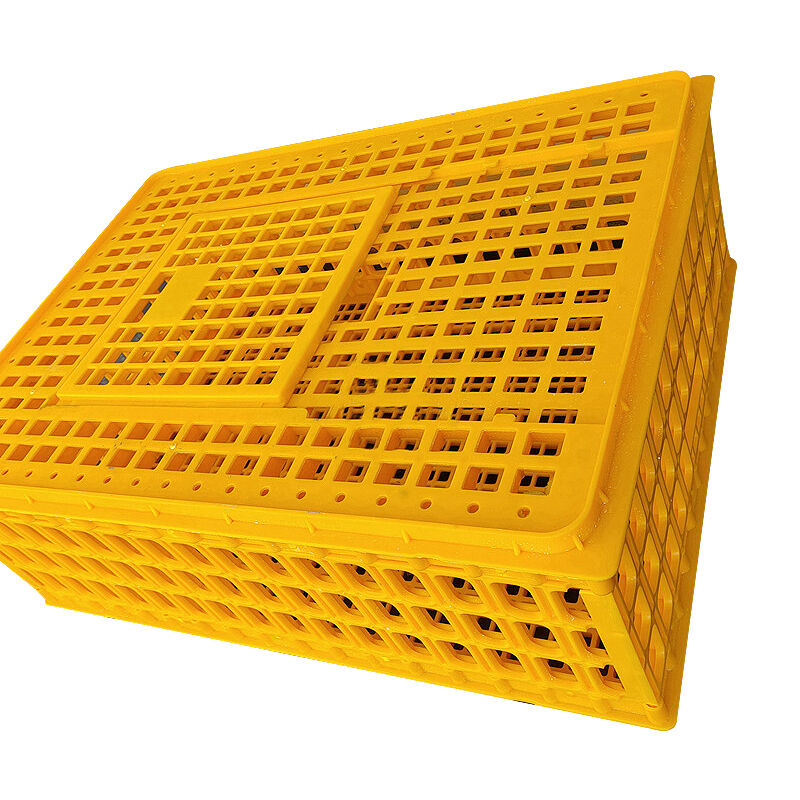

chicken transport crate factory

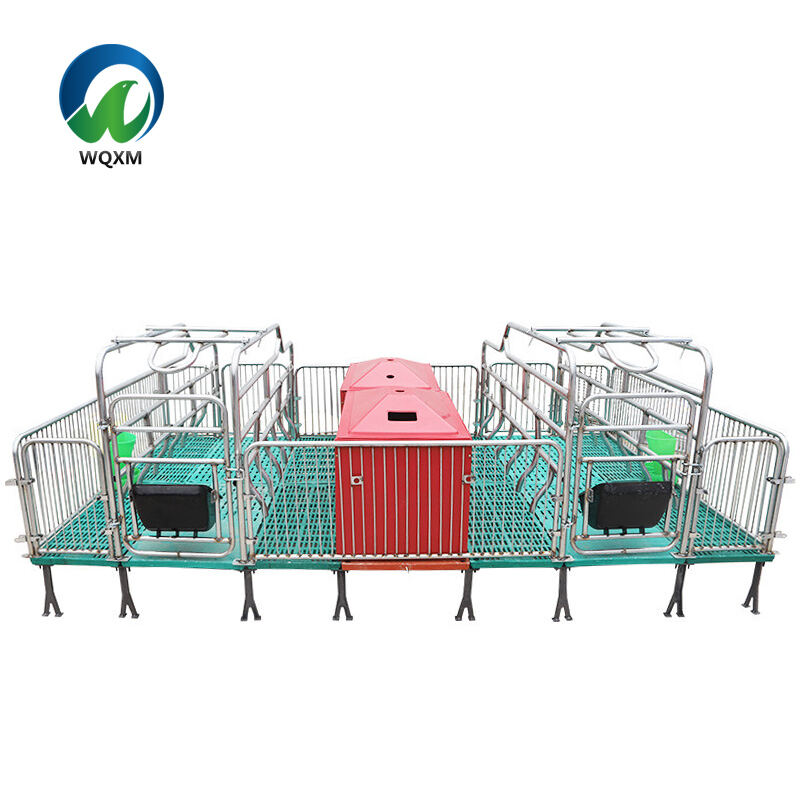

A chicken transport crate factory represents a modern manufacturing facility dedicated to producing high-quality containers designed specifically for the safe and efficient transportation of poultry. These facilities employ advanced automation systems and precision engineering to create durable, ventilated crates that meet international standards for animal welfare. The factory utilizes state-of-the-art injection molding technology to produce plastic crates, or specialized metalworking equipment for wire mesh versions. Quality control systems monitor every stage of production, ensuring consistent product quality and structural integrity. The manufacturing process incorporates food-grade materials that are both lightweight and strong, capable of withstanding repeated use and regular sanitization. These facilities typically feature automated assembly lines, quality testing stations, and advanced storage solutions for finished products. The factory's design prioritizes efficiency in production flow, from raw material handling to final product packaging. Modern chicken transport crate factories also implement sustainable practices, including material recycling systems and energy-efficient manufacturing processes. They maintain strict compliance with agricultural and transportation regulations while providing customization options to meet specific customer requirements.