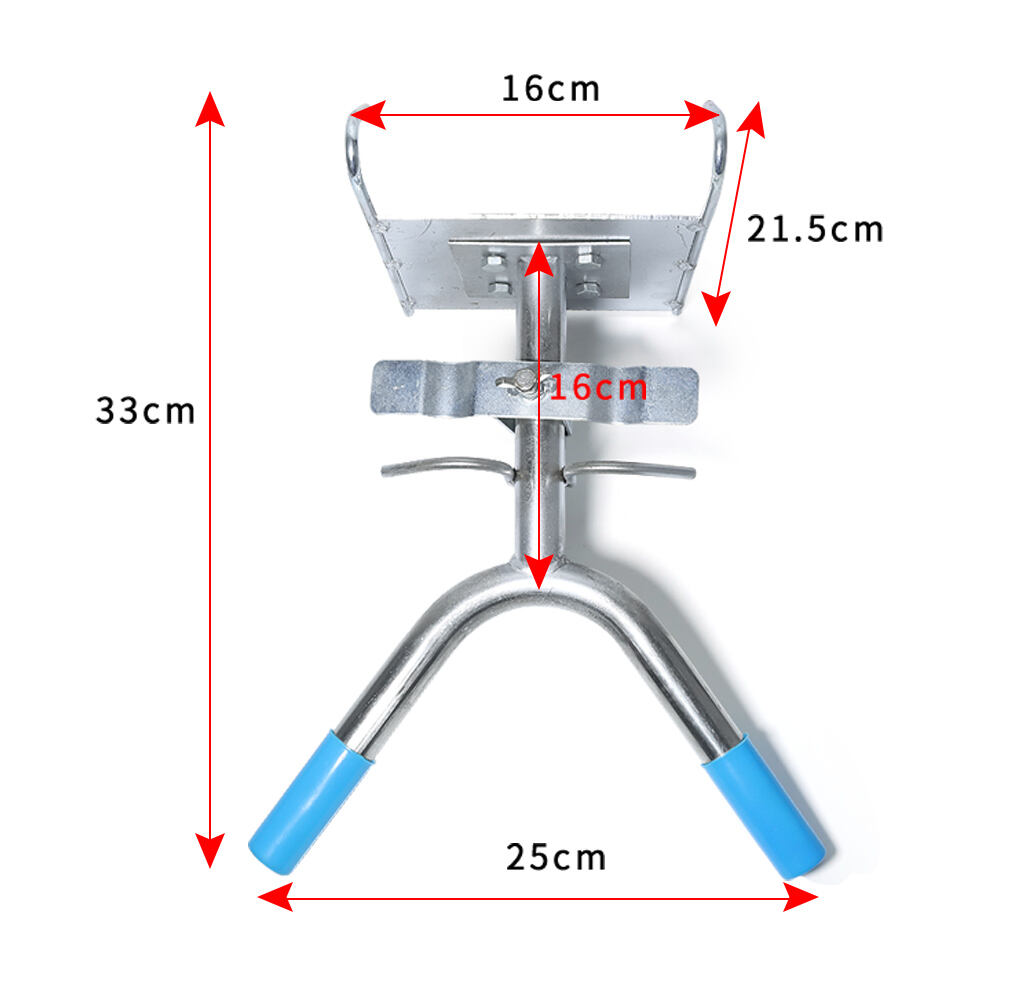

- Taille

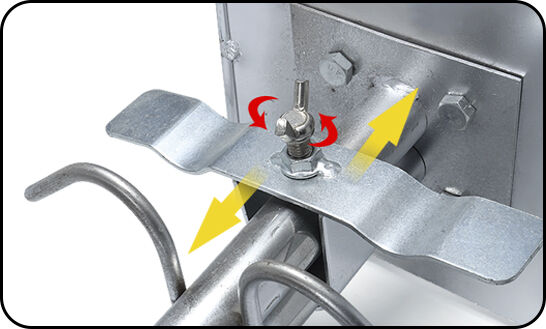

- Détails

- Produits recommandés

Description

Taille

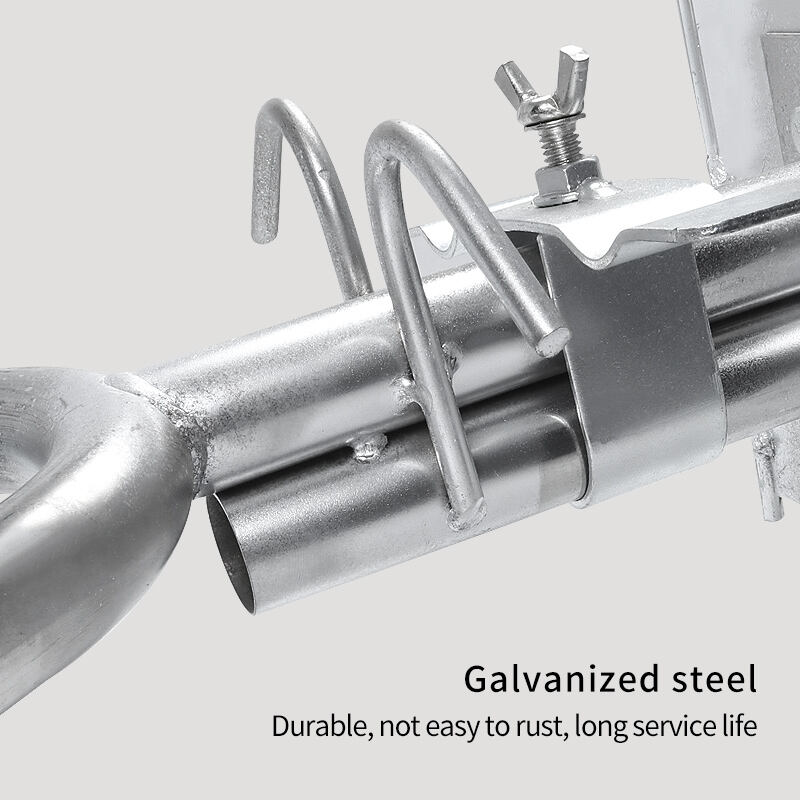

Détails

|

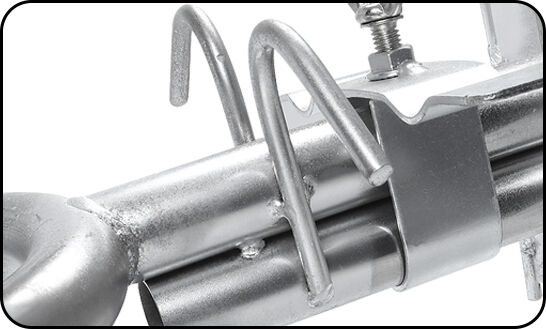

Ajustable SPLINT MOBILE Splint ajustable, support fixe pouvant être réglé vers l'avant et vers l'arrière Plus facile à utiliser |

|

Acier galvanisé Durable, ne rouille pas facilement, longue durée de vie |

|

|

ANTI-USURE Housse protectrice Manchon protecteur anti-abrasion protège la peau du porcelet des dommages. |