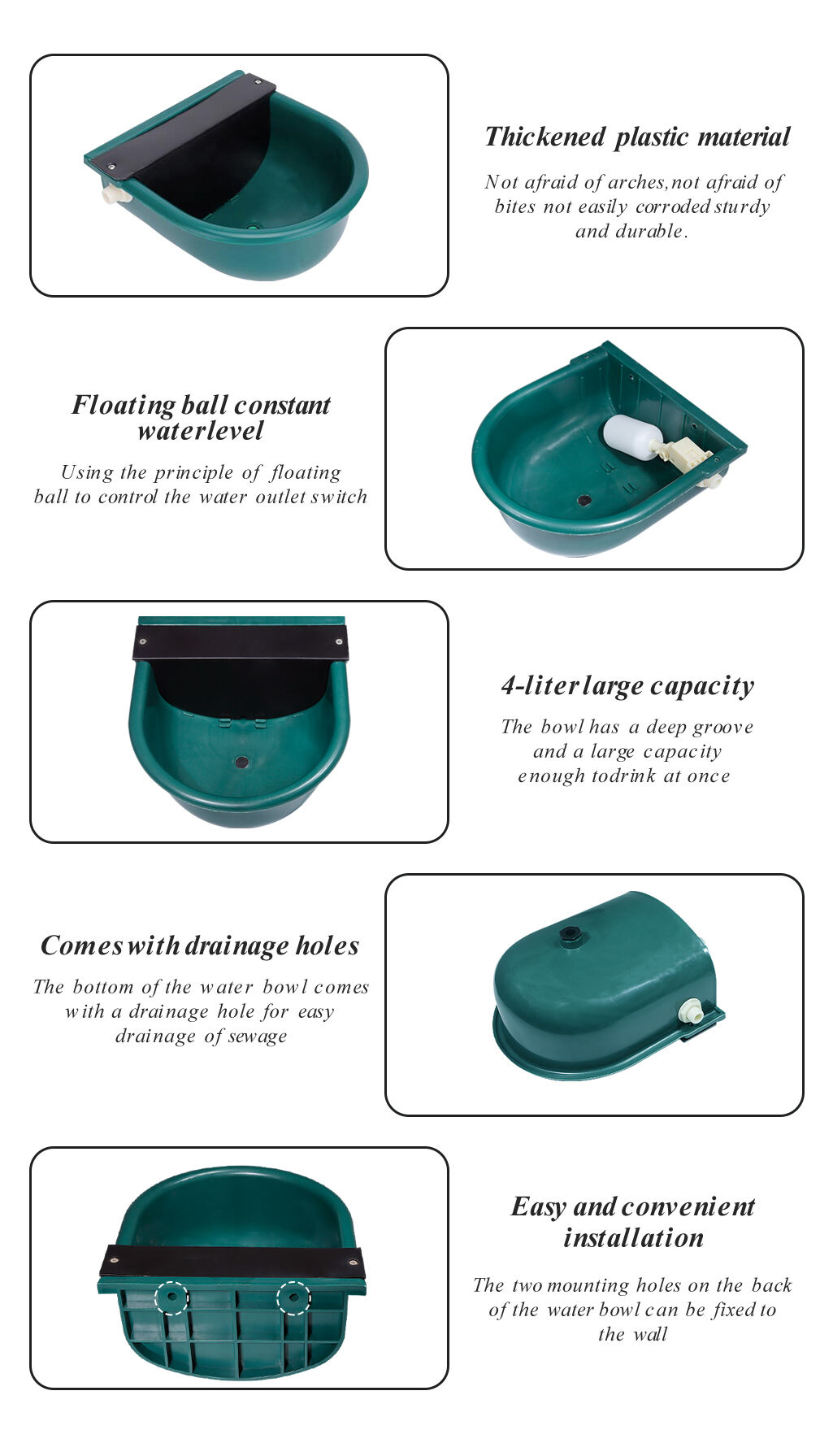

الـ وعاء شرب مائي تلقائي من البلاستيك للماشية تمثل حلاً أساسياً في أنظمة إدارة الثروة الحيوانية الحديثة، وتم تصميمها خصيصاً لتلبية الاحتياجات الحرجة للرعي من حيث الترطيب في عمليات تربية الأبقار عبر بيئات زراعية متنوعة وأسواق دولية. يجمع هذا النظام المبتكر للري بالماكينة بين هندسة البوليمرات المتقدمة والوظائف الزراعية العملية، ويتيح إمكانية الوصول المستمرة إلى المياه مما يدعم صحة الأبقار المثلى والكفاءة التشغيلية سواء في العمليات الزراعية الصغيرة أو في المرافق التجارية الكبيرة لتربية الماشية. ويضمن آلية الصرف التلقائي توفر المياه باستمرار مع تقليل الهدر من خلال التحكم الدقيق في تدفق المياه، ما يجعله عنصراً أساسياً في برامج إدارة الأبقار التقدمية التي تسعى لتحسين استخدام الموارد ومعايير رفاهية الحيوان. ويعتبر فرق الشراء الدولية والموزعون الزراعيون هذه الفئة من المنتجات بنية تحتية أساسية للعمليات المستدامة لتربية الماشية، خاصة في المناطق التي أصبح فيها ترشيد استهلاك المياه وأنظمة التغذية الآلية أولوية متزايدة ضمن مبادرات التنمية الزراعية. وتدمج البنية البلاستيكية القوية مواد متخصصة تم اختيارها لمقاومتها للعوامل البيئية الشائعة في بيئة تربية الماشية، بما في ذلك التغيرات في درجات الحرارة، والتعرض للأشعة فوق البنفسجية، والمقاومة الكيميائية للمنظفات القياسية المستخدمة في بروتوكولات التعقيم الزراعي. وتركز أساليب التصنيع لهذه الأنظمة عادةً على المتانة من خلال تقنيات صب متقدمة تضمن السلامة الهيكلية في ظل ظروف الاستخدام المستمر، مع دمج ميزات تصميم تسهل إجراءات التركيب والصيانة الضرورية للعمليات الزراعية المزدحمة. كما تم تطوير المعالجات السطحية وتركيبات المواد بشكل خاص لمنع نمو البكتيريا وتشكل الأغشية الحيوية، مما يعالج مخاوف النظافة الحرجة التي تؤثر مباشرةً على صحة الأبقار والامتثال التشغيلي للمعايير الزراعية الحديثة. ويوازن فلسفة التصميم الهندسي بين الموثوقية الميكانيكية وسهولة التشغيل للمستخدم، مع دمج ميزات مثل معدلات التدفق القابلة للتعديل، وقدرات مقاومة التجمد للتطبيقات في المناخات الباردة، والتوافق مع أنظمة ضغط المياه المختلفة الموجودة بشكل شائع في البنية التحتية الزراعية. وتمتد إمكانيات التخصيص الوظيفي لما هو أبعد من الصرف الأساسي للمياه لتشمل تكوينات متخصصة لأصناف مختلفة من الأبقار، ومجموعات عمرية، وأنظمة إيواء، مما يمكن العمليات الزراعية من تكييف حلول الترطيب الخاصة بها وفقاً لمتطلبات تشغيلية محددة وممارسات إدارة الماشية الإقليمية. ويشمل نطاق التطبيقات المناسبة بيئات متعددة لتربية الماشية، من عمليات الرعي التقليدية القائمة على المراعي إلى أنظمة التغذية المغلقة الحديثة، ما يجعل هذه الأحواض المائية الآلية حلولاً متعددة الاستخدامات لنماذج أعمال زراعية متنوعة ومناهج زراعية دولية. وتُقدّم البنية البلاستيكية مزايا كبيرة مقارنةً بالبدائل المعدنية التقليدية، بما في ذلك مقاومة التآكل، ووزن أخف مما يسهل المناورة أثناء التركيب والصيانة، وتصنيع اقتصادي يدعم أسعاراً تنافسية في الأسواق الزراعية العالمية. ويظل الاتساق في الجودة أمراً بالغ الأهمية في فلسفة التصنيع، حيث تم تصميم عمليات الإنتاج لضمان خصائص أداء موحدة عبر أحجام إنتاج كبيرة، مما يدعم توقعات الموثوقية لدى الموزعين الدوليين وموردي معدات الزراعة. وتشمل اعتبارات الشحن الموجهة للتصدير تصاميم التعبئة التي تقلل من أضرار الشحن، والبنية المعيارية التي تحسّن استخدام الحاويات، ودعم الوثائق الذي ييسّر إجراءات التخليص الجمركي ومتطلبات الامتثال الدولية. وتوفر فرص التعاون في مجال التخصيص مع مصنعي معدات الزراعة ومتكاملات أنظمة تربية الماشية شراكات OEM وODM التي يمكنها تكييف أنظمة الأحواض المائية هذه وفقاً لمتطلبات إقليمية محددة، وتفضيلات تركيب محلية، وتكوينات أنظمة تغذية متكاملة. وتعكس الخبرة التصنيعية وراء هذه المنتجات خبرة واسعة في تطبيقات البوليمرات الزراعية، مع فهم عميق للتحديات الفريدة التي تواجه عمليات تربية الماشية في ظروف مناخية وبيئات زراعية مختلفة. وتكفل اعتبارات التوافق في التعبئة والخدمات اللوجستية توزيع هذه المنتجات بكفاءة عبر سلاسل الإمداد الزراعية الحالية، مع تغليف واقٍ يحافظ على سلامة المنتج أثناء الشحن الدولي ويدعم نماذج التوزيع الاقتصادية. وتركز توقعات التعاون طويل الأمد مع الموردين على توفر المنتج بشكل مستمر، وتقديم الدعم الفني لأسئلة التركيب والصيانة، والتطوير التعاوني لميزات محسّنة بناءً على الممارسات الزراعية المتغيرة وابتكارات إدارة الماشية. ويعكس الموقع الاستراتيجي للأحواض البلاستيكية الآلية للشرب المخصصة للأبقار داخل النظام البيئي الأوسع لمعدات الزراعة دورها كتكنولوجيا تمكينية تدعم أهدافاً تشغيلية أكبر، تشمل تحسين رفاهية الحيوان، وتقليل متطلبات العمل، وزيادة كفاءة إدارة المياه، والامتثال لمعايير إدارة الماشية التي أصبحت أكثر تعقيداً. وتساهم هذه الأنظمة في الممارسات الزراعية المستدامة من خلال تحسين استخدام المياه، وتقليل الهدر من خلال آليات الصرف المتحكم بها، ودعم بروتوكولات الترطيب المنتظمة التي تسهم في صحة الأبقار وإنتاجيتها بشكل عام.

وعاء شرب مائي تلقائي من البلاستيك للماشية

-

إمداد تلقائي للمياه : مياه نظيفة باستمرار بأقل جهد وتدفق قابل للتعديل.

-

متين ونظيف : هيكل متين من البلاستيك وتنظيف ذاتي للحفاظ على المياه نظيفة.

-

تركيب سهل : تركيب سريع لأي نظام مياه قياسي مع صيانة منخفضة.

-

كفاءة في استخدام المساحة ومقاومة لعوامل الطقس : تصميم مدمج يعمل تحت مختلف الظروف البيئية.

-

فعالة من حيث التكلفة : يقلل من هدر المياه ويقلل فاتورة الخدمات.

- نظرة عامة

- الحجم

- التفاصيل

- المنتجات الموصى بها

الحجم

التفاصيل