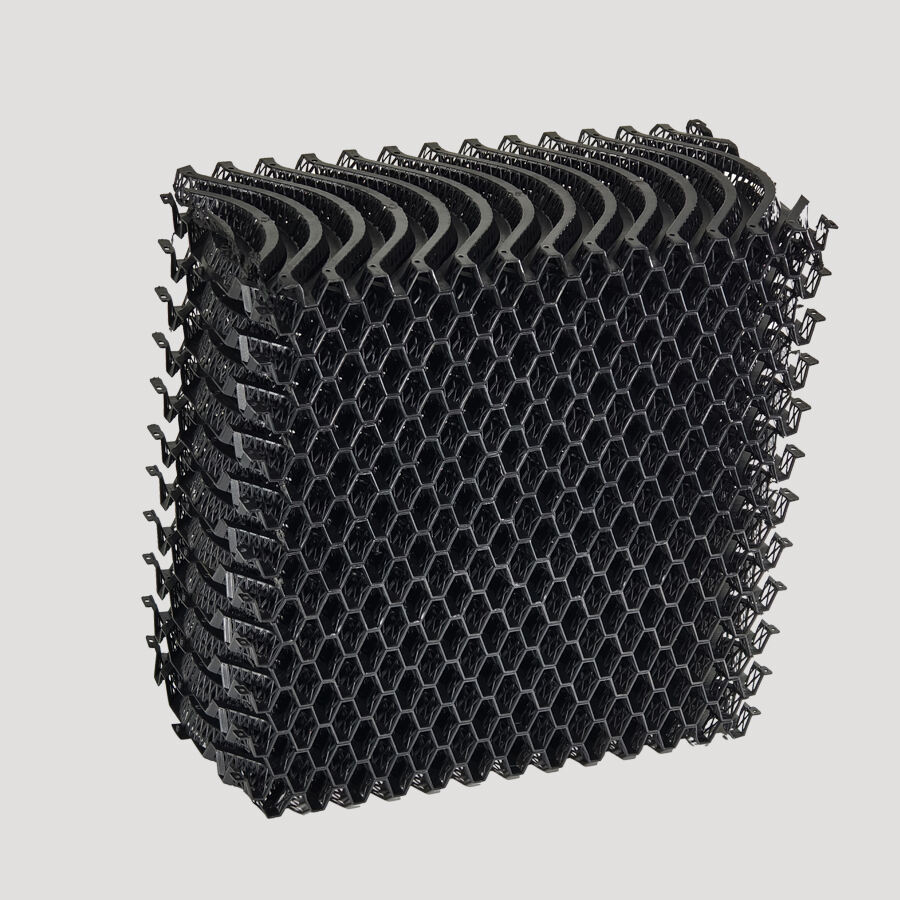

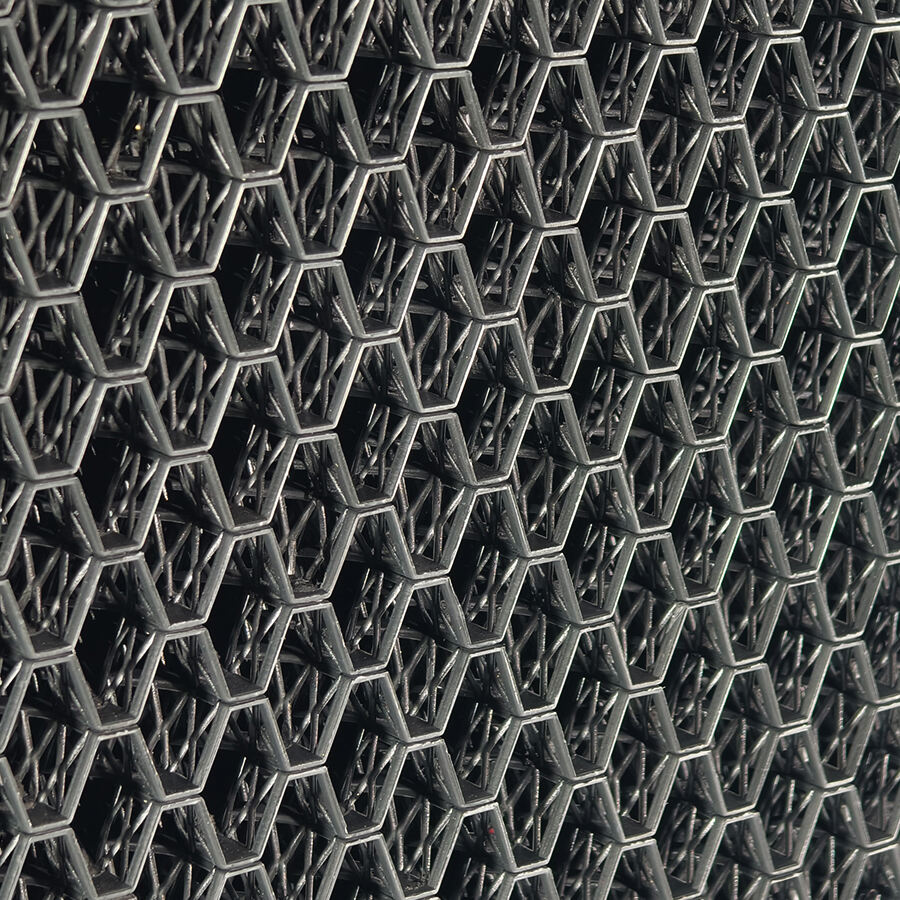

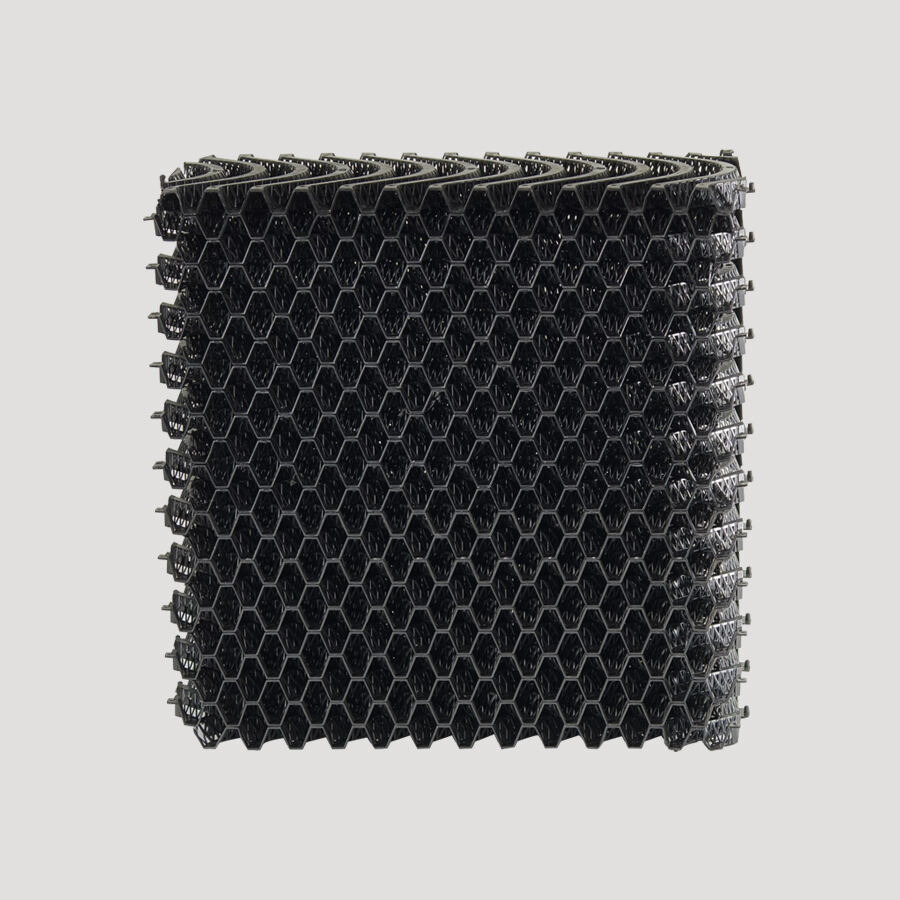

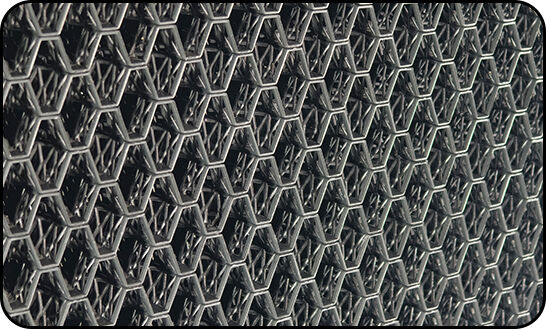

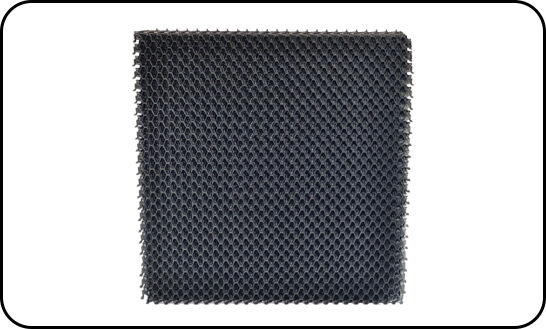

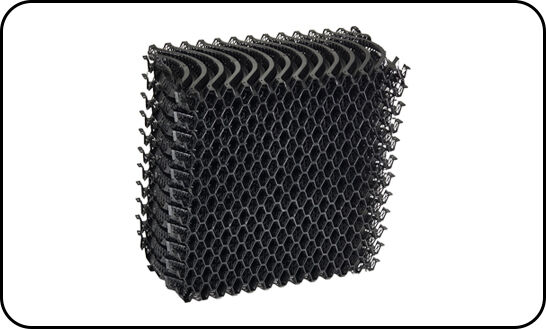

El PP Fill Contracorriente Malla Plástica Negra Anti-UV Relleno Red de Infill para Aviarios y Porcinos Alfombrillas Refrigerantes Corte Personalizado representa una solución sofisticada de ventilación agrícola diseñada específicamente para operaciones modernas de ganadería que buscan un control ambiental mejorado en instalaciones para aves de corral y porcinos. Este sistema especializado de paneles de enfriamiento utiliza una construcción de polipropileno de alta calidad combinada con tecnología avanzada de estabilización contra los rayos ultravioleta, ofreciendo una durabilidad y consistencia de rendimiento excepcionales en diversas condiciones climáticas y entornos operativos. La filosofía de diseño contracorriente inherente a esta configuración de relleno en malla optimiza los patrones de circulación de aire manteniendo la integridad estructural frente a la exposición continua a la humedad y las fluctuaciones térmicas comunes en entornos intensivos de producción ganadera. Los equipos internacionales de aprovisionamiento y distribuidores de equipos agrícolas reconocen esta categoría de producto como infraestructura esencial para mantener condiciones óptimas de crecimiento en granjas avícolas comerciales, establos de cerdos e instalaciones mixtas de ganado, donde la gestión precisa del entorno está directamente relacionada con la eficiencia productiva y los estándares de bienestar animal. La construcción en malla plástica negra proporciona propiedades superiores de filtrado de luz, mientras que el diseño especializado del relleno asegura una superficie de contacto máxima entre el aire en circulación y el medio de enfriamiento por evaporación, creando un mecanismo eficiente de intercambio térmico que reduce significativamente las temperaturas ambiente dentro de estructuras confinadas para animales. Los procesos de fabricación de estos componentes de enfriamiento agrícola implican técnicas precisas de extrusión y tejido que crean patrones uniformes de malla con relaciones constantes de huecos, garantizando características predecibles de flujo de aire y un rendimiento fiable durante períodos operativos prolongados. La formulación anti-UV integrada en toda la matriz de polipropileno ofrece protección esencial contra la degradación solar, evitando la fragilidad del material y manteniendo la estabilidad estructural incluso cuando se expone a intensas condiciones de luz solar típicas de instalaciones agrícolas al aire libre. Las capacidades de corte personalizado representan un diferenciador clave para profesionales de compras que buscan soluciones adaptadas a dimensiones específicas de instalaciones y requisitos de montaje, sin comprometer el rendimiento del sistema ni generar desperdicios excesivos de material durante la implementación. Esta flexibilidad de personalización va más allá de simples modificaciones dimensionales e incluye tratamientos especiales de bordes, configuraciones de montaje y compatibilidad de integración con infraestructuras de ventilación existentes comunes en operaciones ganaderas establecidas. La consistencia de calidad durante los procesos de fabricación asegura que cada sección cortada a medida mantenga características de rendimiento idénticas, independientemente de las dimensiones finales o configuraciones geométricas especificadas por los usuarios finales o contratistas de instalación. La arquitectura del relleno en malla facilita patrones óptimos de distribución de agua al integrarse con sistemas de riego por aspersión o goteo, creando superficies mojadas uniformes que maximizan la eficiencia del enfriamiento por evaporación, minimizando al mismo tiempo el consumo de agua y reduciendo los costos operativos asociados al control climático en instalaciones ganaderas. Las consideraciones de diseño para este sistema de paneles de enfriamiento incluyen compatibilidad con sistemas automatizados de control ambiental, permitiendo una integración perfecta con la infraestructura HVAC existente y capacidades de monitoreo remoto, cada vez más demandadas por las operaciones agrícolas modernas. Las aplicaciones de tratamiento superficial durante la fabricación potencian las propiedades naturales de absorción de agua del sustrato de polipropileno, manteniendo al mismo tiempo la resistencia química frente a desinfectantes comunes y agentes de limpieza utilizados en protocolos de saneamiento ganadero. Compradores internacionales y distribuidores regionales valoran el enfoque de embalaje orientado a la exportación, que garantiza la integridad del producto durante envíos prolongados y facilita un manejo eficiente a través de redes logísticas complejas que abarcan múltiples zonas horarias y entornos regulatorios. La configuración contracorriente aborda específicamente los desafíos asociados con la distribución uniforme del aire en instalaciones de gran tamaño, donde el control constante de la temperatura en amplias áreas de piso resulta crítico para mantener condiciones óptimas de producción y evitar puntos calientes localizados que puedan afectar negativamente el confort y el rendimiento animal. Las oportunidades de colaboración con socios OEM y proveedores de soluciones personalizadas permiten adaptar las especificaciones principales del producto para satisfacer requisitos regionales únicos, consideraciones climáticas y prácticas específicas de manejo ganadero prevalentes en diferentes mercados internacionales. La pigmentación negra cumple funciones dobles: proporciona protección UV y minimiza el crecimiento de algas en aplicaciones de enfriamiento húmedo, reduciendo los requisitos de mantenimiento y extendiendo la vida útil en comparación con alternativas sin pigmentar comúnmente disponibles en mercados agrícolas. La experiencia acumulada en fabricación mediante una amplia cooperación internacional ha perfeccionado las técnicas de producción para asegurar estabilidad dimensional bajo condiciones variables de humedad y ciclos térmicos, características especialmente valoradas por equipos de compras responsables de la planificación a largo plazo de instalaciones y la gestión del ciclo de vida de equipos. Las consideraciones de embalaje para distribución global incorporan medidas protectoras contra la entrada de humedad y daños mecánicos durante el transporte, al tiempo que mantienen una utilización eficiente del espacio en contenedores de carga y almacenes. La construcción en malla plástica ofrece ventajas significativas frente a medios de enfriamiento tradicionales, incluyendo resistencia a la degradación biológica, compatibilidad con protocolos estándar de limpieza y menor riesgo de incendio en comparación con alternativas de fibra orgánica históricamente utilizadas en aplicaciones de ventilación agrícola. La flexibilidad de instalación inherente al enfoque de corte personalizado permite a los diseñadores de instalaciones optimizar la colocación de los paneles de enfriamiento para obtener la máxima eficiencia, adaptándose al mismo tiempo a limitaciones arquitectónicas y configuraciones de equipos existentes dentro de estructuras ganaderas ya establecidas. Las expectativas de cooperación a largo plazo con proveedores se centran en mantener una calidad de producto constante, disponibilidad fiable y soporte técnico ágil durante todo el ciclo de vida del producto, asegurando que las operaciones agrícolas puedan depender de un rendimiento ininterrumpido de sus sistemas de control ambiental, independientemente de las fluctuaciones de demanda estacional o requisitos inesperados de mantenimiento.

PP Fill Contracorriente Malla Plástica Negra Anti-UV Relleno Red de Infill para Aviarios y Porcinos Alfombrillas Refrigerantes Corte Personalizado

- Descripción general

- Tamaño

- Detalles

- Productos recomendados

Descripción

Tamaño: Acepta personalización

Detalles

|

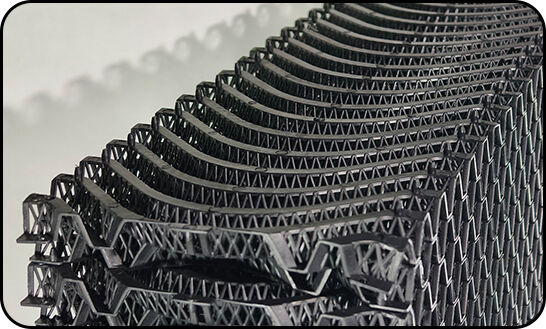

Diseño de doble onda aumenta el área de evaporación Sobre la base del plástico tradicional almohadillas de enfriamiento por evaporación, se añade un diseño de doble onda para aumentar el área de contacto con el agua y aumentar considerablemente el área de evaporación, lo que resulta en un efecto de enfriamiento más eficiente. |

|

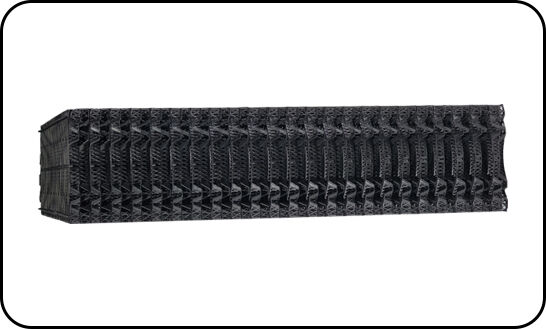

Reducir la velocidad de flujo de agua y aumentar la evaporación tiempo de enfriamiento El panel de enfriamiento doblemente corrugado, con un diseño cruzado, ralentiza eficazmente la velocidad de las gotas de agua y permite que permanezcan en el panel plástico de enfriamiento por evaporación durante más tiempo, aumentando así el tiempo de enfriamiento por evaporación. |

|

|

Seguro y Saludable Fabricado con plásticos nativos, este producto no contiene productos químicos irritantes para la piel como el fenol. Es ecológico, respetuoso con el medio ambiente, rentable, y duraderos. |

|

Control efectivo de olores Utilizado para el control de olores en porquerizas, proporciona un excelente control de olores. |

|

|

Personalizable El grosor del cartón ondulado sencillo almohadilla plástica de enfriamiento por evaporación es de 100 mm y 150 mm. Y el grosor del doble almohadilla plástica ondulada de enfriamiento por evaporación es de 150 mm; El tamaño del área de la almohadilla plástica de enfriamiento por evaporación es personalizado según las necesidades reales de instalación, El especificaciones estándar para plástico almohadillas de enfriamiento evaporativo sin marcos son los siguientes: |