El Sistema de Línea de Alimentación y Bebida Plana Automática para Pollos representa una solución sofisticada de automatización agrícola diseñada para revolucionar las operaciones de avicultura mediante tecnología de alimentación precisa y capacidades integradas de distribución de agua. Esta infraestructura integral de gestión avícola sirve como un pilar fundamental para instalaciones modernas de cría comercial de pollos, proporcionando una distribución constante de nutrientes mientras mantiene niveles óptimos de hidratación en entornos de producción a gran escala. El diseño plano del sistema se adapta a diversas configuraciones de galpones, permitiendo una integración perfecta con la infraestructura existente al tiempo que maximiza la eficiencia del uso del espacio y la optimización del flujo operativo. Fabricantes profesionales de equipos agrícolas han desarrollado esta avanzada tecnología de alimentación y bebederos para responder a la creciente demanda de soluciones automatizadas de manejo ganadero en mercados internacionales, centrándose especialmente en escalabilidad, fiabilidad y consistencia operativa a largo plazo. El enfoque de ingeniería detrás de este sistema automatizado de alimentación de pollos incorpora componentes mecánicos robustos diseñados para soportar operaciones continuas en entornos agrícolas exigentes, con materiales resistentes a la corrosión y mecanismos de distribución de precisión que garantizan una dispensación uniforme del alimento a lo largo de distancias lineales prolongadas. El componente integrado de línea de bebida complementa la funcionalidad de alimentación al proporcionar presión de agua y caudales constantes, utilizando tecnología especializada de bebederos tipo tetina que minimiza el desperdicio de agua mientras mantiene condiciones sanitarias en toda la instalación avícola. Los compradores internacionales que buscan soluciones integrales de automatización avícola encontrarán especialmente valioso a este sistema por su filosofía de diseño modular, que permite configuraciones personalizadas según disposiciones específicas de granjas, requerimientos de capacidad de pollos y preferencias operativas. La arquitectura plana de la línea de alimentación elimina la necesidad de sistemas complejos de elevación, reduciendo la complejidad de instalación mientras mantiene patrones eficientes de distribución de alimento que acomodan aves de diferentes tamaños y comportamientos alimenticios. Los estándares de fabricación de calidad aseguran que todos los componentes del sistema pasen por protocolos rigurosos de pruebas para verificar durabilidad, consistencia de rendimiento y fiabilidad operativa bajo diversas condiciones ambientales comúnmente encontradas en operaciones avícolas comerciales. La integración de la línea de bebida incluye capacidades avanzadas de gestión del agua diseñadas para mantener una calidad óptima del agua, previniendo contaminación y crecimiento bacteriano mediante mecanismos innovadores de control de flujo y principios de diseño sanitario. Distribuidores de equipos agrícolas y profesionales de abastecimiento reconocen la importancia estratégica de seleccionar sistemas de alimentación automatizados con historiales comprobados en instalaciones internacionales, particularmente aquellos que demuestran adaptabilidad a distintas prácticas regionales de agricultura y requisitos regulatorios. El diseño del sistema incorpora múltiples puntos de alimentación posicionados estratégicamente a lo largo de la configuración lineal para asegurar una distribución uniforme del alimento y minimizar la competencia entre las aves, promoviendo patrones de crecimiento más saludables y mejorando la eficiencia de conversión alimenticia durante todo el ciclo productivo. La tecnología de regulación de presión del agua en el componente de la línea de bebida mantiene caudales constantes independientemente de la longitud del sistema o variaciones de elevación, asegurando que todas las aves tengan acceso equitativo a agua limpia y fresca en todo su entorno de alojamiento. La excelencia en la fabricación de equipos avícolas automatizados requiere una comprensión exhaustiva de las demandas operativas agrícolas, los desafíos ambientales y la importancia crítica de la fiabilidad del sistema en contextos de agricultura comercial, donde el tiempo de inactividad del equipo impacta directamente la eficiencia y rentabilidad de la producción. La filosofía de diseño de configuración plana refleja una amplia investigación sobre los comportamientos óptimos de alimentación de pollos y sus requisitos espaciales, resultando en una disposición del sistema que promueve patrones naturales de alimentación mientras maximiza la eficiencia de los mecanismos de distribución automatizados. Las consideraciones profesionales de instalación incluyen una alineación adecuada del sistema, estructuras de soporte suficientes e integración con los sistemas existentes de ventilación y control climático del galpón avícola para garantizar un rendimiento y durabilidad óptimos. El componente de la línea de bebida utiliza materiales avanzados seleccionados por su resistencia a productos químicos agrícolas, agentes limpiadores y los efectos corrosivos de la exposición continua al agua, asegurando integridad operativa a largo plazo y requisitos mínimos de mantenimiento. Las prácticas de fabricación orientadas a la exportación garantizan que los componentes del sistema cumplan con estándares internacionales de calidad, al tiempo que se adaptan a diversos requisitos de envío y protocolos de instalación comúnmente encontrados en redes globales de distribución de equipos agrícolas. Las capacidades de personalización van más allá de simples ajustes de configuración e incluyen adaptaciones especializadas para diseños únicos de granjas, razas específicas de pollos y prácticas agrícolas regionales, demostrando la versatilidad del sistema para atender requisitos de mercado diversos. La experiencia del equipo de ingeniería en automatización agrícola refleja una extensa colaboración con profesionales de la avicultura en todo el mundo, dando lugar a refinamientos de diseño que abordan desafíos operativos reales y maximizan la eficacia del sistema en diversos entornos agrícolas. La precisión en la distribución del alimento representa una característica crítica de rendimiento, con componentes del sistema diseñados para entregar porciones consistentes, minimizando el desperdicio y asegurando que se cumplan los requerimientos nutricionales durante las distintas fases de crecimiento. La integración del sistema de agua incorpora mecanismos de seguridad diseñados para prevenir escasez de agua o fluctuaciones de presión que podrían comprometer la salud de las aves o el rendimiento del sistema, reflejando la importancia crítica de una hidratación confiable en operaciones avícolas comerciales. Las asociaciones a largo plazo con proveedores y compradores de equipos agrícolas suelen incluir soporte técnico completo, recomendaciones de optimización del sistema y servicios de consultoría continua que aseguran el máximo retorno de la inversión y eficiencia operativa durante toda la vida útil del sistema.

Sistema de Línea de Alimentación y Bebida Plana Automática para Pollos

-

Suministro Automatizado y Consistente – Proporciona alimento y agua de manera uniforme y automática, favoreciendo un crecimiento saludable del avicultura.

-

Diseño Ajustable y Limpio – Líneas ajustables en altura con características anti-derrames mantienen el entorno limpio y se adaptan a todas las etapas de crecimiento.

-

Materiales Duraderos y de Larga Duración – Construido con componentes resistentes a la corrosión para un uso fiable y prolongado en la granja.

-

Operación Ahorradora de Mano de Obra y Eficiente – Reduce el trabajo manual mediante un panel de control automático y una gestión diaria sencilla.

-

Modular y Fácil Mantenimiento – Fácil de instalar, limpiar y ampliar, adaptándose a distintos tamaños y necesidades de instalaciones avícolas.

- Descripción general

- Parámetros

- Accesorios

- Detalles

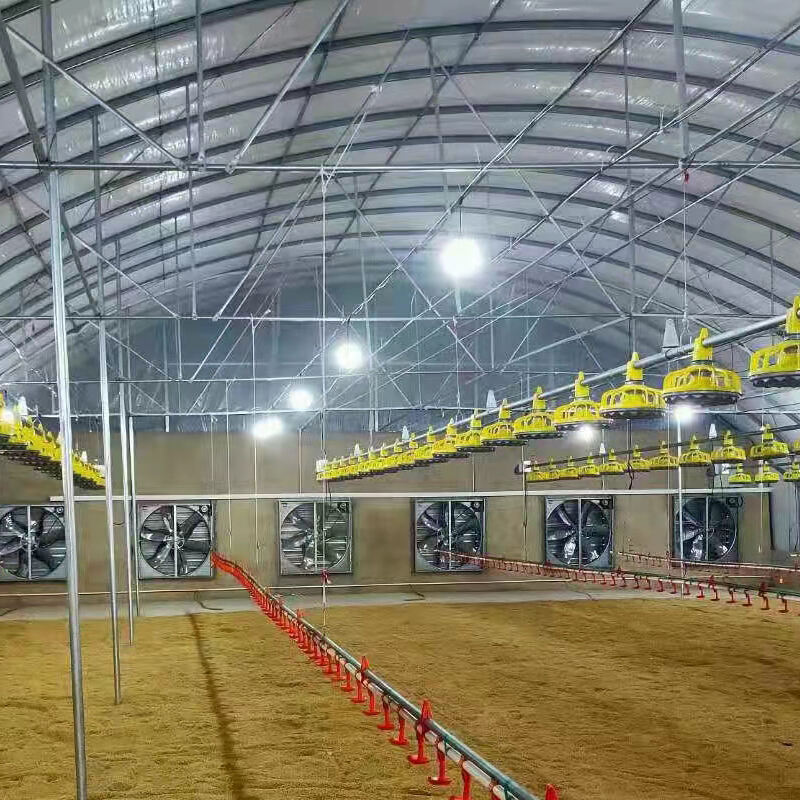

- Aplicación

- Productos recomendados

Descripción

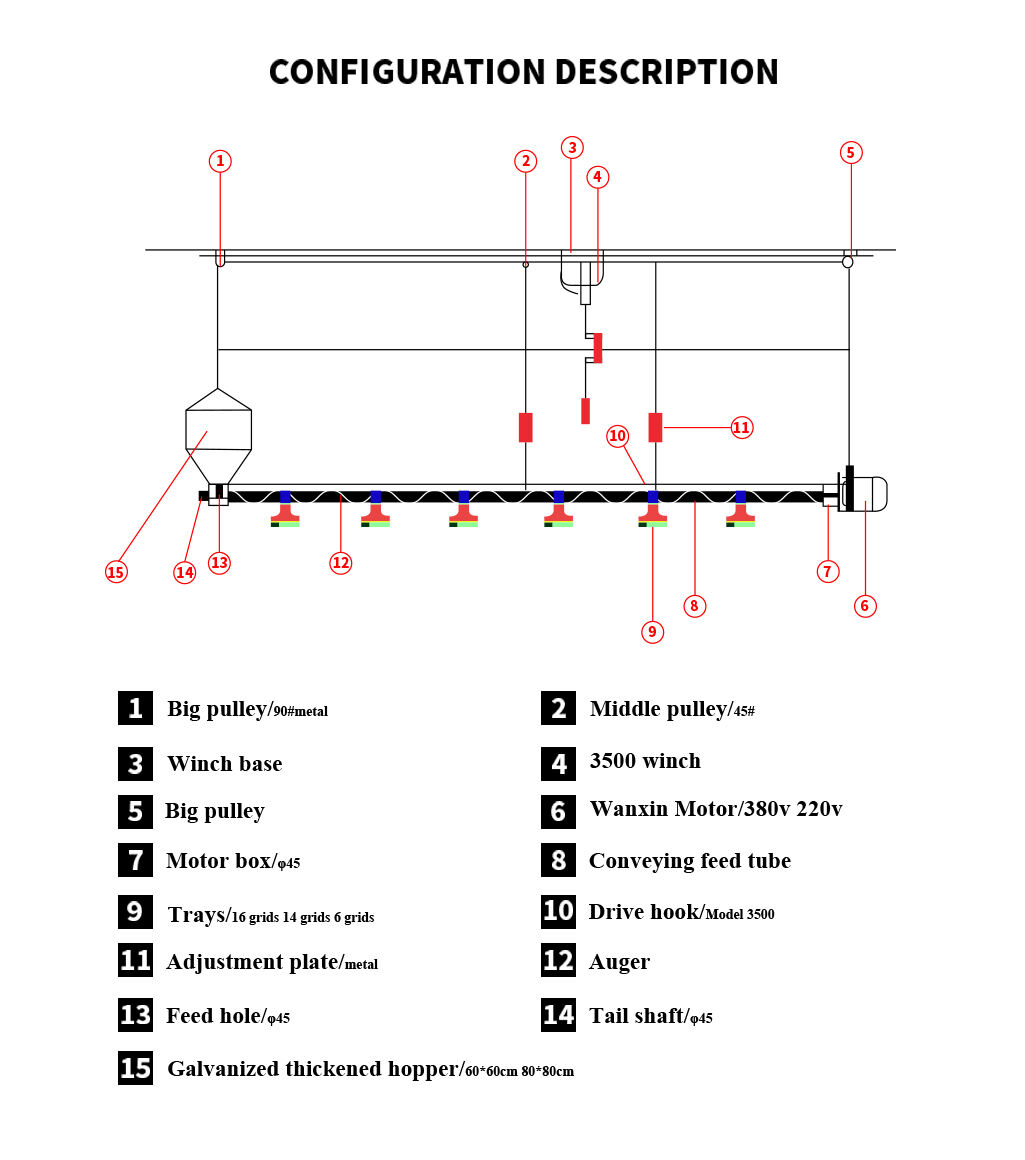

WQXM proporciona un sistema automático para alimentadores de pollos fiable y eficiente, diseñado para optimizar la alimentación avícola. El sistema consta principalmente de una torre de alimentación, bandejas de alimento, tuberías de transporte, tornillo sinfín, motor, sensor de nivel de material y otros componentes esenciales. Las líneas de alimentación avícola se disponen en filas y normalmente se colocan a intervalos regulares respecto a las líneas de bebida, para garantizar una alimentación organizada. Según la longitud del galpón avícola, múltiples salidas de alimento están distribuidas uniformemente a lo largo de la línea de alimentación, cada una equipada con una bandeja dosificadora. Cada bandeja está dividida en 14–16 celdas, capaz de alimentar simultáneamente a 40–70 pollos, asegurando así una dieta equilibrada para todas las aves.

El sistema funciona accionando un tornillo sinfín a través de un eje de transmisión motorizado, el cual entrega el alimento de manera uniforme a cada bandeja a lo largo de la línea. Un sensor de nivel de material en el extremo final de la línea controla automáticamente el inicio y paro del sistema de alimentación. Este diseño inteligente automatiza y optimiza el proceso de alimentación, reduciendo significativamente los costos laborales y el tiempo de alimentado, al mismo tiempo que evita las inconsistencias en el crecimiento ocasionadas por la alimentación manual irregular.

Gracias a su alta eficiencia, confiabilidad y facilidad de operación, el sistema automático de alimentación para aves WQXM es una elección ideal para granjas avícolas modernas que buscan lograr una administración de alimentación intensiva y consistente.

Parámetros

Accesorios

Detalles

|

Alta eficiencia del motor Adopta un nuevo tipo de bobina de cobre puro resistente a 155 grados Celsius, apariencia exquisita, resistencia a la corrosión, fuerte disipación de calor, la adhesión de la pintura es fuerte y no se descascara. La marca es Wanxin, que es una marca especializada en motores para líneas automáticas de alimentación en acuicultura plana. Generalmente, la configuración estándar es de 0.75 kilovatios, y están disponibles 380V y 220V. También puede personalizarse según diferentes voltajes en distintos países |

|

torno elevador modelo 3500 Torno compatible, engranaje con rueda de acero manganeso, carga pesada, resistente y duradero |

|

|

Tolva de aluminio-zinc de grosor aumentado El núcleo aluminizado es grueso, resistente a la corrosión y al desgaste, resistente y duradero. Tamaño: 60*60 cm (opcional 80*80 cm). Todos los modelos están fabricados completamente con chapa de zinc aluminizado de 1,5 mm, lo que los hace más gruesos y pesados |

|

Caja de distribución Además de los interruptores de aire y relés electromagnéticos más básicos, nuestras cajas de distribución también están equipadas con protectores contra fugas, protectores térmicos contra sobrecargas y protecciones contra secuencia de fases defectuosa. ¡Básicamente pueden prevenir que todos los componentes electrónicos importantes, como motores o sondas, resulten dañados por accidentes! |

|

|

Tornillo sinfín importado de Sudáfrica El tornillo sinfín de material especial puramente importado tiene alta dureza superficial y resistencia al desgaste. Buena tenacidad interna, resistencia a la tracción, larga vida útil e instalación sencilla y práctica. |

|

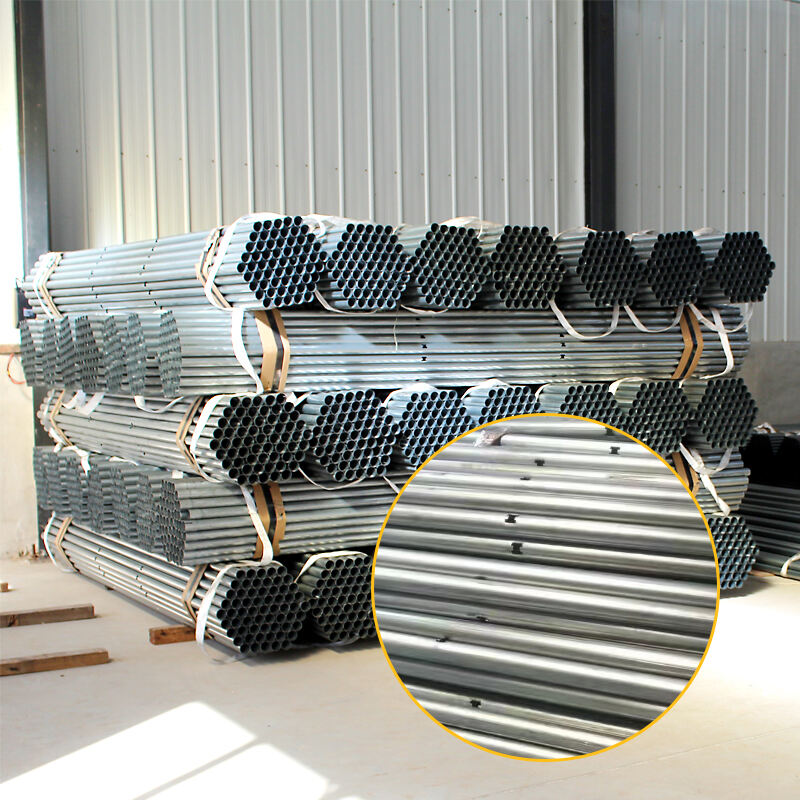

Tubo de material galvanizado en caliente de cuatro orificios El estándar incluye tubería con recubrimiento galvanizado de 275 gramos, tres metros y cuatro orificios, tamaño de 45x3040 mm, y cada tubo viene con un abocinado de 40 mm, lo que facilita la conexión, enchufar y usar, resistente al desgaste y a la corrosión. |

|

|

Bandeja de alta calidad Materias primas puras, pesando 700 gramos, anti-envejecimiento, sin grietas, sin doblarse. El volumen de alimentación es ajustable, con un interruptor; 6, 14 y 16 rejillas son opcionales. |

|

Sensor de Nivel Diseñado especialmente para la línea de material, mayor sensibilidad, mayor resistencia al impacto de corriente; disponible versión nacional e importada (ifm) |

|

Aplicación