El Calentador de Agua para Cría de Aves con Combustible Diesel representa una solución de calefacción sofisticada diseñada específicamente para abordar los requisitos críticos de gestión térmica en operaciones modernas de avicultura, ofreciendo un rendimiento de calentamiento confiable y eficiente mediante tecnología avanzada de combustión diésel. Este sistema de calefacción especializado combina un diseño industrial robusto con capacidades precisas de control de temperatura, lo que lo convierte en un componente esencial para granjeros avícolas comerciales, distribuidores de equipos agrícolas y gestores de instalaciones ganaderas que priorizan condiciones ambientales constantes durante la fase crucial de crianza en el desarrollo avícola. La unidad funciona según un principio de combustión diésel eficiente en el consumo de combustible, que convierte el combustible líquido en una producción térmica sostenida, utilizando un sistema de circulación de aire cuidadosamente diseñado que distribuye el aire caliente por todo el entorno de crianza, manteniendo al mismo tiempo gradientes de temperatura óptimos necesarios para un desarrollo saludable de los pollitos. calentador de diésel la configuración ofrece ventajas significativas frente a los métodos tradicionales de calefacción, proporcionando capacidades de operación autónoma que reducen la dependencia de la infraestructura eléctrica mientras ofrece un rendimiento constante en diversas condiciones ambientales y fluctuaciones estacionales. Los compradores internacionales B2B buscan frecuentemente este tipo de equipos de calefacción agrícola debido a su versatilidad para apoyar diversas razas de aves de corral, opciones escalables de instalación y compatibilidad con los sistemas existentes de infraestructura en granjas. El mecanismo de calefacción incorpora un diseño avanzado de cámara de combustión que maximiza la eficiencia del combustible al tiempo que minimiza las emisiones, con materiales duraderos de construcción en acero que soportan ciclos continuos de operación típicos en instalaciones comerciales avícolas. Los enfoques de fabricación para estas unidades enfatizan la ingeniería de precisión y los procesos de control de calidad que garantizan un rendimiento consistente en diferentes entornos operativos, prestando especial atención a la durabilidad de los componentes y las características de accesibilidad para mantenimiento, que respaldan las expectativas de fiabilidad a largo plazo de los compradores de equipos agrícolas. El sistema de circulación de aire dentro de la unidad utiliza ventiladores y configuraciones de conductos estratégicamente colocados que promueven una distribución uniforme del calor en todo el espacio de crianza, evitando puntos calientes y zonas frías que podrían afectar negativamente la salud y las tasas de desarrollo de los pollitos. Las consideraciones de diseño incluyen tanto los requisitos funcionales de rendimiento como las necesidades prácticas de instalación, incorporando opciones de montaje adecuadas para diversas configuraciones de edificios comúnmente encontradas en instalaciones avícolas en todo el mundo. Los tratamientos superficiales aplicados a la unidad de calefacción suelen incluir recubrimientos resistentes a la corrosión y acabados protectores que aumentan la durabilidad cuando se exponen a entornos húmedos y químicamente desafiantes característicos de las operaciones avícolas, facilitando al mismo tiempo procedimientos rutinarios de limpieza y mantenimiento esenciales para los protocolos de bioseguridad. Las posibilidades de personalización funcional incluyen controles de temperatura ajustables, configuraciones de salida variables y capacidades de integración con sistemas automatizados de gestión de granjas que permiten funciones precisas de monitoreo y control ambiental. El sistema de calefacción demuestra una idoneidad excepcional en múltiples segmentos de la industria avícola, incluyendo operaciones comerciales de pollos de engorde, instalaciones de gallinas ponedoras, establecimientos reproductores y empresas de producción avícola especializada que requieren un manejo preciso de la temperatura durante fases críticas de crecimiento. La filosofía de consistencia en calidad que sustenta el proceso de fabricación enfatiza procedimientos rigurosos de pruebas y métodos estandarizados de producción que garantizan que cada unidad cumpla con especificaciones de rendimiento exigentes esperadas por compradores profesionales de equipos agrícolas y distribuidores internacionales. Las consideraciones para manipulación orientada a exportación incluyen diseños de embalaje robustos que protegen componentes sensibles durante el transporte internacional, documentación completa de instalación traducida a varios idiomas y recursos de soporte técnico accesibles para bases globales de clientes. El sistema de combustible diésel incorpora características de seguridad y controles operativos que cumplen con las normas internacionales para equipos agrícolas, brindando tranquilidad a los responsables de las instalaciones encargados del bienestar del ganado y de los protocolos de seguridad operativa. Las oportunidades de colaboración en personalización se extienden a asociaciones OEM, donde los fabricantes de equipos agrícolas pueden integrar estas soluciones de calefacción en sistemas más grandes para instalaciones avícolas, mientras que los marcos de cooperación ODM permiten a los distribuidores especificar modificaciones que atiendan preferencias regionales del mercado y requisitos regulatorios. La mentalidad de cooperación enfatiza relaciones duraderas con proveedores basadas en experiencia técnica, calidad constante del producto y servicio al cliente ágil que apoya las necesidades operativas continuas de productores avícolas en diversos mercados geográficos. Las características de compatibilidad con empaque y logística aseguran procesos eficientes de almacenamiento y distribución, con dimensiones estandarizadas que optimizan la eficiencia de carga en contenedores y reducen los costos de envío para compradores internacionales que gestionan programas de adquisición de equipos agrícolas a gran escala. La experiencia en la fabricación de soluciones de calefacción agrícola proporciona la base para iniciativas continuas de mejora del producto que incorporan retroalimentación de aplicaciones en campo y requisitos industriales en evolución, asegurando que cada sistema de calefacción para pollitos ofrece un rendimiento confiable en condiciones operativas del mundo real. Las características de salida térmica de la unidad se pueden ajustar para adaptarse a diferentes tamaños de espacio de cría y a las variaciones de temperatura estacionales, lo que proporciona flexibilidad operativa que favorece la utilización eficiente de recursos y prácticas de gestión de instalaciones rentables. La versatilidad en la instalación permite tanto configuraciones de montaje fijo como opciones de despliegue portátil, permitiendo a los productores avícolas adaptar sus estrategias de calefacción según los requisitos operativos cambiantes y los planes de expansión de las instalaciones. Las expectativas de cooperación a largo plazo con los proveedores se centran en mantener la disponibilidad constante de productos, el acceso al soporte técnico y la colaboración continua en mejoras de producto que aborden los desafíos emergentes en entornos modernos de producción avícola, estableciendo asociaciones que apoyen el crecimiento y el éxito de empresas agrícolas en todo el mundo.

Calentador de Agua para Cría de Aves con Combustible Diesel

- Calefacción Eficiente : Calienta rápidamente las zonas de crianza de aves, asegurando temperaturas ideales para los animales.

- Diésel - impulsado : Calefacción basada en combustible estable, adecuada para granjas avícolas a gran escala.

- Diseño portátil : Con ruedas y mango, fácil de mover entre zonas de crianza para un uso flexible.

- Rendimiento fiable : Construcción duradera, proporciona calor continuo, mejorando el éxito de la crianza.

- Puede elegirse múltiples fuentes de energía .Tiene un ventilador interno para expulsar el aire caliente y calentar la granja.

- Descripción general

- Tamaño

- Detalles

- Productos recomendados

Parámetros

| Modelo | SAY-30 | SAY-50 | SAY-70 | SAY-100 |

|---|---|---|---|---|

| Potencia (KW) | 30KW | 50kW | 70kW | 100 kW |

| Potencia eléctrica (KW) | 30KW | 50kW | 70kW | 100 kW |

| Combustible | Aceite Diesel | Aceite Diesel | Aceite Diesel | Aceite Diesel |

| Consumo de combustible (L/h) | 1.5-2.4 | 2.0-4.0 | 2.5-5.4 | 4.0-8.0 |

| Capacidad (L) | 38 | 56 | 68 | 68 |

| Volumen de aire (m³/h) | 720 | 1100 | 1300 | 1300 |

| Peso neto (kg) | 21.5 | 27.4 | 40.8 | 40.8 |

| Peso bruto (kg) | 23.5 | 33 | 45.8 | 45.8 |

| Tamaño del producto (mm) | 920*456*630 | 1050*590*615 | 1215*580*705 | 1215*580*705 |

| Tamaño de embalaje (mm) | 930*450*500 | 1080*500*580 | 1170*570*690 | 1170*570*690 |

Descripción del volumen del área de calefacción

| Volumen (m3) | SAY-30 | SAY-50 | SAY-70 | SAY-100 |

|---|---|---|---|---|

| Pared de doble aislamiento | 1720 | 2867 | 4013 | 5733 |

| Pared de doble ladrillo | 573 | 956 | 1338 | 1911 |

| Pared de ladrillo de un solo piso | 344 | 573 | 803 | 1147 |

| Edificio simple | 246 | 410 | 573 | 819 |

Descripción

Este sistema de calefacción inteligente de temperatura constante está diseñado para ofrecer eficiencia, comodidad y durabilidad. Cuenta con una función de control automático de temperatura: una vez alcanzada la temperatura preestablecida, deja de calentar para ahorrar energía. Cuando la temperatura ambiente desciende por debajo del nivel ajustado, el sistema se reinicia automáticamente, asegurando un entorno estable y cómodo sin un consumo innecesario de combustible.

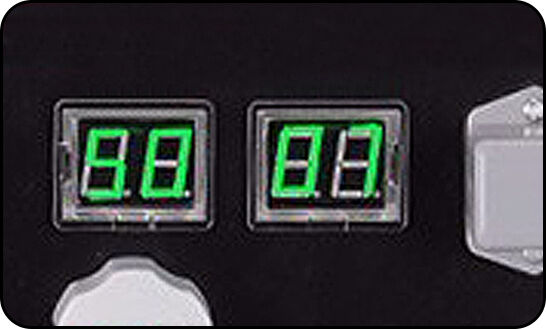

La pantalla digital doble ofrece una monitorización precisa de la temperatura y una operación sencilla mediante un sistema de control inteligente de un solo botón, lo que permite a los usuarios ajustar y mantener fácilmente la temperatura deseada. Equipado con un motor de alta potencia, esta unidad proporciona un calentamiento rápido con bajo consumo energético y reducido ruido, mejorando tanto el rendimiento como la eficiencia.

Su ventilador de aleación de aluminio, tratado con una capa de óxido duradera, garantiza un funcionamiento silencioso con una baja emisión de decibelios, minimizando la perturbación en el entorno circundante. Las palas del ventilador especialmente diseñadas y de gran tamaño generan un mayor flujo de aire y un volumen de aire más caliente, permitiendo un calentamiento rápido y una distribución más eficaz del calor. Construido para ofrecer un rendimiento duradero, este sistema combina una elevada capacidad de calefacción, eficiencia energética y funcionamiento silencioso, lo que lo hace ideal para mantener un calor constante en diversos ambientes.

Vídeo de Introducción del Producto

https://www.youtube.com/embed/mzYDpqDSVgg?si=o9HALAukhFxd8WWg

Tamaño

Detalles

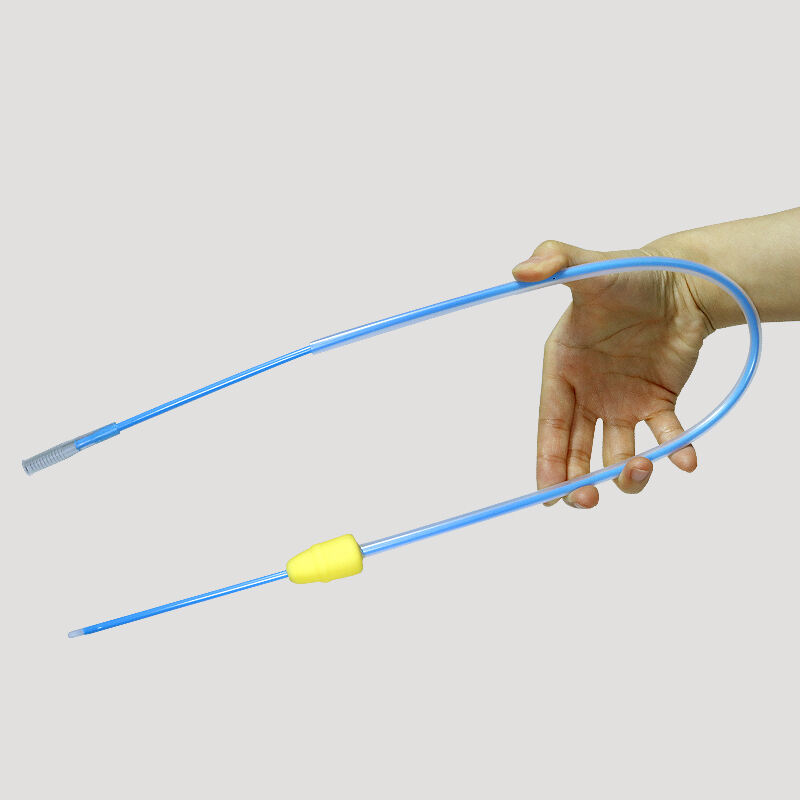

|

Cisterna de acero Anticorrosivos y antirruidos Gran capacidad |

|

Barómetro Controle la presión del aire en cualquier momento Intuitivo y ajustable |

|

|

Medidor de combustible Siempre sepa el nivel de aceite Evite interrupciones en el trabajo |

|

Álabes del ventilador de aleación de aluminio Vientos fuertes Duraderos y no deformados |

|

|

Pantalla dual Visualización intuitiva del conjunto y temperatura ambiente |