The Stainless Steel Syringe with Precision Dosing represents a sophisticated solution for professional applications requiring exceptional accuracy, durability, and chemical resistance in fluid handling and dispensing operations. This premium instrument combines the inherent advantages of high-grade stainless steel construction with advanced engineering principles to deliver consistent, reliable performance across demanding industrial, laboratory, and specialized commercial environments. The precision dosing capability distinguishes this syringe from standard alternatives, enabling users to achieve exacting measurement standards essential for critical applications where volumetric accuracy directly impacts process quality, research outcomes, or product consistency. Manufacturing of these specialized syringes involves carefully controlled metallurgical processes that ensure uniform material properties throughout the entire structure, from the barrel housing to the precision-machined plunger mechanism. The stainless steel composition provides exceptional resistance to corrosion, chemical attack, and thermal stress, making these instruments suitable for use with a broad spectrum of fluids including aggressive solvents, pharmaceutical compounds, food-grade substances, and industrial chemicals that would rapidly degrade lesser materials. Surface finishing techniques employed during production create smooth, non-reactive interfaces that minimize fluid retention, facilitate thorough cleaning protocols, and prevent cross-contamination between different substances or batches. The precision dosing functionality is achieved through meticulous engineering of internal tolerances, specialized sealing systems, and calibrated graduation markings that enable accurate measurement and dispensing of small to medium volumes with exceptional repeatability. International buyers and sourcing professionals recognize these instruments as essential tools for quality-sensitive operations where measurement precision directly correlates with operational success and regulatory compliance. The robust construction methodology ensures consistent performance characteristics across production batches, supporting reliable supply chain integration for distributors and end-users who depend on predictable instrument behavior in their operational workflows. Design considerations extend beyond basic functionality to encompass ergonomic factors that reduce operator fatigue during extended use periods, while maintaining the structural integrity necessary for demanding professional environments. Customization possibilities include various barrel capacity options, specialized tip configurations for specific application requirements, and surface treatments optimized for particular chemical compatibility needs or sterilization protocols. Industries benefiting from these precision dosing capabilities span pharmaceutical research and development, analytical testing laboratories, food science applications, cosmetic formulation, specialty chemical processing, and advanced manufacturing operations where precise fluid control is paramount. The versatility of stainless steel construction enables effective deployment across temperature ranges and environmental conditions that would compromise alternative materials, supporting consistent performance in both controlled laboratory settings and challenging industrial environments. Quality consistency philosophy underlying the manufacturing approach emphasizes rigorous material selection, controlled production parameters, and comprehensive testing protocols that verify dimensional accuracy, surface quality, and functional performance before release to distribution channels. Export-oriented considerations include packaging designs that protect instrument integrity during international shipping while minimizing dimensional footprint for cost-effective logistics, alongside documentation and marking standards that facilitate customs clearance and regulatory compliance in diverse international markets. OEM and ODM cooperation opportunities enable customization of specifications, branding, and packaging configurations to meet specific distributor requirements or end-user applications, supporting flexible business relationships that adapt to evolving market demands and technical specifications. The collaborative approach to custom solutions encompasses engineering consultation for specialized applications, modification of standard designs to accommodate unique operational requirements, and development of application-specific accessories or complementary products that enhance overall system capability. Long-term supplier partnership potential is enhanced by consistent manufacturing quality, responsive technical support capabilities, and flexible production scheduling that accommodates varying order volumes and delivery requirements typical of international B2B relationships. Packaging and logistics compatibility considerations ensure these precision instruments reach international customers in optimal condition, with protective packaging systems designed to prevent damage during transit while maintaining cost-effectiveness for both individual orders and bulk shipments. The commitment to manufacturing excellence reflects extensive experience in precision instrument production, international quality standards compliance, and understanding of diverse market requirements that characterize successful cross-border commercial relationships in specialized equipment sectors.

Stainless Steel Syringe with Precision Dosing

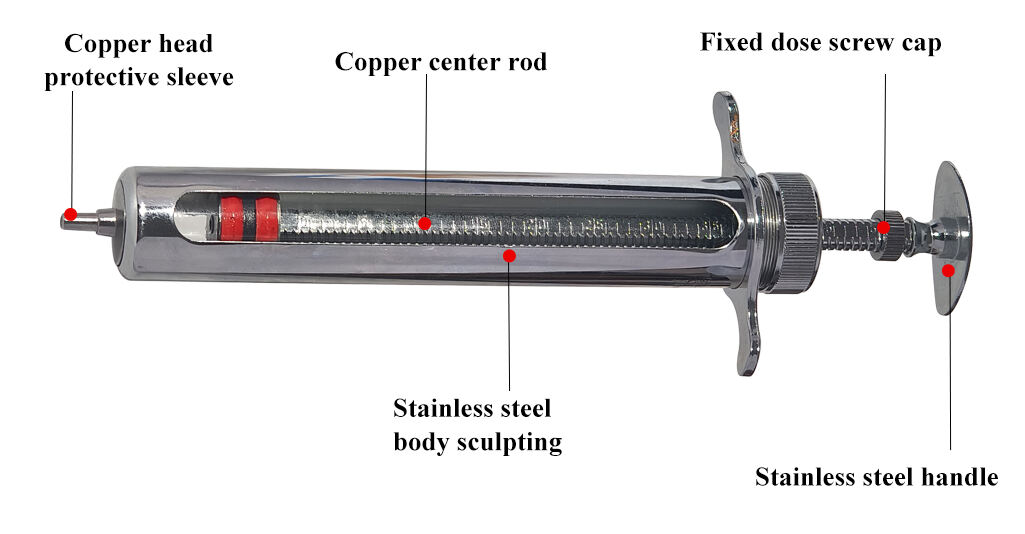

- Durable Material:Features a stainless - steel body, which is sturdy, resistant to impact and corrosion. It’s well - suited for complex farm environments, remains undamaged after long - term and high - frequency use, boasting a long service life.

- Precise Dosage Control:With clear scales, it allows for convenient and accurate dosage adjustment. Capable of meeting the needs of animals of different sizes (e.g., large doses for cattle and sheep, small doses for poultry), ensuring accurate drug administration and enhancing immunization effects.

- Reliable Sealing:Equipped with an excellent sealing design and supported by three - layer sealing rings. It neither jams drugs nor leaks air, reducing liquid waste and ensuring a stable injection process.

- Strong Versatility:Comes with a universal needle base, compatible with various needles. Multiple specifications (ranging from 5ml to 100ml, etc.) are available, meeting the requirements of different breeding scenarios for pigs, cattle, sheep, poultry, etc.

- Overview

- Details

- Details

- Recommended Products

Parameters

Name |

Veterinary syringe |

Material |

Metal/Plastic Steel |

Specification |

Metallic 10/20/30/50ML;Plastic steel 10/20/30/50/100ML |

Explanation |

After use,you need to loosen the cap and piston and wash it clean |

Features |

Not easy to break,simple structure,good air tightness,durable accurate dose |

Description

This high-quality metal syringe is crafted from durable, rust-resistant stainless steel, ensuring long-lasting use and easy cleaning for reliable veterinary performance. It features an adjustable dosage mechanism with a screw lock, allowing precise control over medication delivery tailored to each animal’s needs. Designed with an ergonomic handle, the syringe provides a comfortable grip, enabling quick and effortless operation during veterinary procedures. Ideal for pigs, cattle, sheep, and other livestock, this reusable animal syringe injector offers a cost-effective and versatile solution for various veterinary applications. Its simple and effective design ensures user-friendly operation, making it a preferred choice among veterinary professionals seeking convenience and efficiency. Whether for routine injections or precise dosing, this syringe delivers consistent results with ease, combining durability, accuracy, and comfort in one essential tool for animal healthcare.

Product Introduction Video

https://youtube.com/shorts/tKCNhDPoEsQ?si=I9jZYv9h0kv_Ra_l

Details

Details

|

High-quality materials High-quality glass material,inner rod brass material, enhance the service life! |

|

Exquisite craftsmanship Exquisite grinding process, every detail highlights noble quality |

|

|

Comfortable handle The handle is ergonomically designed for a comfortable grip |

|

Self-contained Screw lock Lock catch design, can adjust the required dose as needed |

|