Полы с высокой несущей способностью из BMC-пластика с решетчатыми секциями для свиноводства, для доращивания и отъемышей представляют революционное достижение в современной инфраструктуре свинарников, разработанной специально для удовлетворения жестких требований объектов интенсивного свиноводства на глобальных рынках. Эти специализированные напольные системы используют Bulk Molding Compound технология, термореактивный пластик, известный своей исключительной структурной целостностью и устойчивостью к суровым климатическим условиям, типичным для коммерческого свиноводства. Методология изготовления BMC включает сочетание рубленого стекловолокна с ненасыщенным полиэфирным связующим, создавая композитный материал, обеспечивающий превосходные несущие характеристики при одновременном поддержании оптимальной эффективности дренажа за счёт точно рассчитанного расстояния между прутьями и текстуры поверхности. Международные разработчики животноводческих объектов и дистрибьюторы сельскохозяйственного оборудования рассматривают такие напольные покрытия как ключевые компоненты для создания гигиеничных, эффективных и соответствующих нормам благополучия животных сред, способствующих оптимальной продуктивности животных на всех этапах производства — от выращивания молодняка до финишных операций и систем содержания маток. Передовой полимерный состав обеспечивает стабильную производительность при постоянном воздействии органических отходов, моющих химикатов и перепадов температур, характерных для современных свинокомплексов, что делает эти полы особенно ценными для экспортно-ориентированных ферм, стремящихся соблюдать международные стандарты благополучия животных. Производственные процессы для этих специализированных систем напольных покрытий включают передовые методы формования, позволяющие точно контролировать текстуру поверхности, схемы дренажа и размерные допуски, обеспечивая совместимость с существующей инфраструктурой помещений и повышенную функциональность по сравнению с традиционными альтернативами из бетона или стальных решёток. Естественная химическая стойкость материалов BMC позволяет этим полам выдерживать агрессивные процедуры дезинфекции без деградации, поддерживая комплексные меры биобезопасности, необходимые для профилактики заболеваний в коммерческом свиноводстве. При проектировании этих напольных систем учитываются различные факторы, включая оптимальную ширину прутьев для различных весовых категорий свиней, подходящее расстояние между просветами для предотвращения застревания копыт при эффективном удалении отходов, а также рисунок текстуры поверхности, обеспечивающий достаточное сцепление без дискомфорта для животных. Специалисты по планированию животноводческих объектов ценят универсальность таких полов при адаптации к различным планировкам помещений и системам вентиляции, поскольку лёгкая, но прочная конструкция обеспечивает гибкость монтажа и снижает нагрузку на несущие конструкции по сравнению с традиционными напольными материалами. Непроницаемая поверхность BMC-пластика исключает риск скопления бактерий внутри самого материала пола, способствуя улучшению общей гигиены объекта и снижению рисков передачи патогенов между группами животных. Стабильность качества является основополагающим принципом в производственной стратегии данных систем напольных покрытий, при этом установленные производственные протоколы гарантируют равномерные свойства материала и точность размеров при крупносерийных заказах, требуемых для коммерческих свинокомплексов. Команды по международным закупкам, оценивающие эти продукты для крупных сельскохозяйственных проектов, получают выгоду от стандартизированных производственных процессов, которые позволяют надёжно планировать проекты и прогнозировать стабильные эксплуатационные характеристики на множестве объектов. Возможности кастомизации выходят за рамки стандартных размерных вариаций и включают специальные виды обработки поверхности, схемы армирования и интеграционные решения, совместимые с конкретными системами вентиляции, оборудованием для удаления отходов и автоматическими системами кормления, часто используемыми в современных свиноводческих комплексах. Модульная концепция проектирования этих напольных систем обеспечивает эффективность транспортировки, хранения и монтажа — особо важные аспекты для международных проектов, где организация логистики и эффективность сборки на месте напрямую влияют на сроки и затраты реализации. Поставщики сельскохозяйственного оборудования, специализирующиеся на комплексных решениях для свиноводства, всё чаще включают эти передовые напольные системы в полные комплекты объектов, признавая их вклад в общую производительность и эксплуатационную эффективность. Долговечность конструкций из BMC-пластика даёт значительные преимущества с точки зрения потребностей в обслуживании и графиков замены, что влияет на расчёты общей стоимости владения в коммерческом свиноводстве. Естественная устойчивость материала к ударным повреждениям, химической деградации и термоциклам обеспечивает стабильную работу в течение длительного срока службы, поддерживая обоснование капитальных вложений для крупных сельскохозяйственных инфраструктурных проектов. Аспекты экспортной подготовки включают методы упаковки, защищающие прецизионные поверхности при международных перевозках и оптимизирующие использование контейнерного пространства, что способствует конкурентоспособности на глобальных рынках сельхозтехники. Возможности сотрудничества с производителями оригинального оборудования и инжиниринговыми компаниями, разрабатывающими комплексные решения для содержания свиней, выходят за рамки простой поставки продукции и включают технические консультации, услуги по индивидуальному проектированию и поддержку интегрированной оптимизации систем. Растущий акцент на устойчивые методы ведения сельского хозяйства усиливает интерес к этим полимерным напольным системам как альтернативе традиционным материалам, особенно на рынках, где оценка экологического воздействия влияет на утверждение проектов. Профессиональные процедуры монтажа этих напольных систем включают конкретные рекомендации по подготовке основания, требованиям к несущей конструкции и методам соединения, обеспечивающим оптимальную производительность и долговечность в сложных сельскохозяйственных условиях. Совместимость полов из BMC-пластика с автоматизированными системами мойки, оборудованием для удаления отходов и технологиями контроля микроклимата делает их особенно подходящими для высокотехнологичных свиноводческих хозяйств, стремящихся максимизировать эффективность и одновременно соблюдать стандарты благополучия животных, необходимые для выхода на международные рынки экспорта свинины.

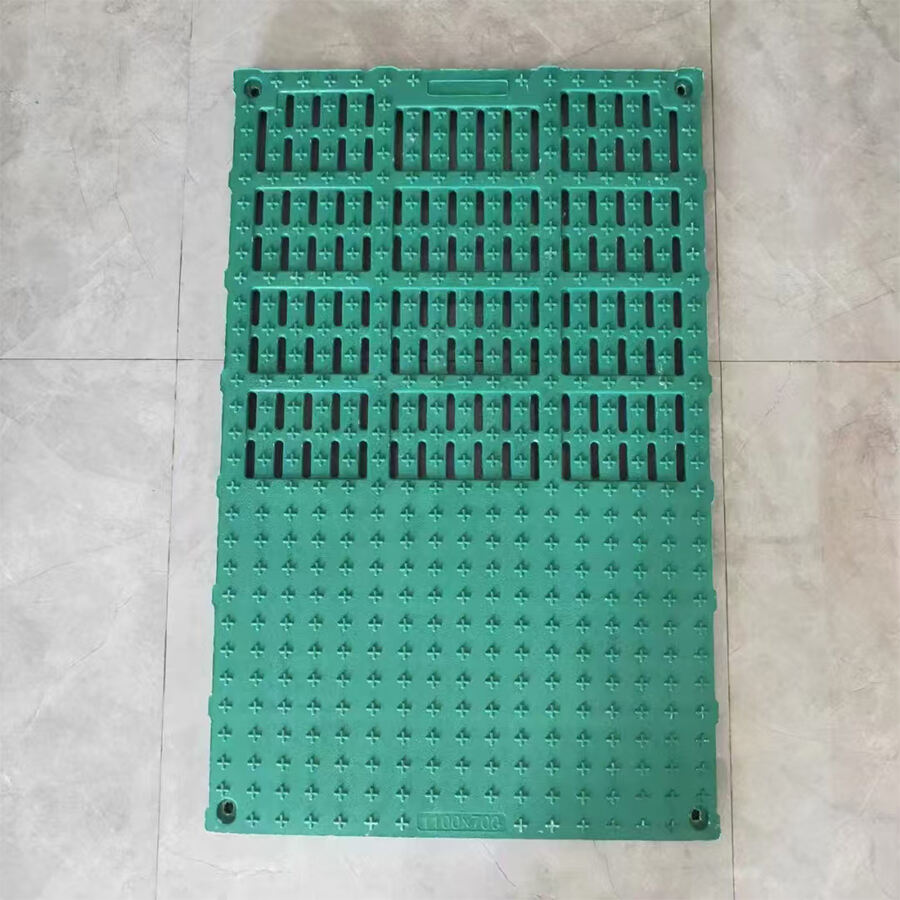

Полы с высокой несущей способностью из BMC-пластика с решетчатыми секциями для свиноводства, для доращивания и отъемышей

-

Высокая грузоподъемность – Изготовлен из высокопрочного материала BMC, подходит для маток, откормочных свиней и поросят-отъемышей без деформации или растрескивания.

-

Безопасная и комфортная конструкция для животных – Поверхность с противоскользящим покрытием и гладкие края снижают риск травм, обеспечивая комфорт и безопасность свиней.

-

Отличный дренаж и гигиена – Оптимизированный шаг решетчатых секций обеспечивает эффективное отделение навоза, улучшая чистоту и снижая риск заболеваний.

-

Прочный и устойчивый к коррозии – Влагостойкий и устойчивый к ржавчине и износу, идеален для длительного использования в тяжелых условиях фермы.

-

Простая установка и обслуживание – Конструкция с замковым соединением позволяет быстро собирать и легко очищать, повышая эффективность и биобезопасность фермы.

- Обзор

- Описание

- Детали

- Ключевые торговые точки

- Применение

- Рекомендуемые продукты

| Название продукта | Единица |

Вес Кг |

Размер Д*Ш*Толщина |

|

| 1,1 м | 45*110 Для поросят | Штук | 14.1 | 1100*450*35 мм |

| 50*110 Для поросят | Штук | 14.5 | 1100*500*40 мм | |

60*110 Для молодняка |

Штук | 19.9 | 1100*600*35 мм | |

| 60*110 Без протечек Для молодняка | Штук | 19.1 | 1100*600*35 мм | |

| 60*110 С полной протечкой (полная балка внутри) Для свиноматки | Штук | 23.4 | 1100*600*40 мм | |

| 60*110 полутечь (полный луч внутри) для свиноматки | Штук | 23.4 | 1100*600*40 мм | |

| 60*110 для откорма свиней, полная течь (полный луч внутри) | Штук | 23 | 1100*600*40 мм | |

| 70*110 полная течь (полный луч внутри) для свиноматки | Штук | 26.2 | 1100*700*40 мм | |

| 70*110 полутечь (полный луч внутри) для свиноматки | Штук | 26.2 | 1100*700*40 мм | |

| 1.2м | 45*120 для поросят | Штук | 15 | 1200*450*40 мм |

| 50*120 для поросят | Штук | 17.8 | 1200*500*40 мм | |

| 60*120 для растущих поросят | Штук | 21 | 1200*600*40 мм | |

| 60*120Для откормочных свиней Полностью проточная (Полная балка внутри) | Штук | 26.2 | 1200*600*40 мм | |

| 60*120Для откормочных свиней Полу-проточная (Полная балка внутри) | Штук | 26.4 | 1200*600*40 мм | |

| 70*120 Полностью проточная (Полная балка внутри) Для маток | Штук | 28.3 | 1200*700*40мм | |

| 70*120 Полу-проточная (Полная балка внутри) Для маток | Штук | 28.3 | 1200*700*40мм | |

| 1.5м | 60*150Для откормочных свиней (Полная балка внутри) | Штук | 32 | 1500*600*40мм |

| 2.4м | 45*240 Для поросят (Полная балка внутри) | Штук | 44 | 2400*450*70мм |

| 70*240 Для материнских свиней (Полная балка внутри) | Штук | 74 | 2400*700*70мм | |

| 3м | 60*300см для откорма свиней (полный брус внутри) | Штук | 99 | 3000*600*70мм |

| Электрическое отопление | Электрический подогреваемый пол 60*110см | Штук | 19.5 | 1100*600*35 мм |

| Электрический подогреваемый пол 60*110см - с бесступенчатым переключателем | Штук | 19.5 | 1100*600*35 мм | |

| Электрический подогреваемый пол 60*120см | Штук | 20 | 1200*600*40 мм | |

| Электрический подогреваемый пол 60*220см | Штук | 50 | 2200*600*70мм | |

| Электрический подогреваемый пол 60*240см | Штук | 60 | 2400*600*70мм |

Сертификат

Описание

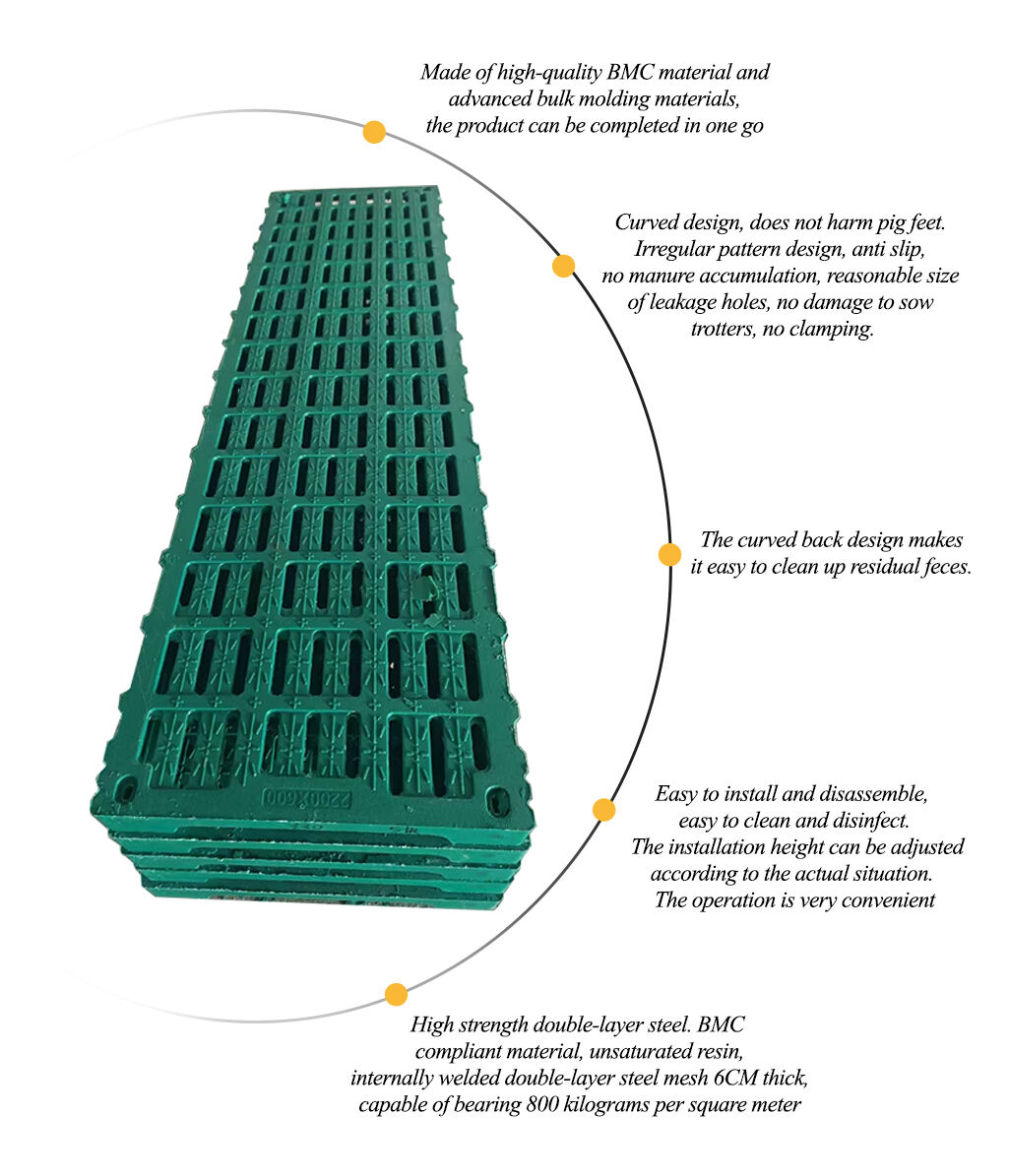

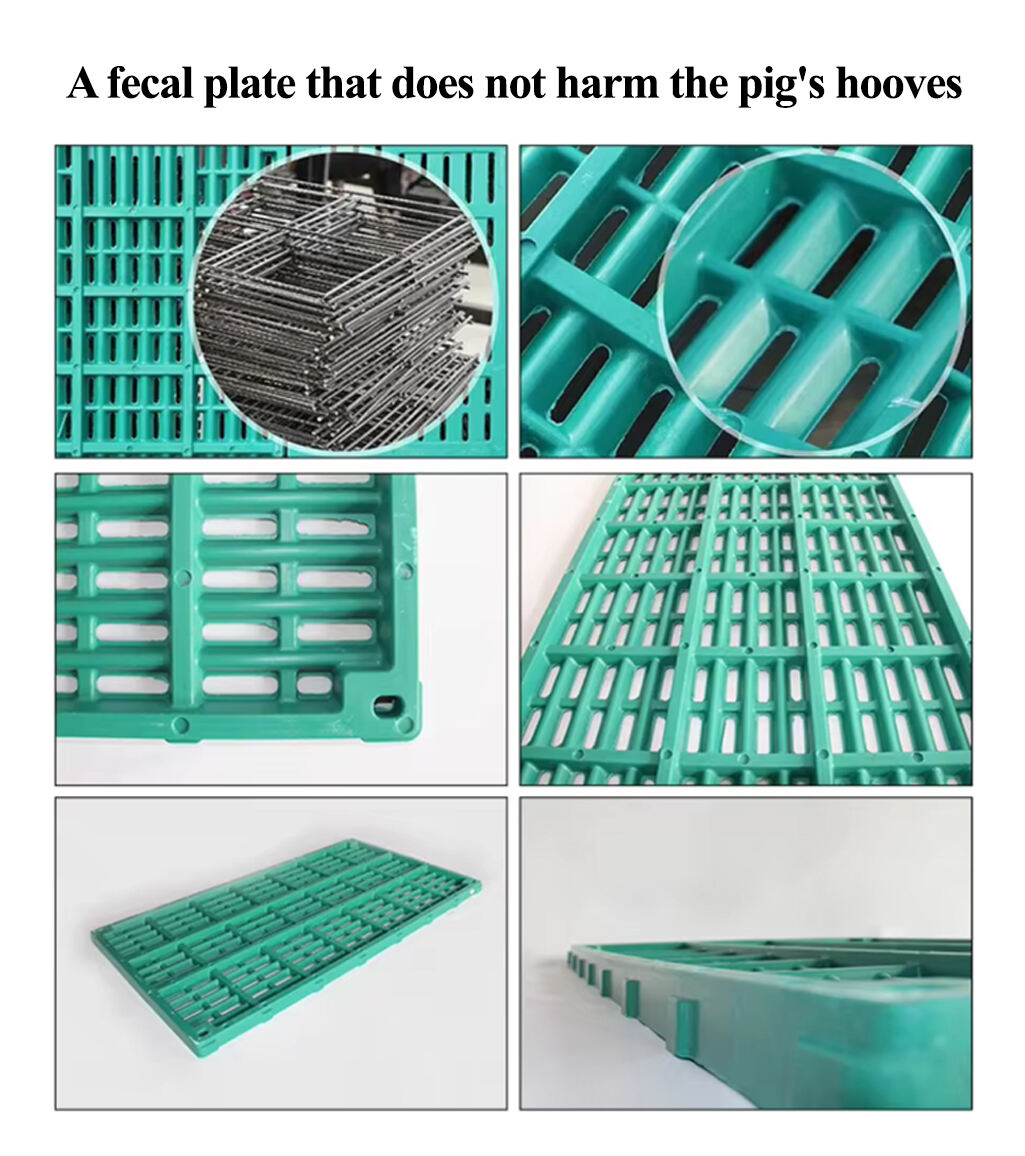

Полы с решетчатым покрытием BMC для свиней и коз изготавливаются из объемного формовочного состава (BMC) — готовой к использованию термореактивной полимерной композиции, армированной стекловолокном, которая в основном применяется при прессовании, литье под давлением и литье методом передачи. Решетки состоят из смолы, стирола, порошка карбоната кальция и светлого карбоната кальция, дополнительно армированных стекловолокном и сталью, в сочетании с передовыми синтетическими материалами, чтобы создать высокопрочный композит. Эта инновационная смесь обеспечивает превосходную прочность, долговечность и функциональность.

Ключевые особенности и преимущества :

-

Легкий вес и простая установка – Каждая решетка легкая и простая в транспортировке. Для установки достаточно закрепить только четыре угла, что экономит время и усилия.

-

Высокая грузоподъемность – Каждая плита выдерживает до 800 кг, отдельные решетки выдерживают 400 кг, обеспечивая долговечность для свиней или коз различных размеров.

-

Отличная вентиляция и гигиена – Решетки обеспечивают вентиляцию круглый год, снижая накопление тепла и микроорганизмов. Материал устойчив к износу, коррозии и поддерживает стабильную разницу температур между днем и ночью.

-

Дизайн, дружелюбный к животным – Углы отверстий в форме дуги защищают копыта свиней, а большие овальные отверстия обеспечивают эффективный сток отходов, минимизируя частоту уборки и затраты на рабочую силу

-

Антипригарная матовая поверхность – Рифленая поверхность повышает коэффициент трения, предотвращая скольжение и падения

-

Легкая очистка и снижение запаха – Эффективный сток отходов уменьшает запах, размножение мух и расход воды, создавая более чистую и здоровую среду для содержания скота

С решетки из композитного материала BMC являются идеальным выбором для современных свиноводческих и козоводческих ферм, сочетая прочность, гигиеничность и безопасность для животных с легкостью монтажа и обслуживания

Видео с презентацией продукта

https://youtube.com/shorts/GyQkWZ6sj9M?si=HnuJD4KmqKScjRBq

Детали

Ключевые торговые точки

|

ПОДХОДЯЩИЙ ШАГ ОТВЕРСТИЙ, ОТСУТСТВИЕ НАКОПЛЕНИЯ ЗАГРЯЗНЕНИЙ НА РЕШЕТКЕ Эллиптическое отверстие для удаления фекалий, легко чистится |

|

ПРОЧНАЯ СТАЛЬНАЯ СЕТКА, ВЫСОКАЯ НАГРУЗОКА Внутри имеется сварная утолщенная стальная сетка |

|

|

КОМПОЗИТНЫЙ МАТЕРИАЛ BMC ПРОЧНЫЙ И ДОЛГОВЕЧНЫЙ Высокая нагрузка, устойчивость к коррозии |

Применение