Le Auge à l'automatique en acier inoxydable 304 pour nourrir les porcelets en cage d'engraissement représente une solution sophistiquée conçue pour répondre aux exigences rigoureuses des opérations modernes d'élevage porcin sur les marchés internationaux, offrant aux éleveurs et aux distributeurs de matériel agricole un système d'alimentation robuste alliant durabilité, hygiène et efficacité opérationnelle. Ce matériel d'alimentation haut de gamme utilise une construction en acier inoxydable de haute qualité pour garantir une résistance exceptionnelle à la corrosion, aux produits chimiques et aux conditions environnementales difficiles généralement rencontrées dans les exploitations porcines commerciales, ce qui en fait un choix idéal tant pour les petites exploitations que pour les complexes industriels de grande taille. Le mécanisme d'alimentation automatique intégré à cette conception d'auge élimine le besoin d'intervention manuelle pendant les cycles d'alimentation réguliers, réduisant ainsi les coûts de main-d'œuvre tout en assurant une distribution uniforme de l'aliment et en minimisant le gaspillage grâce à des systèmes de contrôle précis des portions. Les fonctionnalités de compatibilité avec les cages d'élevage et d'engraissement rendent cette solution particulièrement précieuse pour les exploitations axées sur le développement des jeunes porcs, où maintenir une alimentation optimale est crucial pour atteindre les taux de croissance souhaités et garantir une bonne santé animale globale. Les usines spécialisées dans la fabrication d'équipements agricoles ont développé cette auge à l'aide de techniques de fabrication avancées assurant une construction sans jointures ni arêtes vives ou points pouvant causer des blessures, créant ainsi un environnement d'alimentation sécurisé qui protège à la fois les animaux et les travailleurs lors des opérations quotidiennes et des activités de maintenance. Le fini de surface appliqué aux composants en acier inoxydable subit des traitements spécialisés qui renforcent les propriétés antimicrobiennes naturelles du matériau, réduisant l'accumulation bactérienne et simplifiant les procédures de nettoyage essentielles au maintien des normes de biosécurité dans les exploitations commerciales. Les ingénieurs concepteurs ont intégré des considérations ergonomiques dans la configuration de l'auge, permettant une installation facile dans les systèmes de cages existants tout en offrant un accès adéquat pour des protocoles de nettoyage et de désinfection approfondis conformes aux normes internationales d'hygiène agricole. La capacité d'alimentation et les spécifications dimensionnelles ont été optimisées pour s'adapter aux besoins nutritionnels spécifiques des porcelets durant les phases critiques de croissance, garantissant une accessibilité constante à l'aliment indépendamment des variations de taille des animaux au sein d'une même unité d'hébergement. Les processus de contrôle qualité mis en œuvre tout au long du cycle de fabrication garantissent que chaque auge respecte des normes strictes de durabilité, les soudures et composants structurels étant testés pour leur fiabilité à long terme dans des conditions d'utilisation continue typiques des élevages intensifs. Les acheteurs internationaux approvisionnant du matériel agricole pour les marchés d'exportation apprécieront la compatibilité universelle de ce design, qui permet une intégration avec divers systèmes de cages et technologies d'automatisation couramment utilisés dans différentes régions géographiques et méthodes d'élevage. Le mécanisme d'alimentation automatique peut être personnalisé pour fonctionner avec différents types et niveaux de consistance d'aliments, des suppléments liquides aux aliments granulés secs, offrant une flexibilité opérationnelle adaptée aux programmes nutritionnels variés et aux plannings d'alimentation mis en œuvre par les producteurs porcins professionnels. Les besoins de maintenance de ce système ont été réduits grâce à un choix soigneux des matériaux et des décisions de conception technique qui diminuent la fréquence de remplacement des composants et prolongent la durée de vie opérationnelle, améliorant ainsi la rentabilité pour les exploitations cherchant à maximiser le retour sur investissement en équipement. La construction en acier inoxydable assure la compatibilité avec les produits chimiques de nettoyage et les procédures de désinfection standards utilisés dans les installations commerciales, tandis que la finition lisse empêche l'accumulation de résidus alimentaires pouvant compromettre la santé animale ou attirer des nuisibles. Des considérations liées à la manipulation orientée export ont été intégrées à la conception du produit, garantissant que les auges peuvent supporter les conditions de transport international et les exigences de stockage sans compromettre l'intégrité structurelle ni les performances fonctionnelles après installation. Les distributeurs de matériel agricole desservant plusieurs marchés constateront que cette solution d'alimentation répond aux défis courants rencontrés par les éleveurs porcins dans différents contextes climatiques et cadres réglementaires, ce qui en fait un ajout polyvalent à leurs catalogues complets d'équipements d'élevage. L'approche de fabrication met l'accent sur la cohérence et la fiabilité, s'appuyant sur une vaste expérience dans la production de systèmes d'alimentation agricoles répondant aux exigences exigeantes des exploitations professionnelles, tout en maintenant une position compétitive sur les marchés mondiaux. Les possibilités de personnalisation vont au-delà des simples ajustements dimensionnels et incluent des configurations de fixation spécifiques, des mécanismes de contrôle d'écoulement de l'aliment et l'intégration avec les systèmes d'automatisation existants à la ferme, permettant aux partenaires OEM et aux distributeurs d'offrir des solutions sur mesure répondant aux besoins opérationnels spécifiques de leurs clients. Des relations fournisseur à long terme sont favorisées par un support technique complet et une collaboration continue dans les initiatives de développement de produits qui répondent aux besoins changeants du secteur et aux nouvelles technologies d'alimentation dans la production porcine mondiale, garantissant ainsi que les exploitations puissent conserver un avantage concurrentiel grâce à l'accès à des solutions innovantes améliorant la productivité et le bien-être animal.

Auge à l'automatique en acier inoxydable 304 pour nourrir les porcelets en cage d'engraissement

- Vue d'ensemble

- Taille

- Détails

- Produits recommandés

Description

Certificat

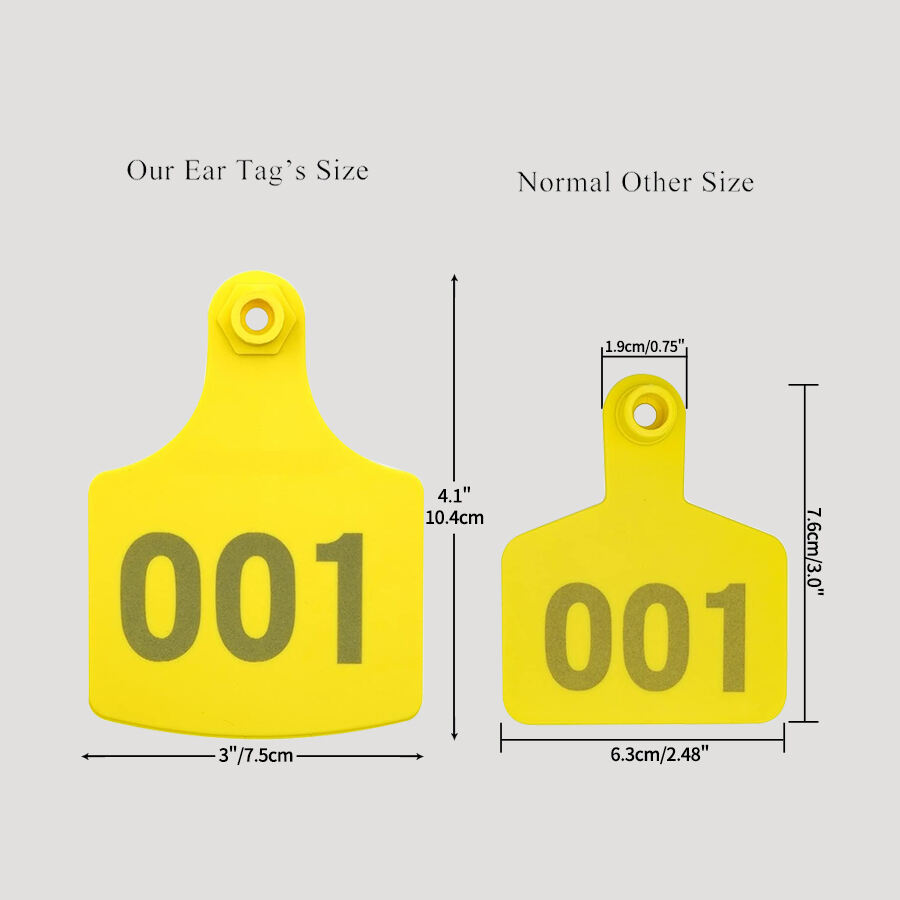

Taille

Détails

|

Le point de soudure est lisse le support de fixation par vis ne blesse pas la bouche du porc assure une bonne stabilité |

|

Ancrage à double trou inférieur fixation directe par plaque avec vis Évite que le porc ne se voûte la mangeoire est durable |

|

|

Alimentation séparée, pas d'attroupement manger, variés spécifications, durables |