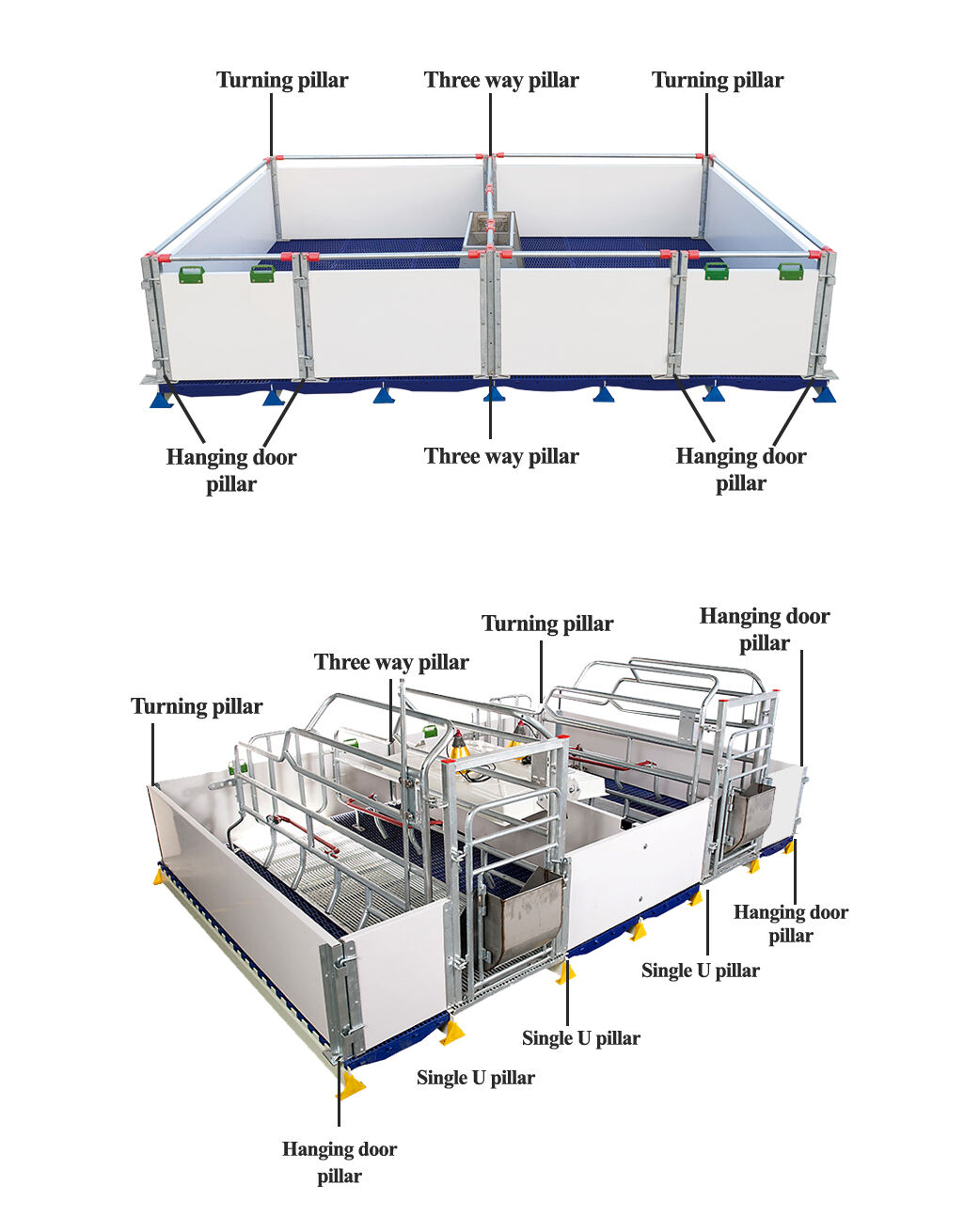

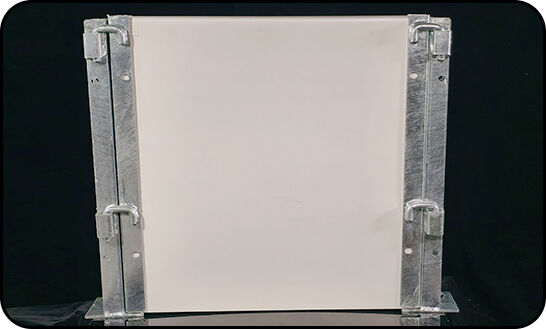

الـ عمود تثبيت لوحة PVC قابل للتعديل مصنوع من الفولاذ المجلفن بالغمس الساخن لحظيرة خنازير الولادة يمثل حلاً هندسيًا متقدمًا تم تصميمه خصيصًا لعمليات تربية الخنازير الحديثة التي تعطي أولوية لرفاهية الحيوانات والكفاءة التشغيلية في منشآتها الإنتاجية. يجمع هذا المكون الهيكلي المتخصص بين متانة الصلب المجلفن بالغمس الساخن ومرونة أنظمة تركيب ألواح البولي فينيل كلورايد (PVC) المدمجة، ما يُشكل أساسًا قويًا للبيئات المهنية لتربية الخنازير التي تتطلب عمرًا افتراضيًا استثنائيًا ومقاومة للظروف القاسية الشائعة في البيئات الزراعية. ويضمن عملية الجلفنة الساخنة مقاومة ممتازة للتآكل من خلال تكوين طبقة واقية من الزنك ترتبط كيميائيًا مع مادة الصلب الأساسية، مما يوفر حماية طويلة الأمد ضد الرطوبة، والأمونيا، والعناصر التآكلية الأخرى التي تُصادف عادةً في تطبيقات إسكان الثروة الحيوانية. وتمكّن إمكانية دمج ألواح البولي فينيل كلورايد (PVC) من التكامل السلس مع أنظمة الجدران والحواجز المختلفة، ما يمكن مصممي المرافق والمزارعين من إنشاء تشكيلات مخصصة لأقفاص ولادة الخنازير بحيث يتم تحسين استخدام المساحة مع الحفاظ على معايير النظافة الصارمة الضرورية لعمليات تربية الخنازير الناجحة. ويعتبر المشترون الدوليون من الشركات والوكلاء الموزعين للمعدات الزراعية هذه الفئة من المنتجات مكونًا أساسيًا في سوق البنية التحتية للثروة الحيوانية العالمي، حيث يستمر الطلب في النمو على حلول عالية الجودة وقابلة للتخصيص يمكنها التكيف مع ممارسات الزراعة المتنوعة والمتطلبات التنظيمية عبر مختلف المناطق. ويمنح هيكل اللب الصلب المتانة الهيكلية اللازمة لتحمل الأحمال الديناميكية والإجهادات البيئية المرتبطة بعمليات تربية الخنازير النشطة، في حين توفر الطبقة المجلفنة مقاومة كيميائية مطلوبة للتنظيف والتعقيم المتكرر الذي يُفرض في منشآت التربية التجارية. وتتيح الطبيعة القابلة للتخصيص لأنظمة الأعمدة هذه للمهندسين الزراعيين ومخططي المرافق تحديد أبعاد دقيقة وتكوينات التركيب وخصائص دمج الألواح التي تتماشى مع متطلبات تشغيلية محددة، ما يجعلها مناسبة لكل من مشاريع الإنشاء الجديدة وتحديث أو توسيع المرافق. وتشمل نُهج التصنيع لهذه المكونات المتخصصة عادةً تشكيل دقيق لمواد الصلب عالية الجودة يليه عمليات جلفنة بالغمس الساخن مضبوطة تضمن سمكًا موحدًا للطلاء والالتصاق الأمثل عبر جميع مناطق السطح، بما في ذلك الأشكال الهندسية المعقدة والوصلات الملحومة الشائعة في التطبيقات الهيكلية الزراعية. وقد تم تصميم عناصر تركيب ألواح البولي فينيل كلورايد (PVC) لاستيعاب سماكات مختلفة من الألواح وآليات التركيب، ما يوفر المرونة لمختلف تصميمات أقفاص الولادة مع الحفاظ على وصلات آمنة تتحمل الإجهادات الميكانيكية الناتجة عن حركة الحيوانات والصيانة الروتينية. وتمتد اعتبارات المعالجة السطحية لما هو أبعد من الجلفنة الأساسية لتشمل إنهاء الحواف، والتحكم في جودة اللحام، والتحقق من الدقة البعدية لضمان أداء متسق في التركيبات الكبيرة حيث يجب أن تعمل عدة أعمدة معًا كنظام متكامل. وتشمل إمكانيات التخصيص الوظيفي مجموعة واسعة من التعديلات مثل أنماط ثقوب التثبيت المحددة، وإضافات التقوية، وتعديلات الارتفاع، والأقواس أو المرفقات الخاصة التي تستوعب تخطيطات المرافق الفريدة أو متطلبات دمج المعدات التي تختلف بشكل كبير بين عمليات الزراعة المختلفة والأسواق الجغرافية. ويمتد مدى الاستخدام المناسب عبر مختلف أحجام عمليات تربية الخنازير، بدءًا من المزارع العائلية الصغيرة التي تسعى لتحديث منشآتها الإنتاجية، وصولاً إلى العمليات التجارية الكبيرة التي تنفذ أنظمة ولادة شاملة تتطلب مئات المكونات الفردية التي تعمل بالتنسيق لتحقيق بيئات تربية مثالية. ويعتبر قطاع المعدات الزراعية هذه المنتجات مكونات بنية تحتية ضرورية تسهم في تحسين معدلات النجاح في التكاثر، وتقليل متطلبات العمل، وتعزيز تدابير الأمن الحيوي التي أصبحت أكثر أهمية في نظم إنتاج الخنازير الحديثة. وتركز فلسفة الاتساق في الجودة أثناء تصنيع هذه الأعمدة المتخصصة على اختيار المواد بدقة، والعمليات الإنتاجية المضبوطة، وبروتوكولات الاختبار الشاملة التي تضمن تحقيق كل وحدة للمعايير الصارمة للأداء المطلوبة لتطبيقات الخدمات الزراعية طويلة الأمد، حيث قد تكون عمليات الاستبدال أو الإصلاح مكلفة وتؤثر سلبًا على العمليات الجارية. وتشمل اعتبارات المناورة الموجهة نحو التصدير طرق التعبئة الوقائية، والتحسين البُعدي لاستخدام حاويات الشحن بكفاءة، ودعم التوثيق الذي يسهل الامتثال التجاري الدولي ومعالجة الجمارك، وهي أمور ضرورية لشبكات التوزيع العالمية التي تخدم أسواقًا زراعية متنوعة. وغالبًا ما يتضمن نهج التعاون مع المشترين الدوليين عمليات استشارات مفصلة يعمل فيها فريق التصنيع ذوي الخبرة بشكل وثيق مع الموزعين وتجار المعدات والمستخدمين النهائيين لتطوير حلول مخصصة تعالج متطلبات إقليمية محددة، ومواصفات البناء المحلية، والتفضيلات التشغيلية التي يمكن أن تختلف بشكل كبير بين البلدان المختلفة وتقاليدها الزراعية. وتوفر فرص التعاون مع OEM وODM للشركاء المؤهلين إمكانية تطوير إصدارات خاصة أو تصاميم معدلة تتضمن ميزات أو عناصر علامات تجارية محددة مع الحفاظ على المبادئ الهندسية الأساسية ومعايير الجودة التي تميز مكونات البنية التحتية الزراعية من الفئة الاحترافية. وتكفل اعتبارات التوافق مع التعبئة والخدمات اللوجستية أن هذه المنتجات يمكن دمجها بكفاءة في سلاسل توريد معقدة غالبًا ما تشمل مراحل متعددة من المناورة، وأوقات نقل طويلة، وظروف تخزين متنوعة قبل الوصول إلى مواقع التركيب النهائية، مما يتطلب إجراءات وقائية قوية وأنظمة تحديد واضحة تمنع التلف وتُسهل إدارة المخزون بدقة. وتشدد التوقعات المتعلقة بالتعاون طويل الأمد مع الموردين في هذا القطاع الخاص على التوفر المستمر، وقدرات الدعم الفني، والقدرة على زيادة أحجام الإنتاج استجابة لأنماط الطلب الموسمية واتجاهات نمو السوق التي تميز صناعة المعدات الزراعية الديناميكية، حيث تعتبر الموثوقية والاستجابة بنفس أهمية جودة المنتج في بناء علاقات تجارية ناجحة تمتد عبر دورات سوقية متعددة ومناطق جغرافية متنوعة.

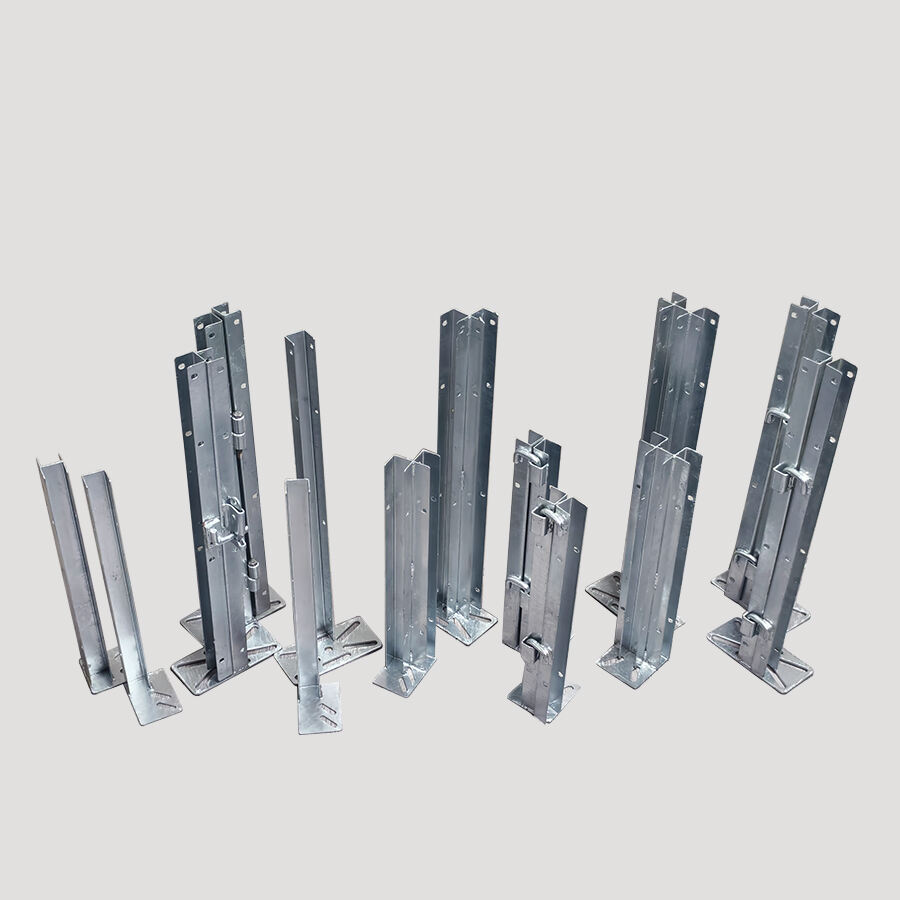

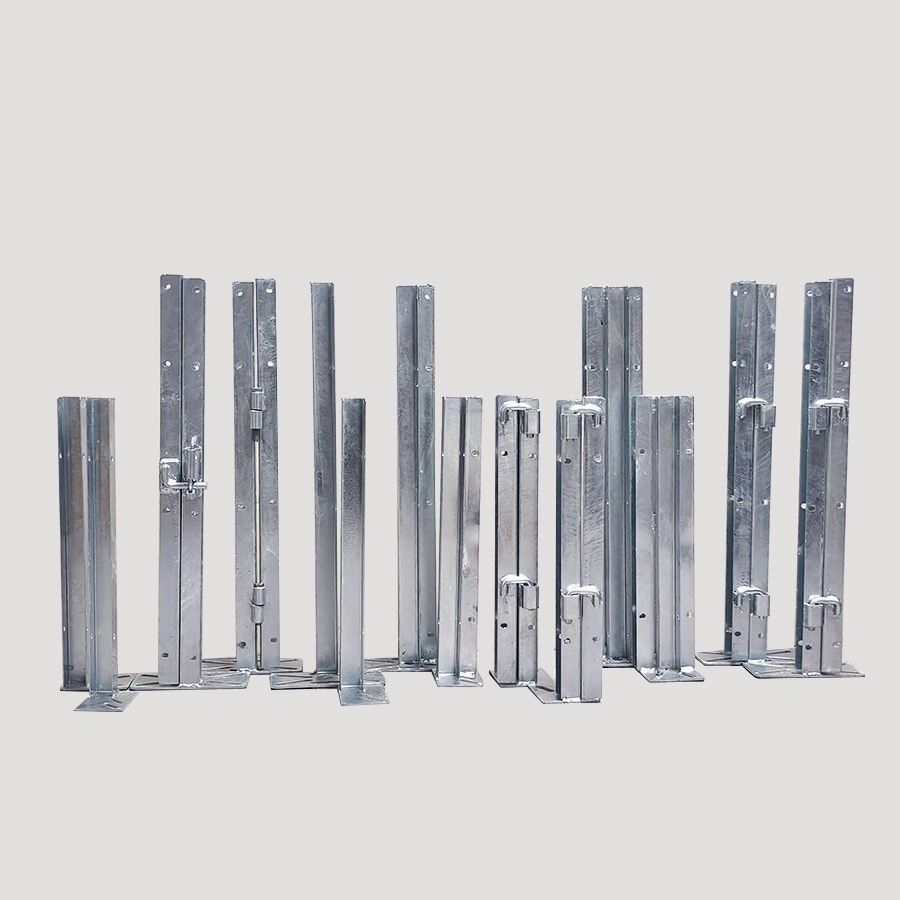

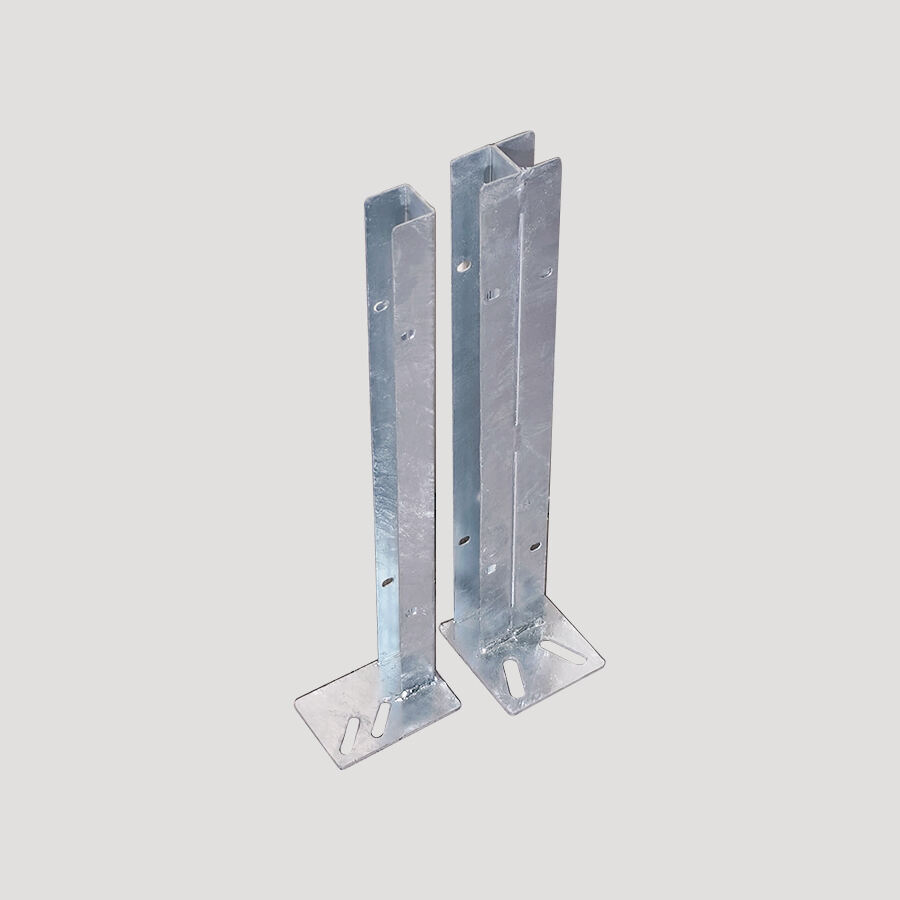

عمود تثبيت لوحة PVC قابل للتعديل مصنوع من الفولاذ المجلفن بالغمس الساخن لحظيرة خنازير الولادة

-

متين ومقاوم للتآكل – مصنوع من الفولاذ المجلفن بالغمس الساخن، مما يضمن عمرًا طويلًا وحماية ممتازة ضد الصدأ في بيئات خنازير الولادة.

-

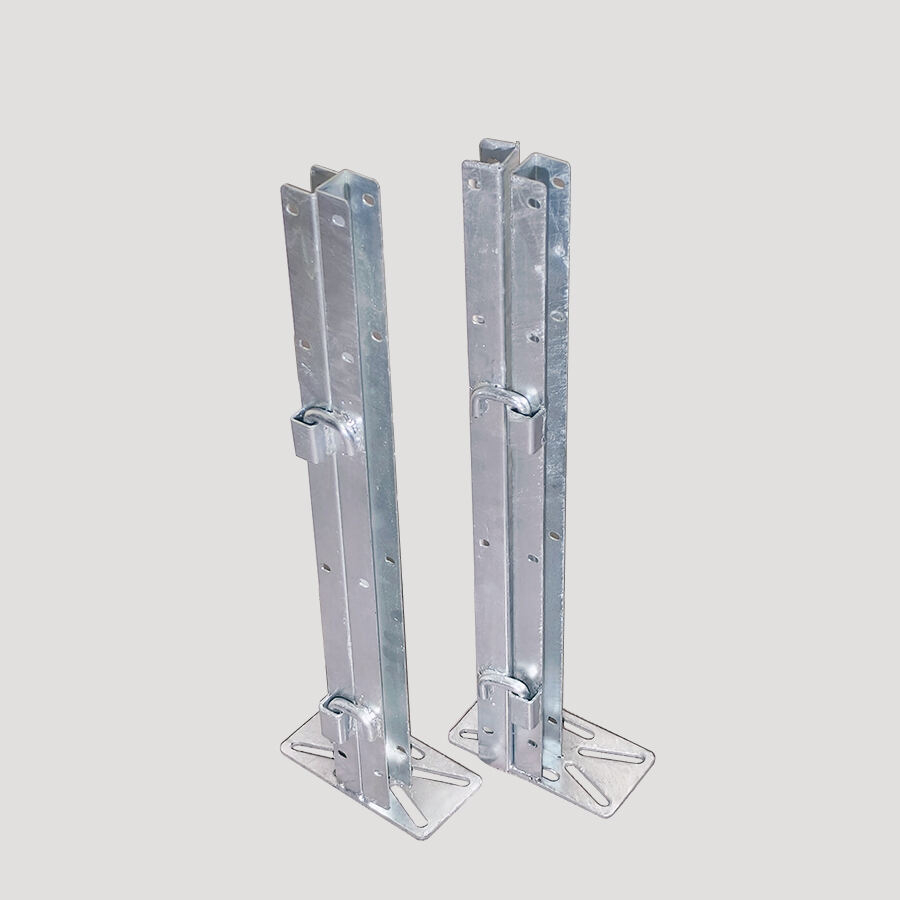

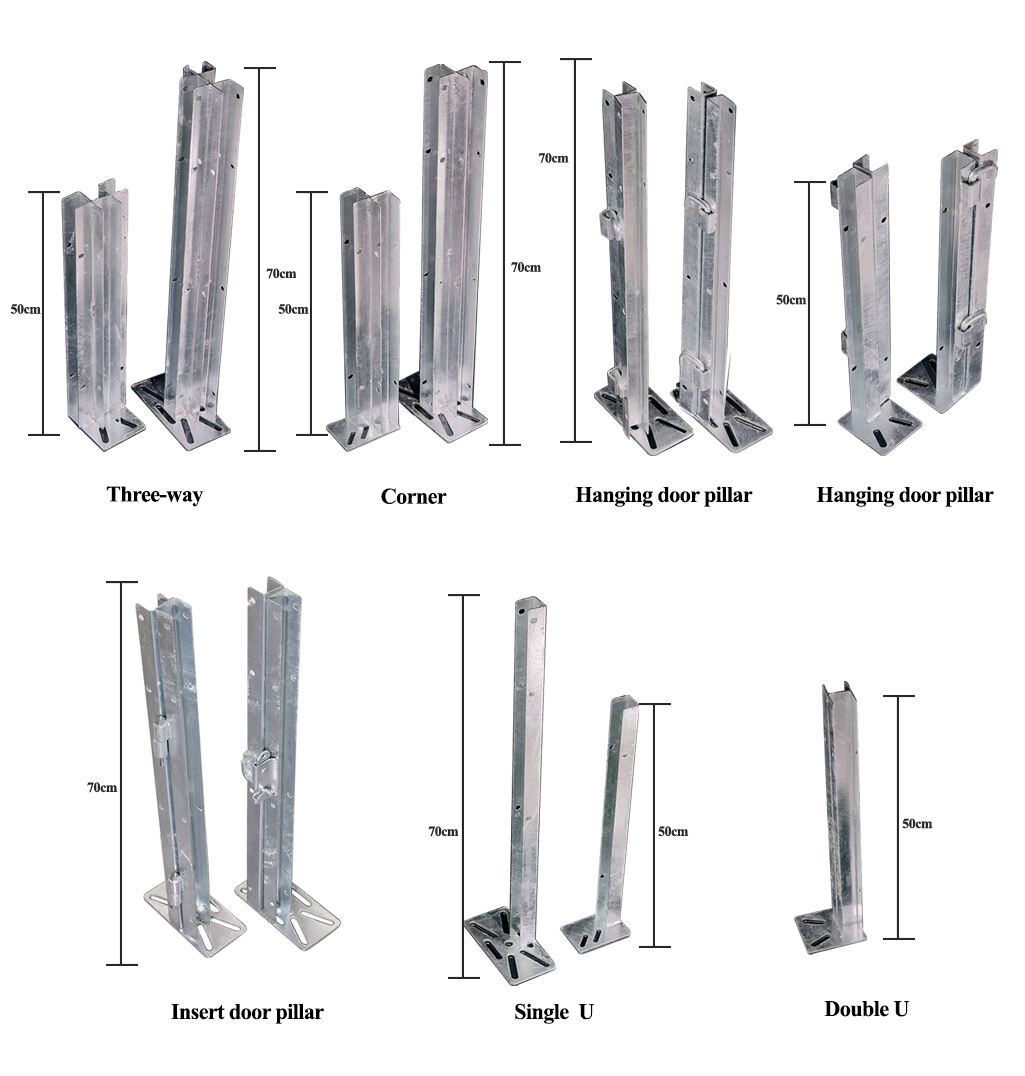

تصميم قابلة للتخصيص – يمكن تعديل حجم وشكل العمود وتركيب لوحة PVC لتلبية متطلبات المزرعة المختلفة وتحقيق أقصى درجات المرونة.

-

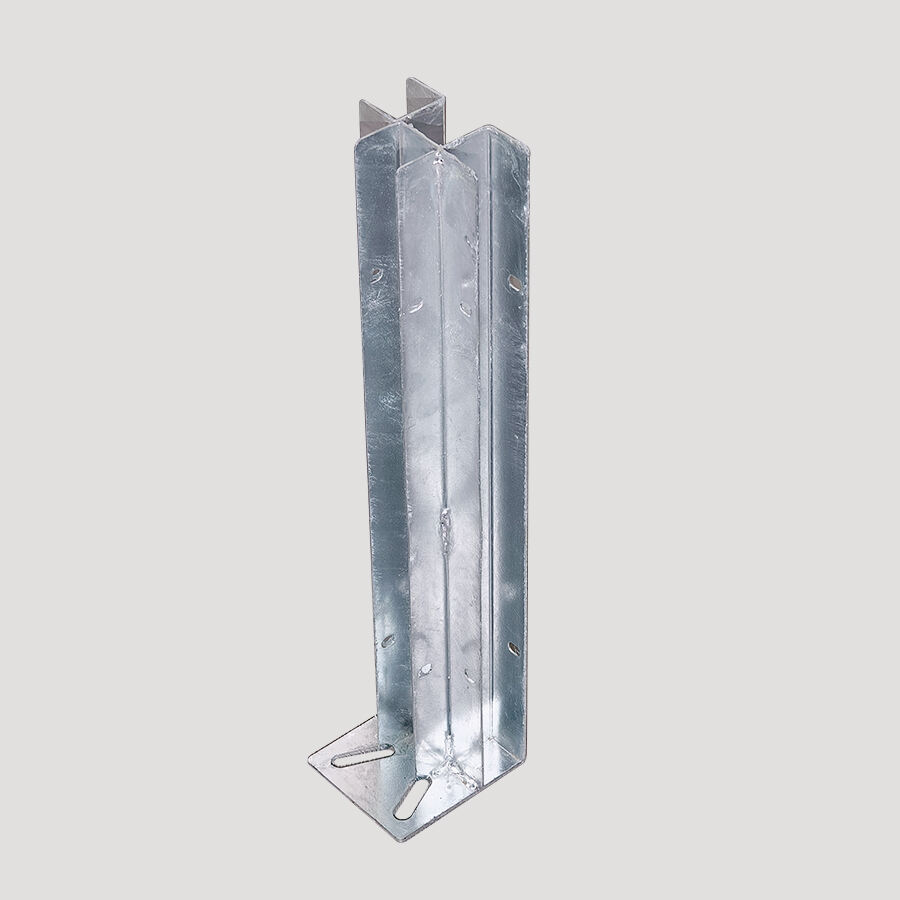

قدرة كبيرة على تحمل الحمل – تم تصميمه ليكون مستقرًا وقويًا، حيث يوفر العمود دعمًا موثوقًا لحظائر الولادة، مما يضمن سلامة الحيوانات والعاملين.

-

سهولة التركيب والصيانة – هيكل وحدوي مع تركيب دقيق يسمح بتركيب سريع، ويقلل تكاليف العمالة ويسهل التنظيف والصيانة.

- نظرة عامة

- الحجم

- التفاصيل

- المنتجات الموصى بها

وصف

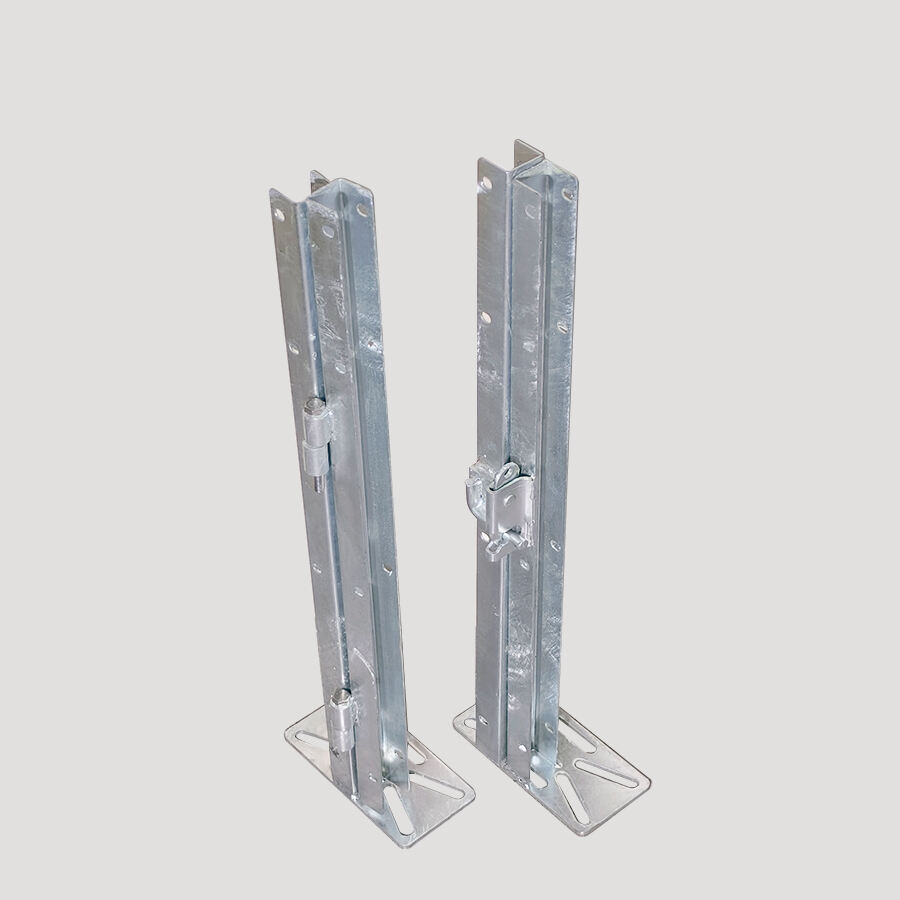

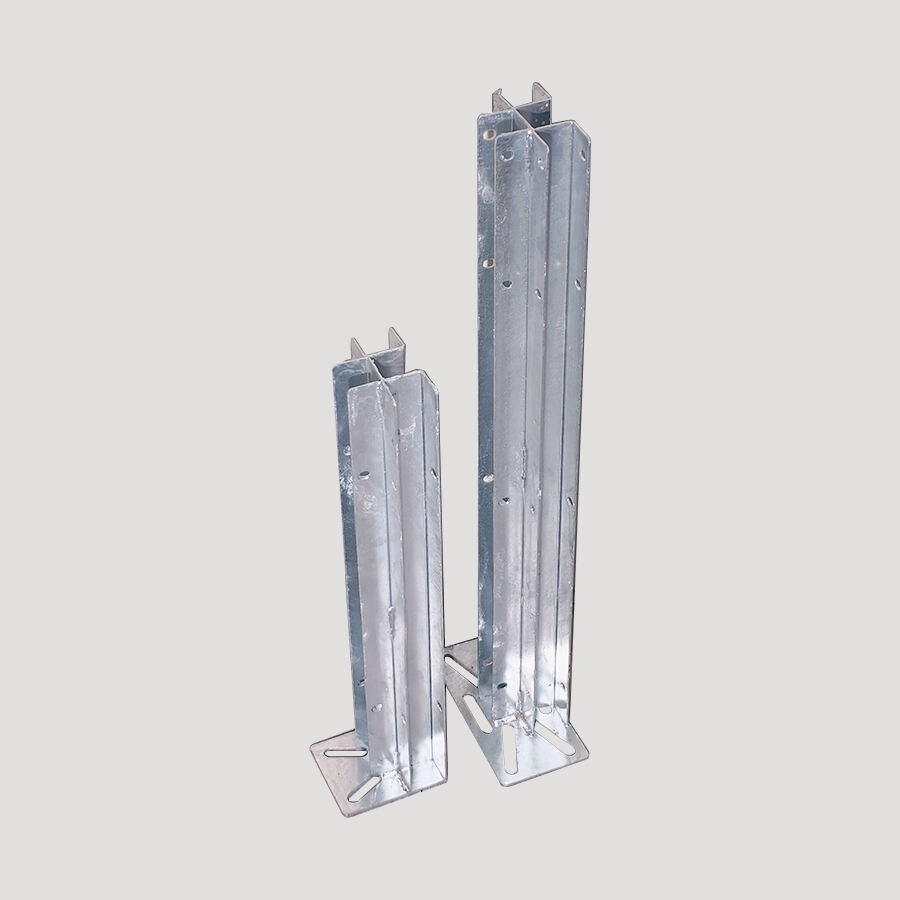

يُصنع هذا العمود الفولاذي المجلفن لقفص ولادة الخنازير بتقنية التغليف بالغمس الساخن، ويتميز بسطح أملس ومقاومة قوية للتآكل وحماية ممتازة من الصدأ. تم تصميمه ليتحمل البيئة الرطبة الغنية بالأمونيا والمليئة بالنفايات في حظائر الخنازير، مما يضمن الثبات والمتانة لفترة طويلة. يتميز العمود بهيكل قوي ومتين ذو سعة تحمل عالية، ويدعم بشكل ثابت الألواح البلاستيكية (PVC) أو مواد الإغلاق الأخرى لضمان سلامة واستقرار نظام قفص الولادة.

تتوفر مجموعة واسعة من المواصفات، ويمكن إجراء تخصيصات وفقًا لتصميم مباني المزارع المختلفة لتلبية الاحتياجات الفردية. يتم التثبيت بطريقة بسيطة وفعالة من خلال ثقوب موضعية بدقة، مما يسمح بتركيب سريع ويوفّر الجهد والوقت. كما أنه سهل الفك والصيانة، مما يتيح تعديلات مرنة لتخطيط المزرعة في المراحل المختلفة.

إن السطح المجلفن لا يحسّن فقط مقاومة البلى ومقاومة الأكسدة، بل يجعل أيضًا عملية التنظيف والتعقيم أسهل، مما يقلل من نمو البكتيريا ويعزز النظافة في المزرعة. يتم معالجة حواف العمود بعناية لتجنب إصابة الخنازير أو العمال، مما يزيد من السلامة.

باختصار، يوفر هذا العمود المجلفن مزايا تتمثل في المتانة والقدرة على التخصيص والتحمل العالي للحمل وسهولة التركيب والسلامة والنظافة، ما يجعله مكونًا أساسيًا لأنظمة أقفاص ولادة الخنازير في المزارع الحديثة.

فيديو تعريفي بالمنتج

https://youtube.com/shorts/Jc7yuc6XRbs?si=yTBMDW3WHnysJj9U

شهادة

الحجم

التفاصيل

|

|