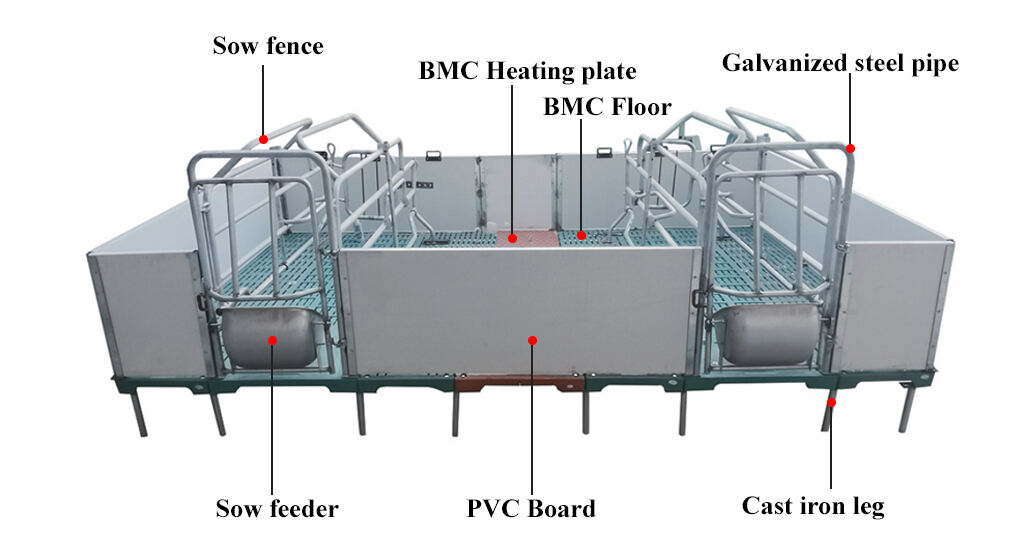

الـ قفص ولادة الخنازير ذو لوحة الجدار من البولي فينيل كلورايد مع BMC أرضية ألواح يمثل هذا الحل تكاملاً متطوراً لتكنولوجيا الحظائر الحديثة للماشية، مصمم خصيصًا لعمليات تربية الخنازير المكثفة التي تسعى إلى تعزيز معايير الأمن الحيوي والكفاءة التشغيلية ورفاهية الحيوانات. يجمع هذا الحل الشامل للتربية بعد الولادة بين مقاومة البولي فينيل كلوريد (PVC) للعوامل الكيميائية والخصائص الهوائية لألواح الجدران، وبين متانة الأرضيات الشبكية المصنوعة من مركب التشكيل السائب (BMC) وقدرتها على التصريف، ما يشكل نظامًا موحدًا يستجيب لمتطلبات معقدة في مزارع إنتاج الخنازير الحديثة حول العالم. تستخدم مكونات لوحة الجدار من مادة PVC مواد بولي فينيل كلوريد عالية الجودة مهندسة خصيصًا للبيئات الزراعية، وتتميز بمقاومة استثنائية لاختراق الرطوبة وعوامل التنظيف الكيميائية والتأثيرات التآكلية الناتجة عن الأمونيا وكبريتيد الهيدروجين الموجودة عادةً في تطبيقات حظائر الماشية، مع الحفاظ على الثبات البُعدي تحت ظروف درجات الحرارة والرطوبة المتغيرة النموذجية لبيئات غرف التربية. تسهل الخصائص السطحية المتماسكة لألواح جدران PVC تنفيذ بروتوكولات التنظيف الشاملة، وهي ضرورية للحفاظ على بيئات خالية من مسببات الأمراض بين دورات الإنتاج، وتدعم التدابير الصارمة للأمن البيولوجي المطلوبة في نظم تربية الخنازير الحديثة، حيث يؤثر الوقاية من الأمراض بشكل مباشر على الربحية التشغيلية ونتائج صحة الحيوان. يكمّل نظام الأرضية الشبكية المدمج من مادة BMC بنية لوحة الجدار من خلال خصائص المواد المركبة التي تجمع بين متانة شبكات البوليمر المقوى والكفاءة في التصريف الضرورية لإدارة الفضلات بكفاءة في بيئات التربية. توفر هذه الحلول الأرضية دعماً مثالياً للأنثى الخنزير بينما تضمن فصل الفضلات بشكل سليم وتهوية مناسبة أسفل منطقة إيواء الحيوانات، مما يسهم في تحسين جودة الهواء وتقليل تركيزات الأمونيا داخل بيئة غرفة التربية. سيجد المشترون الدوليون الذين يقيّمون حلول معدات التربية بعد الولادة أن هذا التركيب المتكامل من ألواح الجدران والأرضيات الشبكية مناسبًا بشكل خاص للمرافق التي تتطلب تحكماً بيئيًا شاملاً، نظرًا لأن تركيب المواد لكلا المكونين يقاوم التصاق البكتيريا وتكوين الأغشية الحيوية التي قد تُضعف فعالية التعقيم في الأساليب التقليدية القائمة على الخرسانة أو الصلب. تتيح فلسفة التصميم الوحداتية الكامنة في نظام قفص التربية هذا تكوينات تركيب مرنة يمكنها التكيف مع تخطيطات المرافق المختلفة ومتطلبات التوسعة، ما يجعلها خيارًا جذابًا لكل من مشاريع البناء الجديدة ومبادرات ترقية المرافق عبر أسواق جغرافية متنوعة. تستخدم عمليات التصنيع المعتمدة في إنتاج ألواح جدران PVC تقنيات متقدمة للبثق والتشكيل تضمن دقة أبعاد متسقة ومستويات جودة سطحية ضرورية للحصول على محاذاة صحيحة للمكونات أثناء التركيب، في حين تستخدم عملية تصنيع الأرضيات الشبكية من مادة BMC تقنية التشكيل بالضغط لتحقيق توزيع متجانس للكثافة والخصائص الميكانيكية عبر جميع عناصر الأرضية. تركز اعتبارات المعالجة السطحية لكلا مكوني لوحة الجدار والأرضية الشبكية على تحقيق ملفات نسيجية مثلى توازن بين متطلبات مقاومة الانزلاق اللازمة لسلامة الحيوانات، وبين الخصائص السطحية الناعمة الضرورية لإجراءات التنظيف والتعقيم الفعالة، مما يعالج متطلبات الوظائف المزدوجة المتأصلة في تطبيقات إيواء الماشية. تضمن التوافقية الكيميائية لمادة ألواح الجدران من البولي فينيل كلوريد مع مطهرات الزراعة ومركبات التنظيف القياسية المستخدمة في عمليات تربية الخنازير الحفاظ على سلامة المادة على المدى الطويل عند التعرض المتكرر لبروتوكولات التعقيم، في حين تُظهر تركيبة الأرضية الشبكية من مادة BMC مقاومة مماثلة للتحلل الكيميائي الناتج عن عوامل التنظيف والنواتج البيولوجية للنفايات. تمتد إمكانيات التخصيص ضمن نظام قفص التربية هذا لما هو أبعد من التغيرات البعدية الأساسية لتشمل خيارات دمج التهوية المتخصصة، وميزات التوافق مع أنظمة المياه والأعلاف، ومرافق استيعاب عناصر التدفئة، ما يمكن مصممي المرافق من تحسين أنظمة التحكم البيئي وفقًا لظروف المناخ الفلسفات الخاصة بإدارة الإنتاج. يتراوح مدى ملاءمة هذا النظام المتكامل من ألواح الجدران والأرضيات الشبكية عبر نطاقات متعددة من عمليات إنتاج الخنازير، بدءًا من المرافق المتخصصة في برامج تحسين السلالات وصولاً إلى عمليات التربية التجارية التي تركز على كفاءة الإنتاج وتحسين العمالة، حيث أثبتت خصائص المواد ومنهجية البناء قابليتها للتكيف مع تصاميم المرافق ذات التحكم المناخي أو التهوية الطبيعية. تؤكد فلسفة الاتساق في الجودة التي تحكم منهجية التصنيع على تدابير التحكم في العمليات التي تضمن انتظام الخصائص المادية والدقة البعدية والخصائص السطحية من دفعة إلى أخرى، مما يدعم توقعات الموثوقية لدى المشترين الدوليين الذين يحتاجون إلى أداء متوقع عبر مشاريع تركيب متعددة ومرافق في مواقع مختلفة. تأخذ اعتبارات التجهيز الموجهة للتصدير المدمجة في تصميم وتعبئة المنتج في الاعتبار التحديات اللوجستية المرتبطة بشحن معدات تربية الماشية دوليًا، حيث تم تحسين أبعاد المكونات وطرق الاتصال لتحقيق الاستخدام الفعال للحاويات مع الحفاظ على السلامة البنائية أثناء دورات النقل الطويلة النموذجية لسلسلة التوريد العالمية. يتيح إطار التعاون الداعم لطلبات التخصيص OEM وODM تلبية متطلبات تصميم المرافق المحددة واحتياجات الامتثال التنظيمي الإقليمي التي تختلف عبر الأسواق الدولية، ما يمكن من تعديل تكوينات ألواح الجدران ومعايير تباعد الأرضيات الشبكية وتفاصيل دمج المكونات لتتوافق مع التعليمات المحلية للبناء ومعايير رفاهية الحيوان. تُعطي منهجيات التعبئة المطورة لنظام قفص التربية الأولوية لحماية المناطق السطحية الحرجة وواجهات الاتصال أثناء الشحن والتخزين، باستخدام مواد واقية وأساليب تثبيت تمنع التلف مع تقليل حجم التعبئة إلى الحد الأدنى لتحسين كفاءة تكلفة الشحن للمشترين الدوليين. تتضمن توقعات التعاون طويل الأمد مع المورد دعماً فنياً مستمراً لتخطيط التركيب، وتوجيهات الصيانة لتحقيق الأداء الأمثل للنظام، وإمكانية توفر مكونات بديلة لدعم دورات التشغيل الطويلة النموذجية لاستثمارات مرافق الماشية، مما يعكس فهماً للطبيعة الاستراتيجية لقرارات البنية التحتية الزراعية ولأهمية العلاقات الموثوقة مع الموردين في ضمان استمرارية التشغيل عبر أسواق دولية متنوعة قد تكون فيها موارد الدعم الفني المحلية محدودة.

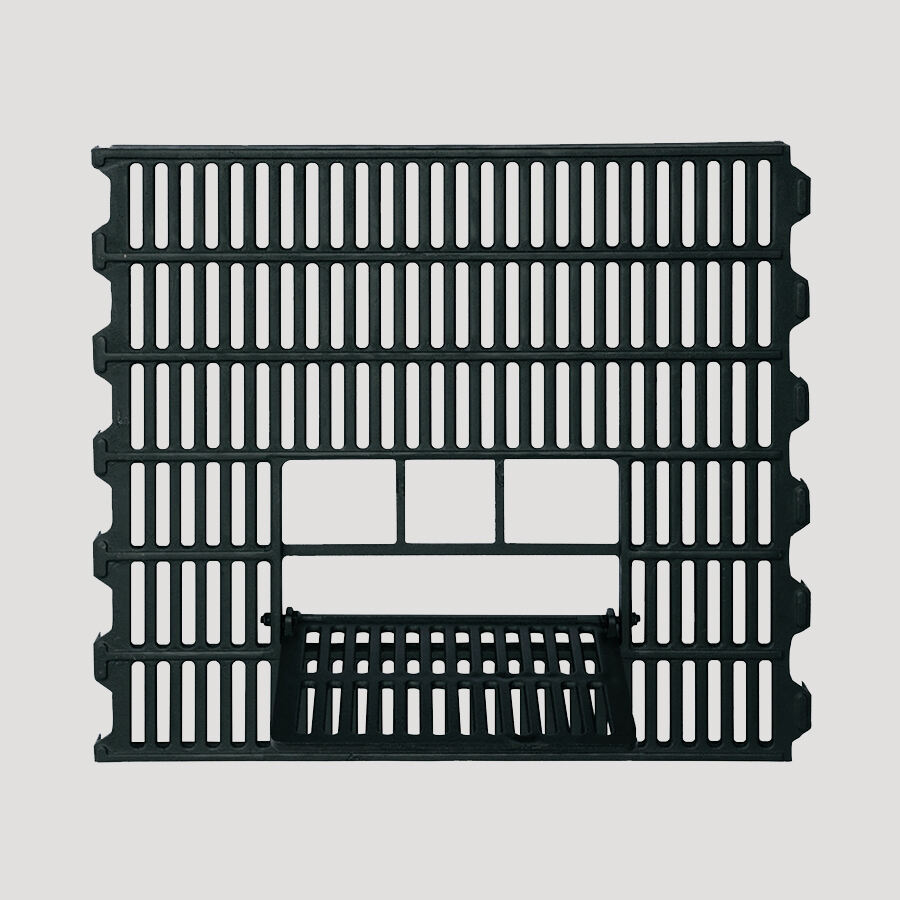

مقصورة خنازير PVC مع أرضية شبكية BMC

-

هيكل متين وصحي – إطار مقاوم لل corrosion، وأرضية شبكية BMC لتصريف المياه، وتصميم مرتفع للحفاظ على النظافة.

-

الحماية الحرارية والبيئية – تمنع ألواح الجدران PVC التوصيل الحراري بشكل فعال، وتحجب التيارات الهوائية وتحافظ على دفء الخنازير الصغيرة وسلامتها.

-

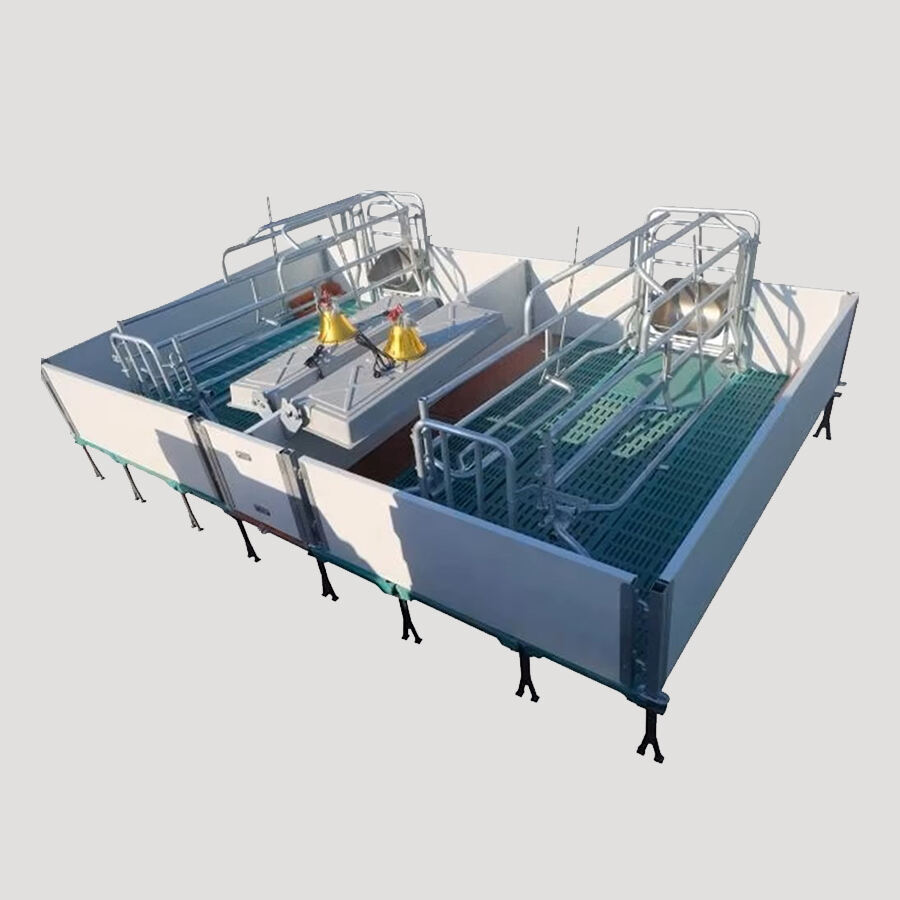

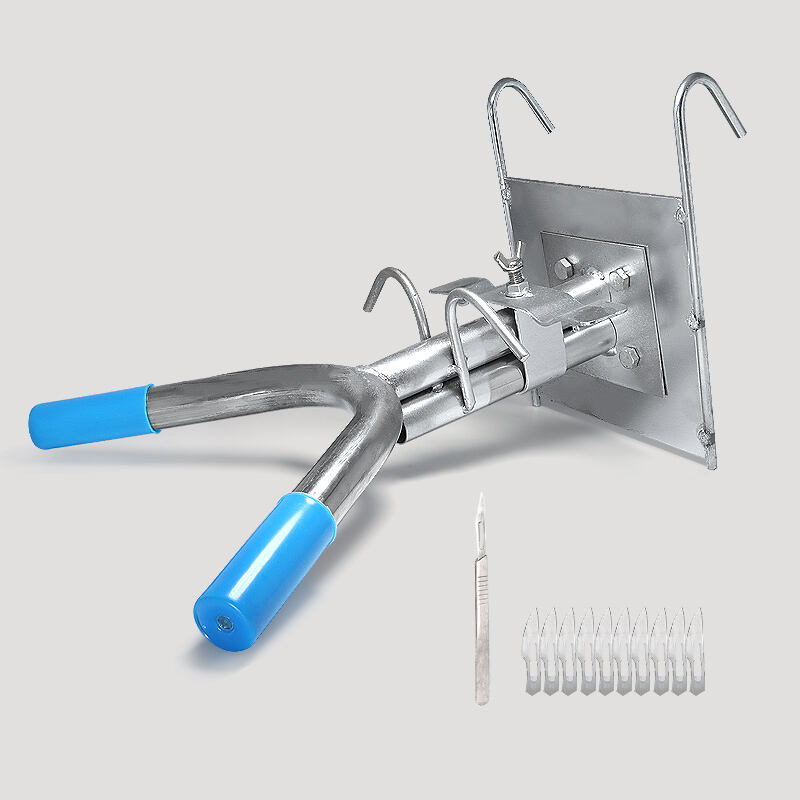

تصميم سلامة الخنازير الصغيرة – قضبان مضادة للسحق وحوامل لمبات التدفئة تقلل من معدل وفيات الخنازير الصغيرة وتحسن نسب البقاء.

-

تغذية وشرب فعّالة – مناطق منفصلة للطعام والماء تمنع التلوث وتعزز صحة الإناث.

-

تصميم معياري وسهل الصيانة – سهل التركيب والتنظيف والإدارة، مما يجعله مناسبًا للمزارع الحديثة الموفرة للعمالة.

- نظرة عامة

- التفاصيل

- المنتجات الموصى بها

وصف

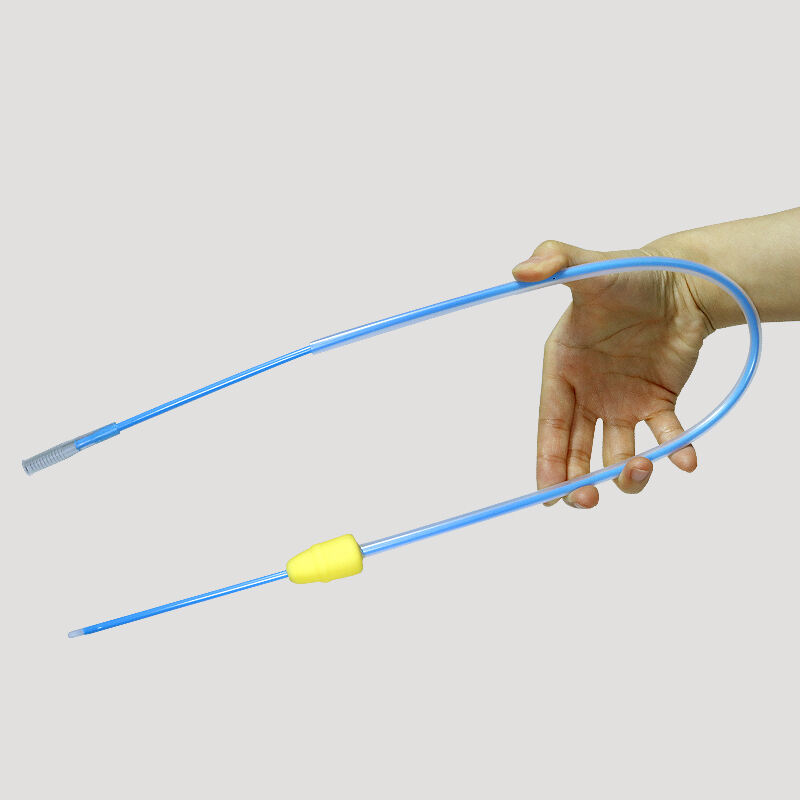

نظام حظيرة الولادة BMC هو حل شامل لتربية الخنازير الحديثة، ومصمم لتوفير بيئة آمنة ومريحة وصحية للإناث والخنازير الصغيرة. يتكون النظام من سياج PVC مع حظيرة من الصلب المجلفن بالغمس الساخن، وأرضية BMC مشبعة، ومقصورة لتغذية الإناث، ومقصورة لتغذية الخنازير الصغيرة وآبار شرب، وأرجل دعم متينة مصنوعة من الحديد الزهر. كما نقبل التصاميم المخصصة لتلبية متطلبات مزرعتك الخنازيرية الفريدة.

تستخدم الحظيرة لحامًا مُحميًا بغاز CO₂، يتبعه جلفنة بالغمس الساخن ومعالجة مضادة للبكتيريا بشكل شامل، مما يضمن أداءً ممتازًا ضد التآكل، ومنعًا للصدأ، وديمومة طويلة. تساعد القضبان المُبطئة في إبطاء حركة الإناث عند الاستلقاء، مما يمنع إصابة الخنازير الصغيرة، بينما تسمح القضبان القابلة للتعديل بملاءمة الحظيرة مع خنازير صغيرة بأعمار مختلفة. وتضمن الباب الخلفي القابل للتعديل والأسوار الجانبية توفير مساحة مريحة وآمنة للإناث بمختلف الأحجام.

تقدم أرضية BMC ذات القضبان سطحًا مسطحًا وغير مسامي مع تسرب ممتاز للروث، وسهولة التنظيف، ومقاومة الاحتكاك، وعمر خدمة يزيد عن 15 عامًا.

بالإضافة إلى ذلك، يوفر حاضنة الخنازير BMC بناءً متينًا وصلبًا مع حفظ ممتاز للحرارة، وعزل صوتي، وسهولة التركيب والتفكيك، مما يضمن مساحة دافئة وهادئة وآمنة للخنازير.

فيديو تعريفي بالمنتج

https://www.youtube.com/embed/Rjm1YVME-4M?si=YS2dnmaGFMt656_U

شهادة

التفاصيل