The Automatic Pig Water Nipple Drinker represents a sophisticated solution for modern swine farming operations seeking to optimize water delivery systems while maintaining exceptional hygiene standards and operational efficiency. This advanced watering system incorporates precision-engineered components designed to provide consistent, on-demand water access for pigs of varying sizes and weights, ensuring optimal hydration management across commercial breeding facilities, finishing operations, and specialized swine production environments. The automatic activation mechanism responds instantly to animal contact, delivering fresh water while simultaneously preventing contamination and minimizing waste through its intelligent flow control design. International B2B buyers and agricultural equipment distributors recognize this product as an essential component for establishing comprehensive livestock management systems that align with contemporary animal welfare standards and operational cost optimization objectives. The robust construction methodology employs corrosion-resistant materials specifically selected for their durability under continuous exposure to moisture, organic matter, and varying temperature conditions commonly encountered in swine housing facilities. Manufacturing processes incorporate advanced machining techniques and precision assembly protocols to ensure consistent performance characteristics across large production volumes, making this solution particularly suitable for procurement managers overseeing multi-site farming operations or agricultural equipment suppliers serving diverse geographic markets. Surface treatment applications enhance the product's resistance to bacterial accumulation and chemical cleaning agents, supporting stringent biosecurity protocols while maintaining structural integrity throughout extended operational periods. The design architecture accommodates various mounting configurations and installation scenarios, allowing seamless integration with existing facility infrastructure or new construction projects without requiring extensive modifications to housing systems or water supply networks. Customization possibilities extend beyond standard specifications to encompass specific flow rate requirements, connection interfaces, and mounting bracket configurations that address unique facility layouts or specialized production methodologies employed by different swine operations. Agricultural equipment distributors value the product's adaptability across diverse application scenarios, from nursery environments requiring gentle water delivery for young piglets to finishing facilities managing mature animals with higher consumption demands. Quality consistency philosophy drives every aspect of the manufacturing process, ensuring that each unit delivered maintains identical performance characteristics regardless of production batch or destination market, a critical consideration for international buyers managing standardization requirements across multiple locations. The automatic pig water nipple drinker demonstrates exceptional compatibility with various water pressure ranges and plumbing configurations commonly found in agricultural settings, reducing installation complexity while maintaining reliable operation across different infrastructure conditions. Export-oriented handling considerations influence packaging design and transportation protocols, ensuring product integrity during international shipping while facilitating efficient warehouse management and distribution processes for overseas buyers. The corrosion-resistant construction methodology addresses the challenges posed by aggressive cleaning chemicals and disinfectants regularly employed in commercial swine facilities, maintaining operational reliability while supporting comprehensive sanitation protocols essential for disease prevention and food safety compliance. Functional design elements incorporate user-friendly maintenance access points that facilitate routine inspection and cleaning procedures without requiring specialized tools or extensive downtime, supporting operational efficiency objectives valued by facility managers and maintenance personnel. Customization collaboration opportunities with OEM and ODM partners enable the development of application-specific variations that address unique market requirements or integrate seamlessly with proprietary facility management systems employed by large-scale agricultural operations. The product's compatibility with automated monitoring systems and water consumption tracking technologies positions it as a forward-thinking solution for data-driven farm management approaches increasingly adopted by progressive swine producers worldwide. Packaging and logistics compatibility considerations ensure efficient handling throughout the international supply chain, from manufacturing facilities to end-user installations, supporting the requirements of freight forwarders and distribution partners managing complex multi-country delivery scenarios. Material selection criteria emphasize long-term performance under challenging environmental conditions while maintaining cost-effectiveness for large-scale procurement initiatives, balancing durability requirements with budget considerations typical of commercial agricultural investments. The automatic activation mechanism's reliability under continuous use scenarios makes this solution particularly valuable for high-density housing systems where consistent water access directly impacts animal performance and facility productivity metrics. Long-term supplier cooperation expectations center on providing comprehensive technical support, product evolution guidance, and market-specific adaptations that help international partners maintain competitive advantages in their respective regional markets while building sustainable business relationships based on mutual growth objectives and shared commitment to advancing modern agricultural practices through innovative equipment solutions.

Automatic Pig Water Nipple Drinker

-

Clean & On-Demand Hydration – Delivers fresh water only when pigs drink, reducing waste and improving hygiene.

-

Durable & Corrosion-Resistant – Made from stainless steel for long-lasting use in harsh farm environments.

-

Water-Saving & Leak-Proof Design – Built-in valve system minimizes leakage and keeps pens dry.

-

Easy Installation & Versatility – Compatible with standard piping and suitable for pigs of all ages and sizes.

-

Low Maintenance & Labor Saving – Simple, reliable design reduces daily upkeep and supports efficient farm operations.

- Overview

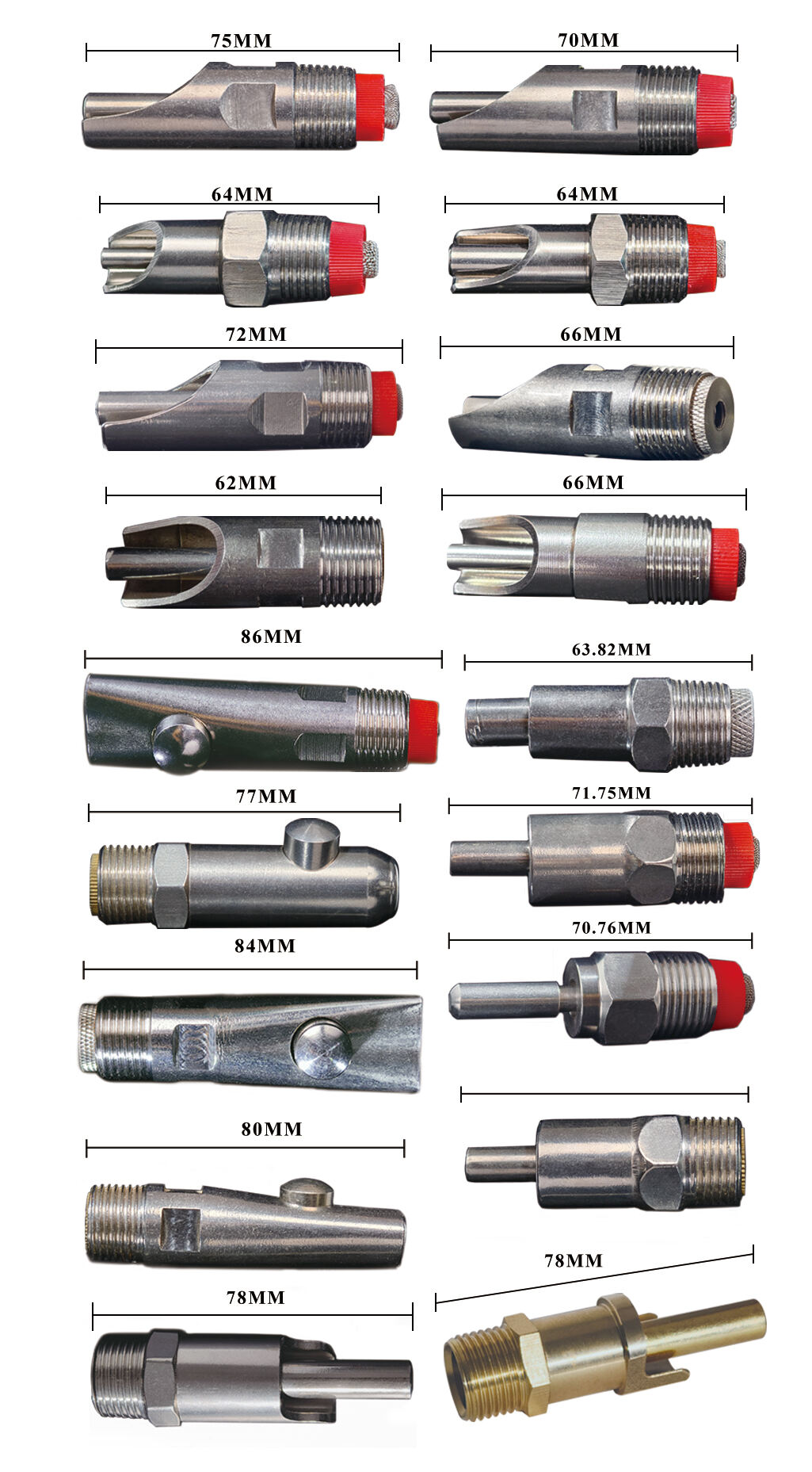

- Size

- Details

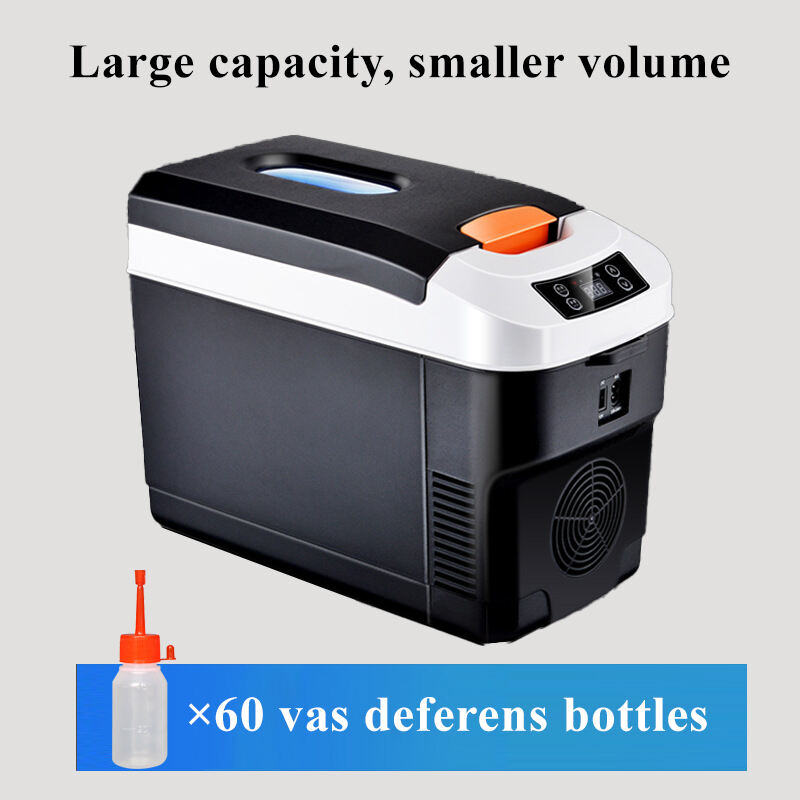

- Recommended Products

Dimensions: 81 × 24.5 mm (L × Ø)

Mounted length: 54 mm

Nipple diameter: 3/4"

Press part diameter: 7.8 mm

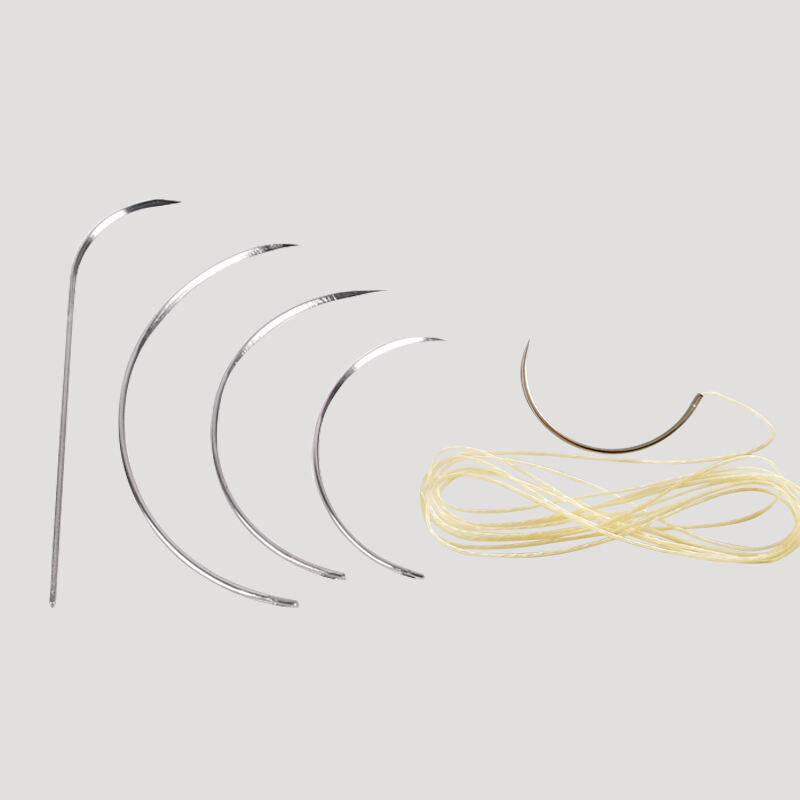

Material: Stainless steel nipple with plastic nozzle

Mounting angle: 15°–45°

-

Recommended heights:

5 kg: 15 cm

10 kg: 20–25 cm

20 kg: 35–40 cm

50 kg: 50–60 cm

100 kg: 70 cm

Description

This high-quality, durable bite nipple is designed to provide a reliable drinking water solution for sows and fattening pigs. Water is dispensed only when the animal pushes or moves the press part, ensuring controlled water flow and minimizing waste. With its adjustable water dispensing feature, it allows farmers to fine-tune the flow according to animal needs, improving efficiency and reducing spillage.

The nipple includes a built-in filter that prevents backflow contamination, maintaining cleaner water for healthier livestock. Its design eliminates the need for catching or drinking trays, simplifying installation and maintenance.

Built with robust materials for long-lasting use, this bite nipple comes with a 1/2" male thread connection for easy integration into existing water systems. Available in multiple models, it is ideal for modern pig farming operations seeking hygienic, water-saving, and efficient watering solutions for sows and finishers.

User Tips:

This bite nipple only releases water when the animal bites it, significantly reducing water spillage and eliminating the need for spill buckets or troughs. The water flow is adjustable using a nozzle with three interchangeable openings (0.8 mm, 1 mm, 2 mm), allowing you to regulate output based on water pressure and animal needs.

Product Introduction Video

https://youtube.com/shorts/Y8igd_brj6g?si=EPfQ28yn23bcgAR9

Product Specifications:

Installation & Use:

For high acid/oxidation resistance, choose our TWC (Total Water Care) nipples, specially developed for use with treated and acidified drinking water.

Size

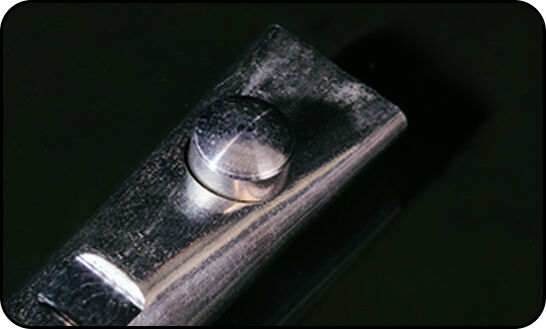

Details

| Smooth water flow, one touch and one exit | ||

|

|

|

| Red filter tip | ||

|

|

|

| No harm to the pig's mouth | ||

|

|

|

| No harm to the pig's mouth | ||

|

|

|