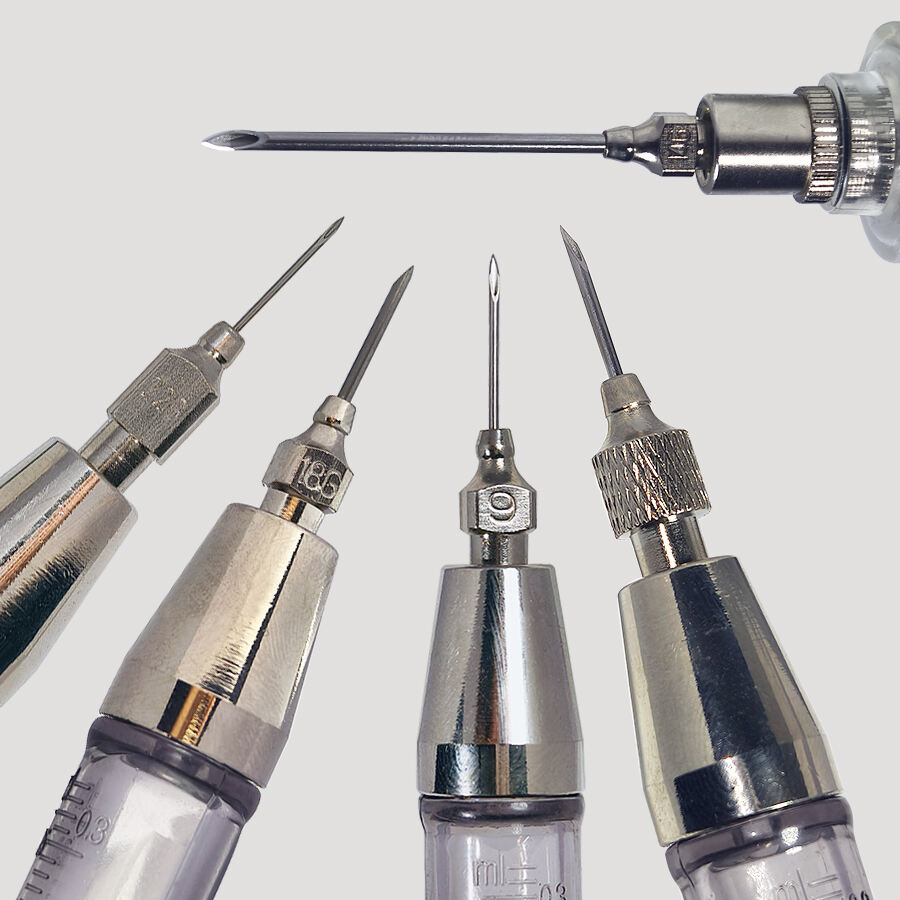

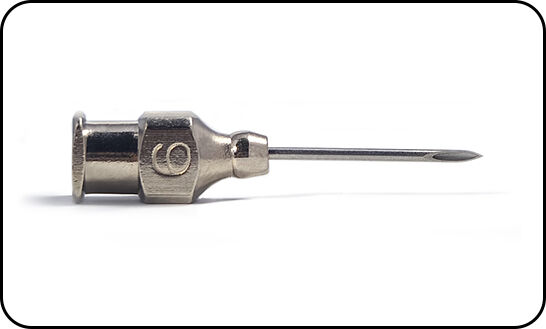

Jeringas Veterinarias Con Aguja de Inyección de Acero Inoxidable representan un componente crítico en los sistemas modernos de atención sanitaria animal, diseñados para cumplir con los rigurosos requisitos de los profesionales veterinarios en diversos entornos clínicos y escenarios de manejo ganadero. Estos instrumentos médicos de precisión combinan una carcasa fabricada en polímero duradero con agujas de acero inoxidable resistentes a la corrosión, ofreciendo un rendimiento confiable en programas de vacunación, administración de medicamentos e intervenciones terapéuticas en prácticas veterinarias de animales de compañía, servicios veterinarios para grandes animales y operaciones ganaderas agrícolas. La sofisticada arquitectura de diseño integra funcionalidad fluida con una operación intuitiva, garantizando una entrega constante de líquidos al tiempo que mantiene la integridad estéril esencial para aplicaciones de salud animal. Las jeringas veterinarias profesionales cuentan con marcas graduadas que permiten un control preciso de la dosificación, lo que permite a los profesionales administrar volúmenes exactos de vacunas, antibióticos, hormonas y otras sustancias terapéuticas con total confianza, en especies que van desde animales de compañía pequeños hasta ganado grande. Las agujas de inyección de acero inoxidable pasan por procesos especiales de fabricación que aseguran una óptima retención de filo, características de penetración suave y resistencia a doblarse o romperse durante procedimientos de inyección complejos, comunes en entornos de práctica veterinaria. La excelencia en la fabricación de dispositivos médicos veterinarios requiere el cumplimiento de normas internacionales de calidad que regulan la biocompatibilidad, la precisión dimensional y la consistencia de rendimiento, asegurando que cada unidad de jeringa ofrezca resultados confiables independientemente de la complejidad de la aplicación o las condiciones ambientales. La construcción de la carcasa de polímero utiliza materiales de grado médico seleccionados específicamente por sus propiedades de resistencia química, evitando la degradación cuando se exponen a diversos compuestos farmacéuticos y fluidos biológicos comúnmente utilizados en terapias veterinarias. Técnicas avanzadas de moldeo por inyección crean superficies internas lisas que minimizan la fricción durante el funcionamiento del émbolo, manteniendo al mismo tiempo una precisión volumétrica exacta en todo el rango de medición, lo que respalda protocolos de dosificación precisos esenciales para lograr resultados efectivos en el tratamiento de animales. La fabricación de agujas de acero inoxidable implica procesos de mecanizado de precisión que crean bordes cortantes afilados y libres de rebabas, capaces de penetrar la piel animal y los tejidos subcutáneos con un trauma mínimo, reduciendo el estrés en los animales durante los procedimientos de inyección y garantizando la seguridad del profesional mediante la integridad confiable de la aguja. Las consideraciones ergonómicas incorporadas en el desarrollo de jeringas veterinarias tienen en cuenta escenarios de uso prolongado comunes en programas masivos de vacunación, con superficies de agarre cómodas y mecanismos de operación intuitivos que reducen la fatiga manual durante procedimientos de inyección repetitivos. Los protocolos de aseguramiento de calidad que rigen la producción de dispositivos médicos veterinarios abarcan metodologías exhaustivas de pruebas que evalúan la consistencia del filo de la aguja, la suavidad del movimiento del émbolo, la precisión de las marcas graduadas y la integridad general del ensamblaje bajo diversas condiciones de temperatura y humedad representativas de los entornos globales de práctica veterinaria. Las jeringas veterinarias profesionales admiten diversas opciones de calibre de aguja, lo que permite a los profesionales seleccionar dimensiones adecuadas según la especie animal, el sitio de inyección y los requisitos de viscosidad del medicamento, desde agujas finas adecuadas para inyecciones subcutáneas de vitaminas hasta opciones de mayor calibre diseñadas para la administración intramuscular de antibióticos. El amplio espectro de aplicaciones de estos instrumentos veterinarios va más allá de los procedimientos clínicos rutinarios e incluye usos especializados en manejo de vida silvestre, medicina zoológica, operaciones en instalaciones de investigación y situaciones de respuesta de emergencia animal, donde el rendimiento confiable del equipo de inyección es fundamental para lograr resultados exitosos en el tratamiento. Las consideraciones internacionales de aprovisionamiento de dispositivos médicos veterinarios enfatizan la capacidad del proveedor para mantener una calidad de producción constante en series prolongadas de fabricación, asegurando que los equipos de compras puedan establecer cadenas de suministro confiables para equipos críticos de atención sanitaria animal sin comprometer los estándares de rendimiento ni la fiabilidad en la entrega. Las oportunidades de personalización en la fabricación de jeringas veterinarias permiten adaptarse a requisitos específicos del mercado, incluyendo colores alternativos de la carcasa para facilitar la identificación, diseños especiales de émbolos optimizados para tipos particulares de medicamentos y configuraciones de empaque que apoyan una gestión eficiente del inventario en entornos de práctica veterinaria. El enfoque colaborativo en asociaciones OEM para el desarrollo de dispositivos médicos veterinarios destaca los servicios de consultoría técnica que ayudan a distribuidores y compradores a optimizar las especificaciones del producto para sus segmentos de mercado específicos, ya sea atendiendo a veterinarios de animales de compañía, instalaciones de producción ganadera o instituciones especializadas en cuidado animal. Las capacidades de fabricación orientadas a la exportación garantizan que las jeringas veterinarias conserven sus características de rendimiento durante los procesos de envío internacional, con soluciones de embalaje diseñadas para proteger el filo de las agujas y prevenir la contaminación de la carcasa durante periodos prolongados de tránsito, comunes en operaciones de cadena de suministro global. Las relaciones a largo plazo con proveedores en el sector de dispositivos médicos veterinarios se benefician de fabricantes que demuestran una capacidad de producción constante, iniciativas de mejora de calidad y un servicio al cliente ágil que responde con experiencia profesional a consultas técnicas y solicitudes de personalización desarrolladas a través de una amplia experiencia en la producción de equipos para la atención sanitaria animal. La integración de las jeringas veterinarias en sistemas integrales de gestión de la salud animal requiere considerar la compatibilidad con diversos tipos de medicamentos, requisitos de almacenamiento y protocolos de eliminación que se alineen con prácticas de sostenibilidad ambiental, cada vez más importantes para las operaciones veterinarias modernas que buscan minimizar su impacto ecológico mientras mantienen altos estándares de cuidado animal.

Jeringas Veterinarias Con Aguja de Inyección de Acero Inoxidable

-

Diseño Duradero y Reutilizable – Aguja de acero inoxidable resistente a la corrosión y cuerpo de jeringa reutilizable para uso prolongado en granjas.

-

Dosis Precisa y Segura – Marcas claras en el barril y control preciso del émbolo aseguran la correcta administración del medicamento para diversos animales.

-

Uso Cómodo y Ergonómico – Mango ergonómico que minimiza la fatiga de la mano durante inyecciones frecuentes o a gran escala.

-

Versátil y Amigable con los Animales – Adecuada para cerdos, ganado, cabras, ovejas y otros animales de granja, con múltiples opciones de volumen.

-

Fácil de limpiar y mantener – Fácil de esterilizar y compatible con accesorios veterinarios estándar para un tratamiento eficiente.

- Descripción general

- Tamaño Tipo

- Detalles

- Productos recomendados

Información de Parámetros del Producto

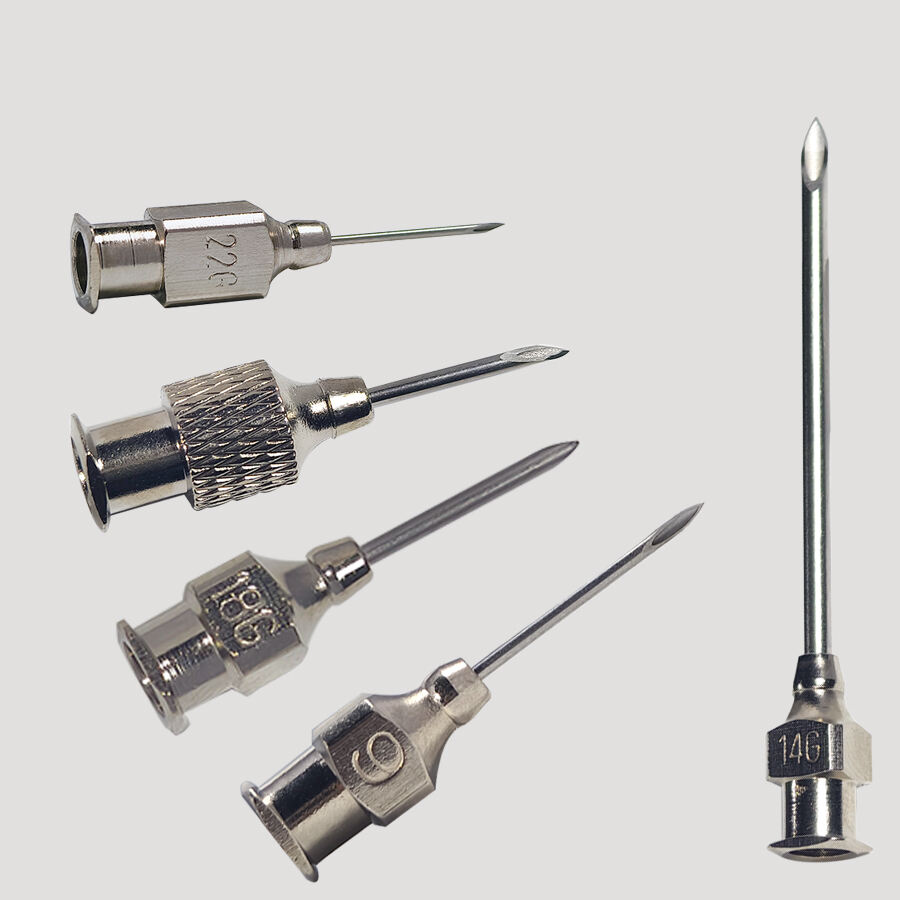

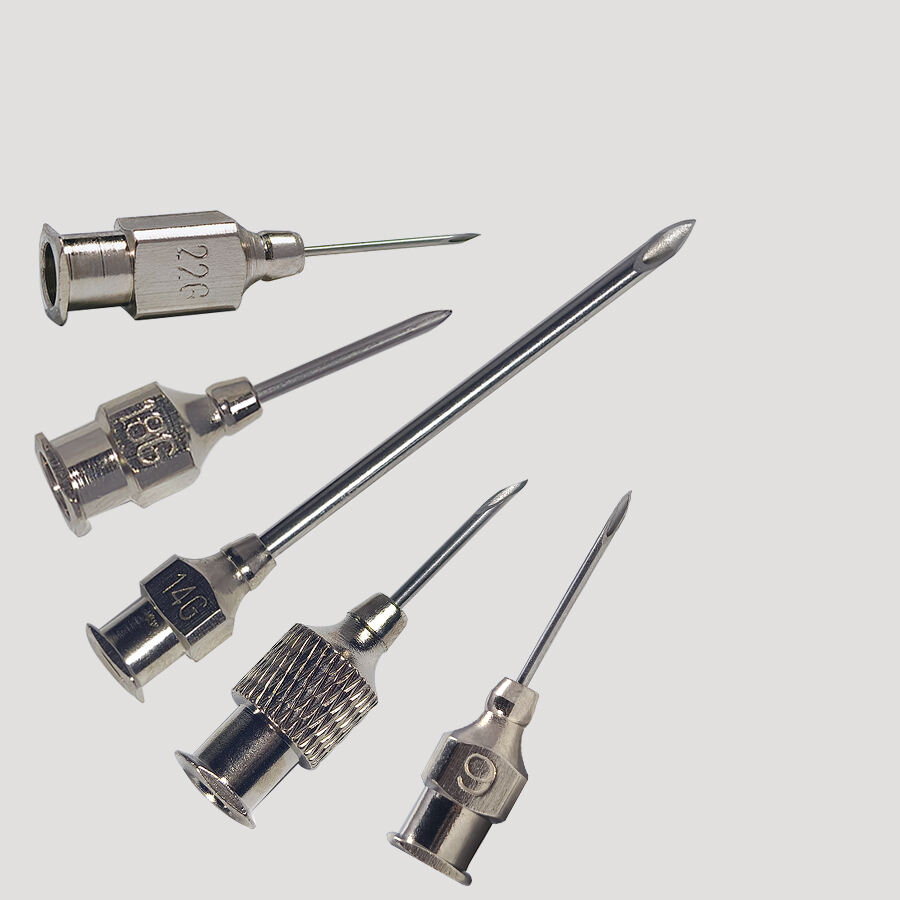

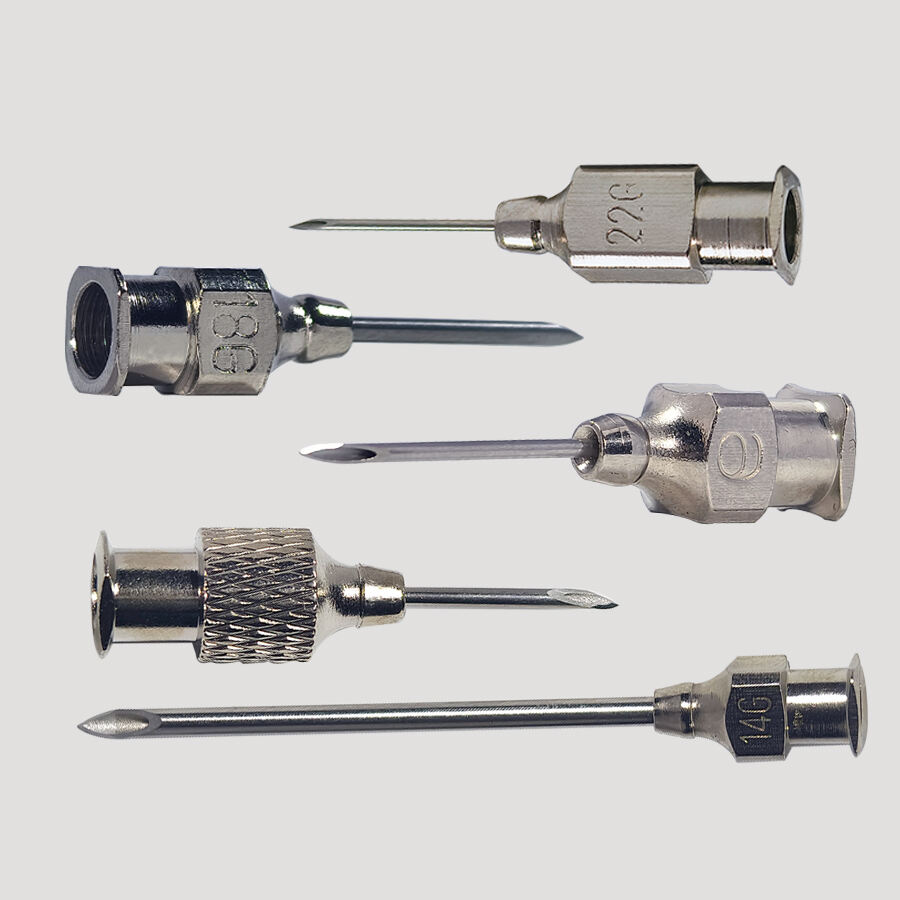

| Nombre | Aguja de acero inoxidable veterinaria |

| Material | El tubo de la aguja es de acero inoxidable 304, los demás son niquelados |

| Especificación |

7x8 7x13 9x15 9x20 12x15 12x20

12x25 12x38 14x20 14x25 14x30 14x38

16x15 16x20 16x25 16x30 16x38 20x50

|

| Características | Variedad de especificaciones/excelente material/seguro e higiénico |

Descripción

Cada caja contiene 10 piezas de jeringas de alta calidad fabricadas con acero inoxidable 304, lo que garantiza una excelente durabilidad y resistencia a la corrosión. Estas jeringas están diseñadas para ser utilizadas en investigación científica, laboratorios, cultivo de plantas y ganadería, ofreciendo un desempeño preciso y confiable. Además de estas aplicaciones, también pueden emplearse para tareas como el reabastecimiento de geles, pinturas u otros fluidos en entornos industriales o técnicos. Ideales para profesionales de la industria, investigación y agricultura, estas jeringas actúan como herramientas versátiles para una variedad de usos especializados. Tenga en cuenta que estas jeringas, incluyendo las agujas adjuntas, están destinadas únicamente a aplicaciones industriales o de laboratorio y no son adecuadas para uso médico ni inyecciones en humanos. Su construcción robusta y diseño preciso las convierten en equipos esenciales para el manejo controlado de fluidos en entornos no médicos, asegurando seguridad y eficiencia en sus operaciones.

Tamaño Tipo

Detalles

|

Fuerte adaptabilidad Calidad según norma nacional, espesor de la pared no se rompe fácilmente |

|

Liso sin rebabas Moldeo por compresión en una sola pieza, pulido preciso en el interior y exterior para evitar rebabas |

|

|

Soldadura de precisión El asiento de la aguja del tubo de aguja está soldado directamente, y es preciso y hermético |

|

Un paquete de diez agujas Alta resistencia, sin obstrucciones, se puede usar repetidamente |

|