El Ventana de Ventilación de PVC para Entrada de Ganado en Granjas Avícolas representa una solución de infraestructura especializada diseñada para satisfacer las complejas necesidades de gestión ambiental en operaciones agrícolas modernas, particularmente en instalaciones avícolas comerciales donde se debe equilibrar cuidadosamente el flujo de aire controlado y el acceso al ganado para mantener condiciones óptimas de producción. Estos innovadores sistemas de ventilación combinan la durabilidad y resistencia química de materiales de cloruro de polivinilo (PVC) de alta calidad con características de diseño específicamente desarrolladas para abordar los desafíos únicos que enfrentan los operadores de granjas avícolas al mantener entornos saludables y productivos para su ganado, garantizando al mismo tiempo flujos de trabajo operativos eficientes. La construcción fundamental de estas ventanas de ventilación incorpora estructuras de PVC impermeables que soportan las duras condiciones típicas de los entornos agrícolas, incluida la exposición a compuestos de amoníaco, variaciones de humedad, fluctuaciones de temperatura y el desgaste general asociado con áreas de ganado de alta actividad, lo que las convierte en un componente esencial para instalaciones que buscan fiabilidad operativa a largo plazo sin intervenciones frecuentes de mantenimiento. Los procesos de fabricación para estas soluciones especializadas de ventilación suelen implicar técnicas de moldeo de precisión que crean perfiles de PVC sin juntas, con espesor de pared consistente y exactitud dimensional, asegurando que cada unidad pueda mantener su integridad estructural bajo las tensiones mecánicas provocadas por ciclos regulares de apertura y cierre, cargas de viento y las presiones ambientales generales presentes en operaciones avícolas activas. Las propiedades inherentes de los materiales de PVC seleccionados proporcionan excelente resistencia a la corrosión, a la degradación química por agentes limpiadores comúnmente utilizados en entornos agrícolas y a los desafíos biológicos planteados por las atmósferas ricas en amoníaco que se desarrollan naturalmente en entornos avícolas, características que posicionan estas ventanas de ventilación como alternativas superiores frente a los sistemas tradicionales con marcos metálicos que pueden sufrir deterioro por corrosión tras largos períodos de uso. Los tratamientos superficiales y los procesos de acabado aplicados durante la fabricación mejoran las ya impresionantes características de durabilidad de los materiales base de PVC, creando superficies lisas e impermeables que evitan la acumulación de materia orgánica, facilitan protocolos de limpieza exhaustivos esenciales para el mantenimiento de la bioseguridad y contribuyen a los estándares generales de higiene exigidos en instalaciones de producción avícola comercial. Las posibilidades de personalización funcional dentro de estos sistemas de ventilación abarcan un amplio espectro de requisitos operativos, permitiendo que diseñadores de instalaciones y operadores de granjas especifiquen configuraciones que se ajusten exactamente a sus estrategias específicas de ventilación, prácticas de manejo del ganado y distribuciones de instalaciones. Las variaciones de diseño pueden incluir mecanismos de apertura ajustables que proporcionan un control graduado del flujo de aire, sistemas de cribado integrados que previenen la infiltración de plagas manteniendo tasas óptimas de intercambio de aire y sistemas de sellado especializados que garantizan un cierre hermético cuando las condiciones ambientales o los protocolos de bioseguridad requieren aislar los espacios internos de las influencias atmosféricas externas. La naturaleza modular de estas ventanas de ventilación de PVC permite una integración perfecta tanto en proyectos de nueva construcción como en aplicaciones de modernización donde las instalaciones existentes requieren capacidades mejoradas de control ambiental, ofreciendo flexibilidad que satisface las necesidades cambiantes de las operaciones avícolas modernas a medida que se adaptan a normativas cambiantes, metodologías de producción y estándares de bienestar animal. La idoneidad de aplicación se extiende más allá de las granjas avícolas tradicionales para abarcar diversas operaciones ganaderas, incluidas instalaciones porcinas, establos lecheros e instalaciones especializadas de cría donde la ventilación controlada a través de puntos de entrada de ganado desempeña un papel fundamental para mantener la salud animal, optimizar la eficiencia de conversión alimenticia y apoyar el rendimiento general de la producción. La versatilidad de estas soluciones de ventilación de PVC las convierte en activos valiosos para operaciones agrícolas de diferentes escalas, desde pequeñas granjas especializadas enfocadas en métodos de producción ecológicos o en libertad hasta grandes instalaciones comerciales que gestionan miles de aves en sistemas de entorno controlado, donde la gestión precisa del medio ambiente impacta directamente en la rentabilidad y el éxito operativo. Los mercados agrícolas internacionales reconocen cada vez más la importancia de los sofisticados sistemas de gestión de ventilación como inversiones esenciales en infraestructura que contribuyen a prácticas de producción sostenibles, cumplimiento de bienestar animal y viabilidad operativa a largo plazo en mercados globales competitivos. La consistencia de calidad durante todo el proceso de fabricación refleja un enfoque integral en la gestión de la producción que abarca la selección de materias primas, monitoreo del control de procesos y verificación del producto final para garantizar que cada ventana de ventilación cumpla con los exigentes estándares de rendimiento requeridos para aplicaciones agrícolas exitosas. Este compromiso con la excelencia en la fabricación respalda el desarrollo de relaciones de confianza con distribuidores internacionales, distribuidores de equipos agrícolas y contratistas de construcción que requieren acceso confiable a soluciones de ventilación consistentes y de alta calidad para sus diversas necesidades de proyecto. Los procedimientos de manipulación orientados a la exportación incorporan métodos de embalaje protector y estrategias de coordinación logística que aseguran que los productos lleguen a destinos internacionales en condiciones óptimas, listos para su instalación inmediata sin retrasos ni problemas de calidad que puedan afectar los plazos del proyecto o los niveles de satisfacción del cliente. La colaboración en personalización entre fabricantes y compradores internacionales suele implicar procesos detallados de consulta que examinan requisitos específicos del sitio, condiciones climáticas locales, códigos de construcción y preferencias operativas para desarrollar soluciones personalizadas que maximicen el rendimiento manteniendo la rentabilidad para los usuarios finales. Las oportunidades de cooperación OEM y ODM ofrecen vías para que distribuidores regionales y proveedores de equipos agrícolas desarrollen líneas de productos especializadas que incorporen estas tecnologías avanzadas de ventilación de PVC en soluciones integrales para instalaciones, creando ofertas con valor añadido que diferencien su posición en el mercado mientras proporcionan a los clientes sistemas integrados que simplifican los procesos de adquisición e instalación. Este enfoque colaborativo se extiende a iniciativas continuas de soporte técnico y desarrollo de productos que incorporan retroalimentación de aplicaciones en campo para refinar constantemente el rendimiento del producto y ampliar las posibilidades de aplicación en diversos entornos agrícolas y requisitos operativos en todo el mundo.

- Descripción general

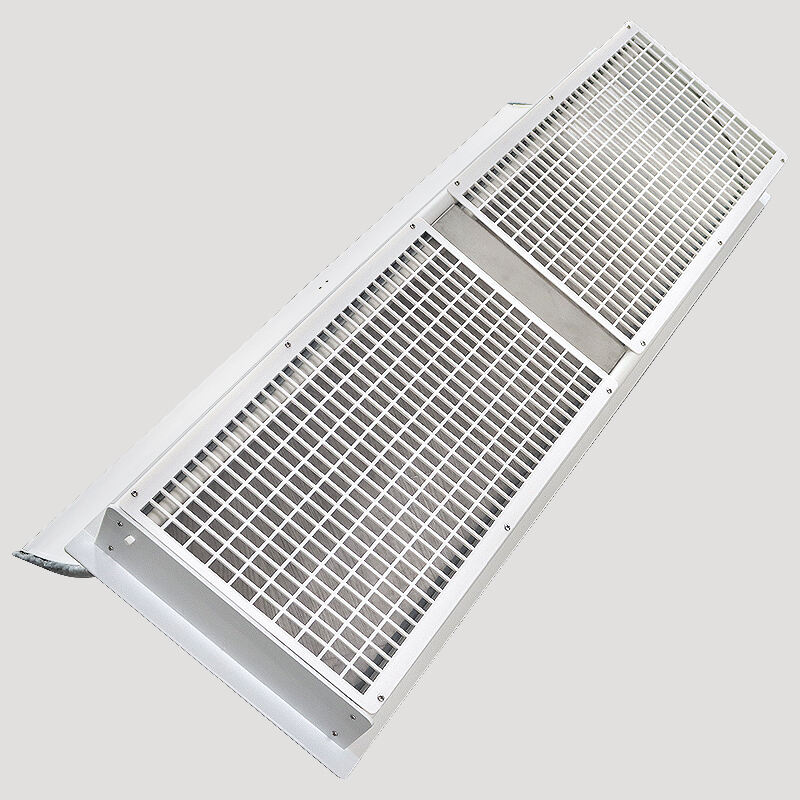

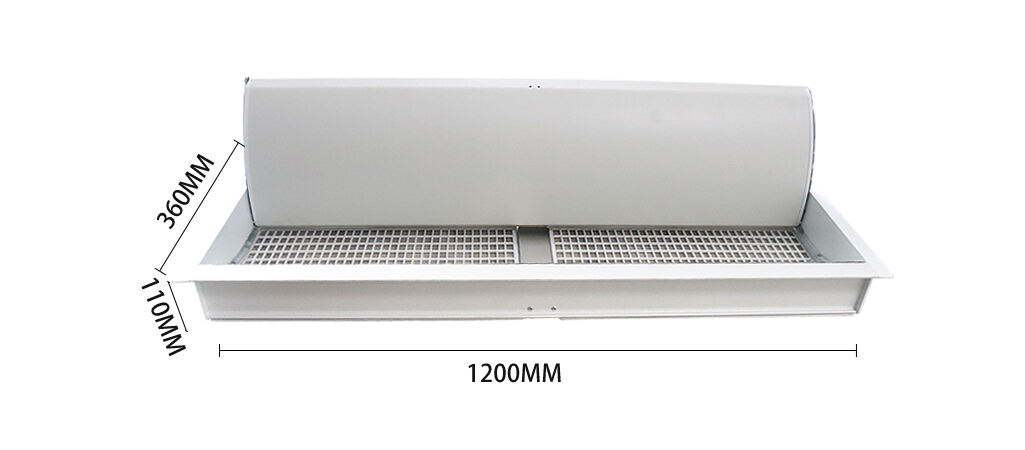

- Tamaño

- Detalles

- Productos recomendados

Descripción

Tamaño

Detalles

|

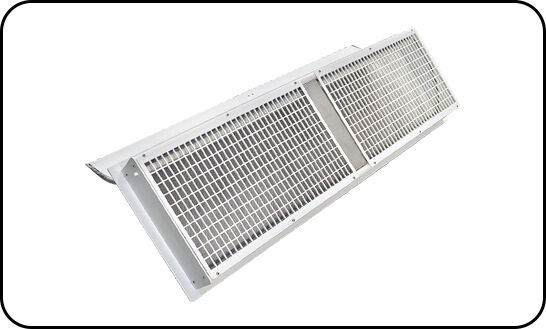

Materia prima de alta calidad Moldeo de una sola pieza Antiultravioleta, anti-envejecimiento Largo vida útil |

|

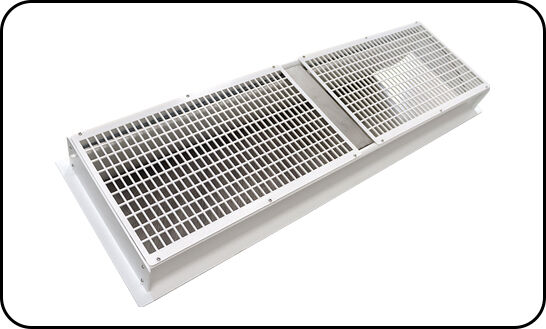

Ventilación uniforme Cerca del ventilador abrir pequeño, lejos lejos del ventilador abrir grande |

|

|

Adecuado para granja a gran escala Reducir eficazmente la temperatura interior y prevenir diversas enfermedades en la granja |

|

Diseño de red de bloqueo de aves Evite que las aves vuelen accidentalmente |

|