La Dosificador automático para cerdos de doble cara/una sola cara en acero inoxidable representa una solución sofisticada para operaciones modernas de producción porcina, combinando una construcción metálica duradera con mecanismos inteligentes de alimentación para optimizar la gestión nutricional del ganado y la eficiencia operativa. Este sistema innovador de alimentación responde a las demandas en evolución de instalaciones comerciales de cría de cerdos, operaciones de reproducción y empresas agrícolas que buscan mejorar sus prácticas de manejo animal mediante tecnología automatizada. El diseño de doble configuración del comedero ofrece una versatilidad notable, permitiendo a los operarios de granjas elegir entre acceso doble para escenarios de alimentación de alta capacidad o configuraciones de un solo lado para diseños especializados de corrales y entornos con limitaciones de espacio. La construcción premium en acero inoxidable forma la base de este sistema de alimentación, ofreciendo una resistencia excepcional a la corrosión, la humedad y las condiciones ambientales adversas comúnmente encontradas en instalaciones ganaderas, manteniendo al mismo tiempo estándares de seguridad alimentaria esenciales para aplicaciones de nutrición animal. El mecanismo de alimentación automática se integra perfectamente con el robusto marco metálico, proporcionando un control constante de las raciones y reduciendo los requisitos de mano de obra asociados con rutinas manuales de alimentación, lo que permite a los operadores de granjas asignar los recursos humanos de manera más eficaz en sus operaciones. Los procesos de fabricación de estos sistemas de alimentación enfatizan la ingeniería de precisión y la consistencia de calidad, incorporando técnicas avanzadas de soldadura y tratamientos de acabado superficial que mejoran tanto la durabilidad como el mantenimiento de la higiene. Las superficies de acero inoxidable pasan por tratamientos especializados para crear acabados lisos y no porosos que resisten la acumulación bacteriana y facilitan protocolos de limpieza exhaustivos, apoyando estándares óptimos de saneamiento en entornos ganaderos comerciales. Las consideraciones de diseño abarcan múltiples factores operativos, incluyendo mecanismos de alimentación ajustables que se adaptan a diferentes tamaños de cerdos y requisitos alimenticios, sistemas de sellado resistentes a las inclemencias del tiempo que protegen los componentes internos de la exposición ambiental, y puntos de acceso ergonómicos que simplifican los procedimientos de mantenimiento y monitoreo para el personal de la granja. La configuración estructural del comedero permite su instalación tanto en interiores dentro de instalaciones climatizadas como en exteriores en entornos tradicionales de corrales, demostrando una adaptabilidad notable en diversos escenarios de cultivo y condiciones geográficas. Las posibilidades de personalización funcional van más allá de las operaciones básicas de alimentación, e incluyen modificaciones especializadas para razas específicas de cerdos, integración con sistemas existentes de gestión de granjas y compatibilidad con varios tipos de alimento, incluyendo pellets, mezclas de granos y suplementos nutricionales especializados. La ingeniería de precisión del mecanismo de alimentación permite una distribución uniforme de raciones mientras minimiza el desperdicio de alimento, contribuyendo a una mayor eficiencia de costos y sostenibilidad ambiental en las operaciones ganaderas. La filosofía de consistencia de calidad guía todos los aspectos de la fabricación, desde la selección inicial de materiales hasta el ensamblaje final y los procedimientos de prueba, asegurando que cada sistema de alimentación cumpla con rigurosos estándares de rendimiento y expectativas de fiabilidad operativa. La experiencia en cooperación internacional demuestra un profundo conocimiento de diversas prácticas agrícolas y requisitos regulatorios en diferentes mercados, permitiendo una integración perfecta con operaciones de granjas existentes independientemente de la ubicación geográfica o las preferencias operativas locales. Las consideraciones orientadas a la exportación incluyen sistemas de embalaje protectores diseñados para prevenir daños durante el envío internacional, paquetes documentales completos que facilitan los trámites de aduana y guías de instalación multilingües que respaldan escenarios de despliegue global. La filosofía de diseño modular del comedero apoya enfoques escalables de instalación, permitiendo a los operadores de granjas implementar sistemas de alimentación gradualmente según sus patrones de crecimiento operativo y ciclos de planificación de inversiones. Las oportunidades de colaboración con distribuidores agrícolas, proveedores de equipos para granjas y desarrolladores de instalaciones ganaderas crean redes de soporte integrales que van más allá de la entrega inicial del producto para incluir asistencia técnica continua y servicios de optimización operativa. Los marcos de cooperación OEM y ODM permiten la personalización de los sistemas de alimentación según requisitos específicos de clientes, incorporando elementos de marca, configuraciones especializadas e integración con tecnologías propietarias de gestión de granjas. Los tratamientos superficiales aplicados a los componentes de acero inoxidable incluyen pulido, pasivación y aplicaciones de recubrimientos protectores que mejoran tanto la estética como el rendimiento funcional, mientras que acabados especiales en los bordes eliminan superficies afiladas que podrían representar riesgos de seguridad para el ganado o el personal de la granja. El mecanismo de alimentación automática incorpora componentes resistentes a las condiciones meteorológicas, diseñados para mantener un funcionamiento constante a través de variaciones estacionales y condiciones ambientales difíciles, respaldado por sistemas de drenaje que evitan la acumulación de agua y características de ventilación que promueven la circulación de aire. Las consideraciones de compatibilidad con embalaje y logística incluyen configuraciones compactas de envío que optimizan la utilización de contenedores, materiales de embalaje estandarizados que facilitan los procedimientos de manipulación y una organización integral de componentes que agiliza los procesos de instalación para los usuarios finales. Las expectativas de cooperación a largo plazo con proveedores se centran en establecer relaciones comerciales sostenibles que apoyen el desarrollo continuo de productos, la innovación técnica y las iniciativas de expansión de mercado, manteniendo al mismo tiempo estándares de calidad constantes y capacidades de servicio al cliente ágiles que respondan a los requisitos cambiantes de la industria agrícola y las oportunidades de avance tecnológico.

Dosificador automático para cerdos de doble cara/una sola cara en acero inoxidable

-

Duradero e Higiénico : Fabricado en acero inoxidable de alta calidad, resistente a la corrosión y fácil de limpiar.

-

Alimentación automática : Alimentación precisa y con bajo desperdicio, con ajuste regulable del caudal.

-

Diseño versátil : Disponible en opciones de doble cara o una sola cara, para un uso flexible en la granja.

-

Ahorrador de mano de obra : Reduce los esfuerzos de alimentación manual y garantiza una nutrición constante.

-

Construcción de alta resistencia : Diseñado para durar en entornos ganaderos exigentes, con consumo mínimo de energía.

- Descripción general

- Tamaño

- Detalles

- Productos recomendados

Descripción

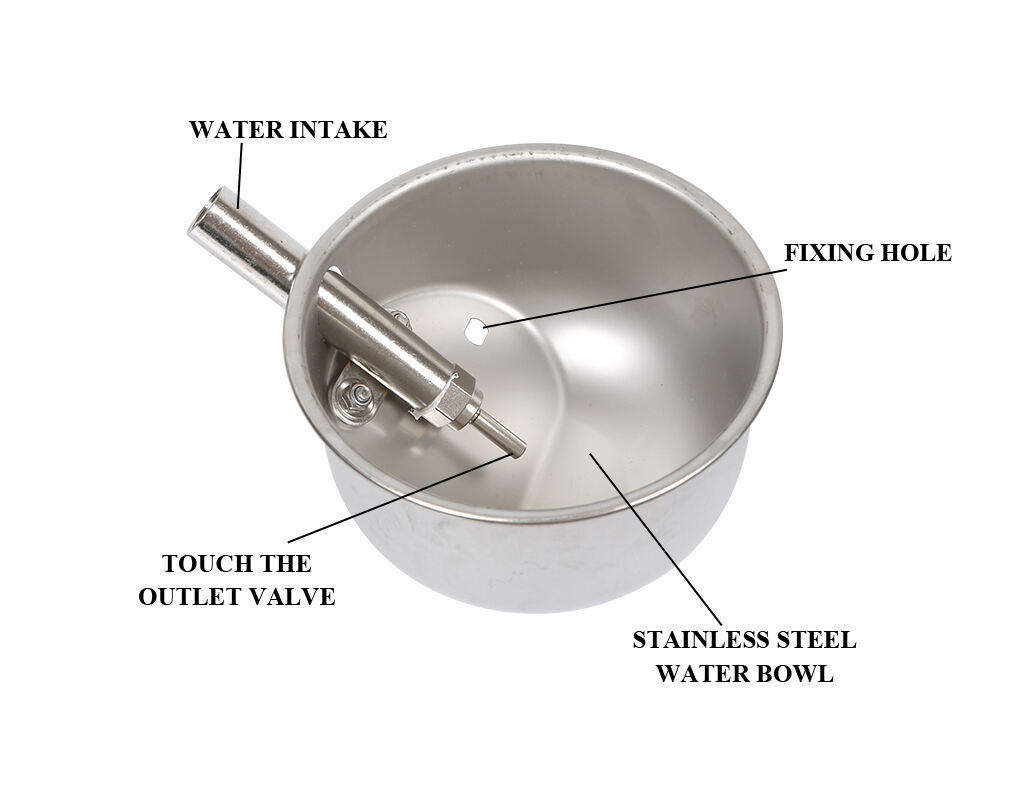

El bebedero automático para cerdos de acero inoxidable ofrece una solución duradera y eficiente para el abastecimiento de agua a cerdos y otros animales. Fabricado con acero inoxidable de alta calidad, este bebedero es resistente a la oxidación, a la corrosión y está construido para durar, garantizando un rendimiento confiable incluso en entornos exigentes de granja.

Equipado con un nipple de agua de 1/2", el sistema funciona automáticamente: cuando el hocico de un cerdo toca el nipple, el agua fresca fluye y se detiene una vez que el hocico es retirado. Esto garantiza que sus animales siempre tengan acceso a agua limpia y fresca, eliminando la necesidad de rellenado constante y reduciendo el desperdicio de agua.

El bebedero está diseñado para una instalación sencilla, conectándose a una manguera de agua de 1/2 pulgada (aproximadamente 20 mm de diámetro) y cuenta con dos orificios preperforados para una fijación segura a la pared (tornillos no incluidos).

Con bordes redondeados lisos de 360 grados, ofrece una bebida segura y sin riesgo de lesiones para los cerdos. Mide 8,3 pulgadas de diámetro, 10,6 pulgadas de altura y 5,5 pulgadas de profundidad, lo que lo hace del tamaño perfecto para uso diario en la granja.

Este práctico y ahorrador de agua comedero para cerdos facilita el cuidado animal, manteniendo mayor limpieza y eficiencia, proporcionando una solución ideal para la moderna cría de cerdos.

Certificado

Tamaño

Detalles

|

Calidad de Materiales Excelente Hecho de acero inoxidable de alta calidad material, resistente y duradero, no es fácil de oxidar, puede garantizar eficazmente la seguridad del agua potable de los cerdos y evitar riesgos para la salud causados por la oxidación del equipo de agua potable. causados por la oxidación del equipo de agua potable. |

|

Diseño científico El diseño único en forma de cuenco se adapta a los hábitos de bebida de los cerdos, facilitando que beban agua, reduciendo salpicadura de agua, manteniendo el establo de cerdos seco y limpio, y reduciendo el riesgo de enfermedades. |

|

|

Tamaño adecuado Hay diversas especificaciones, como un diámetro de 8,3 pulgadas (21 cm), que son adecuadas para cerdos en diferentes etapas de crecimiento y satisfacen diversas necesidades de cría. |

|

Fácil de Limpiar La superficie lisa no facilita la adherencia de suciedad, es fácil de limpiar, puede reducir eficazmente el crecimiento bacteriano, y proporcionar un ambiente de bebida limpio y higiénico para los cerdos. |

|