The Automatic Plastic Cattle Drinking Bowl represents a sophisticated solution for modern livestock management systems, engineered specifically to address the critical hydration needs of cattle operations across diverse agricultural environments. This innovative watering system combines advanced plastic engineering with automated flow control mechanisms to deliver consistent, reliable water access that supports optimal animal health and operational efficiency. Designed with the rigorous demands of commercial livestock facilities in mind, this automatic drinking bowl integrates seamlessly into existing barn infrastructure while providing the durability and functionality required for intensive agricultural use. The product's comprehensive design philosophy prioritizes both animal welfare and operational convenience, making it an essential component for progressive cattle operations seeking to modernize their water delivery systems. International sourcing professionals and agricultural distributors recognize this automatic drinking system as a cornerstone product for livestock equipment portfolios, particularly in markets where efficient water management directly impacts productivity and regulatory compliance. The engineering approach behind this cattle drinking solution emphasizes food-grade material selection, ensuring complete safety for livestock consumption while maintaining structural integrity under continuous operational stress. Advanced plastic formulations utilized in the manufacturing process provide exceptional resistance to environmental factors commonly encountered in agricultural settings, including temperature variations, chemical exposure from cleaning agents, and mechanical stress from animal interaction. The automatic flow control mechanism operates through precision-engineered components that regulate water delivery based on animal demand, eliminating waste while ensuring constant availability. This intelligent design reduces labor requirements typically associated with manual watering systems, allowing farm operators to allocate human resources more effectively across other critical operational areas. The bowl's ergonomic configuration accommodates the natural drinking behavior patterns of cattle, promoting comfortable access that encourages adequate hydration essential for optimal milk production, weight gain, and overall animal health. Surface treatment applications enhance the product's longevity and maintenance characteristics, incorporating specialized finishes that resist bacterial growth and facilitate thorough cleaning protocols required in professional livestock environments. Manufacturing processes employ advanced molding techniques that ensure dimensional consistency and structural uniformity across production runs, supporting reliable performance standards that international buyers expect from professional-grade agricultural equipment. Quality assurance protocols integrated throughout the production cycle guarantee that each unit meets stringent durability requirements while maintaining the precise tolerances necessary for proper automatic operation. The drinking bowl's installation versatility accommodates various mounting configurations, enabling integration into both new construction projects and retrofit applications within existing facilities. Professional installation considerations include compatibility with standard plumbing systems commonly utilized in agricultural applications, ensuring straightforward integration that minimizes disruption to ongoing operations. Customization capabilities extend beyond standard configurations to accommodate specific operational requirements, including specialized mounting brackets, alternative flow control settings, and enhanced drainage features that address unique facility layouts or management preferences. Original equipment manufacturer partnerships facilitate the development of tailored solutions that align with specific distributor requirements or regional market preferences, supporting comprehensive product portfolios that address diverse customer needs. The automatic drinking system's operational reliability stems from simplified mechanical design principles that minimize maintenance requirements while maximizing uptime, crucial factors for agricultural operations where equipment downtime directly impacts animal welfare and production schedules. International compliance considerations built into the design framework ensure compatibility with diverse regulatory environments encountered in global markets, supporting smooth market entry and customer acceptance across different geographical regions. Packaging optimization for this livestock equipment emphasizes protection during international shipping while maintaining cost-effective logistics profiles that support competitive market positioning. The product's compatibility with standard agricultural supply chain infrastructure facilitates efficient distribution through established dealer networks and agricultural equipment suppliers worldwide. Long-term supplier relationships benefit from the manufacturer's commitment to consistent quality delivery and responsive technical support, establishing the foundation for sustainable business partnerships that evolve with changing market demands. Professional buyers appreciate the comprehensive approach to product development that considers not only immediate functional requirements but also long-term operational considerations including parts availability, technical documentation, and upgrade pathways that protect equipment investments over extended service periods.

Automatic Plastic Cattle Drinking Bowl

-

Automatic Water Refill – Built-in float valve maintains a steady water level, reducing manual refilling.

-

Durable & Weather-Resistant – Made of strong, stabilized plastic that resists rust, corrosion, and sun damage.

-

Livestock-Friendly Design – Smooth, non-toxic edges ensure safe and comfortable drinking for various animals.

-

Easy Installation & Maintenance – Simple to mount on walls or pipes, with easy-to-clean parts and accessible valve.

-

Efficient & Versatile Use – Wide bowl design with water-saving function, ideal for cattle, goats, sheep, and horses.

- Overview

- Size

- Details

- Recommended Products

Description

Wanqing Water Bowl for cows is large, deep, easy to clean and lightweightThe smooth plastic material is strong but flexible, withstanding bumps and pressure. Every bowl is strictly tested at the factory for quality. Non-siphoning bowl comes ready to install with 3/4" top and bottom inlets and frost plug.Bowl comes with standard pressure valve for 20 to 50 psi but others areavailable for gravity (less than 20 psi) or high pressure (higher than 50 psi).Flow rate is 3.7 gpm at 40 psi.

Product Introduction Video

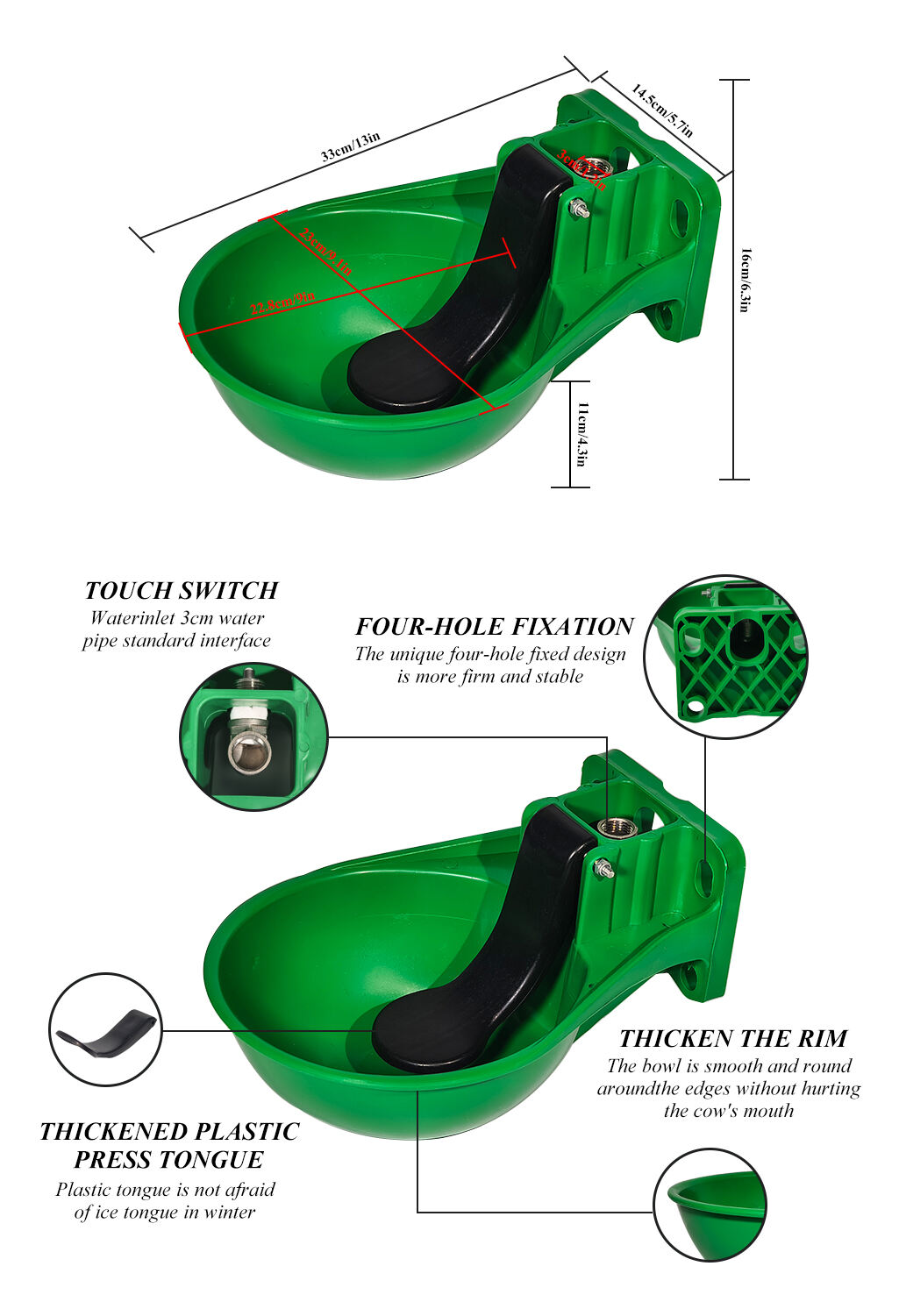

Size

Details

|

Thickened plastic beef bowl Stainless steel valve touch water not afraid of falling not afraid of arch |

|

Copper lock switch design touch water outlet |

|

|

Four-hole fixation The unique four-hole fixed design is more firm and stable |

|

Touch switch Waterinlet 3cm water pipe standard interface |

|

|

Thickened plastic press tongue Plastic tongue is not afraid of ice tongue in winter |

|

Thicken the rim The bowl is smooth and round around the edges without hurting the cow'smouth |

|