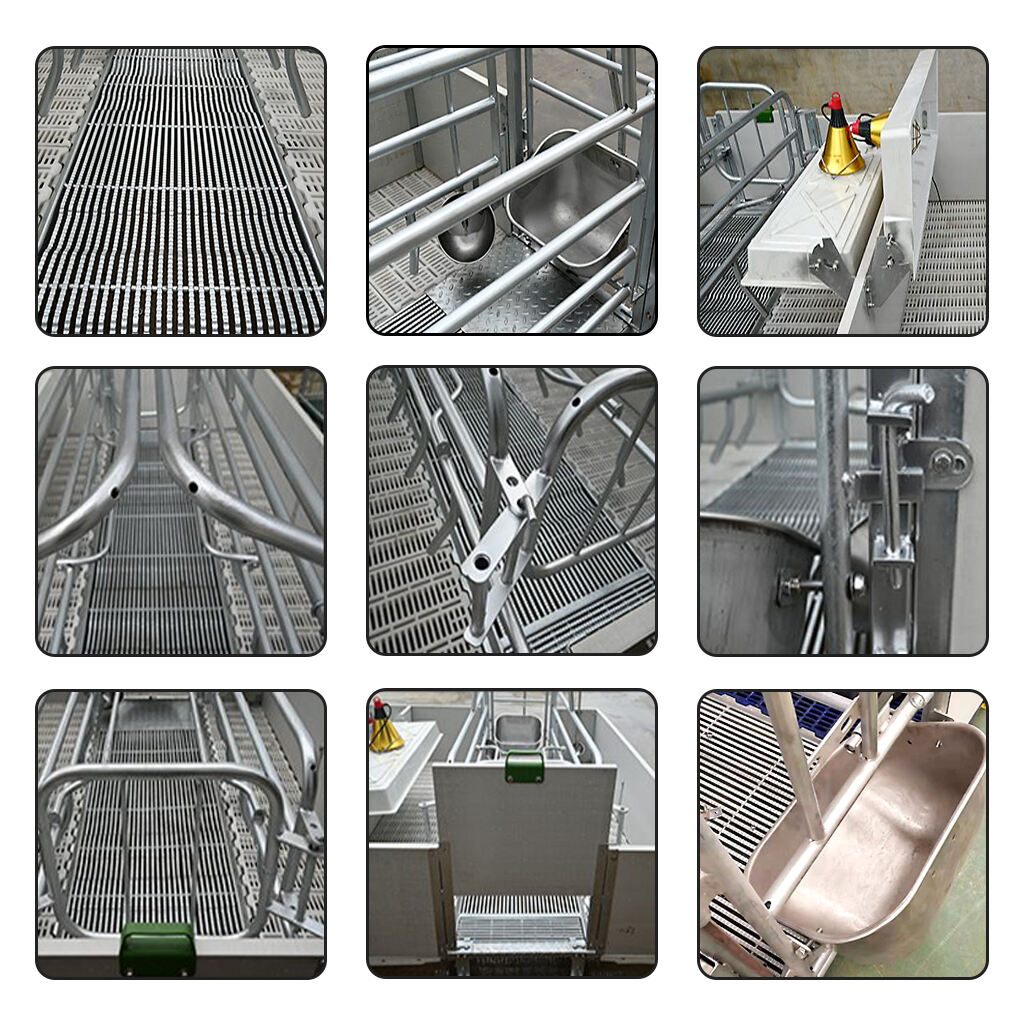

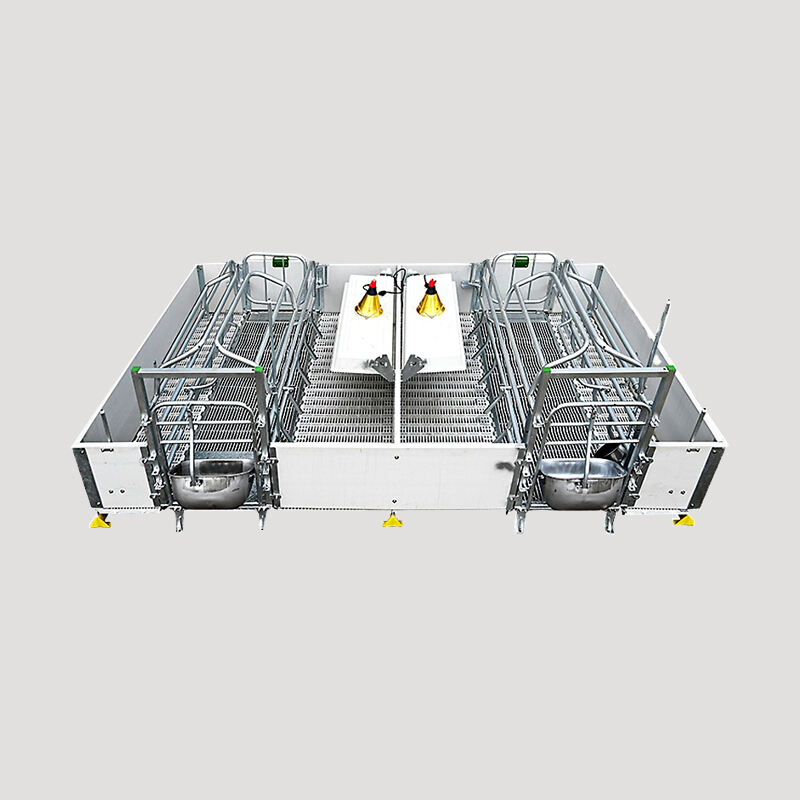

Jaulas de parto tipo europeo para granjas porcinas representan un enfoque sofisticado de la infraestructura moderna para la cría de cerdos, diseñado para cumplir con los rigurosos requisitos de las operaciones contemporáneas de porcicultura en mercados internacionales. Estos sistemas especializados de alojamiento están meticulosamente concebidos para optimizar el proceso de parto mientras garantizan la seguridad y comodidad tanto de las cerdas como de los lechones durante los períodos críticos de nacimiento y lactancia temprana. La filosofía de diseño europea enfatiza consideraciones de bienestar animal junto con la eficiencia operativa, incorporando configuraciones espaciosas que permiten comportamientos maternos naturales, al tiempo que mantienen condiciones ambientales controladas esenciales para lograr altas tasas de supervivencia de los lechones. La excelencia en la fabricación de esta categoría exige un conocimiento profundo de los principios de ingeniería agrícola, requisitos veterinarios y normas internacionales sobre alojamiento ganadero que rigen las instalaciones modernas de producción porcina. La metodología de construcción suele incluir estructuras de acero galvanizado de alta calidad que ofrecen una integridad estructural excepcional y resistencia a la corrosión, características esenciales para un rendimiento duradero en entornos agrícolas exigentes donde la exposición a la humedad, productos químicos de limpieza y uso constante requiere materiales capaces de soportar condiciones operativas intensivas sin comprometer la funcionalidad ni los estándares de seguridad. La arquitectura del diseño de estos sistemas de parto incorpora componentes ajustables que se adaptan a diferentes tamaños de cerda y programas reproductivos, con dimensiones de separación precisamente calculadas que previenen incidentes de aplastamiento de lechones, al mismo tiempo que permiten el acceso materno para la lactancia y el vínculo afectivo. Los procesos de tratamiento superficial emplean técnicas avanzadas de galvanización o aplicaciones especiales de recubrimiento en polvo que crean superficies lisas, fáciles de limpiar y resistentes a la acumulación bacteriana y a la degradación química provocada por los procedimientos rutinarios de sanitización comúnmente utilizados en operaciones profesionales de porcinos. Los sistemas de suelos integran rejillas o paneles de malla estratégicamente colocados, diseñados para favorecer una adecuada gestión de desechos y ventilación, al tiempo que proporcionan un agarre seguro tanto para animales adultos como para lechones en desarrollo durante sus primeras etapas. Las posibilidades de personalización funcional incluyen sistemas de montaje para lámparas calefactoras, opciones de posicionamiento de comederos, mecanismos de suministro de agua y configuraciones de puertas que pueden adaptarse a flujos operativos específicos y distribuciones de instalaciones encontradas en diversos contextos agrícolas internacionales. La filosofía de consistencia en la calidad a lo largo del proceso de fabricación enfatiza tolerancias de ingeniería de precisión, especificaciones uniformes de materiales y protocolos rigurosos de ensamblaje que aseguran la homogeneidad entre lotes de producción, factores críticos para compradores internacionales que gestionan múltiples instalaciones o proyectos de expansión que requieren especificaciones estandarizadas de equipos. La versatilidad de estos sistemas de alojamiento los hace adecuados para diversas escalas operativas, desde pequeñas explotaciones especializadas en programas genéticos selectivos hasta grandes instalaciones comerciales que manejan poblaciones extensas de cerdas con exigentes calendarios productivos y requerimientos de eficiencia. Las consideraciones orientadas a la exportación incluyen elementos de diseño modular que facilitan configuraciones de envío eficientes, reduciendo los costos de transporte al tiempo que garantizan la integridad estructural durante los procesos logísticos internacionales, que pueden implicar periodos prolongados de tránsito y condiciones variables de manipulación a través de distintas rutas marítimas y mercados de destino. Las oportunidades de colaboración en personalización abarcan OEM y Fabricante de equipos originales marcos de cooperación que permiten a los socios de abastecimiento especificar requisitos dimensionales particulares, opciones de acabado o modificaciones funcionales alineadas con estándares regulatorios regionales o preferencias operativas específicas comunes en sus mercados objetivo. El enfoque de fabricación admite diversas alternativas de acabado superficial, incluyendo tratamientos anticorrosivos especializados, sistemas de recubrimiento aptos para contacto con alimentos u opciones de mayor durabilidad diseñadas para condiciones ambientales especialmente exigentes presentes en distintas regiones geográficas con consideraciones climáticas y niveles de intensidad operativa variables. Los procesos de selección de materiales priorizan aspectos de sostenibilidad junto con los requisitos de rendimiento, incorporando componentes reciclables cuando es factible, manteniendo al mismo tiempo las expectativas de integridad estructural y longevidad asociadas a inversiones en equipos agrícolas profesionales. La metodología de ingeniería aborda la optimización de la ventilación mediante una colocación estratégica de aberturas y características de gestión del flujo de aire que promueven condiciones ambientales saludables, al tiempo que evitan corrientes de aire que podrían afectar negativamente a animales recién nacidos vulnerables durante fases sensibles de desarrollo térmico. Las consideraciones ergonómicas para el personal de granja incluyen mecanismos de acceso accesibles, puntos de limpieza convenientes y disposiciones de componentes fáciles de mantener, lo que reduce los requisitos de mano de obra y la complejidad operativa durante actividades rutinarias de manejo animal. Las consideraciones de compatibilidad con embalaje y logística comprenden capacidades de anidamiento eficiente para configuraciones de envío optimizadas en espacio, protocolos de embalaje protector que previenen daños durante el transporte internacional y documentación de montaje que facilita instalaciones sencillas independientemente de la disponibilidad de conocimientos técnicos locales o barreras lingüísticas comúnmente encontradas en escenarios globales de abastecimiento. Las expectativas de cooperación a largo plazo con proveedores se centran en la disponibilidad constante de productos, el acceso a soporte técnico y oportunidades de desarrollo colaborativo que permitan iniciativas de mejora continua basadas en requisitos industriales cambiantes y en mejores prácticas emergentes en la gestión de la cría de cerdos. El enfoque integral hacia la excelencia en fabricación abarca procedimientos de control de calidad que verifican la precisión dimensional, la consistencia del acabado y los estándares de rendimiento funcional antes de que los productos ingresen a canales de distribución internacionales, garantizando características de funcionamiento confiables que satisfacen los requisitos de operaciones agrícolas profesionales en diversos mercados globales. Este compromiso con la integridad en la fabricación apoya el desarrollo de relaciones comerciales duraderas con distribuidores internacionales, concesionarios de equipos agrícolas y explotaciones ganaderas que compran directamente, y que buscan soluciones de alojamiento confiables y de alto rendimiento que contribuyan a resultados exitosos en la producción porcina, manteniendo al mismo tiempo la eficiencia operativa y los estándares de bienestar animal esperados en empresas agrícolas modernas.

Jaulas de parto tipo europeo para granjas porcinas

-

Estructura Duradera e Higiénica – El marco de acero galvanizado y el piso ranurado garantizan un uso prolongado y mantienen un ambiente limpio.

-

Sistema de Protección para Lechones – Las barras antiaplastamiento y las lámparas de calor mejoran la seguridad, comodidad y tasas de supervivencia de los lechones durante la parición.

-

Jaula para Marranas Cómoda y Ajustable – El diseño ajustable se adapta a diferentes tamaños de marranas y asegura una posición adecuada durante la parición.

-

Paneles Laterales Aislados – Los paneles de PVC proporcionan mejor protección térmica, reducen corrientes de aire y promueven un microclima estable.

-

Diseño Eficiente para Gestión – Diseño de fácil acceso, zonas separadas para alimentación/bebida y estructura modular facilitan el cuidado y mantenimiento.

- Descripción general

- Puntos de venta clave

- Detalles

- Productos recomendados

Parámetros

| Color | blanco |

| Objetos Aplicables | Lechón, cordero |

| Tipo | cama para cerdos |

| OEM Piso de lamas | sí |

| Tipo | Cerda |

| Uso | Crecimiento de cerdos |

| MOQ | 1 Conjunto |

| tratamiento superficial | recubierto con PVC |

| Tiempo de vida | 12---15 años |

| Función | Cría de cerdos |

| Mercado principal | Mercados globales |

| Sistema de bebida | Bebedero automático de pezones |

| Aplicación | Paridera de cerdas |

Descripción

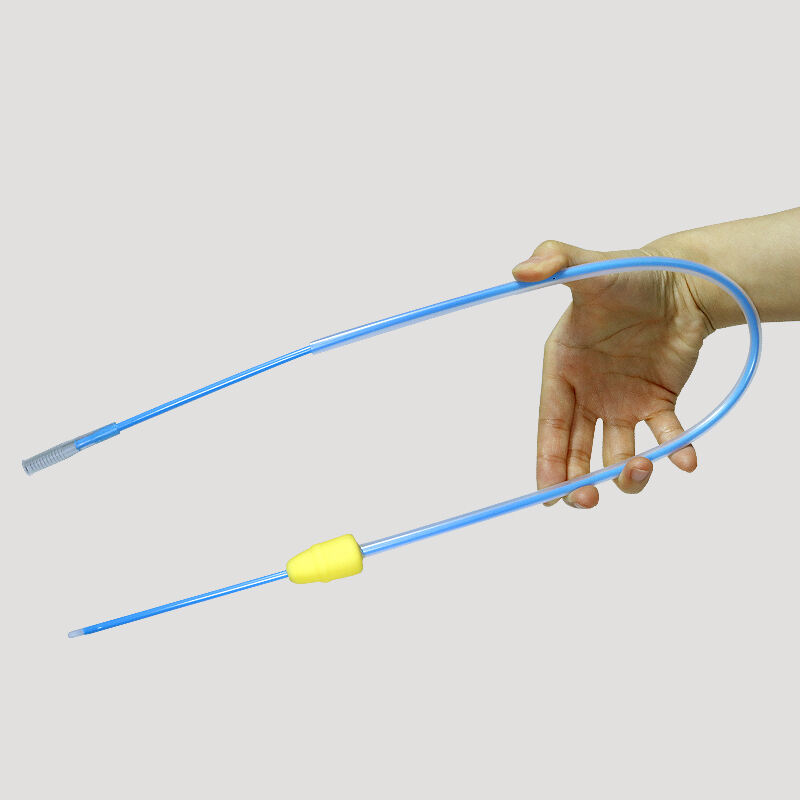

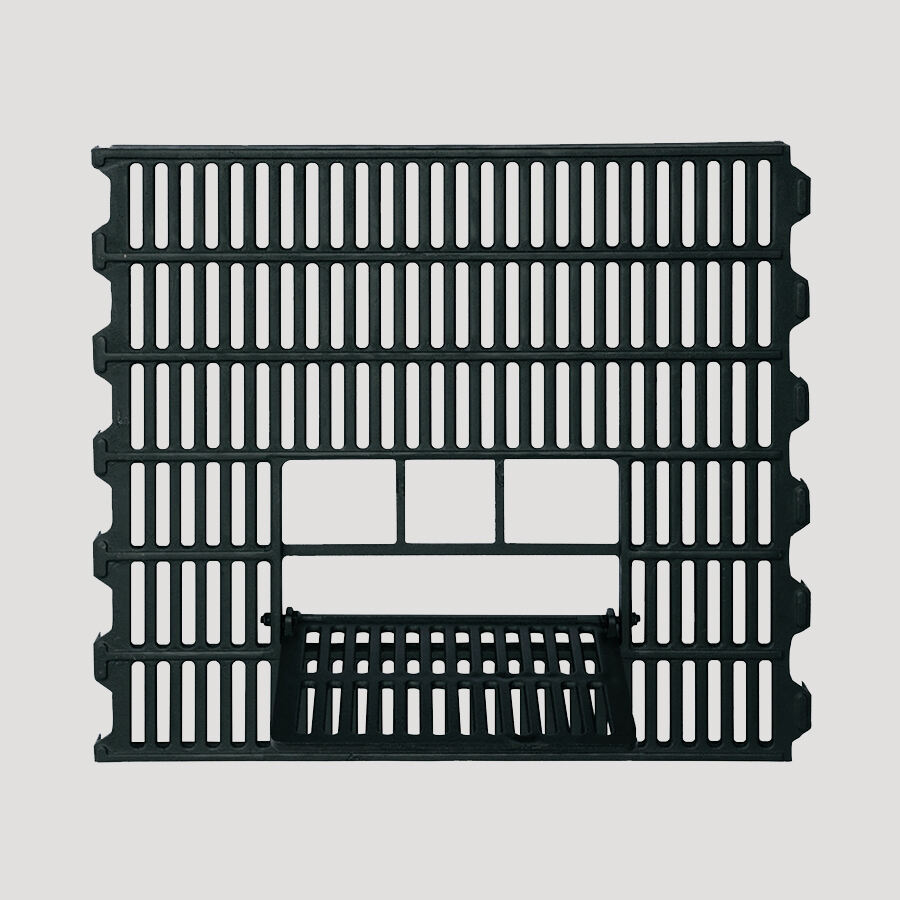

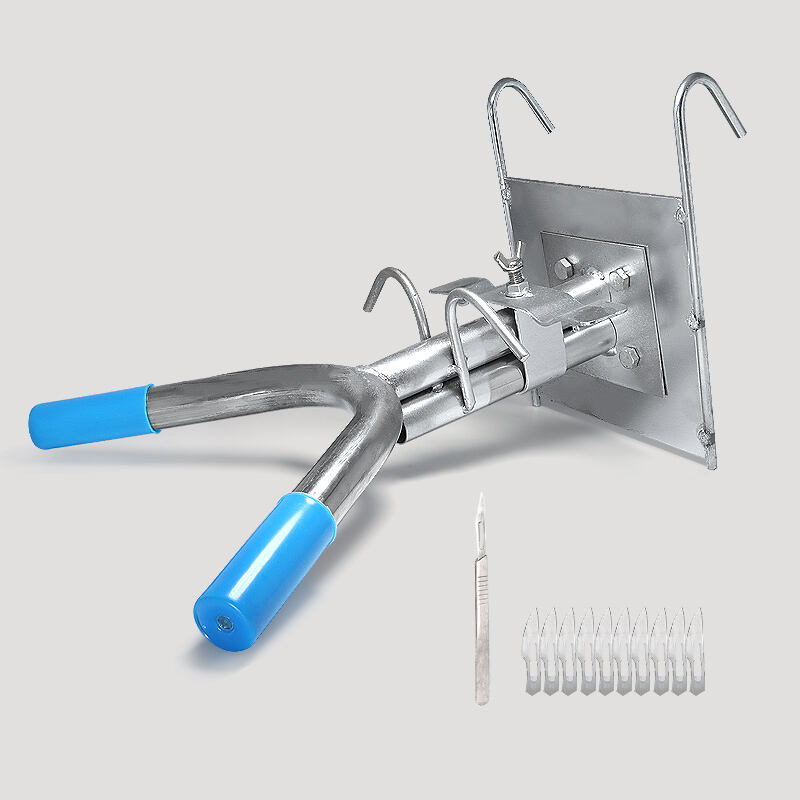

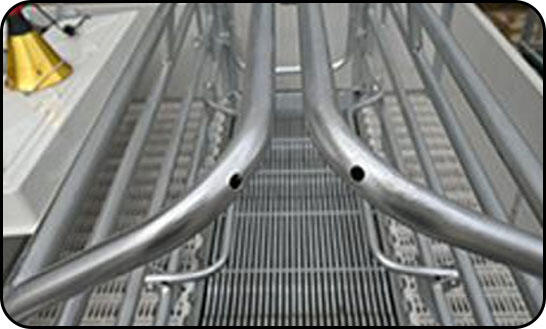

La jaula europea para parto es un sistema de alta calidad diseñado para el cuidado de cerdas y lechones, combinando durabilidad, seguridad y comodidad. Incluye cerca y jaula de acero galvanizado en caliente, piso de lamas de hierro fundido para las cerdas, piso de lamas plástico para los lechones, incubadora con lámpara de calor, comedero para cerdas, comedero y bebederos para lechones, y patas de apoyo de hierro fundido. Utilizando soldadura con protección de gas CO₂ seguida de galvanizado en caliente generalizado, la estructura ofrece una excepcional resistencia a la corrosión y al óxido con una durabilidad prolongada.

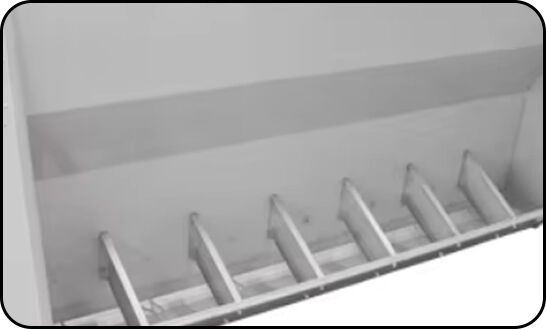

La barra amortiguadora reduce la velocidad de la cerda al tumbarse, protegiendo a los lechones de posibles daños, mientras que las barras ajustables y las puertas traseras se adaptan a diferentes tamaños de cerdas y edades de lechones, garantizando comodidad. El suelo de hierro fundido nodular con rejillas para cerdas soporta hasta 800 kg y tiene una duración de hasta 30 años, mientras que el suelo plástico para lechones soporta 300 kg, cuenta con un diseño suave y redondeado para mayor seguridad y permite un fácil desagüe de residuos. También están disponibles colores personalizables.

Vídeo de Introducción del Producto

Puntos de venta clave

|

Fácil de gestionar Fácil de operar |

|

El espacio general es muy limpio y |

|

|

Valla de PVC, fácil de instalar, Adecuado para usar en situaciones |

|

El espacio general es muy limpio y |

|

|

Placa de acero para filtración de estiércol, Sin acumulación de estiércol, Fácil de Limpiar |

|

Tazón para cerda con placa de acero grande Fuerte y duradero |

|

Detalles