El Jaula para Cerdo de Gestación Galvanizada Pesada representa una solución fundamental en la infraestructura moderna de alojamiento porcino, diseñada específicamente para satisfacer las exigentes demandas de las explotaciones porcinas comerciales en diversos mercados internacionales. Este robusto sistema de contención combina tecnología avanzada de galvanizado con técnicas de fabricación de precisión para ofrecer una durabilidad y rendimiento excepcionales en entornos agrícolas desafiantes. El recubrimiento galvanizado proporciona una resistencia superior a la corrosión, garantizando una integridad estructural duradera incluso cuando se expone a condiciones húmedas y ricas en amoníaco, típicas de las instalaciones ganaderas. La metodología de construcción reforzada empleada en la fabricación de estas jaulas de gestación incorpora diseños de estructura reforzada capaces de soportar los considerables esfuerzos físicos asociados al alojamiento de cerdas preñadas durante todo su período de gestación. Los equipos internacionales de abastecimiento y distribuidores de equipos agrícolas reconocen la importancia crítica de soluciones de contención fiables que mantengan tanto los estándares de bienestar animal como la eficiencia operativa, convirtiendo este producto en un componente esencial para las instalaciones modernas de producción porcina. El proceso de galvanizado aplicado al armazón de acero crea una capa de zinc unida metalúrgicamente que actúa como barrera y como revestimiento sacrificial, protegiendo el sustrato metálico subyacente frente a la degradación ambiental, al tiempo que mantiene las propiedades estructurales necesarias para un alojamiento seguro de los animales. Los métodos de fabricación de estos recintos agrícolas especializados enfatizan la consistencia en la precisión dimensional y la integridad de las uniones, asegurando que cada unidad cumpla con los rigurosos requisitos de las explotaciones ganaderas comerciales. La filosofía de diseño subyacente a estos sistemas de jaulas de gestación tiene en cuenta los patrones conductuales específicos y los requisitos espaciales de las cerdas gestantes, incorporando configuraciones de separación adecuadas y características de acceso que facilitan tanto el confort del animal como la eficiencia del cuidador. Los protocolos de tratamiento superficial van más allá del galvanizado básico e incluyen una atención cuidadosa al acabado de bordes y la preparación de los puntos de conexión, minimizando los riesgos de lesiones potenciales y maximizando la longevidad de la instalación. Las posibilidades funcionales de personalización dentro de esta categoría de productos permiten adaptarse a diseños específicos de instalaciones y preferencias operativas, con modificaciones potenciales que incluyen configuraciones ajustables de paneles, puntos integrados especializados para alimentación y características de drenaje. La versatilidad de estos sistemas de contención los hace adecuados para su aplicación en diversas escalas de producción porcina, desde operaciones regionales de tamaño mediano hasta grandes instalaciones comerciales que sirven a mercados internacionales. Una filosofía de consistencia en la calidad impulsa el proceso de fabricación, con una atención sistemática a la selección de materiales, técnicas de fabricación y estándares de acabado que garantizan que cada jaula de gestación cumpla con las expectativas de rendimiento de los gestores profesionales de ganado. Se han integrado en el diseño del producto consideraciones para manipulación orientada a la exportación, con características de embalaje y transporte que protegen las superficies galvanizadas durante el envío internacional, facilitando al mismo tiempo una instalación eficiente tras la entrega. El enfoque colaborativo hacia la personalización y la cooperación OEM permite a los proveedores de equipos agrícolas trabajar estrechamente con los fabricantes en el desarrollo de configuraciones especializadas que atiendan requisitos regionales específicos u opciones operativas particulares. Esta flexibilidad en la adaptación del diseño apoya las diversas necesidades de los mercados internacionales, manteniendo al mismo tiempo las características estructurales y de seguridad fundamentales que definen los equipos de calidad para el alojamiento ganadero. Las características de compatibilidad con embalaje y logística incluyen diseños modulares de ensamblaje que optimizan la eficiencia del envío sin comprometer la integridad estructural, permitiendo a los distribuidores gestionar eficazmente los costos de inventario y transporte mientras atienden bases de clientes geográficamente dispersas. El énfasis en la cooperación a largo plazo con proveedores refleja la comprensión de que el equipo agrícola representa una inversión significativa para las explotaciones ganaderas, que requiere soporte continuo y capacidades de expansión potenciales a medida que las instalaciones crecen y evolucionan. Las consideraciones medioambientales inherentes al proceso de galvanizado contribuyen al perfil de sostenibilidad de estos productos, ya que el recubrimiento protector prolonga la vida útil operativa y reduce la frecuencia de ciclos de reemplazo. Las normas de construcción profesional aplicadas a estos sistemas de jaulas de gestación aseguran compatibilidad con prácticas modernas de manejo ganadero, incluyendo integración con sistemas automatizados de alimentación, mecanismos de control ambiental y tecnologías de monitoreo de salud. Las características del material del armazón de acero galvanizado proporcionan el equilibrio óptimo entre resistencia y maleabilidad, permitiendo una instalación segura al tiempo que mantiene suficiente flexibilidad para acomodar asentamientos normales del edificio y expansión térmica. La excelencia en la fabricación en este sector especializado de equipos agrícolas requiere un profundo conocimiento tanto de los principios metalúrgicos como de los patrones de comportamiento del ganado, asegurando que el producto final funcione eficazmente en su entorno de aplicación previsto, cumpliendo al mismo tiempo con las expectativas de seguridad y durabilidad de las operaciones agrícolas profesionales.

Jaula para Cerdo de Gestación Galvanizada Pesada

-

Estructura Resistente y Anticorrosiva – Fabricada con acero galvanizado de alta resistencia para durabilidad a largo plazo y protección contra la oxidación.

-

Confortable y Segura para las Cerdas – El tamaño optimizado del compartimiento con bordes suaves reduce el estrés, lesiones y agresividad durante la gestación.

-

Gestión Eficiente de la Granja – Diseño modular, puertas seguras y fácil instalación ahorran tiempo y mano de obra en granjas a gran escala.

-

Permite Atención Individual – Facilita alimentación y manejo separados, asegurando nutrición adecuada y monitoreo de la salud de cada cerda.

- Personalizable :El número de compartimientos y la longitud de los tubos de acero galvanizado pueden personalizarse según la cantidad de cerdos.

- Descripción general

- Detalles

- Productos recomendados

Descripción

Jaula de Gestación para Cerdas: Esencial para una Gestión Eficiente de las Cerdas

También conocidas como jaulas para cerdas, las jaulas de gestación para cerdos se utilizan principalmente durante la época de apareamiento y las 5 semanas anteriores al parto, convirtiéndolas en un elemento fundamental en la ganadería porcina moderna. Su diseño ahorrador de espacio permite una alimentación controlada, programada y cuantitativa, ventajas clave que las han hecho muy populares en operaciones de cría intensiva.

Un beneficio fundamental radica en abordar la tasa de supervivencia de los lechones: las cerdas exóticas suelen sufrir instintos maternales reducidos debido a crías prolongadas e inadecuadas, lo que incrementa el riesgo de que los lechones sean aplastados. Las jaulas de gestación limitan el movimiento de las cerdas, reduciendo significativamente la mortalidad de los lechones.

Fabricadas con tubos galvanizados por inmersión en caliente con un espesor de 2,5 mm, cumpliendo con estándares internacionales, estas jaulas son duraderas y de larga vida útil. Cada conjunto incluye 11 unidades, adecuadas para alojar hasta 10 cerdas.

Ventajas clave :

Maximiza el Espacio : Aumenta la cantidad de cerdas que pueden criarse en un área fija, ideal para la ganadería intensiva

Simplifica el Mantenimiento : Facilita la limpieza en la granja porcina, reduciendo la intensidad laboral para los trabajadores.

Mejora la Gestión : Ofrece una visibilidad clara del estado de cada cerda, minimizando errores operativos.

Reduce los Riesgos : Evita peleas entre cerdas, disminuyendo las tasas de aborto y asegurando una gestación más segura.

Estas jaulas equilibran eficiencia y bienestar animal, haciéndolas indispensables para operaciones porcinas modernas.

Vídeo de Introducción del Producto

https://www.youtube.com/embed/Rjm1YVME-4M?si=YS2dnmaGFMt656_U

Certificado

Detalles

|

Equipo de agua potable gratuita Accesorios gratuitos Connect la tubería de agua lista para usar |

|

Cierre grueso de estilo europeo Producción en hierro galvanizado reforzado Interruptor más conveniente Duradero y resistente a la corrosión |

|

|

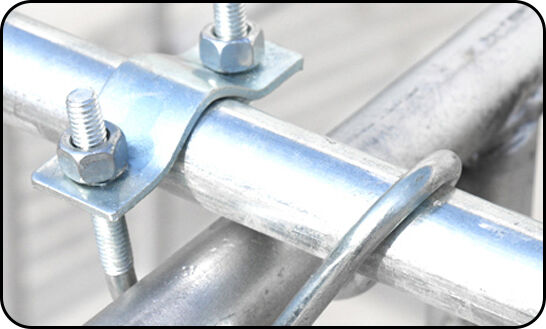

Hebilla en U de hierro galvanizado Uso simultáneo con anti-desenganche barra mantiene la estabilidad general |

|

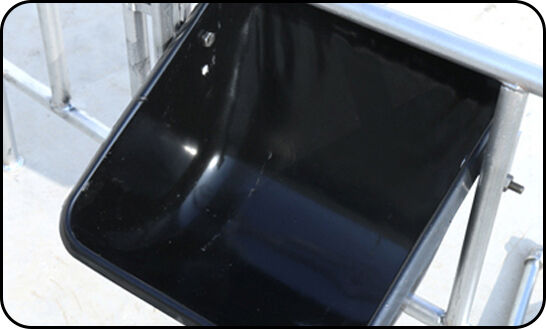

Barniz para horneado Bandeja de placa de acero Cuenco especial para alimento de cerda Tres- diseño estable de mandíbula Semicírculo alrededor, no daña la boca del cerdo |

|

|

Codo redondeado y liso Tubo estándar nacional + alta gama máquina sin rebabas, sin grietas |