El Cadena de enchufes para granja porcina Línea de alimentación automática representa una solución industrial sofisticada diseñada para transformar las operaciones de alimentación ganadera mediante tecnología avanzada de automatización, ofreciendo una eficiencia y fiabilidad excepcionales para instalaciones modernas de producción porcina en todo el mundo. Esta infraestructura integral de alimentación incorpora mecanismos de cadena de émbolo precisos que transportan sin interrupciones los materiales alimenticios a lo largo de instalaciones agrícolas extensas, eliminando la necesidad de mano de obra manual y garantizando una entrega nutricional constante a las poblaciones ganaderas en múltiples secciones de alojamiento. La construcción robusta del sistema utiliza componentes de acero de alta calidad y mecanismos de transmisión especializados diseñados para soportar las exigentes condiciones operativas inherentes a los entornos agrícolas, con tratamientos superficiales resistentes a la corrosión y recubrimientos protectores que mantienen la integridad estructural a pesar de la exposición a la humedad, al amoníaco y a las fluctuaciones térmicas características de las explotaciones porcinas. Los compradores internacionales B2B que busquen soluciones fiables de automatización agrícola apreciarán la filosofía de diseño modular del sistema, que se adapta a diversas configuraciones de instalaciones y requisitos de expansión, manteniendo al mismo tiempo la coherencia operativa en diferentes escalas de instalación, desde operaciones medianas hasta empresas ganaderas comerciales a gran escala que abastecen a los mercados globales de proteínas. La configuración de la cadena de émbolo asegura un flujo suave del material a través de conductos cerrados, minimizando los riesgos de contaminación del alimento y reduciendo el desperdicio mediante mecanismos de control de distribución precisos que entregan porciones medidas según horarios predeterminados y protocolos nutricionales establecidos. La excelencia en la fabricación impulsa el proceso productivo, incorporando técnicas avanzadas de soldadura, mecanizado de precisión y procedimientos de control de calidad que garantizan exactitud dimensional y fiabilidad operativa durante largos períodos de servicio, reflejando un profundo conocimiento de los requisitos de maquinaria agrícola desarrollado a través de extensa colaboración con explotaciones ganaderas internacionales y distribuidores de equipos. El sistema de línea de alimentación se integra perfectamente con la infraestructura agrícola existente, permitiendo configuraciones de instalación flexibles que se adaptan tanto a proyectos de nueva construcción como a aplicaciones de modernización en instalaciones ya establecidas, manteniendo compatibilidad con sistemas eléctricos estándar e interfaces de control comúnmente utilizados en redes modernas de automatización agrícola. Opciones de tratamiento de superficie incluyen recubrimientos galvanizados, aplicaciones de pintura en polvo y acabados protectores especializados diseñados para prolongar la vida útil del equipo manteniendo el atractivo estético y el rendimiento funcional en entornos agrícolas exigentes. Las capacidades de personalización van más allá de modificaciones dimensionales básicas e incluyen sistemas de transmisión especializados, controles de velocidad variable y soluciones de monitoreo integradas que proporcionan retroalimentación operativa en tiempo real mediante interfaces digitales compatibles con plataformas de software de gestión agrícola cada vez más adoptadas por operaciones agrícolas avanzadas en todo el mundo. El diseño cerrado del sistema protege los materiales de alimentación contra contaminación ambiental, al mismo tiempo que facilita un fácil acceso para mantenimiento mediante puertos de inspección y paneles de servicio estratégicamente ubicados, que permiten limpiezas rutinarias y reemplazo de componentes sin necesidad de procedimientos extensos de desmontaje. Consideraciones de embalaje orientadas a la exportación garantizan un transporte seguro a través de redes internacionales de envío, utilizando materiales protectores y métodos de fijación que previenen daños durante la manipulación y el tránsito, adaptándose a las dimensiones estándar de contenedores y configuraciones de carga preferidas por proveedores logísticos globales. La filosofía de consistencia en calidad comprende protocolos rigurosos de pruebas aplicados durante todos los procesos de fabricación, incluyendo pruebas de carga, ciclos operativos y evaluaciones de estrés ambiental que validan las especificaciones de rendimiento bajo condiciones de campo simuladas, asegurando un funcionamiento confiable en diversas regiones climáticas e intensidades operativas encontradas en mercados internacionales. Los marcos de cooperación OEM y ODM apoyan iniciativas colaborativas de desarrollo con distribuidores de equipos e integradores de sistemas agrícolas, facilitando soluciones personalizadas que atienden requisitos regionales específicos, necesidades de cumplimiento regulatorio y preferencias operativas, manteniendo al mismo tiempo las características principales de rendimiento y estándares de calidad. La operación energéticamente eficiente del sistema contribuye a prácticas agrícolas sostenibles al optimizar el consumo de energía mediante sistemas inteligentes de control de accionamientos y elementos de diseño con baja fricción que reducen los costos operativos mientras maximizan la capacidad de producción, apoyando así los objetivos de las empresas agrícolas de mejorar la rentabilidad y el cuidado del medio ambiente. Las asociaciones a largo plazo con proveedores se benefician de recursos completos de soporte técnico, incluyendo guías de instalación, materiales de capacitación operativa y servicios de consultoría continua que aseguran un rendimiento óptimo del sistema durante períodos prolongados de servicio, fomentando relaciones basadas en el éxito mutuo y en iniciativas de mejora continua que se adaptan a los requisitos cambiantes de la industria agrícola y a las oportunidades de avance tecnológico en operaciones agrícolas globales.

Cadena de enchufes para granja porcina Línea de alimentación automática

- Línea automática de alimentación de cerdos ahorra mano de obra, asegura alimento uniforme y mejora la eficiencia ganadera.

- Sistema eficiente de alimentación de cerdos con dosificación precisa, construcción duradera y fácil mantenimiento.

- Línea de alimentación de cerdos duradera para granjas grandes, mejora la productividad y reduce la pérdida de alimento.

- El tiempo de alimentación de las cerdas en el tubo de dosificación es rápido, de 60 a 30 minutos hasta 3 segundos.

- Descripción general

- Puntos de venta clave

- Accesorios

- Detalles

- Productos recomendados

Descripción

Los sistemas de alimentación porcina comprenden tanto el tipo y forma del alimento como el método de entrega a los cerdos. En Estados Unidos, el enfoque predominante es la alimentación seca, en la cual los granos cereales se muelen y se combinan con otros ingredientes secos para crear un alimento completo. Aunque los sistemas de alimentación líquida son menos comunes en EE.UU., están ampliamente adoptados en Europa. Algunos productores también utilizan sistemas combinados, ofreciendo subproductos líquidos, como suero, junto con alimento seco completo para optimizar la nutrición.

El alimento generalmente se entrega a través de líneas de tornillo sinfín desde los silos de almacenamiento hasta corrales individuales o hembras, asegurando una distribución uniforme. Los avances tecnológicos han llevado al desarrollo de sistemas de alimentación computerizados, lo que permite ajustes en tiempo real en la composición de la dieta para alinear mejor con las etapas de crecimiento de los cerdos y sus necesidades nutricionales cambiantes.

Para los productores que utilizan alimentos secos, existen varias opciones de diseño de comederos disponibles, incluyendo comederos secos tradicionales, comederos húmedos-secos, comederos redondos y comederos tubulares. Cada tipo ofrece beneficios y desafíos únicos, lo que requiere estrategias de manejo adaptadas. La selección del sistema de alimentación y diseño del comedero adecuado es fundamental para mejorar la eficiencia alimenticia, el desempeño de crecimiento de los cerdos y los resultados generales de producción.

Puntos de venta clave

|

Operación automatizada |

| Alimentación precisa |  |

|

Reducción de la Contaminación |

| Evitar el crecimiento de moho |  |

|

Control Centralizado |

| Materiales de alta calidad |  |

Accesorios

|

Zapatas de alimentación Lámina antióxido de 1,5 mm. Zapatas vibratorias de doble tubo |

|

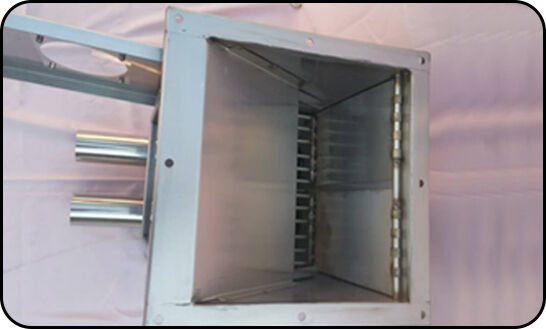

Unidad motriz Carcasa: acero inoxidable de 2,5 mm de espesor. Ruedas motrices y ruedas de transmisión: hierro dúctil. 2,2 kW Transtecno. |

|

|

Rueda de esquina Material de la carcasa: acero inoxidable 304. Material de la rueda interior: hierro dúctil. Otros accesorios: acero inoxidable |

|

Cadena de enchufe El material del enchufe es nailon. Alta tenacidad, alta dureza, resistencia a la fatiga, alta resistencia al desgaste y alta tenacidad. El escalón tiene un diámetro de 70 mm, un diámetro de 45 mm, un diámetro de cadena de 6 mm, y está hecho de acero aleado 20 Mn2. La resistencia a la tracción es de 5,8 toneladas. |

|

|

Sensor Sensor BEDOOK |

|

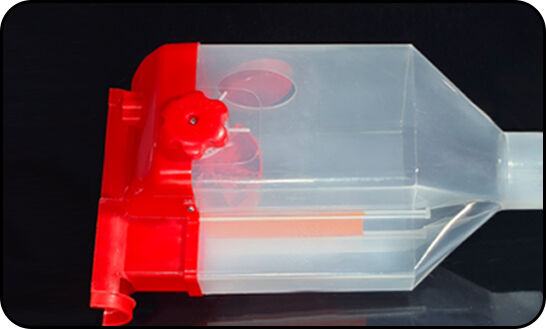

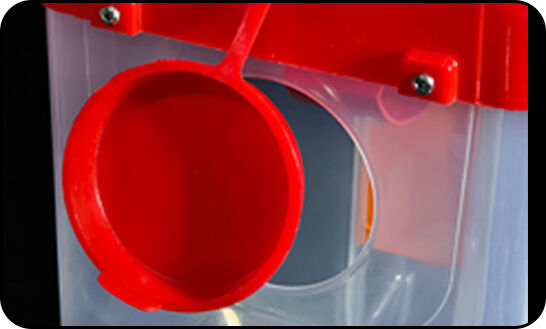

Taza cuantitativa 8L |

|

|

Boca de campana |

Detalles

|

Diseño de alimentación cerrada, reduce ratas y moscas robo y contaminación del alimento |

|

Material PP, inyección única moldura de alimentación cuantitativa, ajuste libre de la cantidad |

|

|

Gestione y utilice convenientemente los datos de las cerdas con abrazadera |

| Medicamento conveniente para la atención médica y el tratamiento de individuos cerdas |

|