El Jeringa de Vacunación Continua Veterinaria 2/5ml con Dosis Ajustable representa un instrumento médico especializado diseñado específicamente para profesionales veterinarios que requieren una administración precisa, eficiente y confiable de vacunas en diversas poblaciones animales. Este sistema de jeringa profesional incorpora mecanismos avanzados de dosificación que permiten a los profesionales pasar sin problemas entre diferentes requisitos de dosis, manteniendo una precisión óptima y minimizando el desperdicio durante los procedimientos de vacunación. La filosofía de diseño para vacunación continua garantiza una gestión eficiente del flujo de trabajo en clínicas veterinarias, operaciones ganaderas y escenarios de vacunación en campo, donde la eficiencia de tiempo y la consistencia en la dosificación impactan directamente tanto en el bienestar animal como en la productividad operativa. Distribuidores internacionales de equipos veterinarios y profesionales de abastecimiento reconocen esta configuración particular de jeringa como una herramienta esencial para la práctica veterinaria moderna, donde la adaptabilidad entre distintos protocolos de vacunación y tamaños de animales exige instrumentación sofisticada pero fácil de usar. La funcionalidad de doble capacidad, que admite volúmenes de dos y cinco mililitros, ofrece una versatilidad excepcional, permitiendo a los equipos veterinarios manejar desde vacunaciones de animales de compañía pequeños hasta programas de inmunización de ganado más grande, sin necesidad de múltiples dispositivos especializados. La excelencia en la fabricación de sistemas de inyección veterinarios requiere una comprensión exhaustiva de las propiedades de materiales médicos, tolerancias de ingeniería de precisión y consideraciones ergonómicas que apoyan patrones de uso prolongado comunes en entornos veterinarios profesionales. El mecanismo de dosificación ajustable incorporado en este diseño de jeringa utiliza sistemas mecánicos sofisticados que aseguran una precisión constante en la entrega, al tiempo que proporciona una operación intuitiva para los profesionales veterinarios que trabajan en diversas condiciones de campo. Los tratamientos superficiales aplicados a los componentes de la jeringa resaltan la biocompatibilidad, resistencia química y protocolos de esterilización sencillos, esenciales para mantener adecuados estándares de control de infecciones durante ciclos repetidos de uso. La filosofía de calidad y consistencia que rige la producción de equipos de inyección veterinarios exige procesos rigurosos de selección de materiales, en los que cada componente se evalúa exhaustivamente en cuanto a durabilidad, inercia química y fiabilidad de rendimiento a largo plazo bajo diversas condiciones ambientales presentes en entornos de práctica veterinaria. La metodología de vacunación continua respaldada por este diseño de jeringa reduce significativamente el tiempo de manipulación entre animales individuales, minimizando así la exposición al estrés en ganado sensible y permitiendo a los equipos veterinarios mantener horarios de vacunación constantes en grandes poblaciones animales. Los proveedores profesionales de equipos veterinarios entienden que la implementación exitosa de programas de vacunación depende en gran medida de la fiabilidad del instrumental, ya que fallos en el equipo o un rendimiento inconsistente pueden comprometer estrategias completas de manejo de salud de rebaños y generar implicaciones económicas significativas para las operaciones agrícolas. Las consideraciones de diseño incluidas en este sistema de jeringa van más allá de la funcionalidad básica para abordar desafíos prácticos a los que se enfrentan los profesionales veterinarios en diversos entornos, desde hospitales veterinarios con control climático hasta ubicaciones exteriores en campo, donde el equipo debe funcionar de manera confiable a pesar de la exposición a temperaturas variables, niveles de humedad y posibles fuentes de contaminación. La capacidad de dosificación ajustable brinda a los profesionales veterinarios una flexibilidad sin precedentes en la gestión de protocolos de vacunación, permitiendo una rápida adaptación a diferentes formulaciones de vacunas, categorías de peso animal y requisitos específicos de inmunización, sin comprometer la precisión de la dosificación ni requerir cambios de equipo que consuman tiempo. La cooperación internacional dentro del sector de fabricación de equipos veterinarios ha establecido estándares de calidad exhaustivos que rigen el desarrollo y la producción de instrumentos médicos de precisión, asegurando que productos como esta jeringa de vacunación cumplan criterios estrictos de rendimiento necesarios para su distribución global y cumplimiento regulatorio en diversos mercados internacionales. Consideraciones de manipulación orientadas a la exportación, incorporadas en todo el proceso de fabricación, abordan los complejos requisitos logísticos asociados con la distribución internacional de equipos veterinarios, donde los productos deben mantener su integridad y características de rendimiento durante largos períodos de envío y diversas condiciones de almacenamiento encontradas en la gestión de cadenas de suministro globales. Las oportunidades de colaboración en personalización disponibles a través de fabricantes consolidados de equipos veterinarios permiten a distribuidores y usuarios finales especificar requisitos particulares de configuración, tratamientos superficiales u opciones de embalaje que se alineen con preferencias regionales específicas, requisitos regulatorios u protocolos operativos predominantes en diferentes mercados veterinarios internacionales. La metodología de construcción robusta empleada en la producción de jeringas veterinarias de vacunación continua enfatiza la durabilidad del material y la fiabilidad mecánica esenciales para soportar patrones de uso intensivo comunes en aplicaciones veterinarias comerciales, donde el equipo debe funcionar consistentemente bajo condiciones exigentes, manteniendo una precisión exacta en la dosificación durante períodos operativos prolongados. Las expectativas de cooperación a largo plazo dentro del sector de equipos veterinarios se centran en establecer asociaciones confiables que apoyen la disponibilidad continua de productos, servicios de asistencia técnica y posibles futuras necesidades de personalización, a medida que las metodologías de práctica veterinaria evolucionan en respuesta a las avanzadas estrategias de manejo de salud animal. La experiencia acumulada en la fabricación extensiva de instrumentos médicos veterinarios proporciona la base para comprender los requisitos matizados que distinguen al equipo profesional de alta gama de las alternativas básicas, asegurando que los productos ofrezcan la consistencia de rendimiento y fiabilidad operativa exigidas por los profesionales veterinarios en todo el mundo.

Jeringa de Vacunación Continua Veterinaria 2/5ml con Dosis Ajustable

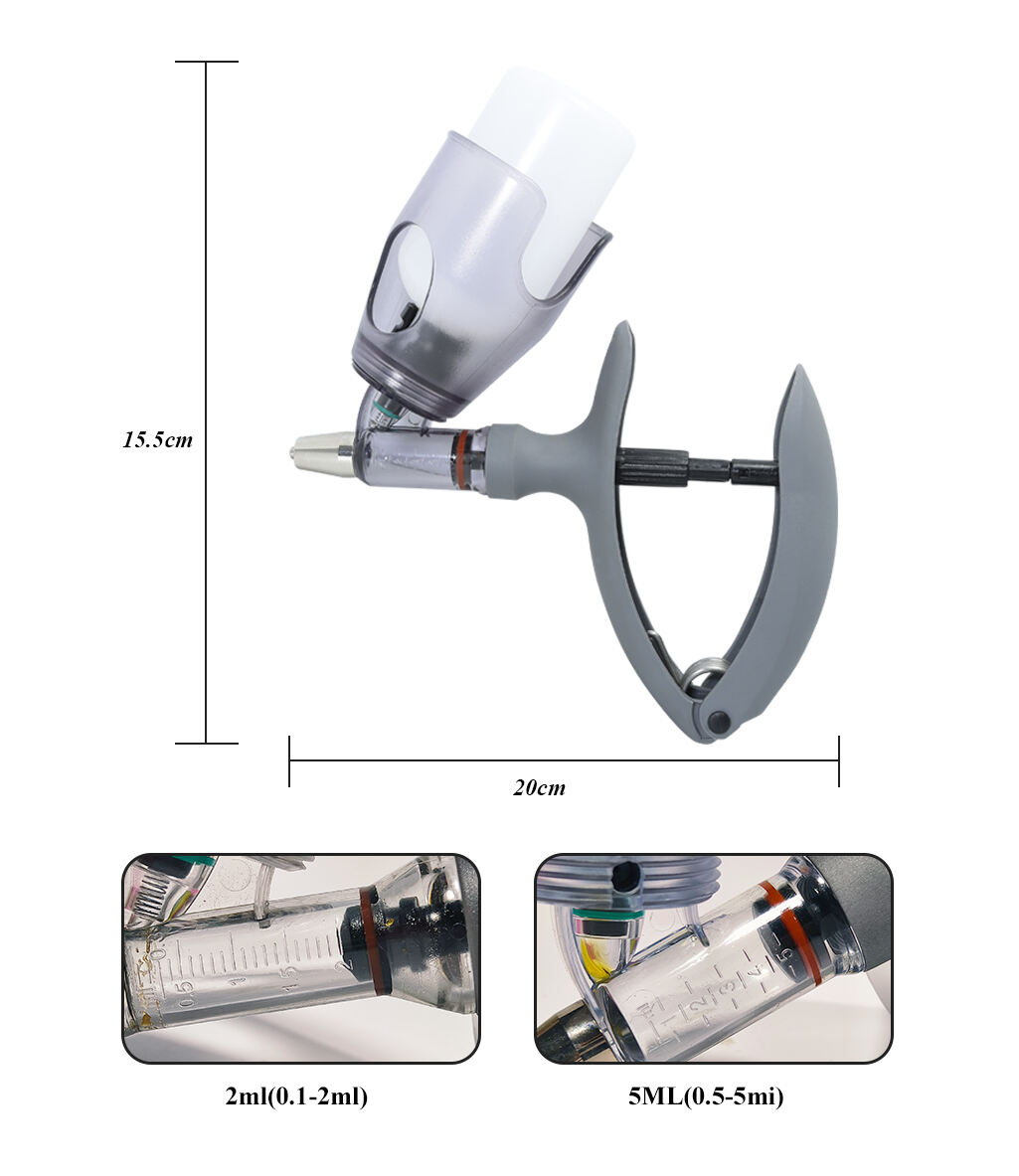

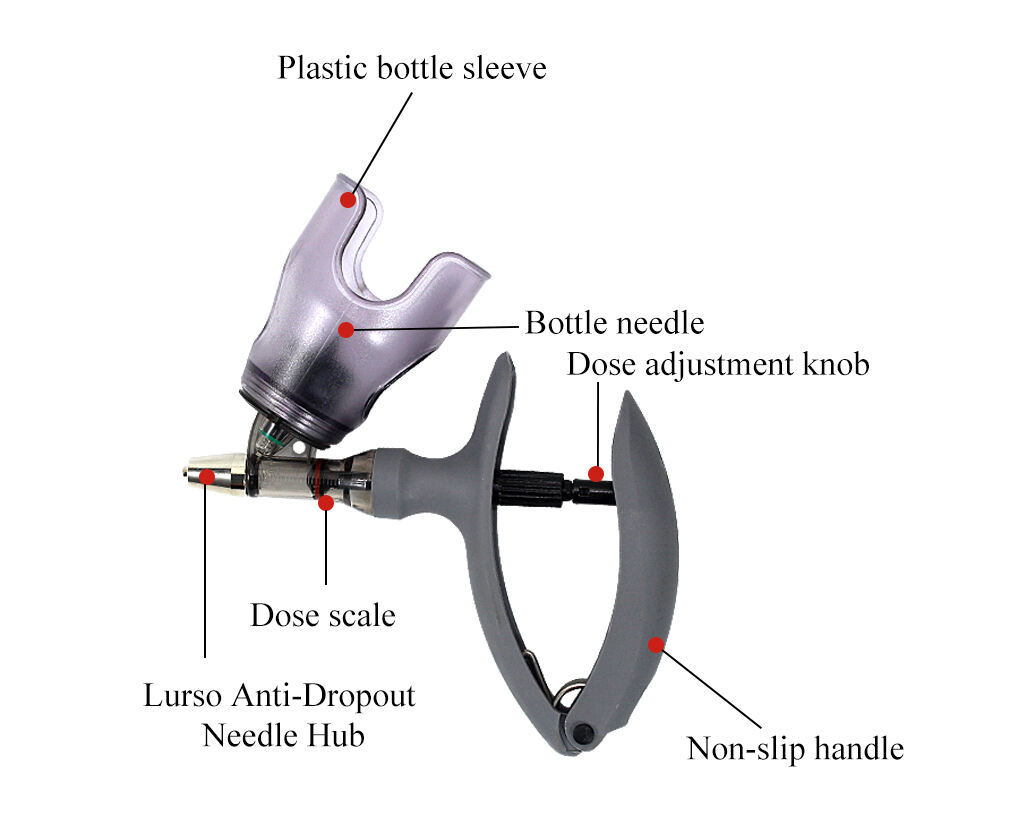

- Control preciso de la dosis : Marcas de escala claras permiten un control preciso de la dosis, asegurando una administración uniforme del medicamento (1 ml, 2 ml, 5 ml).

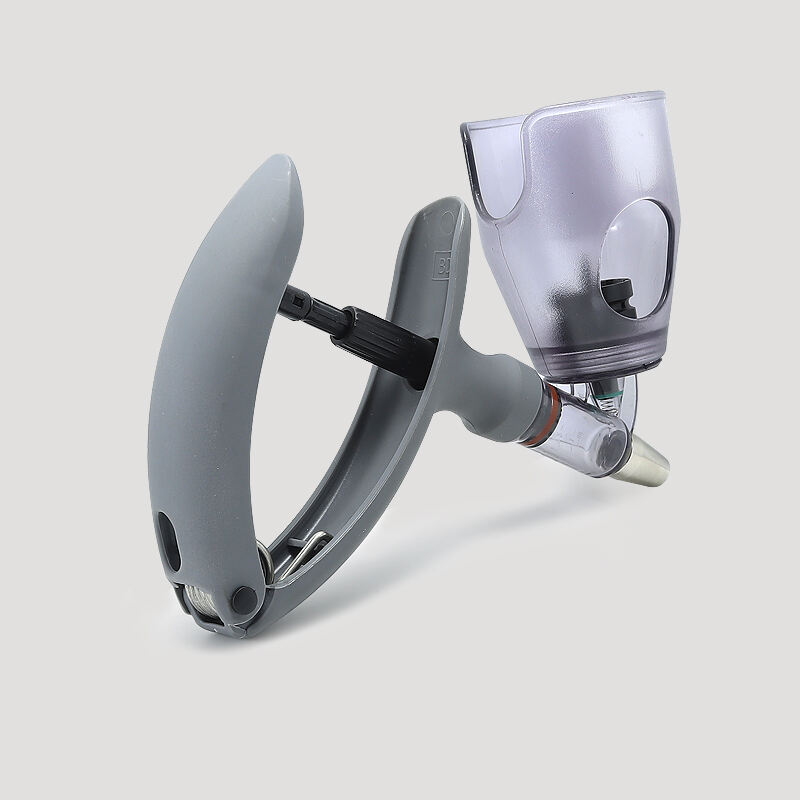

- Operación cómoda : El mango ergonómico ofrece un agarre cómodo. Es fácil de presionar y se puede operar con una mano, simplificando el proceso de inyección.

- MATERIAL SEGURO : Fabricado con materiales de grado médico, no tóxicos y sin olor, resistente a la corrosión y duradero, asegurando la seguridad en el uso y la vida útil del dispositivo.

-

Buen sellado : Conexión ajustada, no es fácil que gotee, asegurando la utilización efectiva del medicamento líquido, reduciendo el desperdicio y mejorando la eficiencia de la inyección.

Amplia Aplicación: Adecuado para diversos escenarios, como alimentación de mascotas, inyección experimental, etc., satisfaciendo diferentes necesidades de inyección de líquidos

- Descripción general

- Tamaño

- Detalles

- Puntos de venta clave

- Productos recomendados

Información de Parámetros del Producto

| Nombre del producto | Jeringa veterinaria para vacunas |

| Aplicación | Pollo Etc. Animal |

| Material | pP+Vidrio |

| Capacidad | 2/5ml |

| Característica | Uso prolongado y continuo |

| MOQ | 100 PCS |

Descripción

Esta funda para frasco de vacuna está diseñada para ser resistente y duradera, asegurando que el frasco de vacuna permanezca fijado de manera segura durante su uso. Cuenta con un orificio de ventilación conectado al pasador, lo que permite que el líquido fluya suavemente hacia el tubo graduado, garantizando dosis consistentes. El portapinzas con bloqueo Luer asegura la aguja en su lugar, mientras que el anillo de goma integrado evita fugas y garantiza un sellado hermético. Un dispositivo de flujo inverso aísla el contenido del aire exterior, asegurando una absorción completa y segura del líquido. El tubo de inyección ámbar ayuda a reducir el impacto de la luz ultravioleta sobre la vacuna, protegiendo su efectividad, y es compatible con frascos de medicamento de 50 ml y 100 ml. Fabricado con una estructura precisa, este inyector ofrece dosis exactas, una absorción suave del líquido y una sensación cómoda al manejarlo. Ligero y fácil de operar, es la herramienta ideal para una administración de vacunas confiable y eficiente.

Vídeo de Introducción del Producto

https://youtube.com/shorts/aUi3y2g8u2w?si=ulIKlYY1gENLcEOs

Certificado

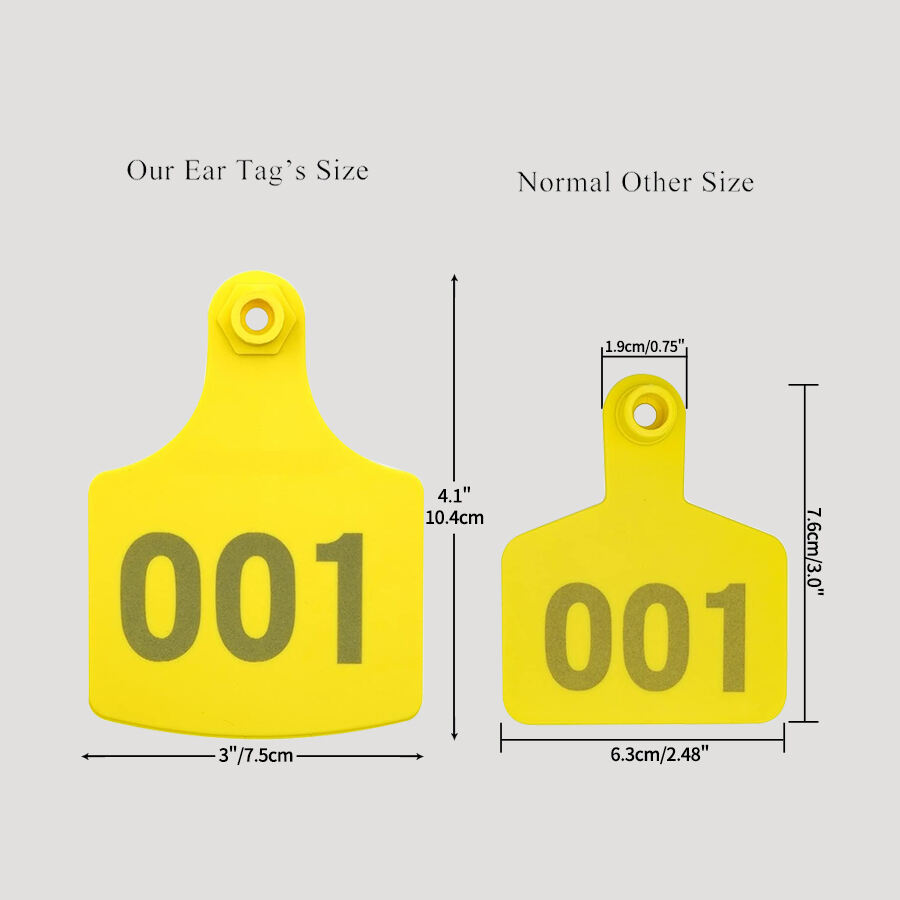

Tamaño

Detalles

Puntos de venta clave

|

La escala de inyección es clara y fácil de observar; Escala precisa, pequeño error de inyección |

|

Diseño de bloqueo Luer en la aguja del asiento, la aguja no se desprende fácilmente |

|

|

Adopta un dispositivo anti-retorno para aislar eficazmente el aire exterior, Asegúrese de que todo el líquido sea inyectado |

|

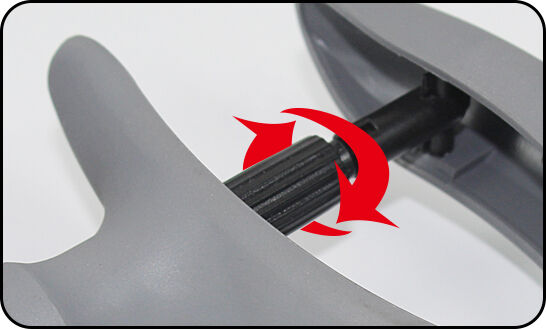

Gire para ajustar la escala de dosis de inyección requerida |

|

|

Mango antideslizante y cómodo, diseño ergonómico ahorro de esfuerzo y fácil de empujar durante mucho tiempo sin cansarse |