الـ دلو تغذية وشرب دجاج أوتوماتيكي يمثل نهجًا متطورًا لأنظمة إدارة الدواجن، تم تصميمه لتبسيط الكفاءة التشغيلية مع ضمان توصيل منتظم للتغذية والترطيب في عمليات تربية الدجاج التجارية والمنزلية. يجمع هذا النظام المبتكر ذو الوظيفة المزدوجة بين آليات التغذية الآلية وقدرات توزيع المياه المتكاملة، ليشكّل حلاً شاملاً يلبّي المتطلبات الأساسية لممارسات تربية الدواجن الحديثة. وقد طوّرت مرافق تصنيع متخصصة في معدات الأتمتة الزراعية هذا الخط المنتج لتلبية الطلب المتزايد من الأسواق الدولية التي تبحث عن حلول تغذية موثوقة وقليلة الصيانة، ويمكنها العمل بكفاءة عبر ظروف مناخية متنوعة وأحجام تشغيلية مختلفة. ويُركّز الفلسفة الهندسية وراء هذه الأنظمة الآلية على المتانة والوظيفية وسهولة التشغيل، ما يجعلها مناسبة بشكل خاص لسيناريوهات الشراء بين الشركات (B2B)، حيث يحتاج الموزعون وموردو معدات الزراعة والمشترون الجملة إلى أداء ثابت عبر تركيبات متعددة. وعادةً ما تتضمن منهجية البناء مواد آمنة للاتصال بالغذاء تقاوم التآكل والتدهور الناتج عن الأشعة فوق البنفسجية ونمو البكتيريا، مما يضمن سلامة تشغيلية طويلة الأمد في البيئات الخارجية التي تُجرى فيها عمليات تربية الدواجن عادةً. وتمتد اعتبارات التصميم لهذه الأنظمة الآلية للتغذية والشرب لما هو أبعد من الوظائف الأساسية لتشمل سهولة الصيانة، وإمكانية الوصول لإعادة التعبئة، والقدرات القابلة للتعديل التي تتناسب مع أحجام القطيع المختلفة وجداول التغذية. وعادةً ما يستخدم جهاز التغذية مبادئ التوزيع بالجاذبية مقرونة بمكونات دقيقة التصميم تنظم كمية التوزيع مع تقليل الهدر ومخاطر التلوث. وتتكامل أنظمة توصيل المياه بسلاسة مع جهاز التغذية، وغالبًا ما تحتوي على مشابك شرب أو موزعات على شكل أكواب تحافظ على توفر مياه نظيفة ومنع الانسكاب والحفاظ على الظروف الصحية. وتشمل المعالجات السطحية المطبقة أثناء عمليات التصنيع عادةً طلاءات واقية أو اختيار مواد تتحمل بروتوكولات التنظيف المتكررة والتعرض للمواد الكيميائية الزراعية المستخدمة عادةً في إجراءات تعقيم مرافق الدواجن. وتتيح إمكانيات التخصيص ضمن هذه الفئة المنتجة تباينات في السعة، وتكوينات التركيب، وميزات الدمج التي تتكيف مع متطلبات تشغيلية محددة عبر أساليب إدارة دواجن مختلفة. ويُقدّر موزعو المعدات الزراعية بشكل خاص مرونة هذه الأنظمة، حيث يمكنها خدمة عمليات تربية الدجاج في الحدائق الخلفية صغيرة الحجم، والمزارع التجارية متوسطة الحجم، والمرافق الصناعية الكبيرة لتربية الدواجن، مع التعديلات المناسبة في الحجم والتكوين. وتمتد ملاءمة الاستخدام عبر سلالات دواجن مختلفة وأنماط الإدارة، بدءًا من العمليات الحرّة التي تتطلب حلولًا قابلة للحمل، وحتى أنظمة الإيواء المغلقة التي توفر التركيبات الثابتة فيها الكفاءة المثلى. وتكفل فلسفة الاتساق في الجودة التي تقوم عليها عملية التصنيع أن كل وحدة تقدم أداءً موثوقًا بغض النظر عن الظروف البيئية أو تكوينات التركيب أو المتطلبات التشغيلية المفروضة على النظام. ويُقدّر فرق الشراء الدولية النهج الموحّد لمواصفات المكونات، الذي يسهل إدارة المخزون وشراء قطع الغيار عبر سلاسل التوريد العالمية. وتشمل اعتبارات الشحن الموجهة للتصدير أنظمة تغليف قوية تحمي المكونات الحساسة أثناء الشحن الدولي مع الحفاظ على ملف لوجستي فعّال من حيث التكلفة يدعم هياكل أسعار تنافسية للمشترين في الخارج. وتشمل فلسفة التصميم مبادئ الوحدات المعيارية التي تسمح بإصلاحات ميدانية واستبدال المكونات دون الحاجة إلى استبدال النظام بالكامل، مما يدعم الفعالية الاقتصادية الطويلة الأمد للمستخدمين النهائيين، ويخلق فرص عمل مستمرة للموزعين الذين يديرون خدمات الدعم ما بعد البيع. وقد صقلت مرافق التصنيع ذات الخبرة الواسعة في مجال أتمتة الزراعة عمليات الإنتاج لتحقيق جودة بناء متسقة مع الحفاظ في الوقت نفسه على المرونة اللازمة للتكوينات المخصصة المطلوبة من خلال شراكات OEM. وغالبًا ما تشمل فرص التعاون مع الموزعين الدوليين خدمات تكييف المنتج، حيث تبقى الوظائف الأساسية متسقة بينما يتم تعديل الميزات الخارجية، أو أنظمة التركيب، أو مواصفات السعة لتلبية تفضيلات السوق الإقليمية أو المتطلبات التنظيمية. ويمتد العقلية التعاونية إلى توفير الدعم الفني، حيث يعمل المصنعون بشكل وثيق مع شبكات الموزعين لضمان إيصال إرشادات التركيب المناسبة ودعم استكشاف الأخطاء وإصلاحها للمستخدمين النهائيين بشكل فعّال. وتشمل اعتبارات التوافق في التغليف والخدمات اللوجستية تصاميم قابلة للتراص تُحسّن استخدام حاويات الشحن مع حماية المكونات أثناء النقل الدولي. وعادةً ما يشمل إطار التعاون طويل الأمد مع الموردين تعاونًا مستمرًا في تطوير المنتجات، حيث يؤثر التغذية المرتدة من الأسواق الدولية في تحسينات التصميم وتعزيز الميزات للأعمال الإنتاجية اللاحقة. ويشكّل نظام دلو التغذية والشرب الآلي للدجاج هذا منتجًا أساسيًا للشركات التي تسعى إلى إنشاء محافظ شاملة من معدات تربية الدواجن، حيث يقدم الموثوقية والاتساق في الأداء اللذين يبنيان ولاء العملاء ويدعمان علاقات تجارية مستدامة بين المصنّعين والموزعين والمستخدمين النهائيين عبر الأسواق الزراعية العالمية.

دلو تغذية وشرب دجاج أوتوماتيكي

-

تزويد تلقائي ومستمر – يوفر تدفقًا مستمرًا من العلف والماء، ويقلل التدخل اليدوي ويوفر ترطيبًا وпитание مناسبين للدواجن.

-

مواد متينة وآمنة للاستخدام الغذائي – مصنوعة من بلاستيك عالي الجودة ومقاوم للعوامل الجوية، وهي آمنة وطويلة الأمد وسهلة التنظيف.

-

تصميم مضاد للانسكاب وصحي – يمنع الانقلاب والانسكاب، ويبقي منطقة التغذية نظيفة ويقلل هدر العلف/الماء.

-

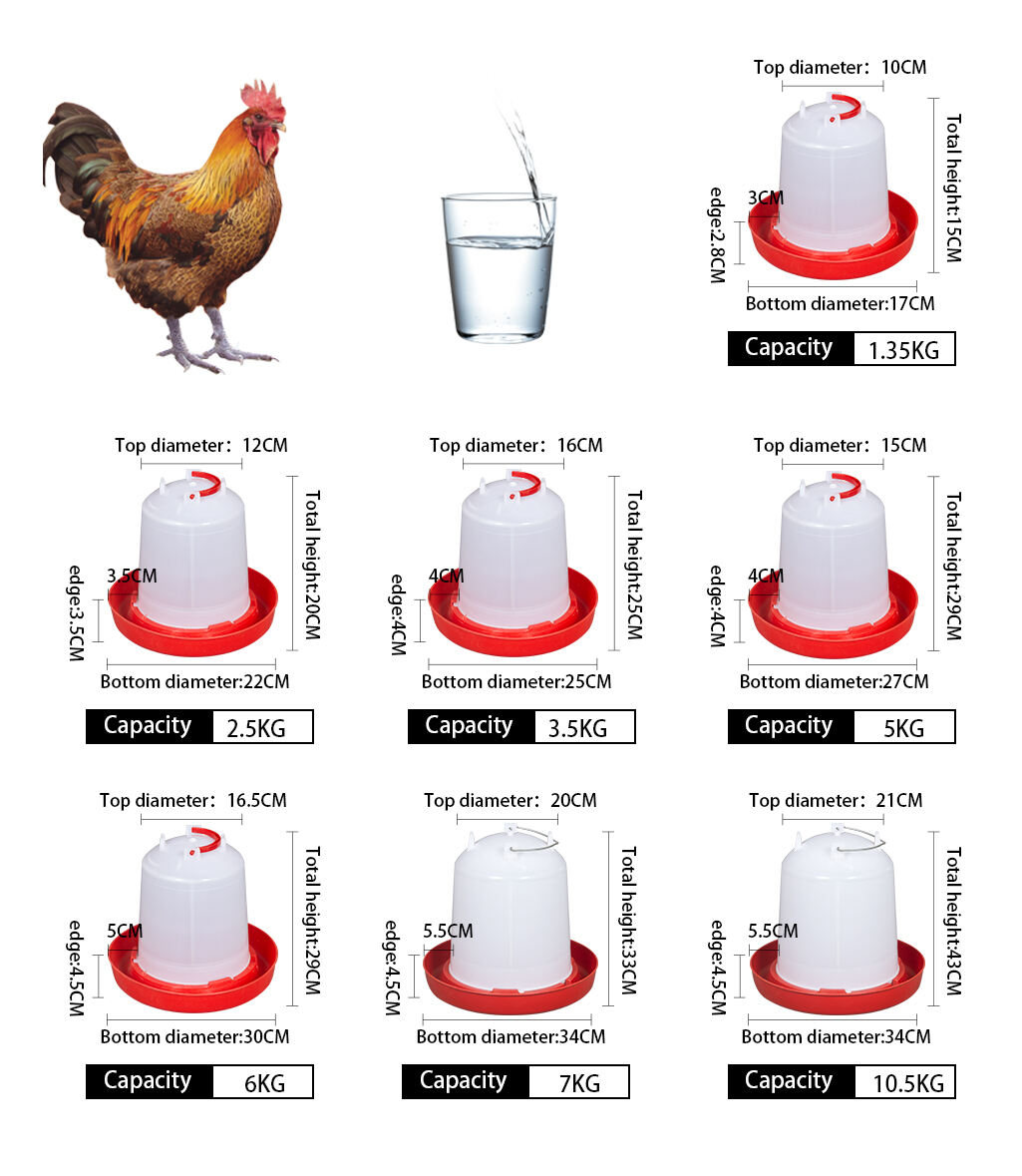

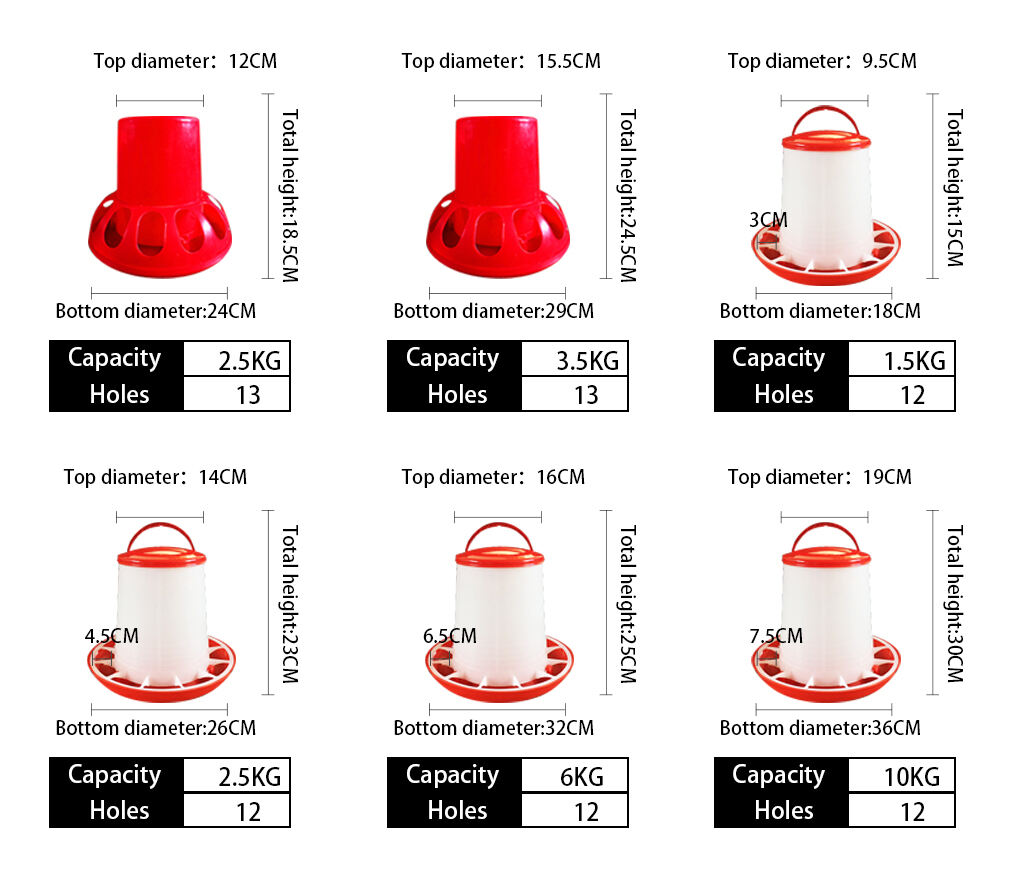

سعة كبيرة ومراقبة سهلة – السعة الكبيرة والثقوب قابلة للتخصيص، ويمكن تخصيص عدد الثقوب حسب الطلب.

-

متعدد الاستخدامات وسهل الاستخدام – خفيفة الوزن، وقابلة للنقل، ومناسبة لأنواع مختلفة من الدواجن وللإعدادات الداخلية/الخارجية.

- نظرة عامة

- الحجم

- التفاصيل

- المنتجات الموصى بها

الميزات الرئيسية:

إن دلو تغذية الأغنام البلاستيكي هو أداة أساسية لمزارعي الأغنام. خفيف الوزن ولكنه قوي، مصنوع من البلاستيك عالي الجودة الذي يقاوم التشقق والتلف. فتحته الواسعة تجعل عملية الملء والتنظيف سهلة، بينما يضمن المقبض الارتجالي حملًا سهلاً. تصميم الدلو يسمح بتغذية مريحة، مما يساعد الأغنام على الوصول إلى غذائها براحة ويشجع على إدارة الرعي بكفاءة.

الحجم

التفاصيل

|

متين، سهل الإمساك |

| يمكن ملء أنبوب المياه مباشرةً |  |

|

هيكل محكم، لا يسهل ترخية |

| سهلة التفكيك والتنظيف |  |

|

متين، سهل الإمساك |

|

هيكل محكم، لا يسهل ترخية |

|

|

سهلة التفكيك والتنظيف |

|

مادة بولي بروبيلين جديدة تمامًا، كتلة خزفية سميكة |

|